Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 538

26-1

GROUP 26

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .

FRONT AXLE DIAGNOSIS . . . . . . . .

INTRODUCTION. . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING STRATEGY . . . . . .

SYMPTOM CHART. . . . . . . . . . . . . . . . . . .

SYMPTOM PROCEDURES . . . . . . . . . . . .

SPECIAL TOOLS. . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE. . . . . . . . . . .

HUB END PLAY CHECK . . . . . . . . . . . . . .

HUB BOLT REPLACEMENT . . . . . . . . . . .

FRONT AXLE HUB ASSEMBLY . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION . . . . . . . . . . . . . . . . . . . . . . .

KNUCKLE . . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

DRIVE SHAFT ASSEMBLY . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

DISASSEMBLY AND ASSEMBLY . . . . . . .

BJ BOOT REPLACEMENT . . . . . . . . . . . . .

SPECIFICATIONS . . . . . . . . . . . . . . .

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . .

GENERAL SPECIFICATIONS . . . . . . . . . .

SERVICE SPECIFICATIONS . . . . . . . . . . .

GENERAL DESCRIPTION

TSB Revision

FRONT AXLE

26-2

.

G EN ER A L DESC RIPTIO N

M1261000100109

FRONT AXLE

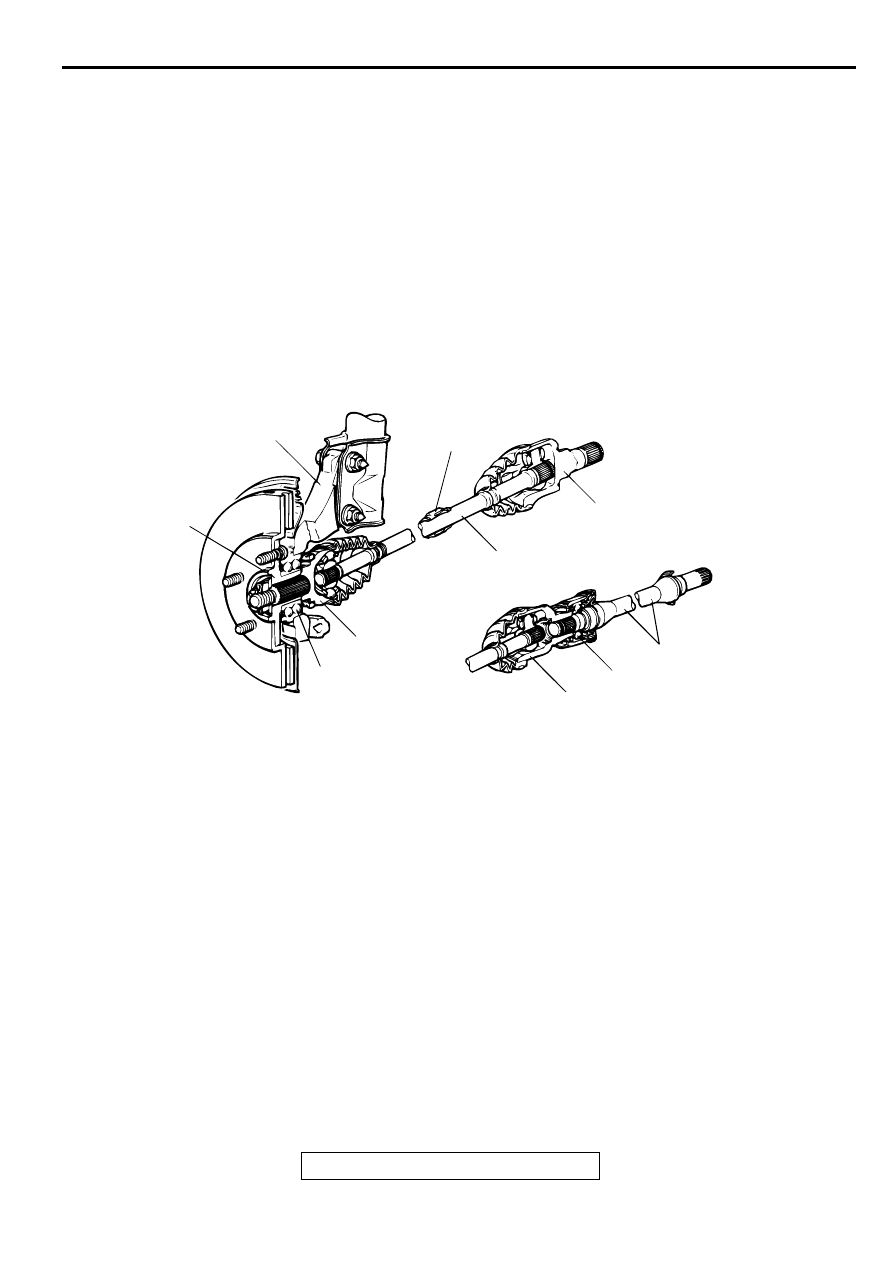

The front axle consists of a knuckle, front hub, unit

bearing and drive shaft. The unit bearing is press-

fitted to the front hub and bolted to the knuckle. Also,

the unit bearing utilizes a double row angular contact

ball bearing. The drive shaft has a tripod joint (TJ) on

the transaxle side and a birfield joint (BJ) on the

wheel side. A center bearing and an inner shaft have

been adopted in 3.0L engine.

CONSTRUCTION DIAGRAM

FR O N T A XLE D IA G N O SIS

INTRODUCTION

M1261005500061

Noise from driveshaft or inner shaft can be caused

by a component defect.

TROUBLESHOOTING STRATEGY

M1261005600079

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

front axle fault.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

AC001145

KNUCKLE

FRONT HUB

UNIT

BEARING

BJ

DYNAMIC

DAMPER

DRIVESHAFT

TJ

INNER SHAFT

CENTER BEARING

TJ

<3.0L ENGINE-RH>

AB

<2.4L ENGINE, 3.0L ENGINE-LH>

FRONT AXLE DIAGNOSIS

TSB Revision

FRONT AXLE

26-3

SYMPTOM CHART

M1261005700098

SYMPTOM PROCEDURES

INSPECTION PROCEDUR 1: Noise during Wheel Rotation

DIAGNOSIS

STEP 1. Check the driveshaft and inner shaft for

bending.

Q: Is the driveshaft and inner shaft bent?

YES :

Replace the part. Then go to Step 4.

NO :

Go to step 2.

STEP 2. Check the inner shaft bearing for wear.

Q: Is the inner shaft bearing worn?

YES :

Replace the bearings. Then go to Step 4.

NO :

Go to Step 3.

STEP 3. Check the driveshaft assembly for wear,

damage or bending.

Q: Is the driveshaft assembly worn, damaged or bent?

YES :

Replace the driveshaft assembly. Then go

to Step 4.

NO :

There is no action to be taken.

STEP 4. Check symptoms.

Q: Is the abnormal noise eliminated?

YES :

Repeat to Step 1.

NO :

This diagnosis is complete.

INSPECTION PROCEDUR 2: Noise due to Excessive Play of Wheel in Turning Direction

DIAGNOSIS

STEP 1. Check for play in the inner shaft and side

gear serration, the driveshaft and side gear, or

the driveshaft and drive flange.

Q: Is the play found?

YES :

Adjust or replace the part. Then go to Step

NO :

This diagnosis is complete.

STEP 2. Check symptoms.

Q: Is the abnormal noise eliminated?

YES :

Repeat to Step 1.

NO :

This diagnosis is complete.

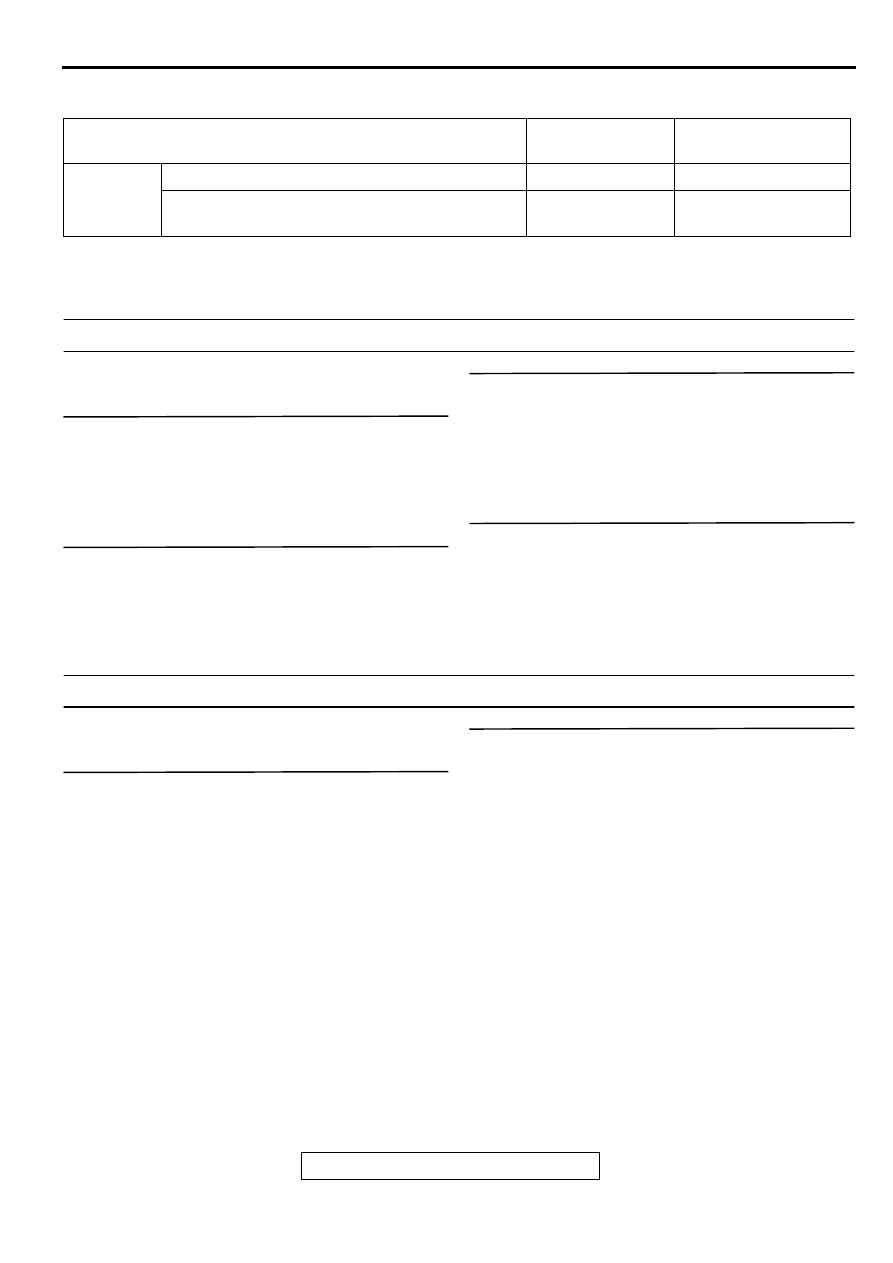

SYMPTOMS

INSPECTION

PROCEDURE

REFERENCE PAGE

Driveshaft,

inner shaft

Noise during wheel rotation

1

Noise due to excessive play of wheel in turning

direction

2

SPECIAL TOOLS

TSB Revision

FRONT AXLE

26-4

SPECIA L TO O LS

M1261000600096

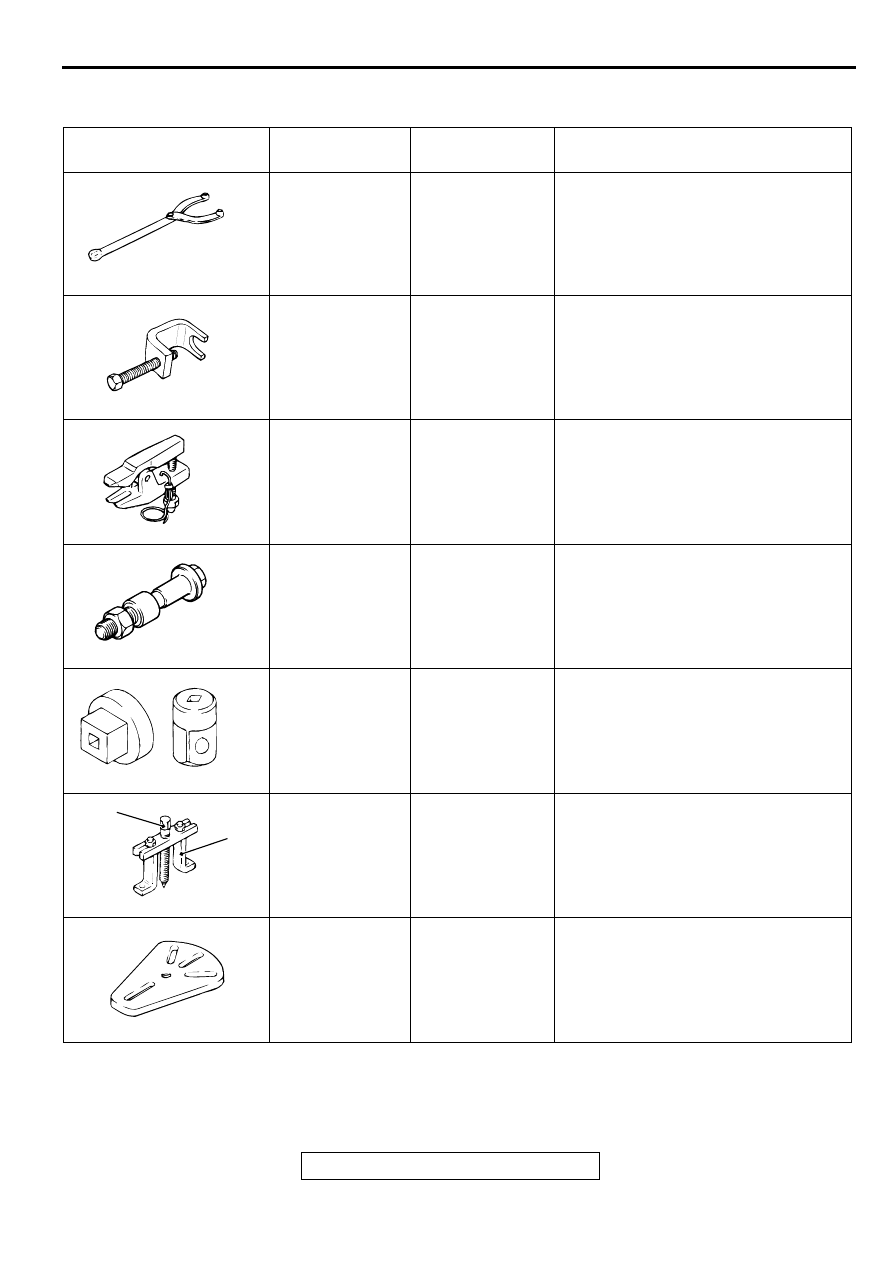

TOOL

TOOL NUMBER

AND NAME

SUPERSESSION APPLICATION

MB990767

End yoke holder

MB990767-01

Hub fixing

MB991618

Hub bolt remover

General service

tool

Driving out of hub bolt

MB990635 or

MB991113

Steering linkage

puller

MB991113-01,

MB990635-01 or

General service

tool

Knuckle and tie rod end ball joint

disconnection

MB990998

Front hub

remover and

installer

MB990998-01 or

General service

tool

•

Removal of or pressing-in the hub

•

Provisional holding of the wheel

bearing

MB990326

Preload socket

General service

tool

Wheel bearing breakaway torque

measurement

MB990241

Axle shaft puller

A: MB990244

Puller shaft

B: MB990242

Puller bar

MB990241-01 or

General service

tool

Drive shaft removal

MB991354

Puller body

MB990241-01 or

General service

tool

Drive shaft removal

MB990767

MB991618

MB990635

MB990998

MB990326

MB990241AB

A

B

MB991354

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст