Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 607

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-23

PO W ER STEERIN G G EA R B O X A SSEM B LY

REMOVAL AND INSTALLATION

M1372003900075

WARNING

Before removing the steering gear box, refer to GROUP 52B. Center the front wheels and

remove the ignition key. Failure to do so may damage the SRS clock spring and render the

SRS system inoperative, risking serious injury.

Pre-removal Operation

•

Power Steering Fluid Draining (Refer to

•

Center Member Removal (Refer to GROUP 32, Engine

Roll Stopper, Centermember

•

Front Exhaust Pipe Removal (2.4L Engine: Refer to

GROUP 15, Exhaust Pipe and Main Muffler

, 3.0L

Engine: Refer to GROUP 15, Exhaust Pipe and Main Muf-

fler

•

Stabilizer Bar Removal <2.4L Engine> (Refer to GROUP

33A, Stabilizer Bar

Post-installation Operation

•

Check the Dust Cover for Cracks or Damage by Pushing

it with Finger.

•

Stabilizer Bar Installation <2.4L Engine> (Refer to

GROUP 33A, Stabilizer Bar

.)

•

Front Exhaust Pipe Installation (2.4L Engine: Refer to

GROUP 15, Exhaust Pipe and Main Muffler

, 3.0L

Engine: Refer to GROUP 15, Exhaust Pipe and Main Muf-

fler

•

Center Member Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember

.)

•

Power Steering Fluid Supplying (Refer to

.)

•

Power Steering Fluid Line Bleeding (Refer to

•

Checking Steering Wheel Position with Wheels Straight

Ahead.

•

Front Wheel Alignment Adjustment (Refer to GROUP

33A, On-vehicle Service

−

Front Wheel Alignment Check

and Adjustment

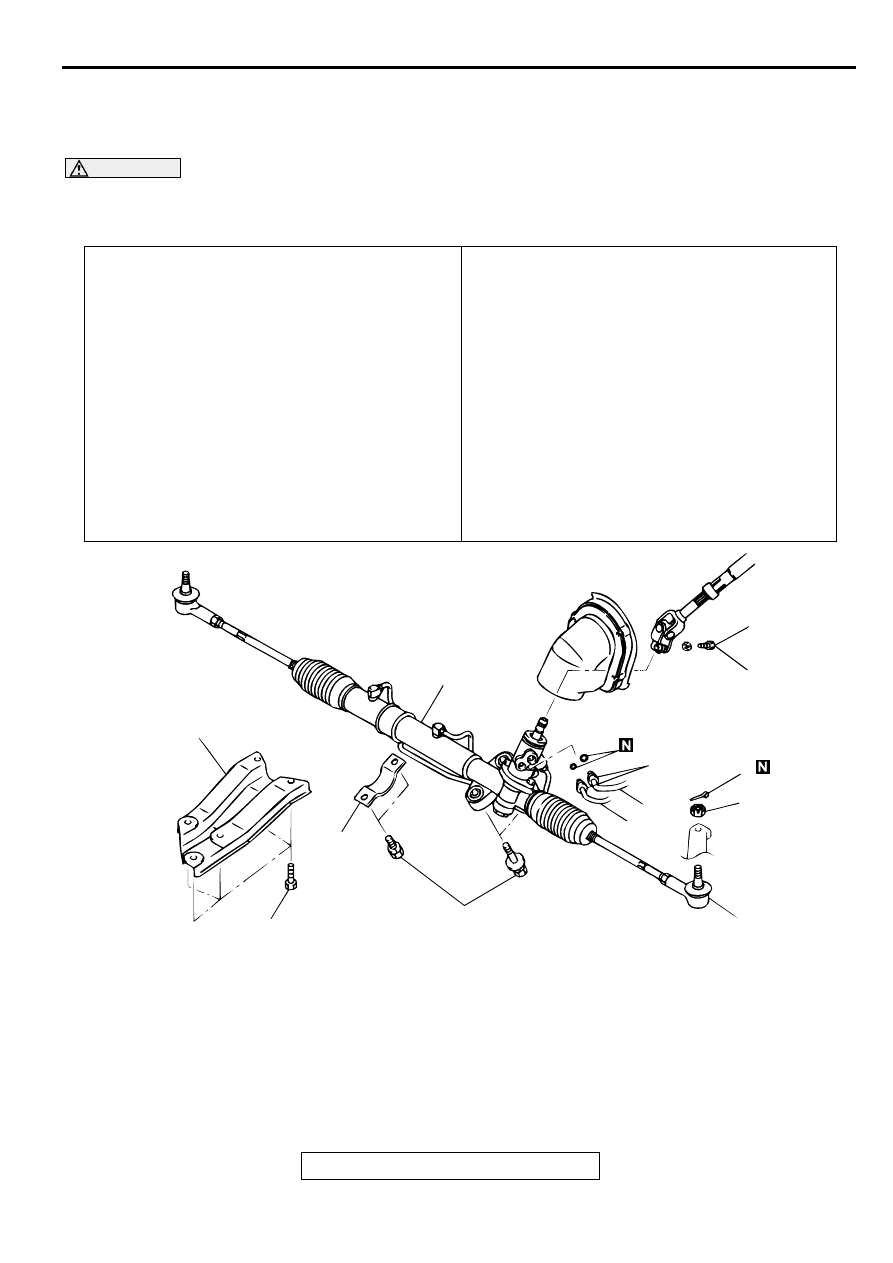

AC000994 AD

1

8

7

6

5

4

3

2

18 ± 2 N·m

13 ± 1 ft-lb

15 ± 3 N·m

11 ± 2 ft-lb

29 ± 4 N·m

21 ± 4 ft-lb

74 ± 4 N·m

55 ± 3 ft-lb

69 ± 9 N·m

51 ± 7 ft-lb

<2.4L ENGINE>

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-24

Required Special Tools:

•

MB990228 or MB991006: Preload Socket

•

MB991113 or MB990635: Steering Linkage Puller

REMOVAL SERVICE POINTS

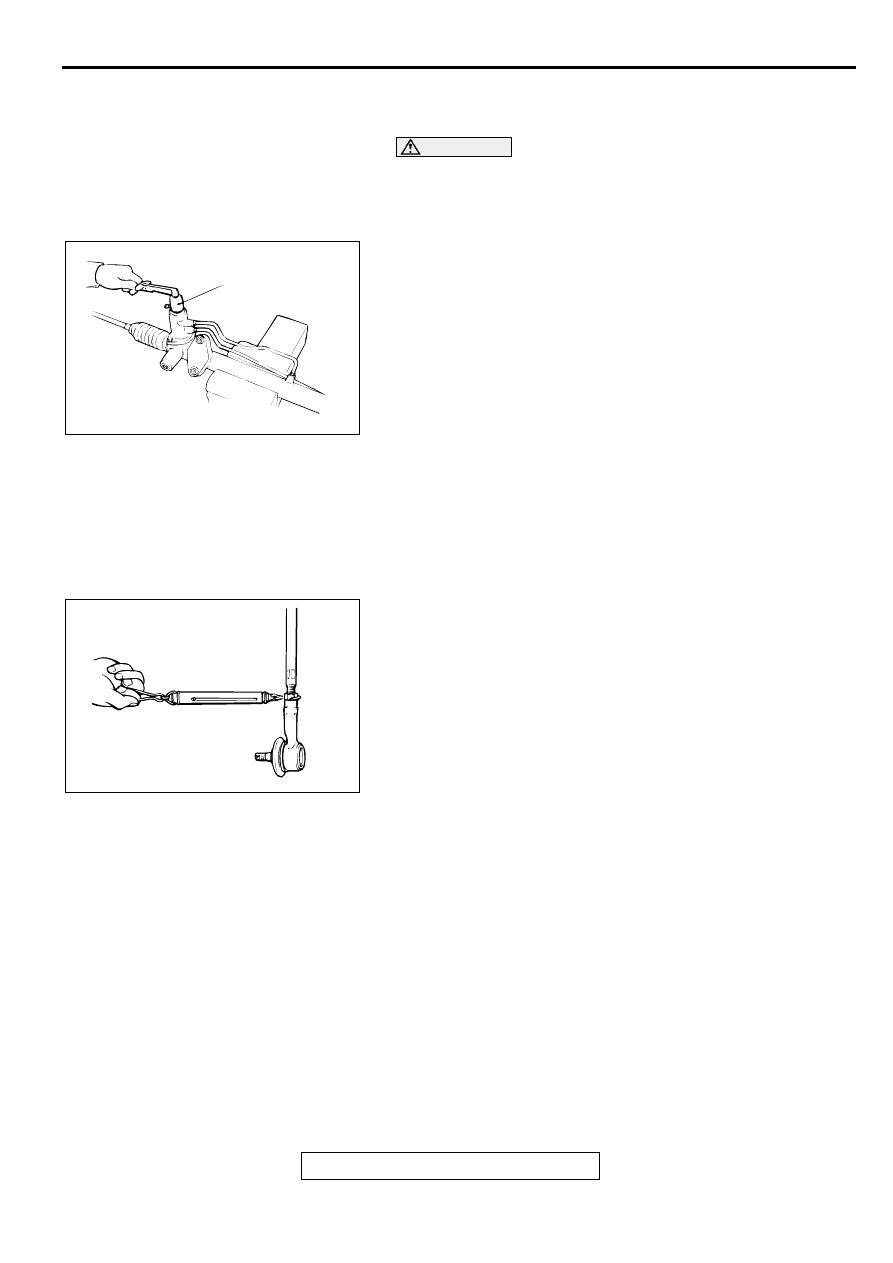

<<A>> TIE ROD END DISCONNECTION

CAUTION

•

Loosen the nut from the ball joint instead of removing

it.

•

Hang special tool MB991113 or MB990635 with ropes to

prevent it from falling.

Use special tool MB991113 or MB990635 to disconnect the ball

joint.

<<B>> GEAR BOX ASSEMBLY REMOVAL

CAUTION

Be sure not to damage the bellows and the tie rod end dust

cover when removing the gear box assembly.

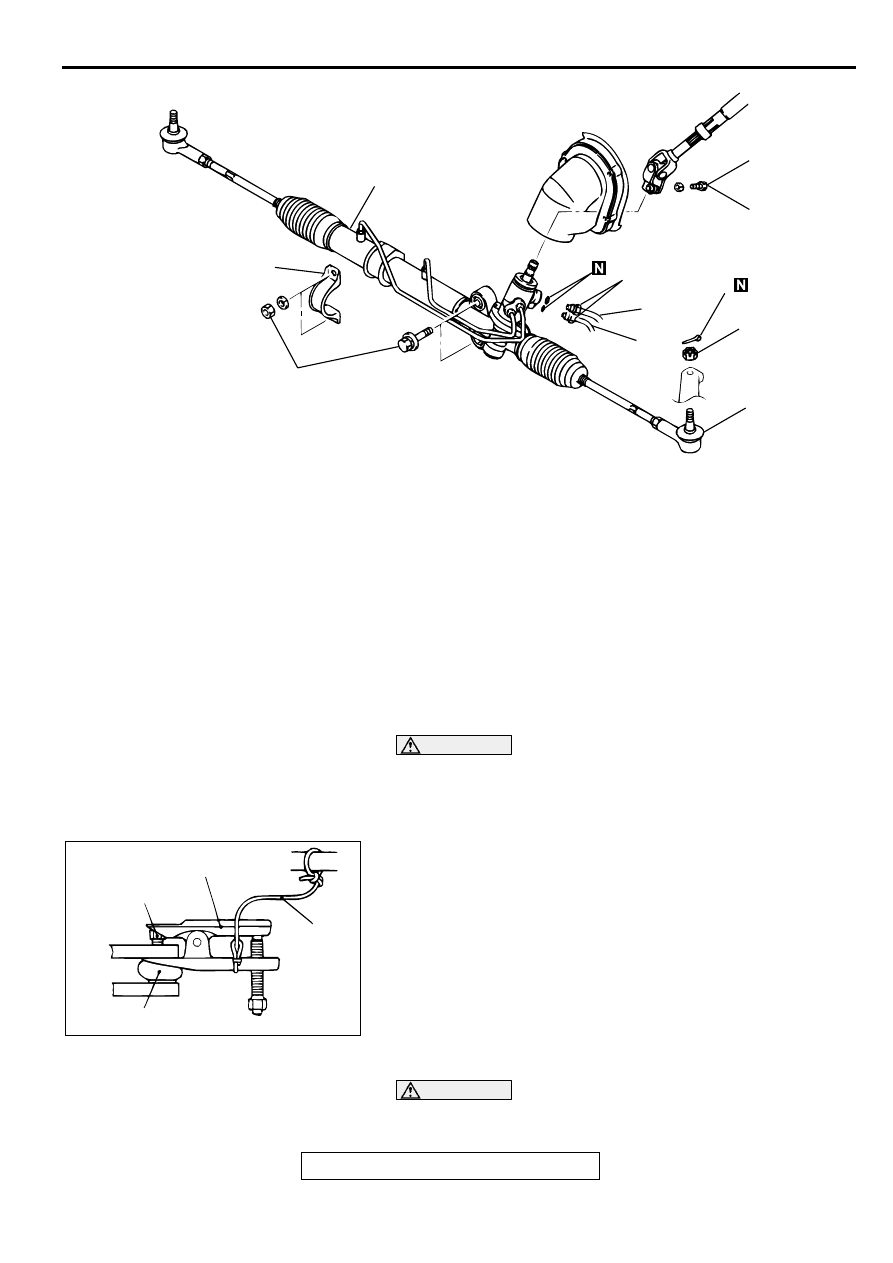

AC003541AC

1

8

7

6

5

4

3

18 ± 2 N·m

13 ± 1 ft-lb

15 ± 3 N·m

11 ± 2 ft-lb

29 ± 4 N·m

21 ± 4 ft-lb

69 ± 9 N·m

51 ± 7 ft-lb

<3.0L ENGINE>

REMOVAL STEPS

1.

STEERING SHAFT ASSEMBLY AND

GEAR BOX CONNECTING BOLT

2.

STAY <2.4L ENGINE>

3.

COTTER PIN

<<A>>

4.

TIE ROD END AND KNUCKLE

CONNECTION

5.

RETURN HOSE CONNECTION

6.

PRESSURE TUBE CONNECTION

7.

CYLINDER CLAMP

<<B>>

8.

GEAR BOX ASSEMBLY

REMOVAL STEPS (Continued)

ACX01123AB

NUT

BALL JOINT

CORD

MB991113 OR MB990635

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-25

INSPECTION

M1372003200032

GEAR BOX TOTAL PINION TORQUE CHECK

CAUTION

When holding the steering gear box assembly in a vice,

secure its mounting positions. If it is secured in any other

places, the gear housing may become deformed or

damaged.

Using special tool MB990228 or MB991006, rotate the pinion

gear at the rate of one rotation in approximately 4 to 6 seconds

to check the total pinion torque.

Standard value: 0.8

−

1.9 N

⋅

m (6.9

−

16.5 in-lb)

[Change in torque: 0.7 N

⋅

m (6.1 in-lb) or less]

NOTE: When measuring, remove the bellows from the rack

housing. Measure the pinion torque through the whole stroke of

the rack.

If the measured value is not within the standard range, first

adjust the rack support cover, and then check the total pinion

torque again.

If the total pinion torque cannot be adjusted to within the

standard range by adjusting the rack support cover, check the

rack support cover, rack support spring, rack support and

replace any parts if necessary.

TIE ROD SWING RESISTANCE CHECK

1. Give 10 hard swings to the tie rod.

2. Measure the tie rod swing resistance with a spring scale.

Standard value: 4.0

−

18.6 N (17.8

−

82.7 lb) [1.0

−

4.9

N

⋅

m (8.7

−

43.4 in-lb)]

3. If the measured value exceeds the standard value, replace

tie rod.

4. If the measured value is below the standard value, the tie

rod can be re-used if it swings smoothly without excessive

play.

TIE ROD END BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing it

with your finger.

2. If the dust cover is cracked or damaged, replace the tie rod

end. (Refer to

NOTE: Cracks or damage of the dust cover may damage

the ball joint. If it is damaged during service work, replace

the dust cover. (Refer to

AC000996 AB

MB990228

OR

MB991006

AC000997

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-26

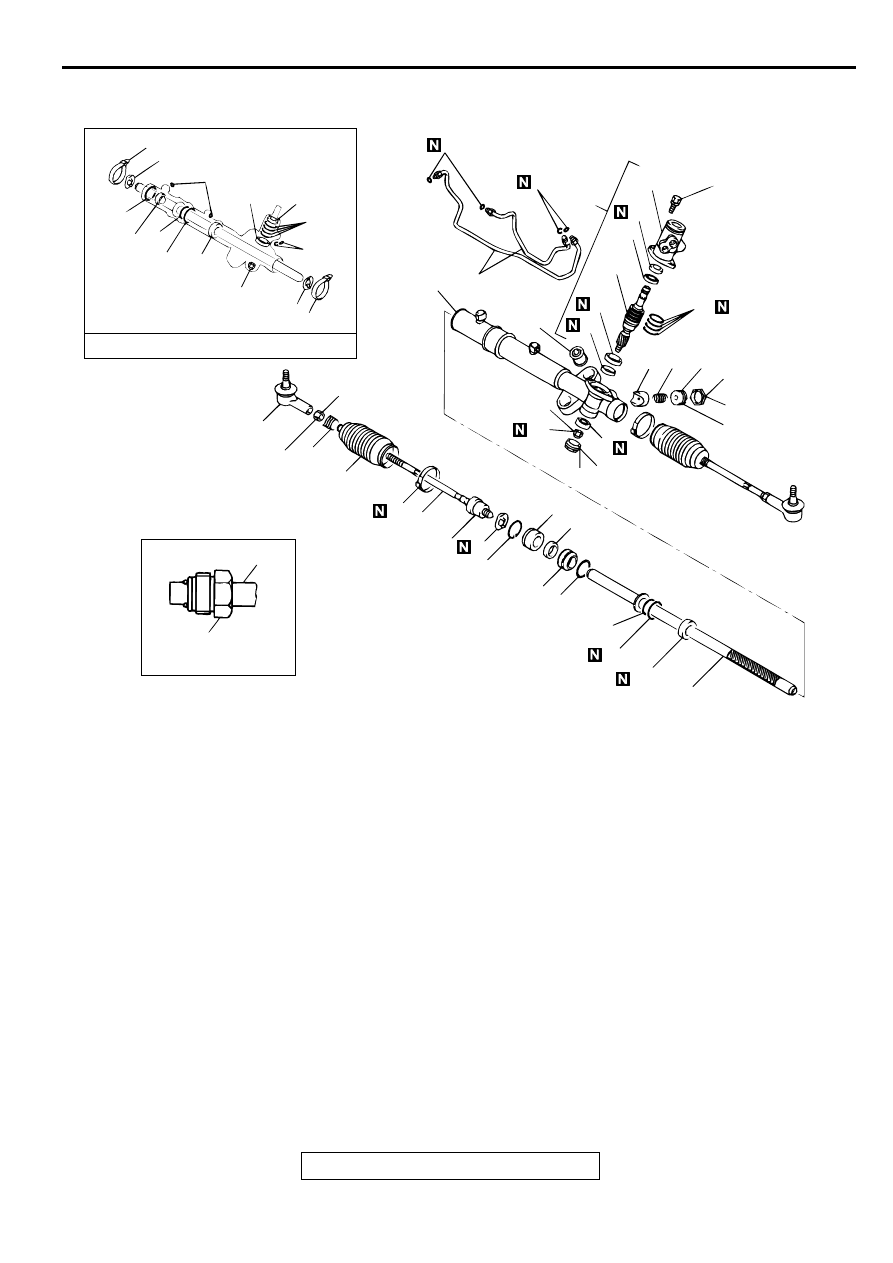

DISASSEMBLY AND ASSEMBLY

M1372004100072

AC000999

1

13 12 11

10

9

8

7

6

5

4

3

2

14

15

18

17

16

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1

9

6

2

15

19

2

21

27

28

29

30

33

9

6

17

52 ± 2 N·m

38 ± 2 ft-lb

88 ± 10 N·m

65 ± 7 ft-lb

13 ± 3 N·m

113 ± 26 in-lb

59 ± 10 N·m

44 ± 7 ft-lb

13 ± 2 N·m*

109 ± 21 in-lb*

59 ± 10 N·m

44 ± 7 ft-lb

25 ± 4 N·m

18 ± 4 ft-lb

STEERING GEAR SEAL KIT

FLARE NUT

NOTE

*: Return the rack support cover

–

10˚.

AB

19 ± 3 N·m

14 ± 2 ft-lb

DISASSEMBLY STEPS

1.

FEED TUBE

2.

O-RING

>>O<<

3.

TIE ROD END JAM NUT

>>O<<

4.

TIE ROD END

5.

BELLOWS CLIP

>>N<<

6.

BELLOWS BAND

7.

BELLOWS

<<A>> >>M<<

8.

TIE ROD

<<A>> >>M<<

9.

TAB WASHER

>>L<<

•

TOTAL PINION TORQUE

ADJUSTMENT

>>K<<

10.

JAM NUT

<<B>> >>K<<

11.

RACK SUPPORT COVER

12.

RACK SUPPORT SPRING

13.

RACK SUPPORT

>>J<<

14.

END PLUG

15.

JAM NUT

16.

VALVE HOUSING ASSEMBLY

<<C>> >>I<<

17.

OIL SEAL

<<C>>

18.

PINION AND VALVE ASSEMBLY

<<D>> >>H<<

19.

SEAL RING

<<E>> >>G<<

20.

BALL BEARING

<<E>> >>G<<

21.

OIL SEAL

22.

VALVE HOUSING

<<F>> >>F<<

23.

CIRCLIP

24.

RACK STOPPER

>>E<<

25.

RACK BUSHING

<<G>> >>D<<

26.

RACK

>>C<<

27.

O-RING

<<H>> >>C<<

28.

OIL SEAL

29.

SEAL RING

30.

O-RING

<<I>>

>>B<<

31.

BALL BEARING

<<J>> >>B<<

32.

NEEDLE ROLLER BEARING

<<K>> >>A<<

33.

OIL SEAL

34.

BUSHING

35.

RACK HOUSING

DISASSEMBLY STEPS (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст