Mitsubishi Colt Ralliart. Manual — part 668

SENSORS

AUTOMATIC AIR CONDITIONER

55B-33

SENSORS

REMOVAL AND INSTALLATION

M1554001900163

AC207765

2

1

4

5

AB

3

Air mixing damper control motor

and potentiometer removal step

•

Lower panel (Refer to GROUP 52A,

Instrument Panel

1.

Air mixing damper control motor

and potentiometer

Interior temperature sensor

removal steps

•

Lower panel (Refer to GROUP 52A,

Instrument Panel

2.

Interior temperature sensor

3.

Aspirator hose

Power transistor removal step

•

Glove box (Refer to GROUP 52A,

Instrument Panel

•

Front scuff plate and cowl side trim

(Refer to GROUP 52A, Interior Trim

4.

Power transistor

Photo sensor removal step

•

Combination meter (Refer to

GROUP 54A, Combination Meter

<<

A

>>

5.

Photo sensor

Main

Index

Group

TOC

SENSORS

AUTOMATIC AIR CONDITIONER

55B-34

REMOVAL SERVICE POINT

<<A>> PHOTO SENSOR REMOVAL

AC208508AB

Steering wheel

Photo sensor

connector

String

Tie the photo sensor connector with string so that the

connector can be connected easily.

INSPECTION

M1554002000163

CHECK THE INTERIOR TEMPERATURE

SENSOR

AC103488

20

15

10

5

0

-10 0

20

40

60

80

AB

Resis

tance

(k

Ω)

Temperature (˚C)

Check that the resistance shown in the graph is

almost satisfied when measuring the resistance

between the terminals under two or more different

temperature conditions.

NOTE: The temperature condition in checking

should be within the range shown.

CHECK THE AIR MIXING DAMPER CON-

TROL MOTOR AND POTENTIOMETER

AC206696

MAX COOL

position

4

1 2 3

7

5 6

AB

MAX HOT

position

CAUTION

Stop energizing when the lever is set to the oper-

ation stopping position.

MOTOR CHECK

Battery

connection (+)

terminal

Battery

connection (-)

terminal

Lever

operation

1

2

Rotate to the

HOT side.

2

1

Rotate to the

COOL side.

Potentiometer check

When the resistance value between connector termi-

nals 3 and 5 is measured while checking the motor,

check that the resistance value changes gradually

within the standard value.

Standard value: 1.20 (MAX HOT)

− 4.80 (MAX

COOL) k

Ω

CHECK THE PHOTO SENSER

1. Connect the M.U.T.-III, and check the data list of

the photo sensor.

2. Check that the displayed value changes when

the photo sensor is covered with hands.

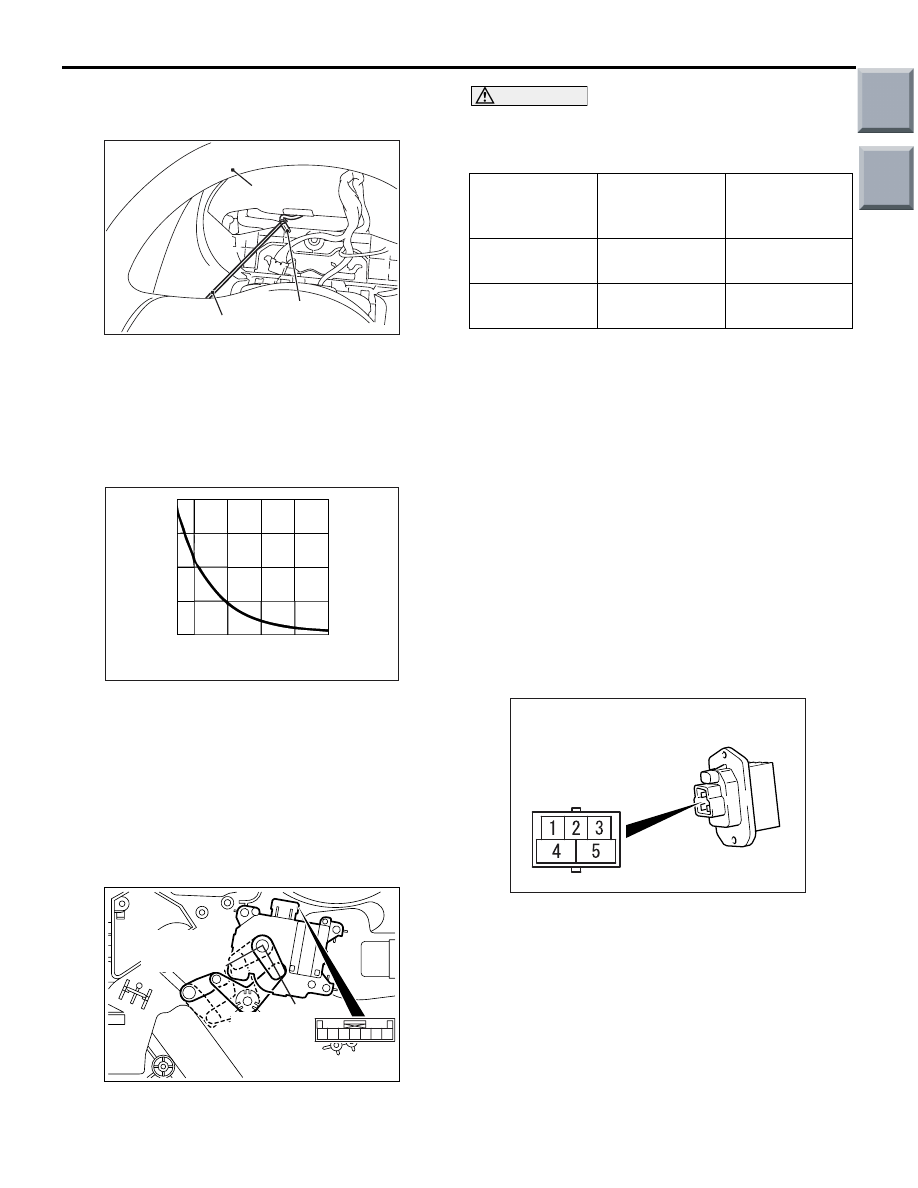

CHECK THE POWER TRANSISTOR

Check the thermal fuse.

AC309768

When the resistance between connector terminals 3

and 4 is measured, check that the resistance value is

within the standard value.

Standard value: Approximately 11 k

Ω

TRANSISTOR CHECK

Connect the (-) side clip of the tester to connector

terminal No.4 and the (+) side clip of the tester to ter-

minal No.5, and check that there is not a short or

open circuit in the transistor.

Main

Index

Group

TOC

COMPRESSOR ASSEMBLY

AUTOMATIC AIR CONDITIONER

55B-35

COMPRESSOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>

M1552004400815

Pre-removal Operation

• Refrigerant Discharging (Refer to

.)

• Front under cover panel assembly (Refer to GROUP 51,

Front Bumper Assembly

Post-installation Operation

• Refrigerant Charging (Refer to

• Drive Belt Tension Adjustment (Refer to GROUP 11C,

On-Vehicle Service, Drive Belt Tension Check And Adjust-

• Front under cover panel assembly installation (Refer to

GROUP 51, Front Bumper Assembly

.)

AC206956

1, 2

3

3

N

4

2

1

6

5

AB

25 ± 4 N·m

7

48 ± 6 N·m

-Pipe coupling

A/C compressor oil:

SUN PAG 56

Removal steps

<<

A

>>

1.

Flexible suction hose connection

<<

A

>>

2.

Flexible discharge hose connection

3.

O-ring

<<

B

>>

4.

Drive belt

<<

C

>>

>>

A

5.

A/C compressor assembly

6.

A/C compressor bracket

7.

A/C drive belt tensioner assembly

Removal steps (Continued)

Main

Index

Group

TOC

OTHER PARTS

AUTOMATIC AIR CONDITIONER

55B-36

REMOVAL SERVICE POINTS

<<A>> FLEXIBLE SUCTION HOSE AND

FLEXIBLE DISCHARGE HOSE DISCON-

NECTION

CAUTION

Use the plug which is not breathable because

A/C compressor oil or receiver have high hygro-

scopicity.

Plug the removed nipple of the pipe, hose and

expansion valve to prevent the entry of dust and dirt.

<<B>> A/C COMPRESSOR DRIVE BELT

REMOVAL

AC205665AB

Adjusting bolt

Tensioner

pulley

Locking nut

1. Loosen the locking nut of the tensioner pulley

CAUTION

To reuse the drive belt, draw an arrow indicating

the rotating direction (clockwise) on the back of

the belt using chalk, etc.

2. Rotate the adjusting bolt to the anti-clockwise

direction (to the left), and remove the drive belt.

<<C>> A/C COMPRESSOR REMOVAL

Be careful not to spill the A/C compressor oil and

remove the A/C compressor.

INSTALLATION SERVICE POINT

>>A<< A/C COMPRESSOR INSTALLA-

TION

When installing the new A/C compressor, install the

A/C compressor after adjusting the oil volume as fol-

lows.

1. Measure the oil of A/C compressor removed.(X

cm

3

)

2. Drain the oil (Y cm

3

) given by the following

expression from a new A/C compressor, and then

install the A/C compressor.

140 cm

3

- X cm

3

= Y cm

3

NOTE:

.

•

140 cm

3

shows the oil volume contained in the

new A/C compressor.

•

Y cm

3

shows the oil volume stored in the

refrigerant line, condenser, and cooling unit,

etc.

OTHER PARTS

OTHER PARTS

M1554004000363

The other service procedures and components are

the same as the heater and the manual air condi-

tioner.

• On-vehicle service

• Air intake box

• Blower motor and outside/inside air selection

damper control motor

• Ambient temperature sensor

• Compressor

• Condenser assembly

• Refrigerant line

• Ducts

• Ventilation

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст