Mitsubishi Colt Ralliart. Manual — part 761

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-369

OIL FEEDER CONTROL VALVE CHECK

M1131053800061

OPERATION CHECK

1. Disconnect the oil feeder control valve connector.

CAUTION

To prevent the coil from burning, keep the dura-

tion of the voltage application as short as possi-

ble.

2. Apply battery voltage to the terminals of the

connector at the oil feeder control valve, and

make sure the oil feeder control valve makes a

clicking sound.

MEASUREMENT OF RESISTANCE

BETWEEN TERMINALS

1. Disconnect the oil feeder control valve connector.

2. Measure the resistance between the terminals of

the connector at the oil feeder control valve.

Standard value: 6.9

− 7.9 Ω (at 20°C)

3. If resistance is outside the standard value, replace

the oil feeder control valve.

FUEL PRESSURE SOLENOID VALVE

CHECK

M1131053700031

OPERATION CHECK

1. Remove the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect the hand vacuum pump to nipple A of the

solenoid valve.

4. Use a jumper wire to connect the solenoid

terminals to the battery terminals.

5. Interrupt the jumper wire on the battery (

−)

terminal side and apply negative pressure to

check for airtightness.

Standard value:

COIL RESISTANCE CHECK

1. Measure the resistance between terminals of the

solenoid valve.

Standard value: 29

− 35 Ω (at 20 °C)

AK402207

1 2

AC

Oil feeder

control valve

Oil feeder

control valve side

connector

AK402131

1

2

AC

Equipment side

connector

Fuel pressure solenoid valve

Jumper wire Condition

of nipple B

Normal condition

Disconnect

Open

Negative pressure

leaks

Blocked

Negative pressure

is retained

Connect

Open

Negative pressure

is retained

AK200256AC

A

B

Battery

AK200257

Main

Index

Group

TOC

INJECTOR

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-370

INJECTOR

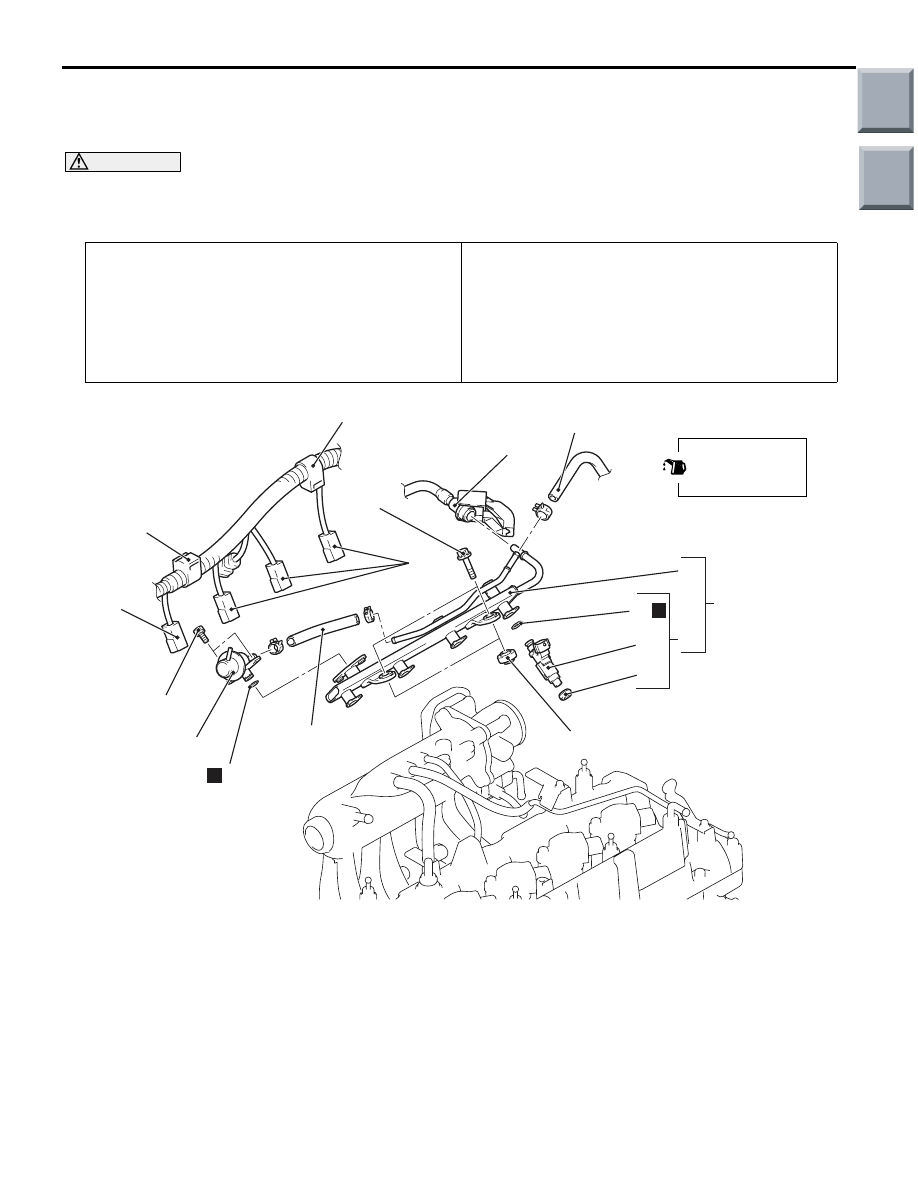

REMOVAL AND INSTALLATION

M1131007101772

CAUTION

When the fuel injector replacement is performed, use the M.U.T.-III to initialise the learning value

(Refer to GROUP 00, Precautions Before Service

− Initialisation Procedure for Learning Value in MPI

Engine

Pre-removal Operation

• Fuel Discharge Prevention (Refer to

).

• Engine Cover Removal (Refer to GROUP 11C, Camshaft

and Valve Stem Seal

).

• Air Cleaner Assembly Removal (Refer to GROUP 15, Air

Cleaner

).

• Air Pipe B Removal (Refer to GROUP 15, Intercooler

).

Post-installation Operation

• Air Pipe B Installation (Refer to GROUP 15, Intercooler

).

• Air Cleaner Assembly Installation (Refer to GROUP 15,

Air Cleaner

).

• Fuel Leakage Inspection

• Engine Cover Installation (Refer to GROUP 11C, Cam-

).

AC403099

1

1

12 ± 1 N·m

10

N

13

12

AB

7

11

14

3

4

2

8

9

2

N

6

5

12 ± 1 N·m

Apply engine oil to

the O-ring before

installation.

Removal steps

1.

Fuel injector connector

2.

Control harness clamp connection

3.

Fuel high-pressure hose

connection

4.

Fuel return hose connection

>>A<<

5.

Fuel pressure regulator

6.

O-ring

7.

Fuel hose

<<B>> >>B<<

8.

Fuel delivery pipe and fuel injector

assembly

9.

Fuel delivery pipe insulator

>>A<<

10. Fuel injector assembly

11. O-ring

12. Fuel injector insulator

13. Fuel injector

14. Fuel delivery pipe

Removal steps (Continued)

Main

Index

Group

TOC

INJECTOR

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-371

REMOVAL SERVICE POINTS

<<A>> FUEL HIGH-PRESSURE HOSE

DISCONNECTION

1. Remove the stopper.

2. Raise the retainer, and pull out the fuel

high-pressure hose.

NOTE: If the retainer comes off, install it securely

after pulling out the fuel high-pressure hose.

<<B>> FUEL DELIVERY PIPE AND FUEL

INJECTOR ASSEMBLY REMOVAL

CAUTION

Do not drop the fuel injector.

Remove the fuel delivery pipe with the fuel injector

assembly attached to it.

INSTALLATION SERVICE POINTS

>>A<< FUEL INJECTOR ASSEM-

BLY/FUEL PRESSURE REGULATOR

INSTALLATION

CAUTION

Do not let the engine oil get into the fuel delivery

pipe will be damaged.

1. Apply a drop of new engine oil to the O-ring.

2. Turn the fuel injector assembly and fuel pressure

regulator to the right and left to install to the fuel

delivery pipe. Be careful not to damage the

O-ring. After installing, check that the item turns

smoothly.

3. If it dose not turn smoothly, the O-ring may be

trapped, remove the item, re-install it into the fuel

delivery pipe and check again.

4. Tighten the fuel pressure regulator to the specified

torque.

Tightening torque: 12

± 1 N⋅m

>>B<< FUEL DELIVERY PIPE AND FUEL

INJECTOR ASSEMBLY INSTALLATION

CAUTION

Securely bring the insulator into contact with the

injector to prevent air leak from the insulator

area.

Be sure that there is no clearance between the insu-

lator area and the injector, and install them to the cyl-

inder head.

AC402313AB

Fuel high-pressure hose

Stopper

AC402314AC

Fuel high-pressure

hose

Retainer

AC601238AB

Injector

Insulator

Main

Index

Group

TOC

INJECTOR

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-372

>>C<< FUEL HIGH-PRESSURE HOSE

CONNECTION

CAUTION

• After connecting the fuel high-pressure hose,

check that it has been securely installed by

slightly pulling in the removal direction. At

this time, also check that there is approxi-

mately 3-mm play.

• Do not let the engine oil get into the fuel deliv-

ery pipe will be damaged.

Apply a small amount of new engine oil to the fuel

delivery pipe, and install the fuel high-pressure hose

to the fuel delivery pipe.

AC208465AE

3 mm

Fuel high-pressure hose

Fuel delivery pipe

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст