Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 365

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-37

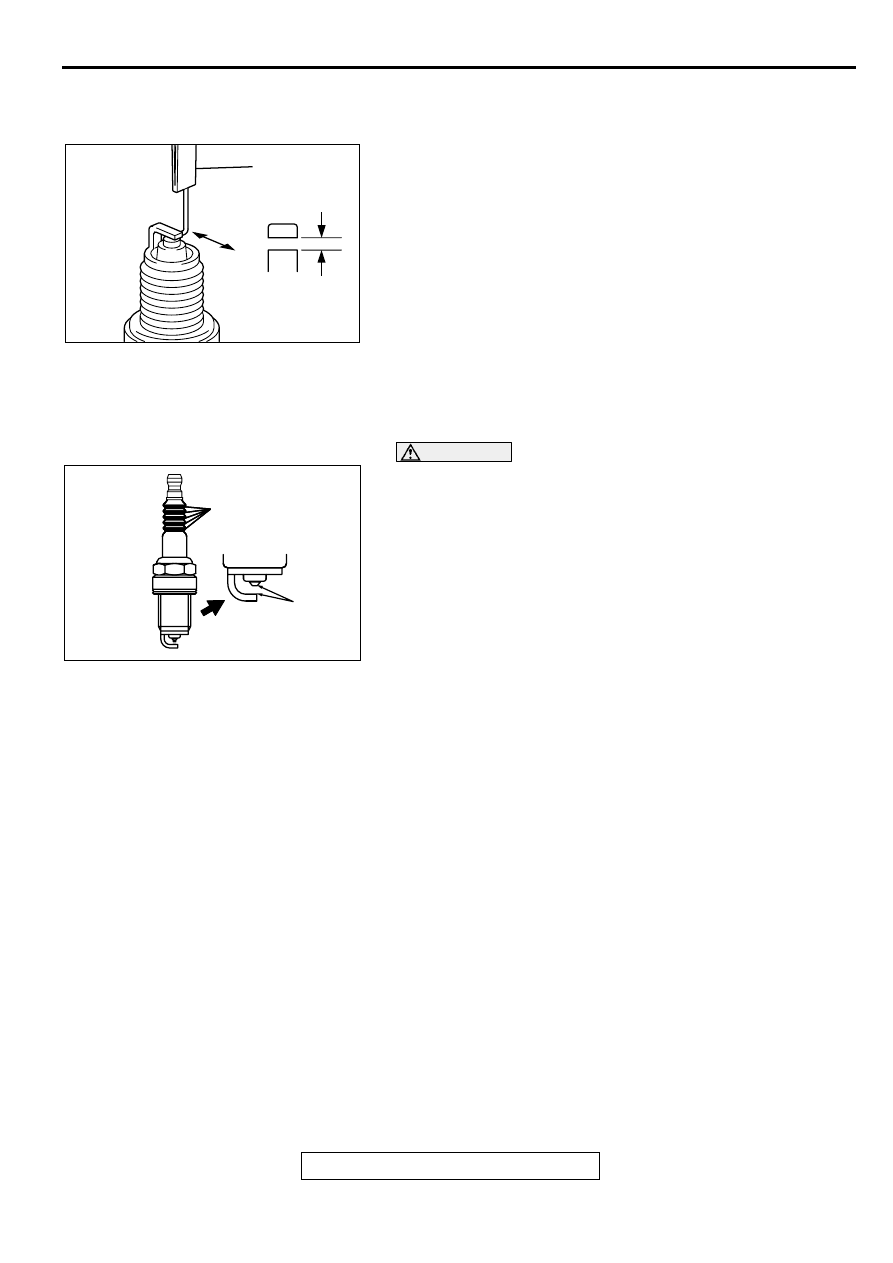

SPARK PLUG CHECK AND CLEANING

M1163004300029

<2.4L ENGINE>

1. Check that the plug is not burned, that the insulator plug is

not damaged, and that the seizure state is good.

2. If cleaning is required due to carbon deposits, etc., clean

using a plug cleaner or wire brush, etc.

3. Check the plug gap using a plug gap gauge, and adjust if not

within the standard value.

Standard value: 1.0

−

1.1 mm (0.039

−

0.043 inch)

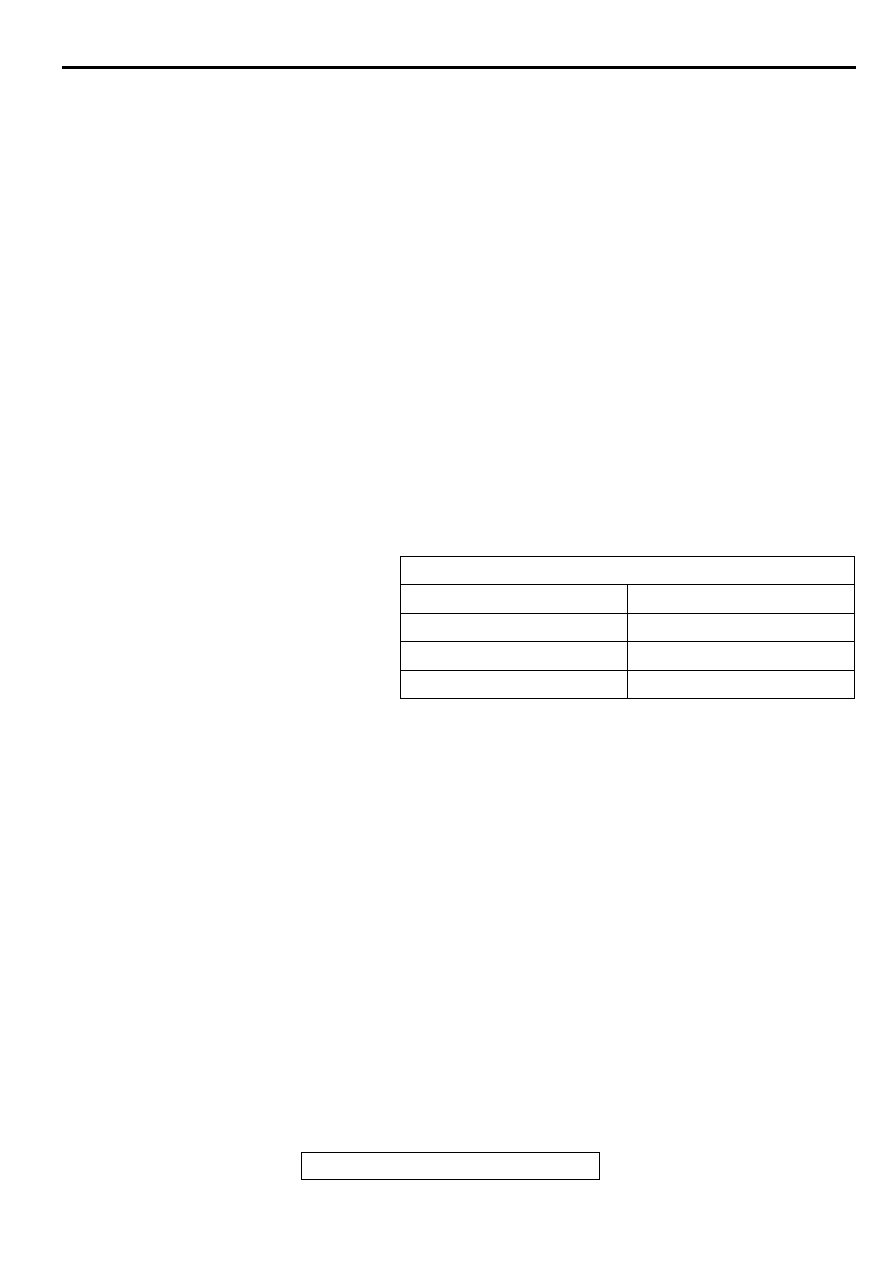

SPARK PLUG CHECK AND CLEANING

M1163004300063

<3.0L ENGINE>

CAUTION

•

Do not attempt to adjust the gap of the platinum plug.

•

Cleaning of the platinum plug may result in damage to

the platinum tips. Therefore, if carbon deposits must be

removed, use a plug cleaner and complete cleaning

within 20 seconds to protect the electrode. Do not use a

wire brush.

Check the plug gap and replace if the limit is exceeded.

Standard value: 1.0

−

1.1 mm (0.039

−

0.043 inch)

Limit: 1.3 mm (0.051 inch)

CAMSHAFT POSITION SENSOR CHECK

M1163004400037

<2.4L ENGINE>

Refer to GROUP 13A, Multiport fuel injection (MFI) diagnosis

−

Diagnostic trouble code procedures

−

Camshaft position

sensor circuit malfunction (

).

CRANK ANGLE SENSOR CHECK

M1163004500034

<2.4L ENGINE>

Refer to GROUP 13A, Multiport fuel injection (MFI) diagnosis

−

Diagnostic trouble code procedures

−

Crankshaft position

sensor circuit malfunction (

).

CRANK ANGLE SENSOR CHECK

M1163004500045

<3.0L ENGINE>

Refer to GROUP 13B, Multiport fuel injection (MFI) diagnosis

−

Diagnostic trouble code procedures

−

Crankshaft position

sensor circuit malfunction (

).

AKX01272

AKX01272

PLUG GAP

GAUGE

MEASU-

REMENT

DIRECTION

AB

AKX00383

AKX00383

BLUE LINES

PLATINUM

TIPS

AE

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-38

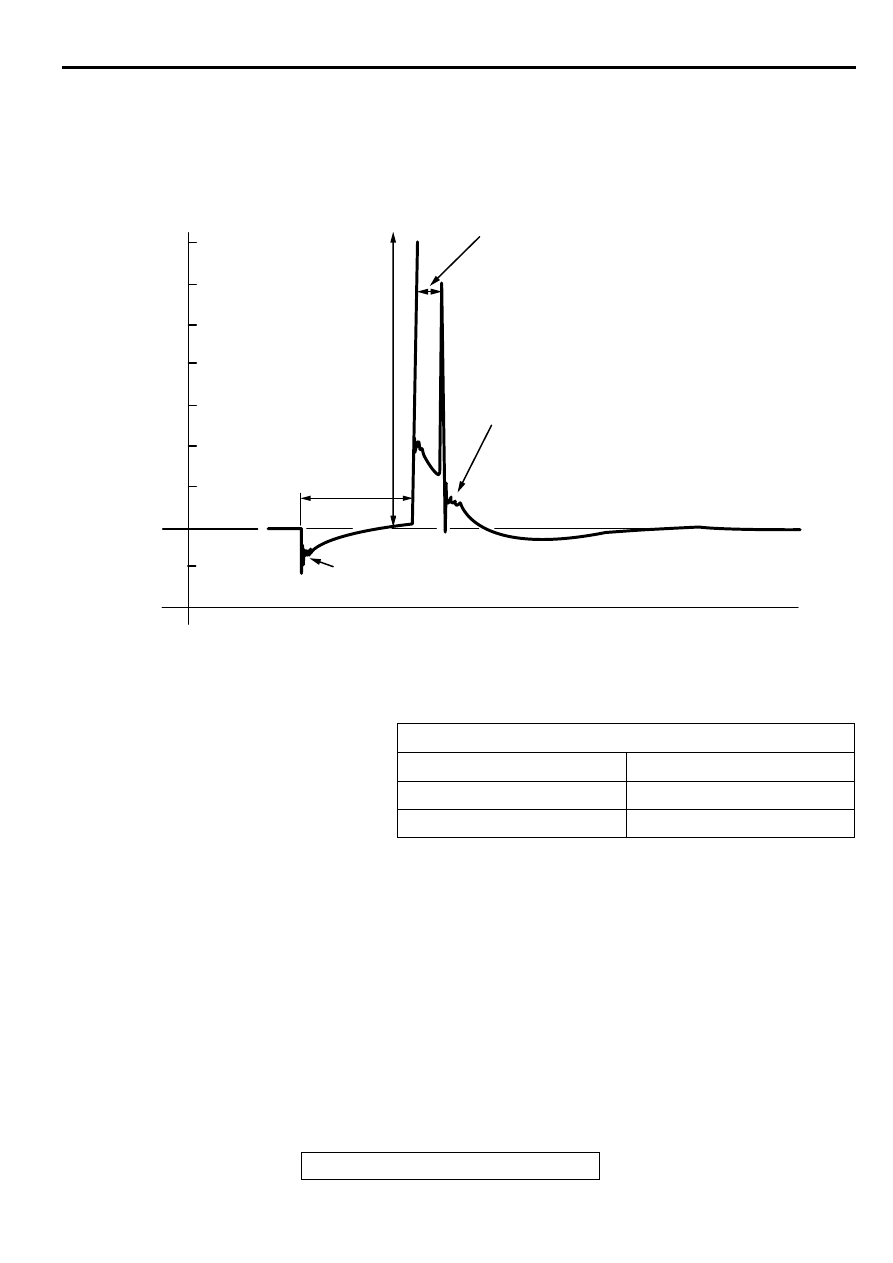

IGNITION SECONDARY VOLTAGE WAVE

PATTERN CHECK USING AN OSCILLOSCOPE

M1163001700073

<2.4L ENGINE>

MEASUREMENT METHOD

1. Clamp the spark plug cable (Number 1 or 3) with the

secondary pickup.

NOTE: Because of the two-cylinder simultaneous ignition

system, the waves for two cylinders in each group appear

during wave observation. However, wave observation is

carried out for the cylinder (Number 1 or 3) with the spark

plug cable which has been clamped by the secondary

pickup.

NOTE: Identification of which cylinder wave pattern is

displayed can be difficult, but the wave pattern of the

cylinder which is clamped by the secondary pickup will be

stable, so this can be used as a reference.

2. Clamp the spark plug cable (Number 1 or 3) with the trigger

pickup.

NOTE: Clamp the same spark plug cable as the one which

has been clamped by the secondary pickup.

STANDARD WAVE PATTERN

Observation Conditions

FUNCTION

SECONDARY

Pattern height

High (or low)

Pattern selector

Raster

Engine speed

Curb idle speed

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-39

Observation Conditions

Pattern selector

Display

Pattern height

High (or low)

Engine speed

Curb idle speed

AKX00278

kV

0

SECONDARY

IGNITION

VOLTAGE

WAVE PATTERN

IGNITION VOLTAGE

(POINT D)

SPARK LINE(POINT A)

DWELL SECTION

WAVE DAMPING REDUCTION SECTION(POINT B)

POINT C

TIME

AB

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-40

WAVEFORM OBSERVATION POINTS

NOTE: Abnormal waveform examples are shown

subsequently.

Point A:

The height, length and slope of the spark line (refer to

abnormal waveform examples 1, 2, 3 and 4) show the

following trends.

Point B:

Number of vibrations in reduction vibration section (Refer to

Abnormal Waveform Example 5)

Point C:

Number of vibrations at beginning of dwell section (Refer to

Abnormal Waveform Example 5)

AKX01275

kV

SECONDARY IGNITION

VOLTAGE

WAVE

PATTERN

0

2

NO. 1 CYLINDER

NO. 3 CYLINDER

IGNITION NOISE

NEUTRAL SECTION

NO. 4 CYLINDER

NO. 2 CYLINDER

IGNITION NOISE

TIME

AB

SPARK LINE

PLUG

GAP

CONDITION

OF

ELECTRODE

COMPRESSION

FORCE

CONCENTRATION

OF AIR MIXTURE

IGNITION

TIMING

SPARK

PLUG

CABLE

Length Long

Small

Normal

Low

Rich

Advanced

Leak

Length Short

Large

Large wear

High

Lean

Retarded

High

resistance

Height

High

Large

Large wear

High

Lean

Retarded

High

resistance

Height

Low

Small

Normal

Low

Rich

Advanced

Leak

Slope

Large

Plug is fouled

-

-

-

-

NUMBER OF VIBRATIONS

COIL AND CAPACITOR

Three or more

Normal

Except above

Abnormal

NUMBER OF VIBRATIONS

COIL

5

−

6 or higher

Normal

Except above

Abnormal

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст