Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 67

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-39

REMOVAL SERVICE POINT

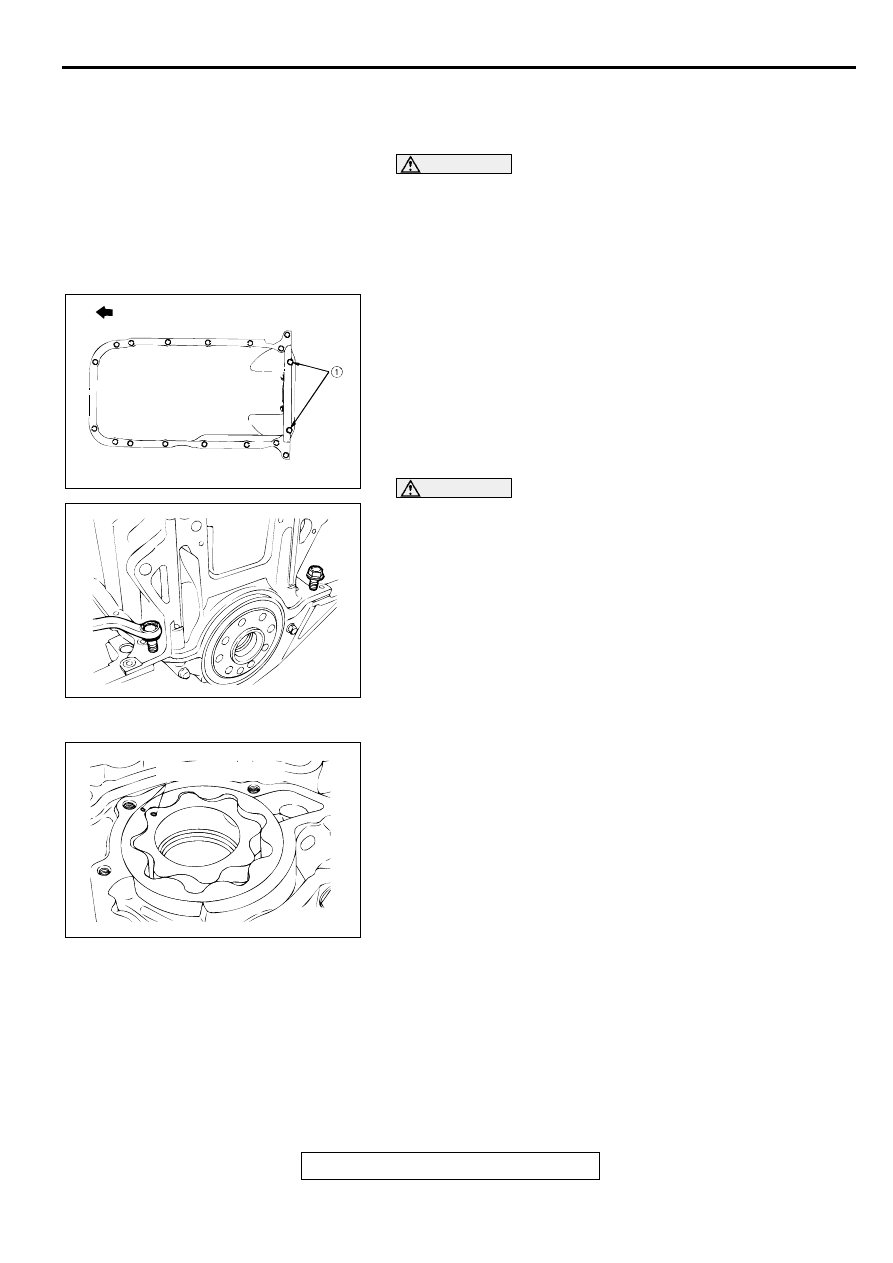

<<A>> OIL PAN, LOWER REMOVAL

1. Remove the lower oil pan mounting bolts.

CAUTION

Do not use a scraper or special tool to remove the oil pan.

2. Remove the lower oil pan by tapping on the side wall with a

plastic hammer (mallet) through a wooden plank held

against it.

<<B>> OIL PAN, UPPER REMOVAL

1. Remove the long bolts "A" shown in the illustration first.

2. Remove all other bolts.

CAUTION

Do not use a scraper or special tool to remove the oil pan.

3. Screw M10 bolts into the two bolt holes in the oil pan to

break the joint and remove the oil pan.

<<C>> OUTER ROTOR/INNER ROTOR REMOVAL

Make alignment dots on the outer and inner rotors for

assembly.

AKX00746

TIMING BELT SIDE

"A"

AB

AKX00658

AKX00742AB

ALIGNMENT DOTS

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-40

INSTALLATION SERVICE POINTS

>>A<< INNER ROTOR/OUTER ROTOR INSTALLATION

Apply engine oil to the rotors. Then, install the rotors ensuring

that the alignment dots made at disassembly are properly

aligned.

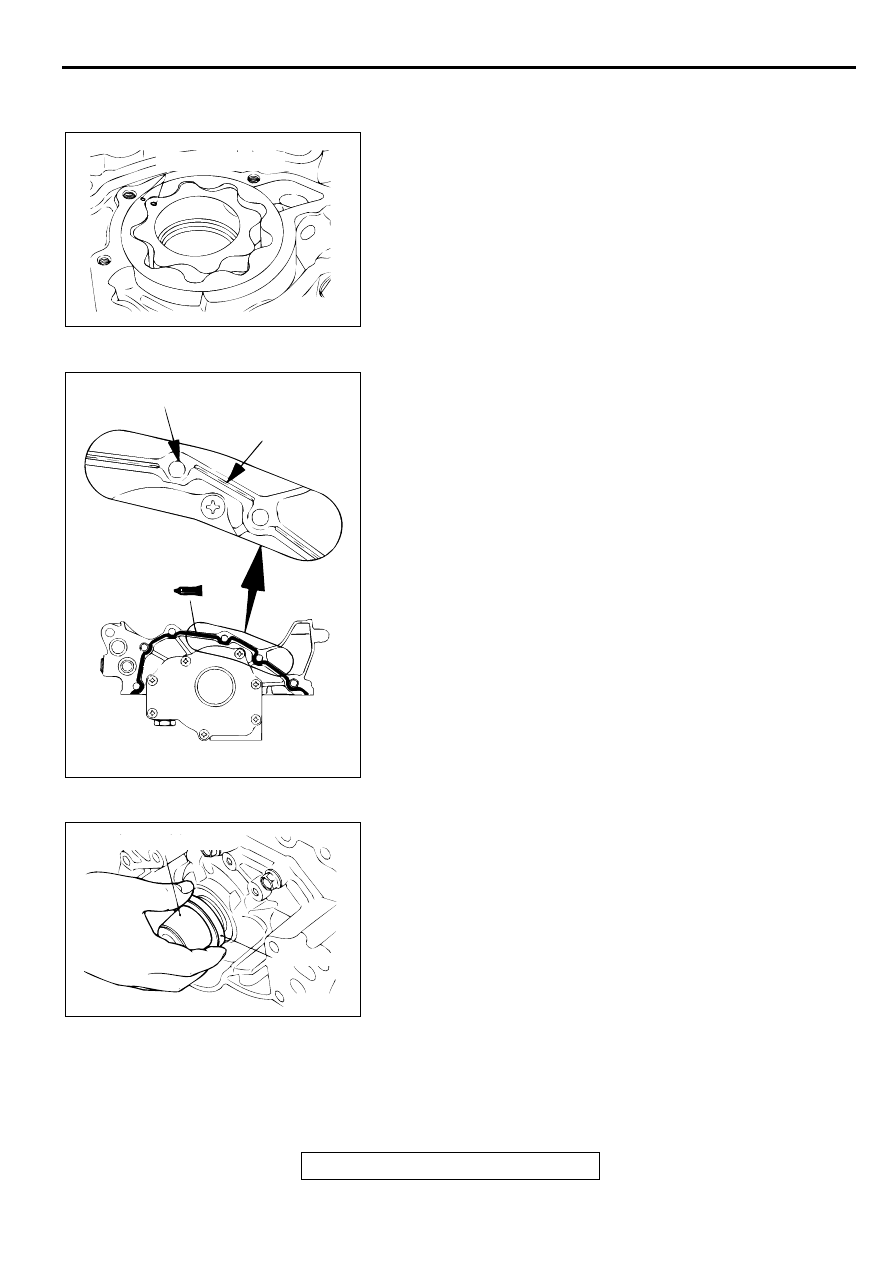

>>B<< OIL PUMP CASE ASSEMBLY INSTALLATION

1. Clean the gasket mating surfaces of oil pump case and

cylinder block.

2. Apply a 3-mm (0.1-inch) diameter bead of sealant

(Mitsubishi Genuine Parts number MD970389 or equivalent)

to the oil pump case.

Apply sealant as indicated by the broken line in the

illustration; the grooves must be traced and the bolt holes

must be surrounded with a bead of sealant.

3. Install the oil pump case assembly to the front of the cylinder

block.

NOTE: Be sure to install the oil pump case quickly while the

sealant is wet (within 15 minutes).

4. Tighten the oil pump case mounting bolts to the specified

torque.

Tightening torque:

14

±

1 N

⋅

m (122

±

9 in-lb) <M8 bolt>

41

±

8 N

⋅

m (30

±

6 ft-lb) <M10 bolt>

NOTE: After installation, keep the sealed area away from oil

and coolant for approximately one hour.

>>C<< CRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Install the guide of special tool MD998717 to the front end of

the crankshaft.

2. Apply engine oil to the lip area of a new oil seal and push it

in until it contacts the oil pump case.

AKX00742AB

ALIGNMENT DOTS

AKX00674

BOLT HOLE

GROOVE

AB

AKX00659 AB

MD998717 (GUIDE)

OIL SEAL

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-41

3. Using special tool MD998717, press-fit the oil seal into the

oil pump case.

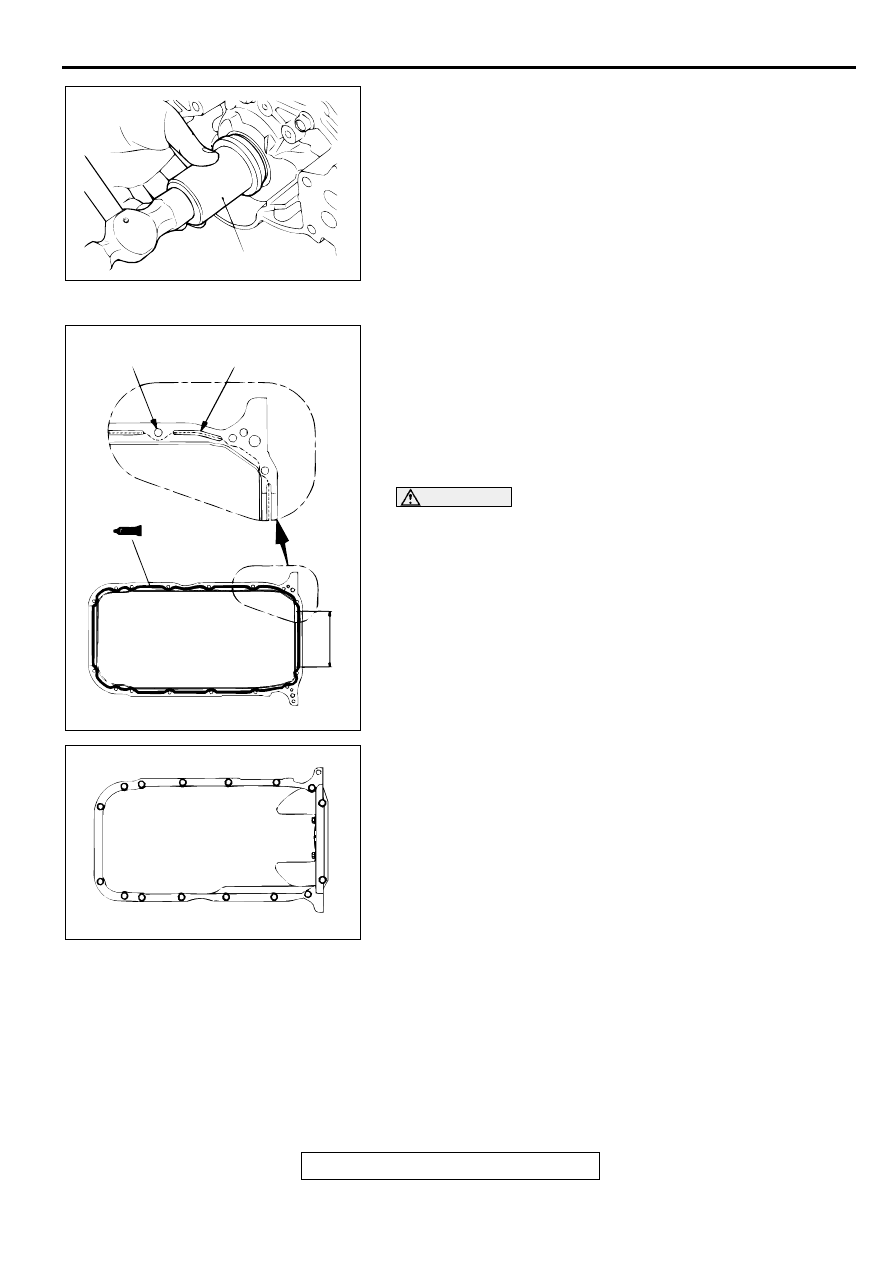

>>D<< OIL PAN, UPPER INSTALLATION

1. Clean both gasket surfaces of the upper oil pan and cylinder

block.

2. Apply a 4 mm (0.2 inch) diameter bead of sealant

(Mitsubishi Genuine Parts number MD970389 or equivalent)

to the upper oil pan.

Apply sealant as indicated by the broken line in the

illustration; the grooves must be traced and the bolt holes

must be surrounded with a bead of sealant.

CAUTION

When installing the upper oil pan, be sure not to expel the

sealant from the oil pan flange at portion A in the

illustration.

3. Install the oil pan to the bottom of the cylinder block.

NOTE: Be sure to install the oil pan quickly while the sealant

is wet (within 15 minutes).

4. Tighten the upper oil pan bolts in the sequence shown.

Tightening torque: 5.9

±

1 N

⋅

m (52

±

9 in-lb)

NOTE: After installation, keep the sealed area away from

the oil and coolant for approximately one hour.

AKX00660

MD998717

AB

AKX00675

BOLT HOLE

GROOVE

A

AB

AKX00676

9

5

1

4

8

12

16

15

11 7

3

2

6

10

14

13

AB

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-42

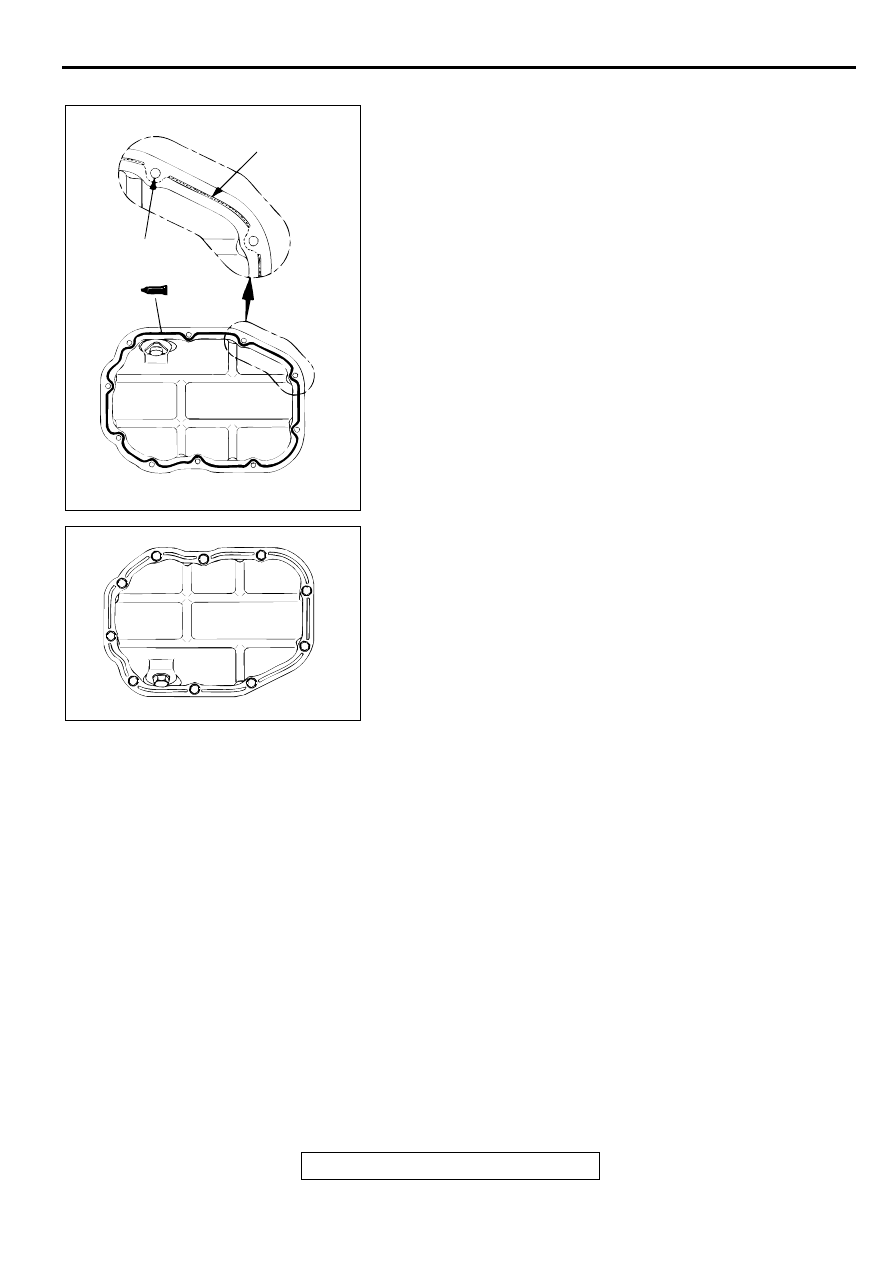

>>E<< OIL PAN, LOWER INSTALLATION

1. Clean both gasket surfaces of the upper and lower oil pans.

2. Apply a 4 mm (0.2 inch) diameter bead of sealant

(Mitsubishi Genuine Parts number MD970389 or equivalent)

to the lower oil pan.

Apply sealant as indicted by the broken line in the

illustration; the grooves must be traced and the bolt holes

must be surrounded with a bead of sealant.

3. Install the lower oil pan to the upper oil pan.

NOTE: Be sure to install the oil pan quickly while the sealant

is wet (within 15 minutes).

4. Tighten the lower oil pan bolts in the sequence shown.

Tightening torque: 11

±

1 N

⋅

m (95

±

9 in-lb)

NOTE: After installation, keep the sealed area away from oil

for approximately one hour.

AKX00677

GROOVE

BOLT HOLE

AB

AKX00678

4

9

7

3

1

5

8

10

6

2

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст