Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 543

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-21

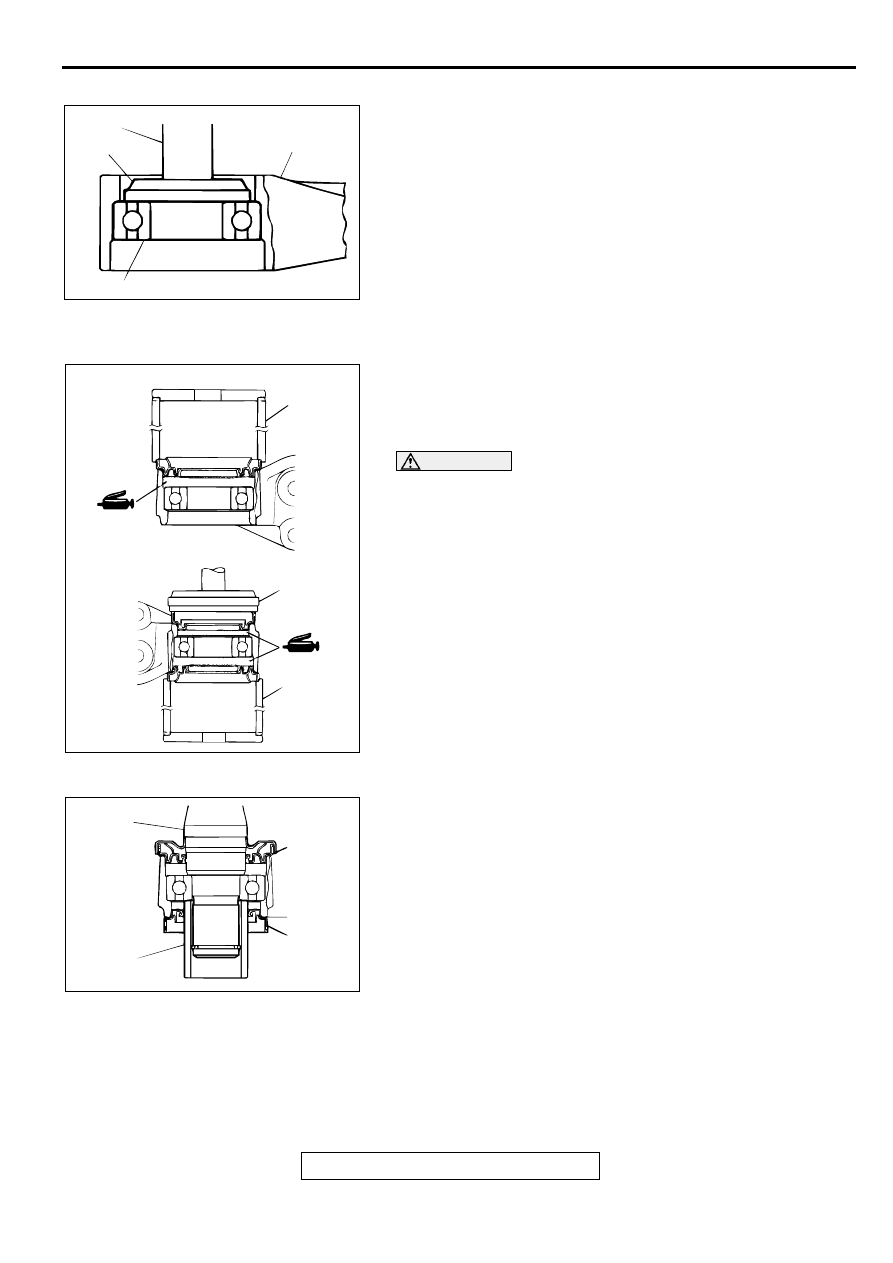

>>C<< CENTER BEARING INSTALLATION

Use special tools MB990930 and MB990938 to press the

center bearing into the center bearing bracket.

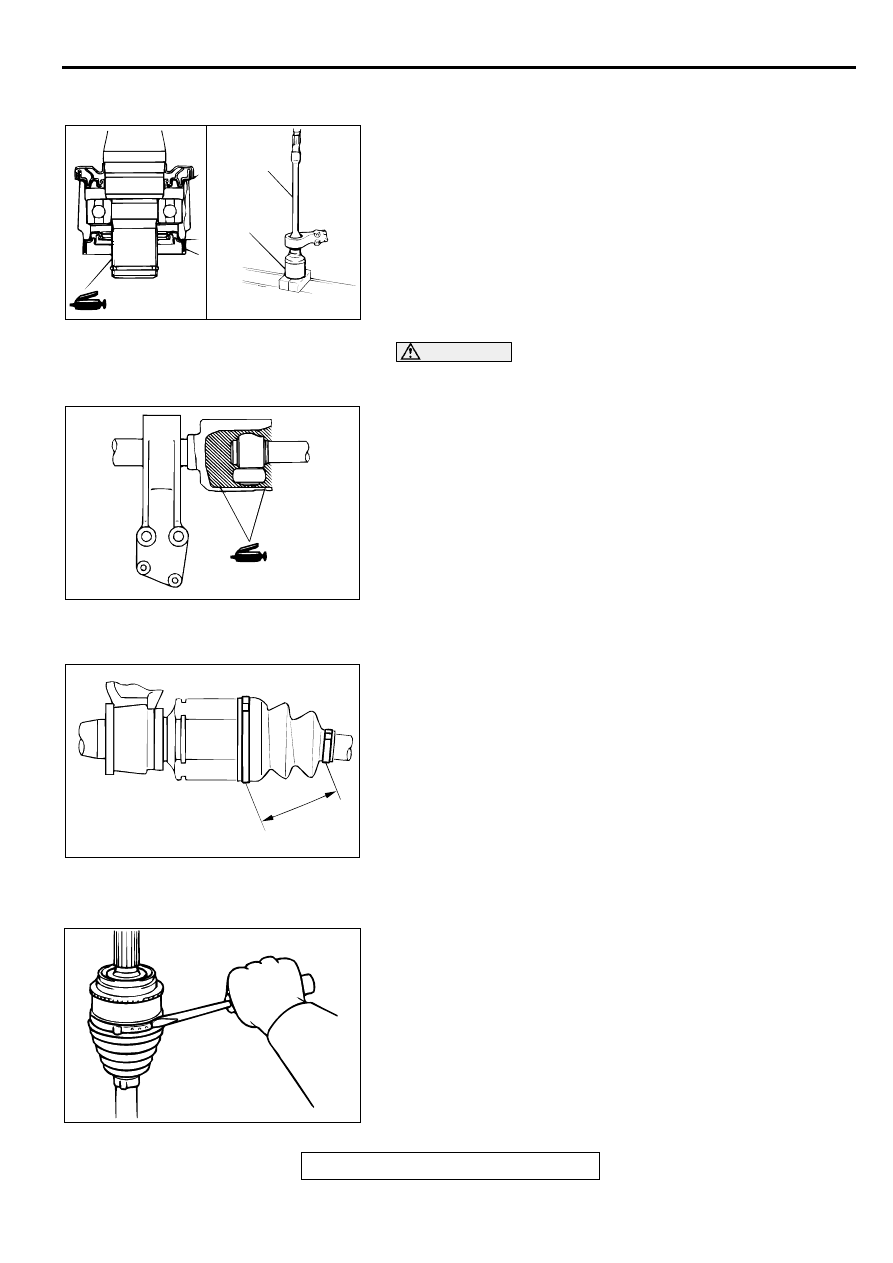

>>D<< DUST SEAL INNER/DUST SEAL OUTER

INSTALLATION

1. Pack multipurpose grease in the places shown in the figure.

Quantity:

14

−

20 g (0.5

−

0.7 oz) <Dust seal inner>

8

−

12 g (0.3

−

0.4 oz) <Dust seal outer>

CAUTION

Do not damage the rubber portion of the dust seal outer

surface when packing the multipurpose grease, otherwise

grease will leak.

2. Use special tools MB990890 and MB990934 to press the oil

seal into the center bearing bracket.

3. Apply multipurpose grease to the lip of the dust seal.

NOTE: Do not apply the specified grease to the outside of

the lip.

>>E<< INNER SHAFT INSTALLATION

Use special tool MB991172 to hold the center bearing inner

race, and then press-in the inner shaft.

AC001168

MB990938

CENTER BEARING

CENTER

BEARING

BRACKET

AB

MB990930

AC001169

DUST SEAL INNER

MB990890

MB990934

MB990890

AB

DUST SEAL OUTER

AC001170

INNER

SHAFT

AB

MB991172

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-22

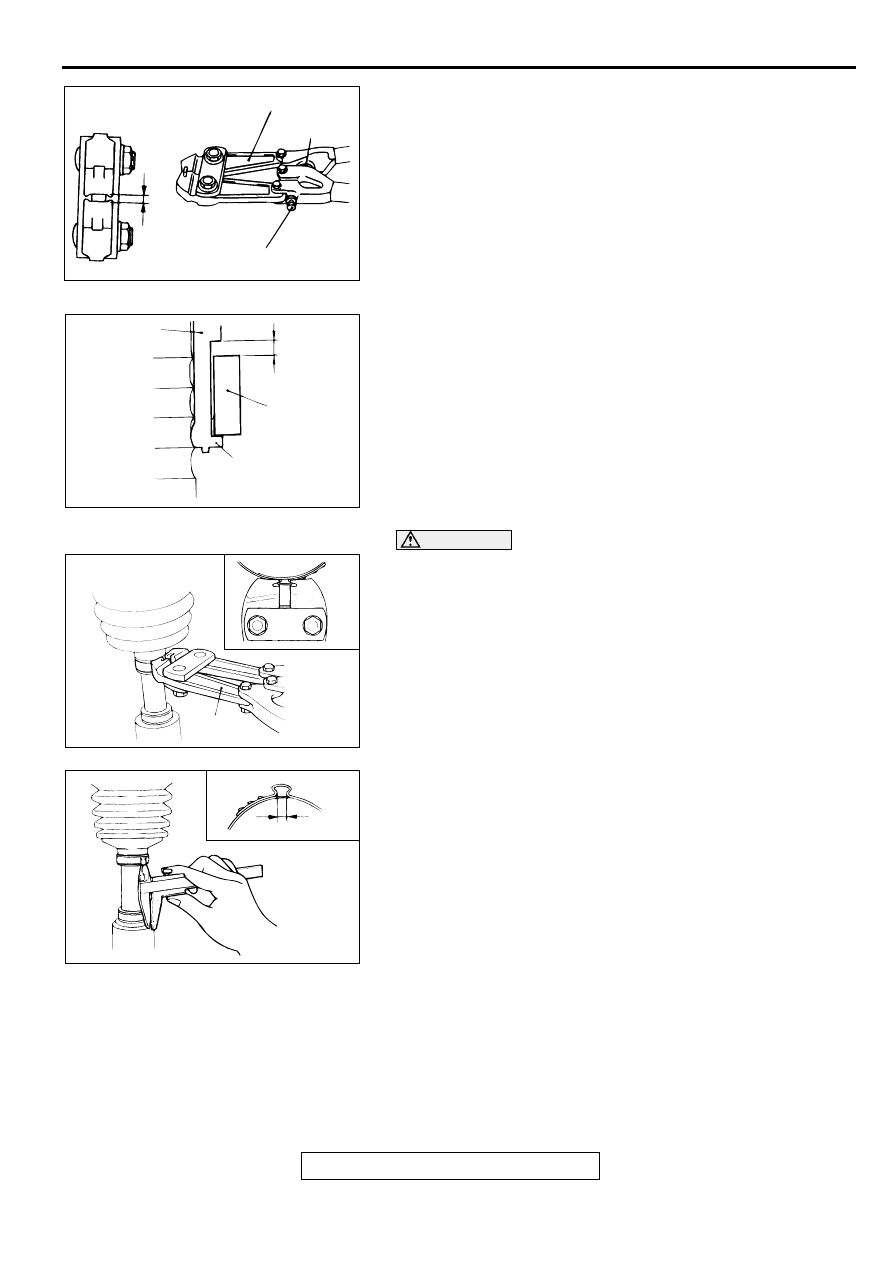

>>F<< TJ CASE AND INNER SHAFT ASSEMBLY

INSTALLATION

1. Apply multipurpose grease to the inner shaft serration, and

then press the inner shaft assembly into the TJ case.

CAUTION

The driveshaft joint uses special grease. Do not mix old

and new or different types of grease.

2. Fill the TJ case with repair kit grease and insert the

driveshaft, and then refill the TJ case with repair kit grease.

Grease quantity:

100

±

10 g (3.5

±

0.4 oz) <2.4L ENGINE>

105

±

10 g (3.7

±

0.4 oz) <3.0L ENGINE>

NOTE: The grease in the repair kit should be divided in half

for use, respectively, at the joint and inside the boot.

>>G<< TJ BOOT BAND (SMALL)/TJ BOOT BAND (LARGE)

INSTALLATION

1. Position the TJ outer race so that the distance between the

boot bands is at the standard value.

Standard value (A): 85

±

3 mm (3.3

±

0.12 inch)

2. Remove part of the TJ outer race to release the air pressure

inside the boot.

BJ BOOT REPLACEMENT

M1261005200071

1. Remove the boot bands (large and small).

NOTE: The BJ boot bands cannot be re-used.

2. Remove the BJ boot.

AC001171

TJ CASE

AB

INNER

SHAFT

ASSEMBLY

AC001172

AC001173AB

A

ACX00982 AB

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-23

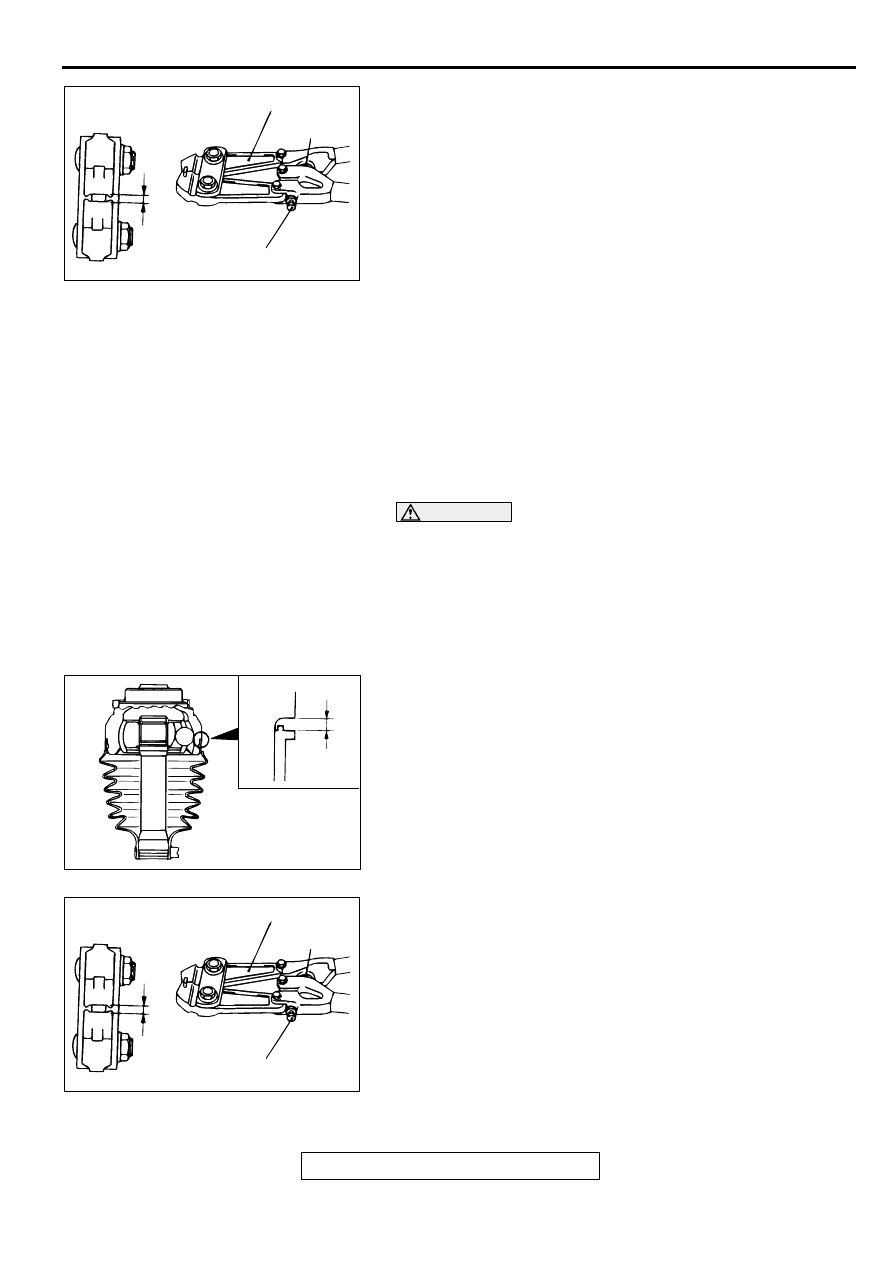

3. Turn the adjusting bolt on the special tool MB991561 so that

the size of the opening (W) is at the standard value.

Standard value (W): 2.9 mm (0.12 inch)

<If it is larger than 2.9 mm (0.12 inch)>

Tighten the adjusting bolt.

<If it is smaller than 2.9 mm (0.12 inch)>

Loosen the adjusting bolt.

NOTE: The value of W will change by approximately 0.7 mm

(0.03 inch) for each turn of the adjusting bolt.

NOTE: The adjusting bolt should not be turned more than

once.

4. Place the BJ boot band (small) against the projection at the

edge of the boot, and then secure it so that there is a

clearance left as shown by (A) in the illustration.

CAUTION

•

Secure the driveshaft in an upright position and clamp

the part of the BJ boot band to be crimped securely in

the jaws of the special tool MB991561.

•

Crimp the BJ boot band until the special tool MB991561

touches the stopper.

5. Use special tool MB991561 to crimp the BJ boot band

(small).

6. Check that crimping amount (B) of the BJ boot band is at the

standard value.

Standard value (B): 2.4

−

2.8 mm (0.10

−

0.11 inch)

ACX00993AB

STOPPER

ADJUSTING BOLT

(W)

MB991561

AC001175

BJ BOOT

A

BJ BOOT BAND

(SMALL)

PROJECTION

AB

ACX00995AB

MB991561

ACX00996AC

B

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-24

<If the crimping amount is larger than 2.8 mm (0.11

inch)>

Readjust the value of (W) in step 4 according to the

following formula, and then repeat the operation in

step 6.

[W = 5.5 mm (0.22 inch)

−

B]

Example: If B = 2.9 mm (0.11 inch), then W = 2.6 mm

(0.10 inch).

<If the crimping amount is smaller than 2.4 mm (0.09

inch)>

Remove the BJ boot band, readjust the value of (W) in

step 4 according to the following formula, and then

repeat the operations in steps 5 and 6 using a new BJ

boot band.

[W = 5.5 mm (0.22 inch)

−

B]

Example: If B = 2.3 mm (0.10 inch), then W = 3.2 mm

(0.13 inch).

7. Check that the BJ boot band is not sticking out past the

place where it has been installed. If the BJ boot band is

sticking out, remove it and then repeat the operations in

steps 4 to 6 using a new BJ boot band.

CAUTION

The driveshaft joint uses special grease. Do not mix old

and new grease or different types of grease.

8. Fill the inside of the BJ boot with the specified amount of the

repair kit grease.

Grease quantity:

<2.4L ENGINE> 110

±

10 g (3.9

±

0.4 oz)

<3.0L ENGINE> 120

±

10 g (4.2

±

0.4 oz)

9. Install the BJ boot band (large) so that clearance (C)

between it and the BJ housing is at the standard value.

Standard value (C): 0.1

−

1.55 mm (0.004

−

0.061 inch)

10.Follow the same procedure as in step 3 to adjust the size of

the opening (W) on special tool MB991561 so that it is at the

standard value.

Standard value (W): 3.2 mm (0.13 inch)

ACX00993AB

STOPPER

ADJUSTING BOLT

(W)

MB991561

AC001176

C

AB

ACX00993AB

STOPPER

ADJUSTING BOLT

(W)

MB991561

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст