Mitsubishi Colt Ralliart. Manual — part 759

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-361

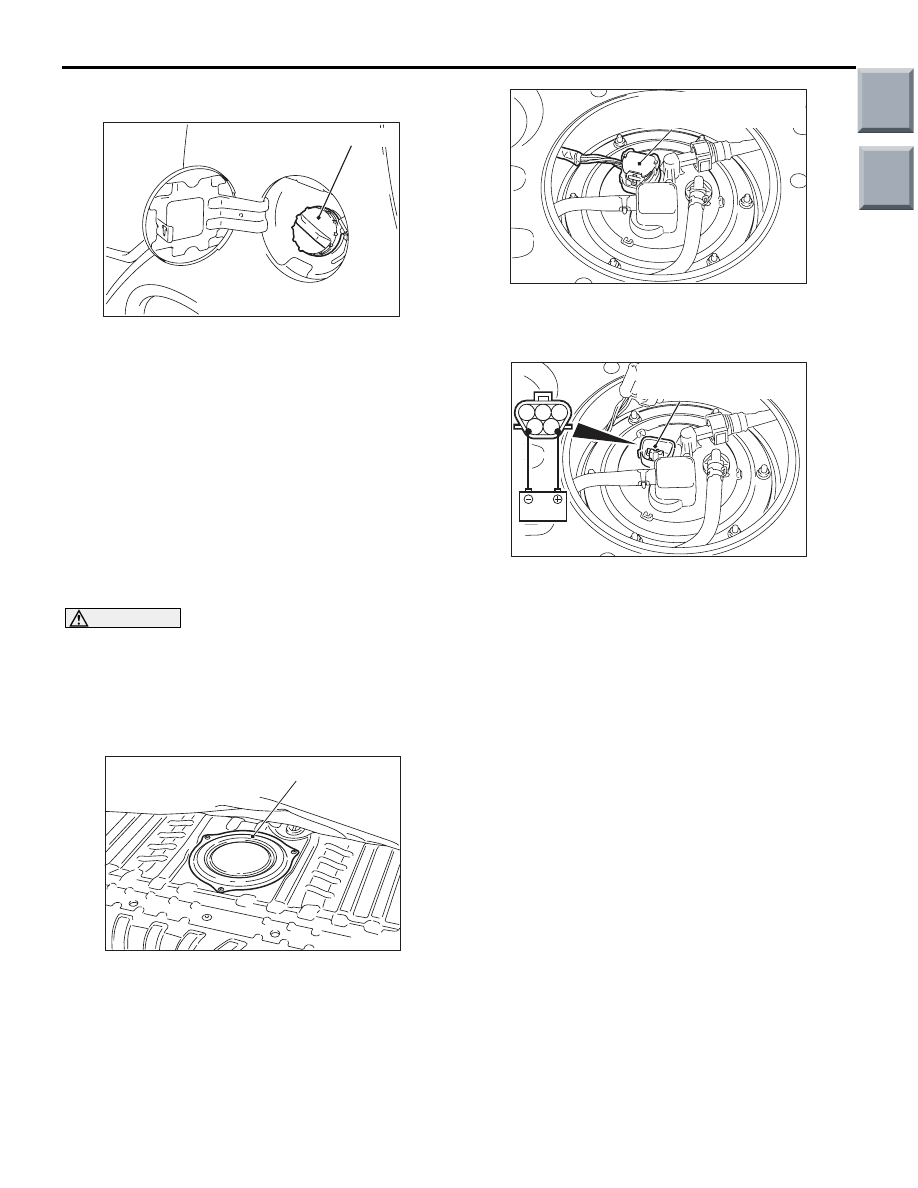

FUEL TANK PUMP OPERATION CHECK

M1131002001510

1. Remove the fuel tank cap.

NOTE: As the fuel tank pump is an in-tank type,

the fuel tank pump sound is hard to hear. Then

check the sound from the tank inlet.

2. Check the operating of the fuel tank pump by

M.U.T.-III to force-drive the fuel tank pump.

3. Install the fuel tank cap.

4. If the fuel tank pump will not operate, check by

using the following procedure. If normal, check

the fuel tank pump drive circuit.

(1) Turn the ignition switch to the "LOCK" (OFF)

position.

(2) Lift up the rear seat assembly.

CAUTION

Moulding type of floor carpet is used. Be careful

not to change the shape of carpet when turning it

over for operation.

(3) Remove the rear scuff plate, and turn over the

floor carpet. (Refer to GROUP 52A, Interior

Trims

).

(4) Remove the service hole cover.

(5) Disconnect the fuel tank pump and gauge

assembly connector.

(6) Remove the fuel tank cap.

(7) When the fuel tank pump and gauge assembly

connector terminal is connected directly to the

battery, check if the sound of the fuel tank

pump operation can be heard. If no operating

sound is heard, replace the fuel tank pump

(Refer to GROUP 13C, On-vehicle Service

).

NOTE: As the fuel tank pump is an in-tank

type, the fuel tank pump sound is hard to hear.

Then check the sound from the tank inlet.

(8) Install the fuel tank cap.

(9) Check for fuel pressure by pinching the fuel

hose with fingertips.

(10)Connect the fuel tank pump and gauge

assembly connector.

(11)Install the service hole cover.

(12)Return the floor carpet to the original state,

and install the rear scuff plate. (Refer to

GROUP 52A, Interior Trims

(13)Return the rear seat assembly to the original

state.

AC207379AD

Fuel tank cap

AC207365AD

Service hole cover

AC403097AB

Fuel tank pump and

gauge assembly connector

1

4

2 3

5

AC403098 AB

Fuel tank pump and

gauge assembly connector

Main

Index

Group

TOC

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-362

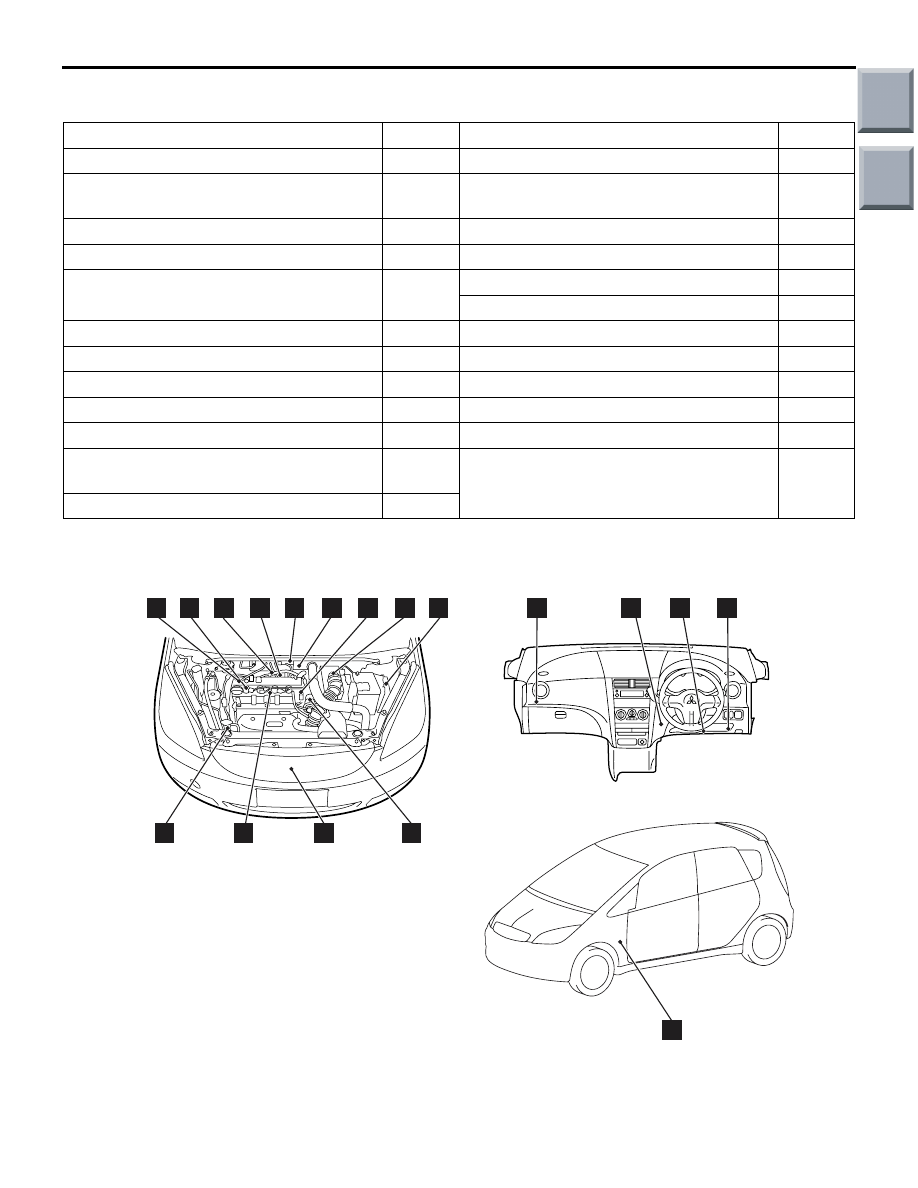

COMPONENT LOCATION

M1131002101799

Name

Symbol Name

Symbol

Accelerator pedal position sensor

Q

Fuel pump relay

N

Air flow sensor (with intake air temperature

sensor)

H

Ignition coil (with power transistor)

B

A/C compressor relay

N

Injector

D

Camshaft position sensor

G

Oil feeder control valve

A

Cooling fan control relay

N

Oxygen sensor (front)

L

Oxygen sensor (rear)

R

Crank angle sensor

J

Purge control solenoid valve

E

Detonation sensor

K

Stop lamp switch

P

Diagnosis connector

O

Throttle position sensor

F

Engine control relay

N

Throttle valve control servo

F

Engine coolant temperature sensor

M

Throttle valve control servo relay

N

Engine-ECU (with barometric pressure

sensor)

I

Waste gate solenoid valve

M

Fuel pressure control solenoid valve

C

AK600594

R

A

B

D

G

N

O

P

Q

C

E

F

H

I

L

M

J

K

AB

Main

Index

Group

TOC

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-363

ENGINE CONTROL RELAY CONTINUITY

CHECK

M1131050000914

FUEL PUMP RELAY CONTINUITY CHECK

M1131033000632

Tester

Connection

Terminal

Battery Voltage

Normal State

1

− 2

No voltage

Continuity

3

− 4

No voltage

No

continuity

Voltage (Connect

positive (+) terminal of

battery to terminal No. 1

and negative (

−) terminal

of battery to terminal

No. 2.)

Continuity

AK402727

3

1

2

4

AB

J/B (front side)

Engine control

relay

Equipment side

connector

Tester

Connection

Terminal

Battery Voltage

Normal State

1

− 2

No voltage

Continuity

3

− 4

No voltage

No

continuity

Voltage (Connect

positive (+) terminal of

battery to terminal No. 1

and negative (

−) terminal

of battery to terminal

No. 2.)

Continuity

AK402728

3

1

2

4

AB

J/B (front side)

Fuel pump relay (2)

Fuel pump relay (1)

Equipment side

connector

Main

Index

Group

TOC

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-364

THROTTLE VALVE CONTROL SERVO

RELAY CONTINUITY CHECK

M1131053500134

INTAKE AIR TEMPERATURE SENSOR

CHECK

M1131002800944

1. Disconnect the air flow sensor connector.

2. Measure resistance between terminals No. 1 and

No. 4.

Standard value:

13

− 17 kΩ (at −20°C)

5.4

− 6.6 kΩ (at 0°C)

2.3

− 3.0 kΩ (at 20°C)

1.0

− 1.5 kΩ (at 40°C)

0.56

− 0.76 kΩ (at 60°C)

0.31

− 0.43 kΩ (at 80°C)

3. Remove the air flow sensor.

4. Measure resistance while heating the sensor

using a hair drier.

Normal condition:

5. If the value deviates from the standard value or

the resistance remains unchanged, replace the air

flow sensor assembly.

6. Install the air flow sensor and tighten it to the

specified torque.

Tightening torque: 1.8

± 0.6 N⋅m

Tester

Connection

Terminal

Battery Voltage

Normal State

1

− 2

No voltage

Continuity

3

− 4

No voltage

No

continuity

Voltage (Connect

positive (+) terminal of

battery to terminal No. 1

and negative (

−) terminal

of battery to terminal

No. 2.)

Continuity

AK402729

3

1

2

4

AB

J/B (front side)

Throttle valve

control servo relay

Equipment side

connector

Temperature (

°C)

Resistance (k

Ω)

Higher

Smaller

AK402126

1

2

3 4

AC

Equipment side

connector

Intake air temperature

sensor

AK203040

Intake air

temperature

sensor

AD

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст