Mitsubishi Colt Ralliart. Manual — part 671

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-9

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOW

M1131150001367

Refer to

, GROUP 00

− How to Use Trouble-

shooting/Inspection Service Points

− How to Cope

with Intermittent Malfunctions.

DIAGNOSIS FUNCTION

M1131155501851

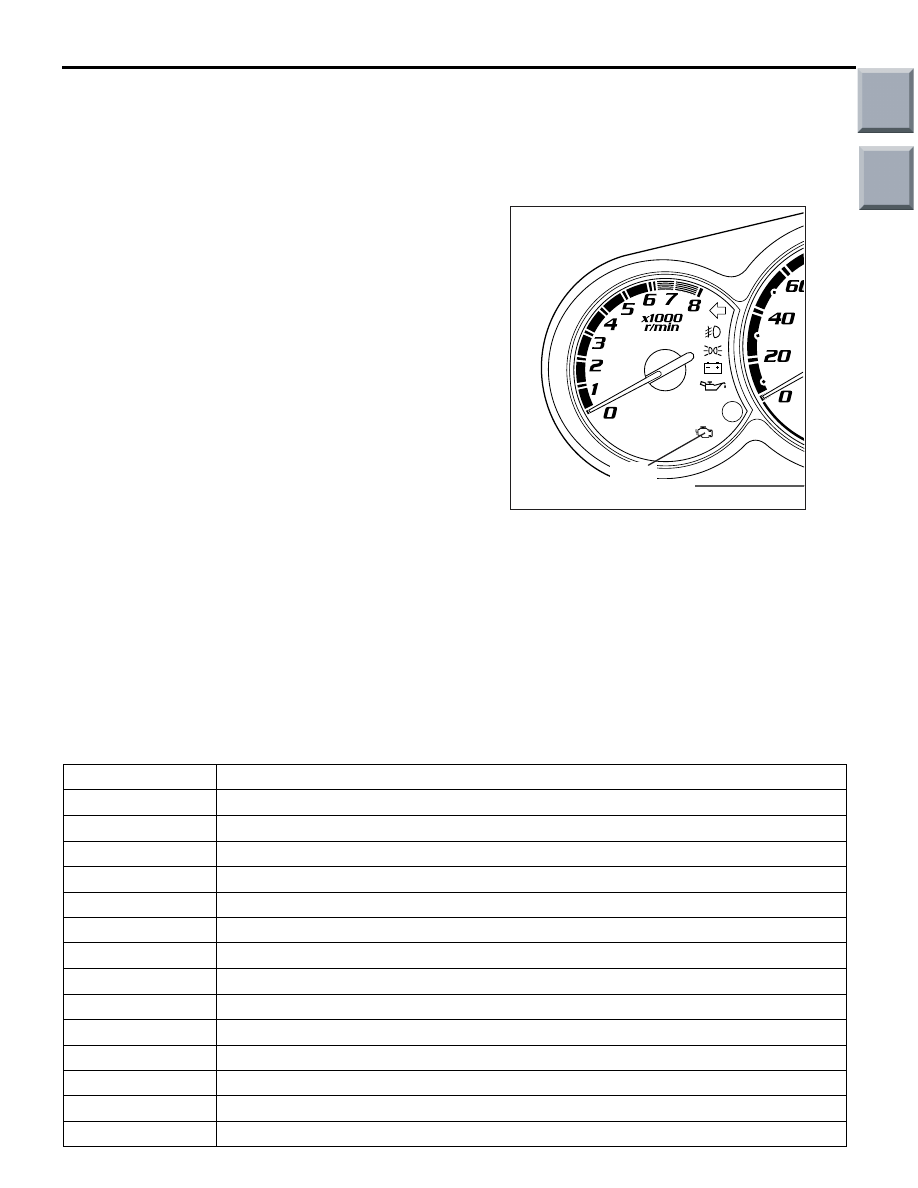

ENGINE WARNING LAMP (CHECK

ENGINE LAMP)

The engine warning lamp illuminates in the event of

an abnormality in any of the diagnosis items related

to the Multipoint Fuel Injection (MPI) system listed

below. Check diagnosis code outputs both when the

lamp stays illuminated and when it lights up or

flashes while the engine is running. Even when there

is no problem, the lamp is caused to illuminate for

about 5 seconds after turning the ignition switch to

the ON position for the blown bulb checking pur-

poses.

ENGINE WARNING LAMP INSPECTION ITEMS

AK402082AD

Engine

warning lamp

Code No.

Diagnosis item

P0090

Fuel pressure solenoid valve system

P0100

Airflow sensor system

P0105

Barometric pressure sensor system

P0110

Intake air temperature sensor system

P0115

Engine coolant temperature sensor system

P0122

Throttle position sensor (main) circuit low input

P0123

Throttle position sensor (main) circuit high input

P0125

Feedback system monitor

P0130

Oxygen sensor (front) system

P0135

Oxygen sensor (front) heater system

P0136

Oxygen sensor (rear) system

P0141

Oxygen sensor heater (rear) system

P0170

Abnormal fuel system

P0201

No. 1 injector system

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-10

P0202

No. 2 injector system

P0203

No. 3 injector system

P0204

No. 4 injector system

P0222

Throttle position sensor (sub) circuit low input

P0223

Throttle position sensor (sub) circuit high input

P0243

Waste gate solenoid valve system

P0300

Random/multiple cylinder misfire detected

P0301

No. 1 cylinder misfire detected

P0302

No. 2 cylinder misfire detected

P0303

No. 3 cylinder misfire detected

P0304

No. 4 cylinder misfire detected

P0325

Detonation sensor system

P0335

Crank angle sensor system

P0340

Camshaft position sensor system

P0421

Warm up catalyst malfunction

P0443

Purge control solenoid valve system

P0500

Vehicle speed sensor system

P0606

Microcomputer malfunction

P0638

Throttle valve control servo circuit range/performance problem

P0642

Throttle position sensor power supply

P0657

Throttle valve control servo relay circuit malfunction

P1021

Oil feeder control valve system

P1233

Trustful check throttle position sensor (main)

P1234

Trustful check throttle position sensor (sub)

P1235

Trustful check air flow sensor

P1236

A/D converter system

P1237

Trustful check accelerator pedal position sensor

P1238

Air flow sensor trustful for torque monitoring

P1239

Trustful check engine speed

P1241

Torque monitoring

P1602

Communication malfunction (btween engine-ECU main processor and system LSI)

P1603

Battery backup circuit malfunction

P2100

Throttle valve control servo circuit (open)

P2101

Throttle valve control servo magneto malfunction

P2108

Throttle valve control servo processor malfunction

P2122

Accelerator pedal position sensor (main) circuit low input

P2123

Accelerator pedal position sensor (main) circuit high input

P2127

Accelerator pedal position sensor (sub) circuit low input

P2128

Accelerator pedal position sensor (sub) circuit high input

Code No.

Diagnosis item

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-11

CAUTION

The engine warning lamp illuminates steadily if

any abnormality has occurred in the engine-ECU.

NOTE: The engine warning lamp flashes if the electronically controlled throttle valve system is forced to stop

by activation of the fail-safe function.

METHOD FOR READING AND ERASING

DIAGNOSIS CODES

Refer to GROUP 00 – How to Use Troubleshoot-

ing/Inspection Service Points – How to Cope with

Intermittent Malfunctions

.

DIAGNOSIS USING INCREASED SENSI-

TIVITY DIAGNOSIS MODE

When the increased sensitivity diagnosis mode is

selected on the M.U.T.-III, the engine-ECU shifts into

the mode in which it causes the engine warning lamp

to light and stores the relevant diagnosis code imme-

diately after detection of a malfunction. Since this

mode allows the ECU to determine and store the

diagnosis code with a shorter delay time after detec-

tion of a malfunction (1 second instead of standard 4

seconds), it helps to reduce workload required for

fault condition identification and post-repair checking

operations. To revert from the increased sensitivity

diagnosis mode to the standard sensitivity diagnosis

mode, the ignition switch must be turned to the

"LOCK" (OFF) position or the standard sensitivity

mode must be re-selected on the M.U.T.-III. The

diagnosis code and the freeze-frame data retained in

memory during the increased sensitivity diagnosis

mode must, if necessary, be recorded before per-

forming the mode switching operation because they

will be automatically erased as soon as the standard

sensitivity diagnosis mode is re-selected.

Diagnosis Procedure

1. Connect the M.U.T.-III to the vehicle connector,

set the engine-ECU diagnosis mode to the

increased sensitivity diagnosis mode, and per-

form a road test.

2. Read diagnosis code(s) and repair the faulty

location(s).

3. Either re-select the standard sensitivity diagnosis

mode on the M.U.T.-III or turn the ignition switch

to the "LOCK" (OFF) position and then back to

the ON position.

NOTE: Turning the ignition switch to the "LOCK"

(OFF) position has the effect of causing the

engine-ECU to switch its diagnosis mode from

the increased sensitivity diagnosis mode to the

standard sensitivity diagnosis mode.

INSPECTION USING M.U.T.-III DATA LIST

AND ACTUATOR TEST FUNCTIONS

Using the data list display function and actuator test

function of the M.U.T.-III, you can check vehicle har-

nesses and components for any abnormalities. The

data list display function allows inputs from sensors

and outputs to actuators both in numerical value and

graph formats. The actuator test function allows forc-

ing desired actuators to operate (turning on an actua-

tor and turning it off after predetermined period).

Diagnosis Procedure

1. Connect the M.U.T.-III to the vehicle connector

and carry out necessary inspections using the

data list function and/or actuator test function.

2. If any abnormality is found, inspect the relevant

vehicle harnesses or components and repair

them if necessary.

3. After the repair, check that the input/output levels

have returned to normal ranges levels.

4. Clear any diagnosis code that has resulted from

inspection and repair operations.

5. Disconnect the M.U.T.-III and perform a road test

or other necessary tests to confirm that there are

no problems remaining.

FREEZE FRAME DATA

When the engine-ECU detects a malfunction and

stores the corresponding diagnosis code, it also

stores the data showing the state of the engine at the

time of malfunction detection. These data are called

"freeze frame data". Analyzing the data using the

M.U.T.-III will help you to perform troubleshooting

efficiently.

NOTE: Freeze frame data are displayed in terms of

the items listed below.

P2135

Throttle position sensor (main and sub) range/performance problem

P2138

Accelerator pedal position sensor (main and sub) range/performance problem

U1108

Combination meter time-out

Code No.

Diagnosis item

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-12

DATA DISPLAY ITEM LIST

NOTE:

*1

: A state in which fuel control is performed using oxygen sensor signals fed back to the engine-ECU.

NOTE:

*2

: A state in which the closed-loop conditions are not yet met, making the engine-ECU perform fuel

control without feedback data from the oxygen sensors.

NOTE:

*3

: A state in which open-loop control is needed due to repeated acceleration and deceleration.

NOTE:

*4

: A state in which open-loop control is performed in consequence of a system malfunction.

DRIVE CYCLE

The following three drive cycle patterns are performed on the diagnosis codes monitored during the vehicle

driving. The vehicle driving requires the patterns to identify the fault. In other words, doing such a drive allows

to regenerate any kind of trouble which involves illuminating the engine warming lamp (check engine lamp)

and to verify the repair procedure has eliminated the trouble [the engine warming lamp (check engine lamp) is

no longer illuminated].

CAUTION

Two technicians should always be in the vehicle when carrying out a test drive.

NOTE: Check that the diagnosis code is not output before traveling in the drive cycle pattern. Erase the diag-

nosis code if it has been output.

DRIVE CYCLE PATTERN LIST

Item No.

Data

Unit/state

12

Air flow sensor

g/sec

13

Intake air temperature sensor

°C

21

Engine coolant sensor

°C

22

Crank angle sensor

r/min

24

Vehicle speed

km/h

44

Ignition timing

deg

79

Throttle position sensor (main)

mV

81

Long-term fuel consumption

%

82

Short-term fuel consumption

%

87

Calculation load value

%

88

Fuel control condition

Closed loop

*1

CL

Open loop

*2

OL

Open loop owing to drive condition

*3

OL-DRV.

Open loop owing to system malfunction

*4

OL-SYS.

89

Fuel control condition

−

Procedure

Monitor item

Diagnosis code No.

Catalytic converter monitor

P0421

Oxygen sensor (front) monitor

P0130

Other monitor

P0135, P0136, P0141,

P0300, P0301, P0302,

P0303, P0304, P0325,

P0500, P0638

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст