Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 70

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-51

>>E<< CONNECTING ROD CAP INSTALLATION

1. Mate the correct bearing cap with the correct connecting rod

by checking with the alignment marks marked during

disassembly. If a new connecting rod is used which has no

alignment mark, position the notches for locking the bearing

on the same side.

2. Check if the thrust clearance in the connecting rod big end is

correct.

Standard value: 0.10

−

0.25 mm (0.004

−

0.009 inch)

Limit: 0.4 mm (0.02 inch)

INSPECTION

M1113008500042

PISTON

Replace the piston if scratches or seizure is evident on its

surfaces (especially the thrust surface). Replace the piston if it

is cracked.

PISTON PIN

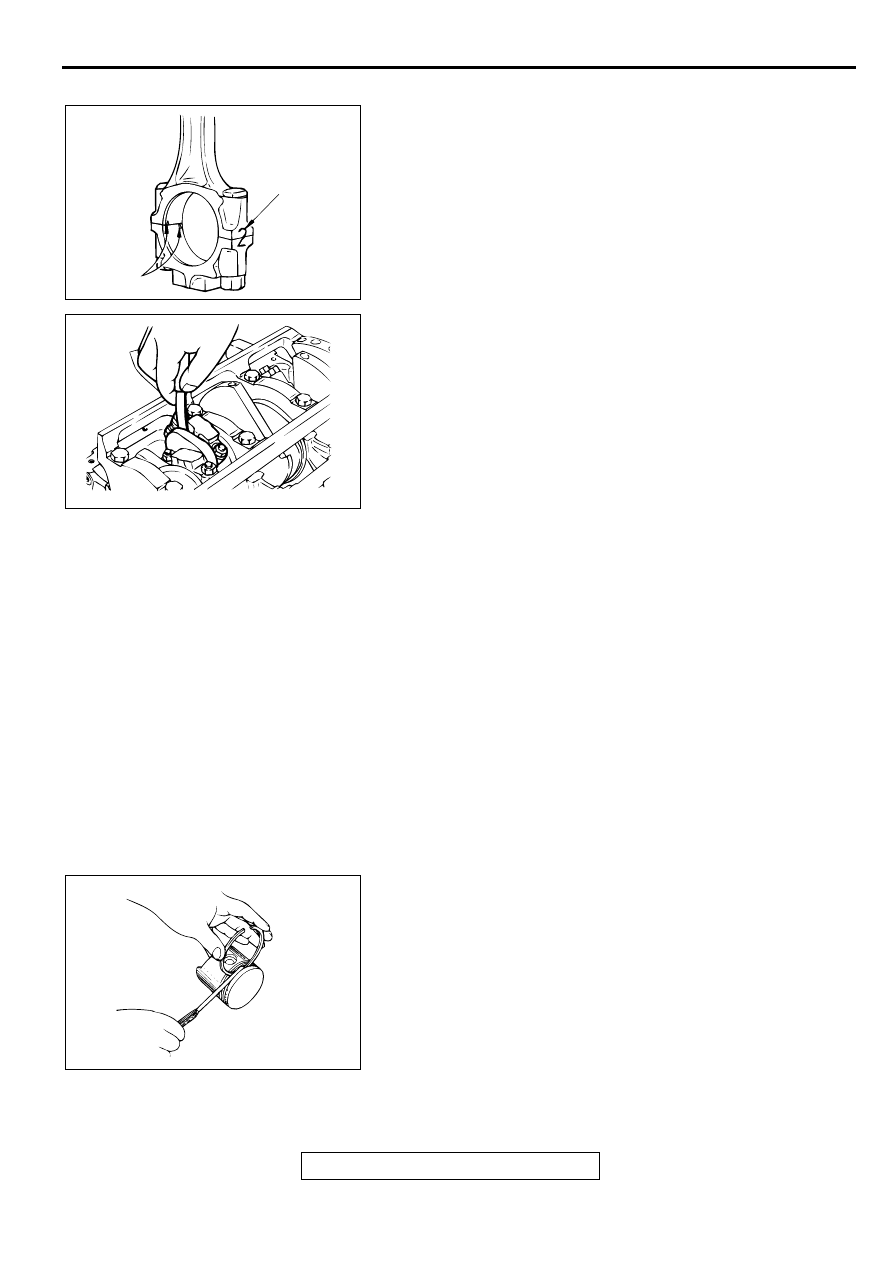

1. Insert the piston pin into the piston pin hole with your thumb.

You should feel a slight resistance. Replace the piston pin if

it can be easily inserted or there is an excessive play.

2. The piston and piston pin must be replaced as an assembly.

PISTON RING

1. Check the piston ring for damage, excessive wear, and

breakage. Replace if defects are evident. If the piston has

been replaced, the piston rings must also be replaced.

2. Check for clearance between the piston ring and ring

groove. If it exceeds the limit, replace the ring or piston, or

both.

Standard value:

Number 1 0.03

−

0.07 mm (0.0012

−

0.0027 inch)

Number 2 0.02

−

0.06 mm (0.0008

−

0.0023 inch)

Limit: 0.1 mm (0.003 inch)

AKX00735

CYLINDER NO.

NOTCHES

AB

AKX00736

AKX00612

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-52

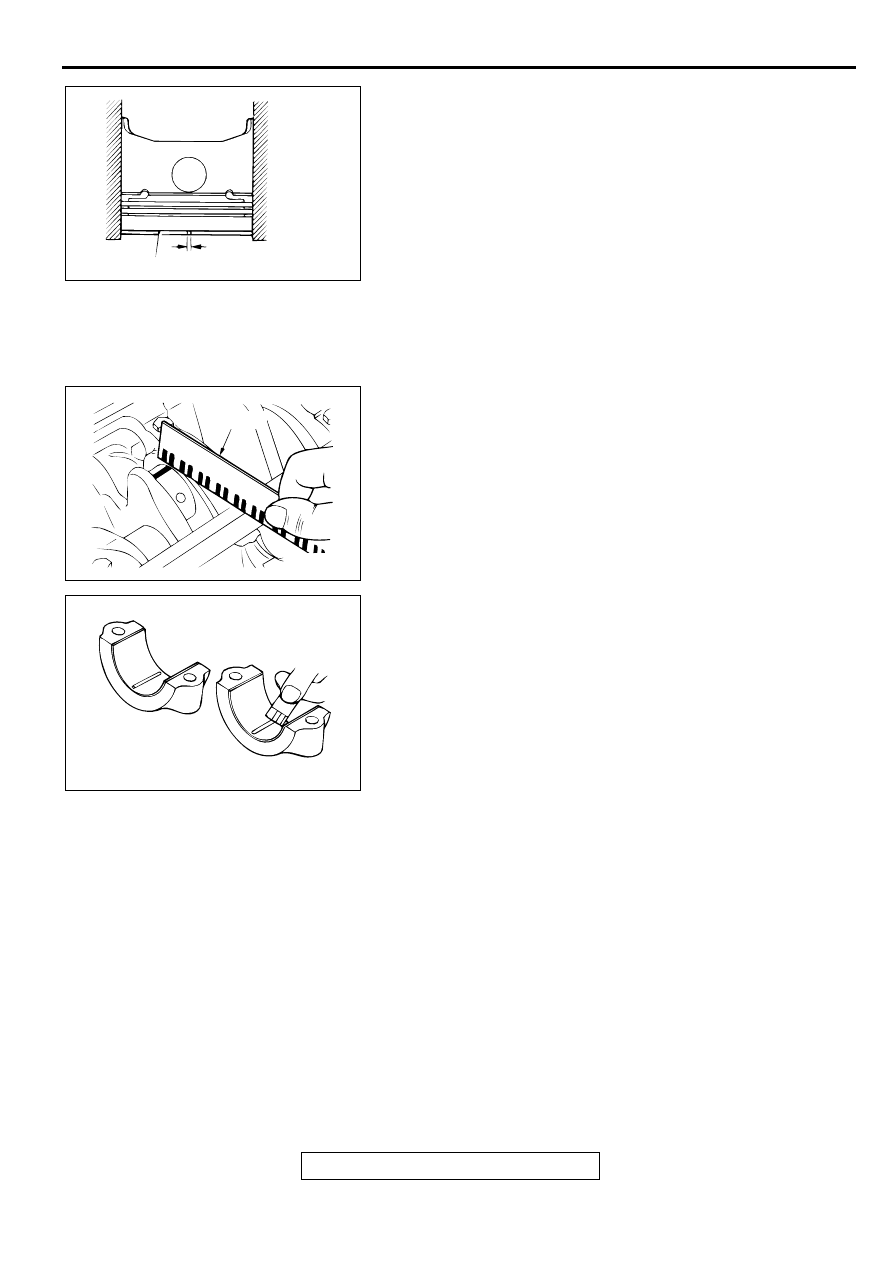

3. Insert the piston ring into the cylinder bore. Force the ring

down with a piston, the piston crown being in contact with

the ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a feeler gauge.

If the ring gap is excessive, replace the piston ring.

Standard value:

Number 1: 0.30

−

0.45 mm (0.012

−

0.017 inch)

Number 2: 0.45

−

0.60 mm (0.018

−

0.023 inch)

Oil: 0.20

−

0.60 mm (0.008

−

0.023 inch)

Limit:

Number 1, Number 2: 0.8 mm (0.03 inch)

Oil: 1.0 mm (0.03 inch)

CRANKSHAFT PIN OIL CLEARANCE (PLASTIC GAUGING

MATERIAL METHOD)

1. Remove oil from the crankshaft pin and the connecting rod

bearing.

2. Cut plastic gauging material to the same length as the width

of the bearing and place it on the pin in parallel with its axis.

3. Install the connecting rod cap carefully and tighten the nuts

to the specified torque.

4. Carefully remove the connecting rod cap.

5. Measure the width of the plastic gauging material at its

widest part by using a scale printed on the plastic gauging

material package.

Standard value: 0.02

−

0.05 mm (0.0008

−

0.0019 inch)

Limit: 0.1 mm (0.003 inch)

AKX00719

PUSH IN BY

PISTON

PISTON

RING

GAP

PISTON RING

AB

AKX00731AB

SCALE

AKX00609

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-53

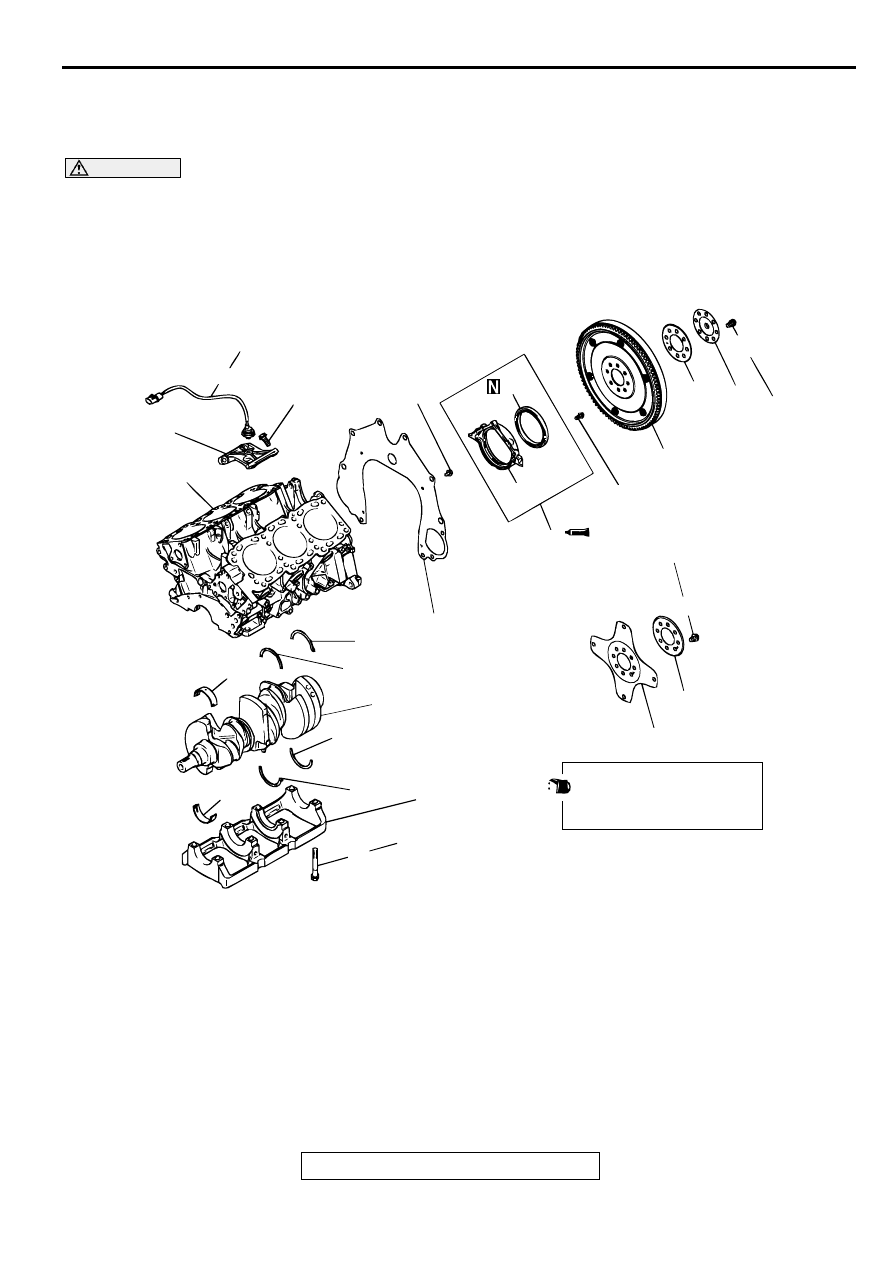

C R A N K SH A FT A N D C YLIN D ER B LO C K

REMOVAL AND INSTALLATION

M1113008700046

CAUTION

On the flexible flywheel equipped engines, do not remove any of the bolts "A" of the flywheel shown

in the illustration. The balance of the flexible flywheel is adjusted in an assembled condition.

Removing the bolt, therefore, can cause the flexible flywheel to be out of balance and result in

damage.

AKX00683

11

APPLY ENGINE OIL TO ALL

MOVING PARTS BEFORE

INSTALLATION.

23 ± 2 N·m

17 ± 1 ft-lb

28 ± 2 N·m

21 ± 1 ft-lb

11 ± 1 N·m

95 ± 9 in-lb

74 ± 2 N·m

54 ± 1 ft-lb

11 ± 1 N·m

95 ± 9 in-lb

74 ± 2 N·m

54 ± 1 ft-lb

93 ± 5 N·m

69 ± 4 ft-lb

1

21

10

3

2

22

4

23

9

5

8

19

20

18

17

6

15

14

16

13

12

AB

7

REMOVAL STEPS

1. FLYWHEEL BOLT <M/T>

2. ADAPTER PLATE <M/T>

3 PLATE <M/T>

4. FLYWHEEL <M/T>

5. DRIVE PLATE BOLT <A/T>

6. ADAPTOR PLATE <A/T>

7. DRIVE PLATE <A/T>

8. REAR PLATE

>>F<<

9. OIL SEAL CASE ASSEMBLY

>>E<<

10.CRANKSHAFT REAR OIL SEAL

11. OIL SEAL CASE

>>D<<

12.BEARING CAP BOLT

>>D<<

13.BEARING CAP

>>C<<

14.THRUST BEARING A

>>C<<

15.THRUST BEARING B

>>B<<

16.CRANKSHAFT BEARING, LOWER

17.CRANKSHAFT

>>C<<

18.THRUST BEARING B

>>C<<

19.THRUST BEARING A

>>B<<

20.CRANKSHAFT BEARING, UPPER

21.KNOCK SENSOR

REMOVAL STEPS (Continued)

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-54

Required Special Tool:

MD998718: Crankshaft Rear Oil Seal Installer

INSTALLATION SERVICE POINTS

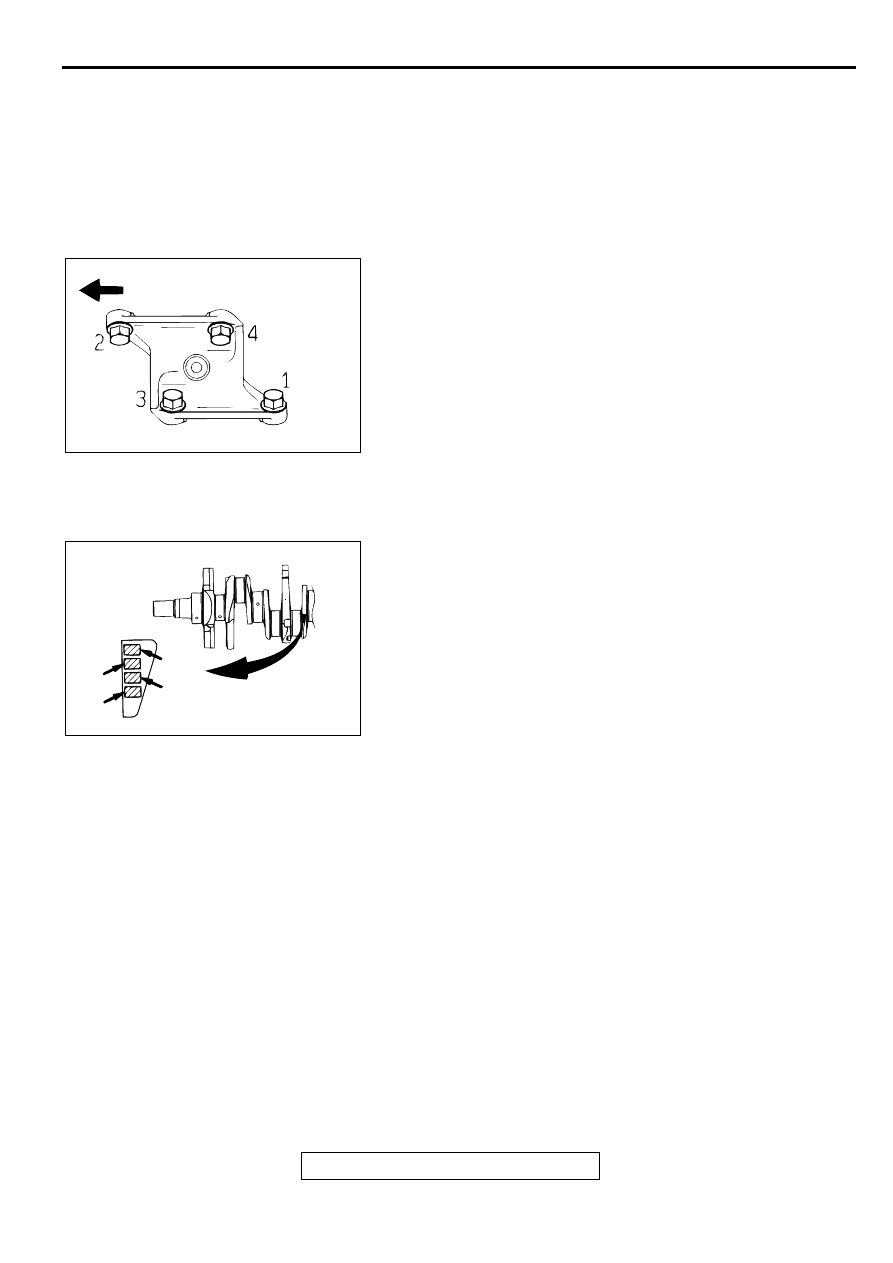

>>A<< KNOCK SENSOR BRACKET INSTALLATION

Check that the bracket is in proper contact with the cylinder

block boss and tighten to the specified torque in the order

shown.

Tightening torque: 28

±

2 N

⋅

m (21

±

1 ft-lb)

>>B<< CRANKSHAFT BEARING INSTALLATION

When bearing replacement is required, select and install the

correct bearing by the following procedure.

1. Measure the crankshaft journal diameter and confirm its

classification from the following table. In the case of a

crankshaft supplied as a service part, identification colors/

marks of its journals are painted/stamped at the positions

shown in the illustration.

>>A<<

22.KNOCK SENSOR BRACKET

23.CYLINDER BLOCK

REMOVAL STEPS (Continued)

AKX00649

TIMING BELT SIDE

AB

AKX00647

NO. 2

JOURNAL

LOCATION OF IDENTIFICATION COLOR

NO. 1

JOURNAL

NO. 3

JOURNAL

NO. 4

JOURNAL

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст