Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 457

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-120

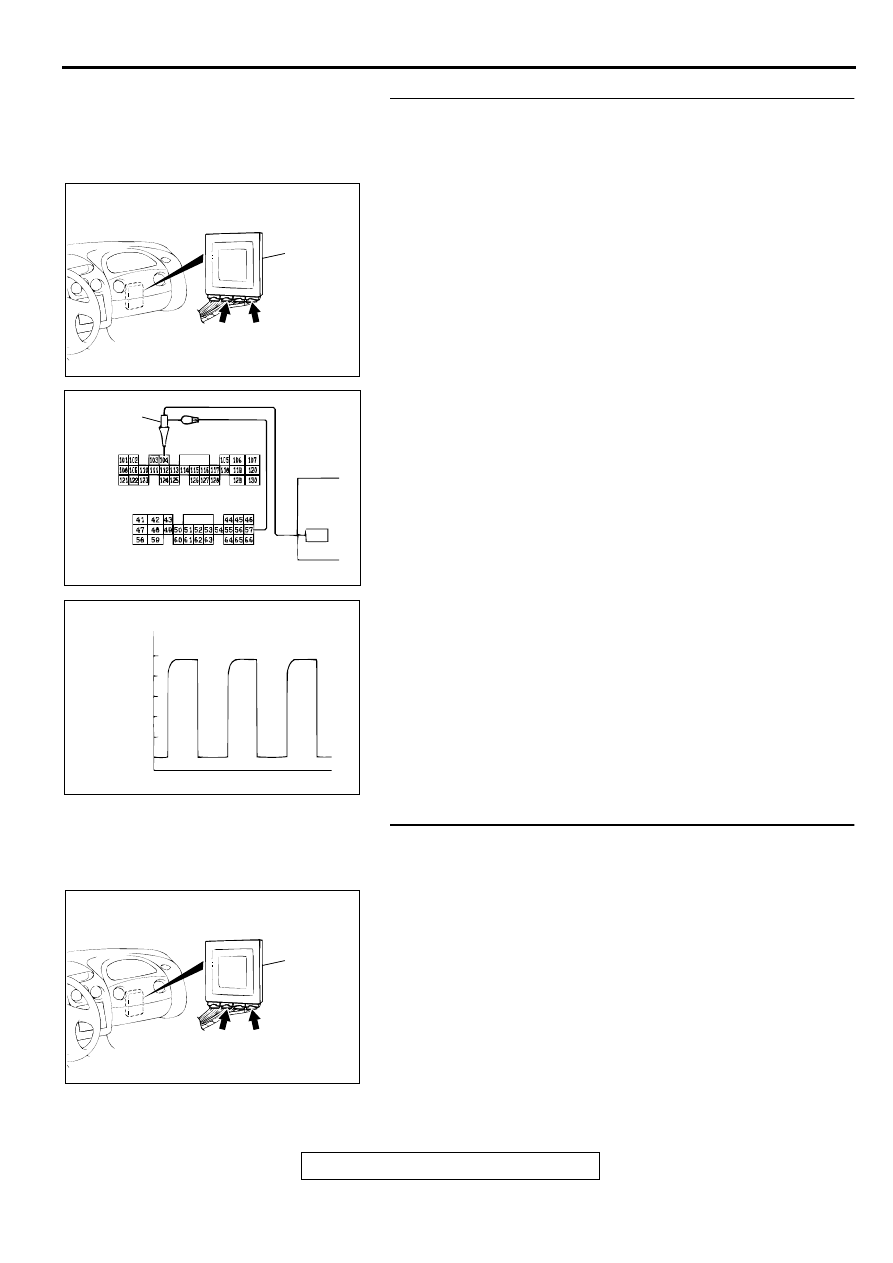

STEP 8. Using the oscilloscope, check the waveform at

PCM connectors C-54 <2.4L Engine> or C-55 <3.0L

Engine> and C-61 <2.4L Engine> or C-63 <3.0L Engine> by

backprobing.

(1) Do not disconnect connectors C-54 <2.4L Engine> or C-55

<3.0L Engine> and C-61 <2.4L Engine> or C-63 <3.0L

Engine>.

(2) Connect an oscilloscope probe to PCM connector C-54

<2.4L Engine> or C-55 <3.0L Engine> terminal 57 and to

PCM connector C-61 <2.4L Engine> or C-63 <3.0L Engine>

terminal 104 by backprobing.

(3) Start the engine and run at constant speed of 50km/h

(31mph). (Gear range: 3rd gear)

(4) Check the waveform.

•

The waveform should show a pattern similar to the

illustration. The maximum value should be 4.8 volts and

more and the minimum value 0.8 volts and less. The

output waveform should not contain the noise.

(5) Turn the ignition switch to "LOCK" (OFF) position.

Q: Is the waveform normal?

YES : Go to Step 9.

NO : Go to Step 10.

STEP 9. Check connectors C-54 <2.4L Engine> or C-55

<3.0L Engine> and C-61 <2.4L Engine> or C-63 <3.0L

Engine> at PCM for damage.

Q: Are the connectors in good condition?

YES : Go to Step 4.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

.

AC001657

CONNECTORS: C-54 <2.4L ENGINE> OR

C-55 <3.0L ENGINE>, C-61 <2.4L ENGINE>

OR C-63 <3.0L ENGINE>

PCM

AM

C-54 <2.4L ENGINE>

OR

C-55 <3.0L ENGINE>

C-61 <2.4L ENGINE>

OR

C-63 <3.0L ENGINE>

AC001900

C-61 <2.4L ENGINE> OR C-63 <3.0L ENGINE>

CONNECTOR HARNESS SIDE VIEW

C-54 <2.4L ENGINE> OR C-55 <3.0L ENGINE>

CONNECTOR HARNESS SIDE VIEW

OSCILLO-

SCOPE

PROBE

AD

ACX02131

NORMAL WAVEFORM

AB

(V)

5

0

AC001657

CONNECTORS: C-54 <2.4L ENGINE> OR

C-55 <3.0L ENGINE>, C-61 <2.4L ENGINE>

OR C-63 <3.0L ENGINE>

PCM

AM

C-54 <2.4L ENGINE>

OR

C-55 <3.0L ENGINE>

C-61 <2.4L ENGINE>

OR

C-63 <3.0L ENGINE>

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-121

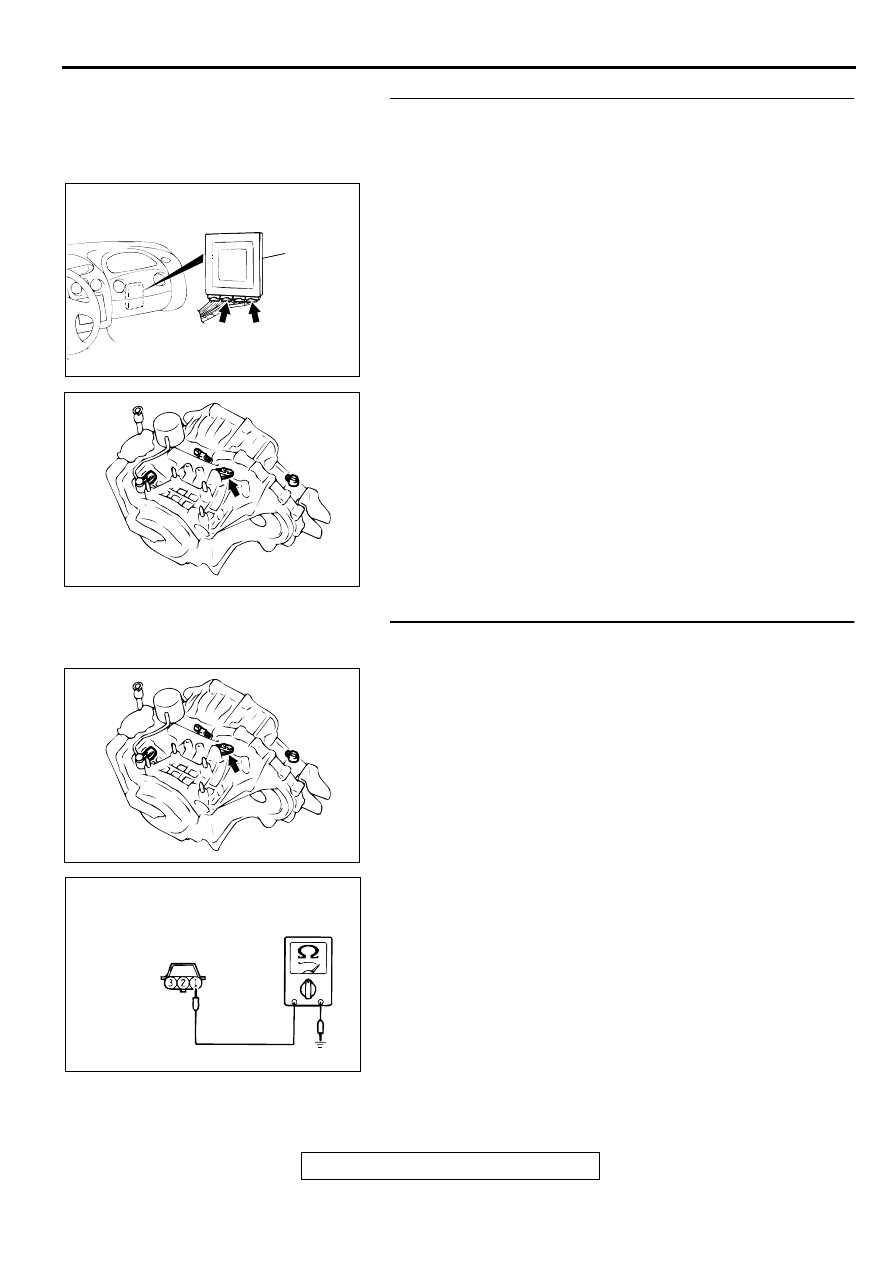

STEP 10. Check connectors C-54 <2.4L Engine> or C-55

<3.0L Engine> and C-61 <2.4L Engine> or C-63 <3.0L

Engine> at PCM and B-38 at output shaft speed sensor for

damage.

Q: Are the connectors in good condition?

YES : Go to Step 11.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

.

STEP 11. Check the continuity at output shaft speed

sensor connector B-38.

(1) Disconnect connector B-38 and measure at the harness

side.

(2) Check for the continuity between terminal 1 and ground.

•

Should be less than 2 ohm.

Q: Is the continuity normal?

YES : Go to Step 12.

NO : Repair it because of harness open circuit or damage

between output shaft speed sensor connector B-38

terminal 1 and PCM connector C-54 <2.4L Engine> or

C-55 <3.0L Engine> terminal 57.

AC001657

CONNECTORS: C-54 <2.4L ENGINE> OR

C-55 <3.0L ENGINE>, C-61 <2.4L ENGINE>

OR C-63 <3.0L ENGINE>

PCM

AM

C-54 <2.4L ENGINE>

OR

C-55 <3.0L ENGINE>

C-61 <2.4L ENGINE>

OR

C-63 <3.0L ENGINE>

AC001837AE

CONNECTOR: B-38

AC001837AE

CONNECTOR: B-38

ACX02136AE

HARNESS

CONNECTOR: B-38

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-122

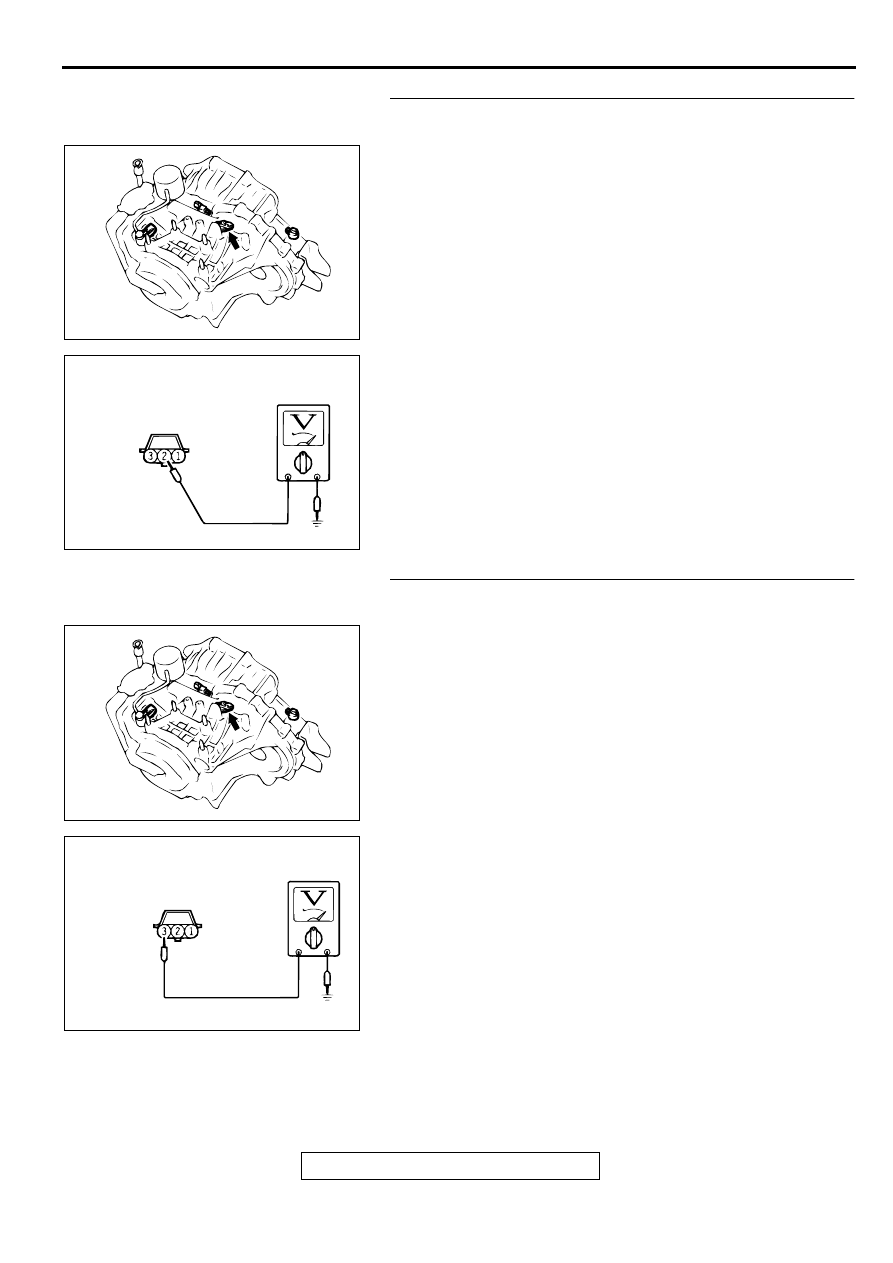

STEP 12. Check the sensor output voltage at output shaft

speed sensor connector B-38.

(1) Disconnect connector B-38 and measure at the harness

side.

(2) Turn the ignition switch to "ON" position.

(3) Measure the voltage between terminal 2 and ground.

•

Voltage should be between 4.8 and 5.2 volts.

(4) Turn the ignition switch to "LOCK" (OFF) position.

Q: Is the voltage normal?

YES : Go to Step 13.

NO : Repair it because of harness open circuit between

output shaft speed sensor connector B-108 terminal 2

and PCM connector C-61 <2.4L Engine> or C-63

<3.0L Engine> terminal 104.

STEP 13. Check the power supply voltage at output shaft

speed sensor connector B-38.

(1) Disconnect connector B-38 and measure at the harness

side.

(2) Turn the ignition switch to "ON" position.

(3) Measure the voltage between terminal 3 and ground.

•

Voltage should be battery positive voltage.

(4) Turn the ignition switch to "LOCK" (OFF) position.

Q: Is the voltage normal?

YES : Go to Step 15.

NO : Go to Step 14.

AC001837AE

CONNECTOR: B-38

ACX02135

HARNESS

CONNECTOR: B-38

AE

AC001837AE

CONNECTOR: B-38

ACX02134AE

HARNESS

CONNECTOR: B-38

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-123

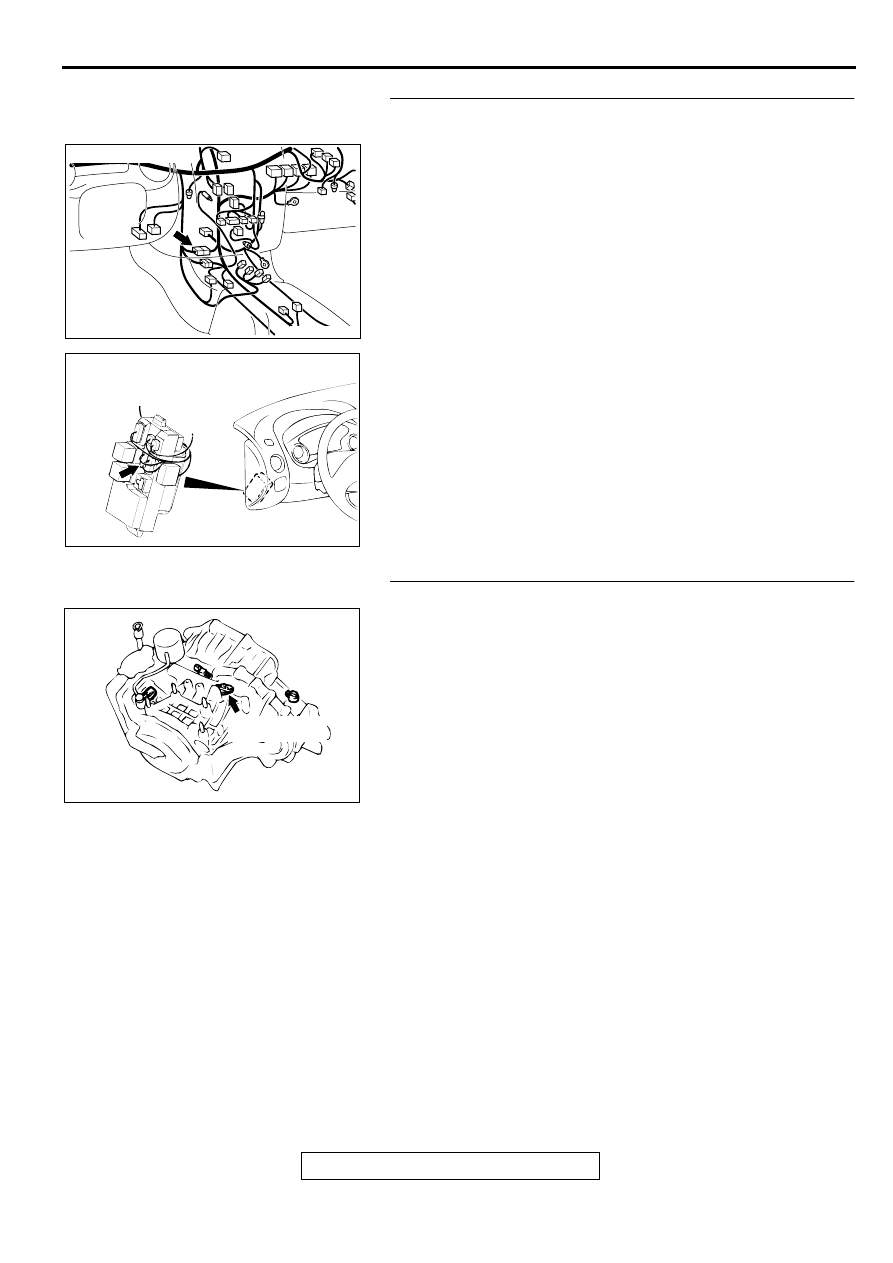

STEP 14. Check connectors C-28 at intermediate

connector and C-107 at junction block for damage.

Q: Are the connectors in good condition?

YES : Repair it because of harness open circuit or short

circuit to ground between output shaft speed sensor

connector B-38 terminal 3 and junction block

connector C-107 terminal 12.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

.

STEP 15. Replace the output shaft speed sensor.

(1) Replace the output shaft speed sensor. Refer to GROUP

23B, Transaxle

(2) Carry out a test drive.

(3) Read in the A/T diagnostic trouble code.

Q: Is the A/T diagnostic trouble code "23" output?

YES : Go to Step 18.

NO : The inspection is complete.

AC001741 AJ

CONNECTOR: C-28

AC001691

CONNECTOR: C-107

JUNCTION BLOCK

(FRONT VIEW)

AO

AC001837AD

OUTPUT SHAFT

SPEED SENSOR

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст