Mitsubishi Colt Ralliart. Manual — part 112

ON-VEHICLE SERVICE

INTAKE AND EXHAUST

15-4

WASTE GATE ACTUATOR CHECK <4G1>

M1151001200297

AK402022

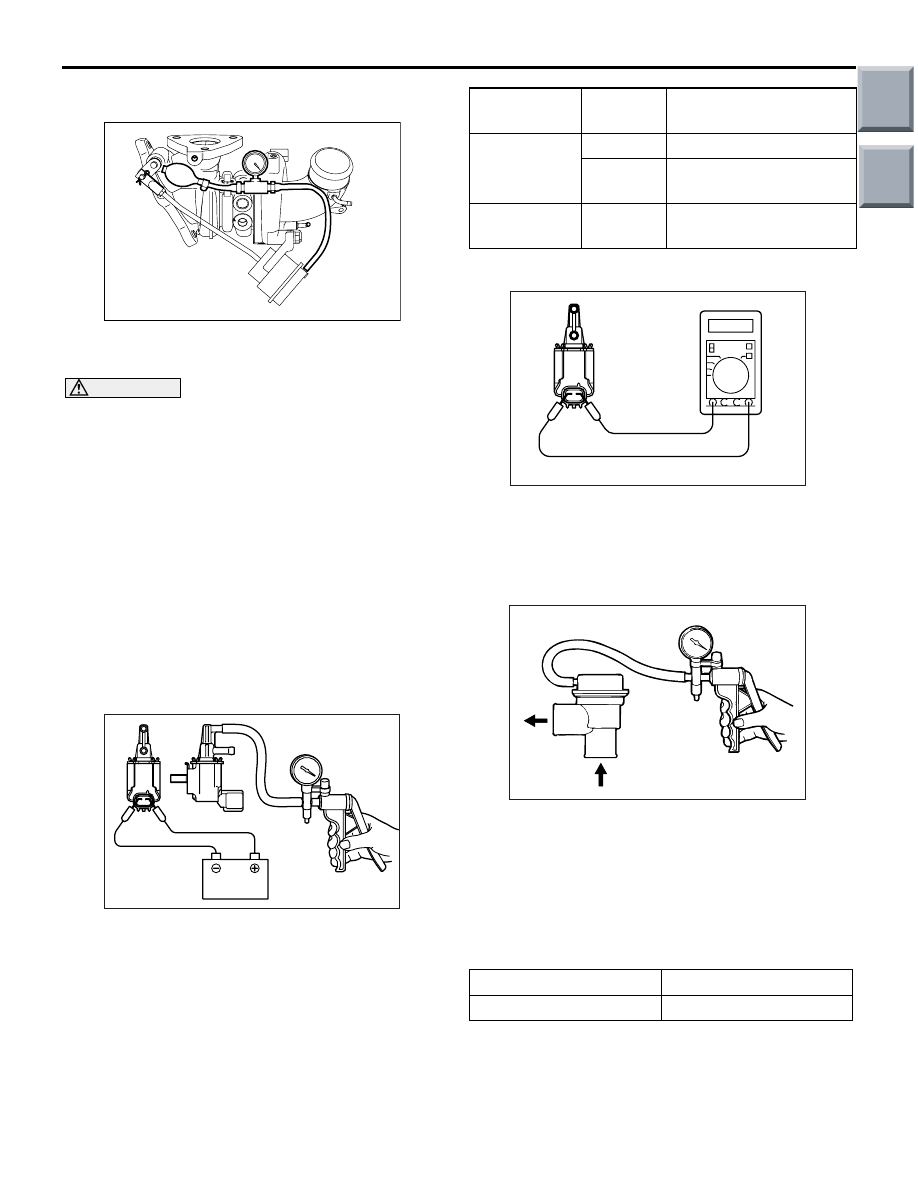

1. Connect a manual pump (pressure-application

type) to nipple.

CAUTION

In order to avoid damage to the diaphragm, do

not apply a pressure of 75 kPa or higher.

2. While gradually applying pressure, check the

pressure that begins to activate (approximately 1

mm stroke) the waste gate actuator rod.

Standard value: Approximately 60 kPa

3. If there is a significant deviation from the standard

value, check the actuator or the waste gate valve:

replace actuator or turbocharger assembly if

necessary.

WASTE GATE SOLENOID VALVE CHECK

<4G1>

M1151001300205

OPERATION CHECK

AK200441

Battery

A

B

AC

1. Connect a hand vacuum pump to the solenoid

valve nipple A.

2. Using a jumper wire, connect between the

solenoid valve terminal and battery terminal.

3. Connecting and disconnecting the jumper wire at

the battery negative terminal to apply a negative

pressure, check tightness.

Jumper wire B nipple

condition

Normal condition

Connected

Opened

Negative pressure leaks.

Closed

Negative pressure is

held.

Disconnected Opened

Negative pressure is

held.

COIL RESISTANCE CHECK

AK200442

Measure the resistance between solenoid valve ter-

minals

Standard value: 29

− 35 Ω (at 20°C)

AIR BY-PASS VALVE CHECK <4G1>

M1151001600165

AK200443

1. Remove the air bypass valve.

2. Connect the hand vacuum pump to the nipple of

the air bypass valve.

3. Apply a negative pressure of approximately 93

kPa, and check that air tightness is maintained.

4. Also check operation of the valve.

Standard value:

Negative pressure

Valve operation

Approximately 53 kPa

It starts opening

INTAKE MANIFOLD VACUUM CHECK

M1151001800266

Refer to GROUP 11A

− On-vehicle Service

. <4A9>

Refer to GROUP 11C

− On-vehicle Service

. <4G1>

Main

Index

Group

TOC

AIR CLEANER

INTAKE AND EXHAUST

15-5

AIR CLEANER

REMOVAL AND INSTALLATION <4A9>

M1151002101177

AC601194AB

9.0 ± 1.0 N·m

1

4

6

3

5

2

7

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m

9.0 ± 1.0 N·m

7

8

10

4.0 ± 1.0 N·m

8

4.0 ± 1.0 N·m

9

<M/T>

<CVT>

Removal steps

1.

Air cleaner intake duct

2.

Air cleaner cover

3.

Air cleaner element

4.

Fuel vapour control hose

5.

Breather hose

6.

Air cleaner body assembly

7.

Clip

8.

Breather hose connection

9.

Engine air intake hose <M/T>

10. Engine air intake hose <CVT>

Removal steps (Continued)

Main

Index

Group

TOC

AIR CLEANER

INTAKE AND EXHAUST

15-6

REMOVAL AND INSTALLATION <4G1>

M1151002101315

AC600110AB

9.0 ± 1.0 N·m

1

4

6

3

5

2

7

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m

9.0 ± 1.0 N·m

8

9

10

11

13

1.8 ± 0.6 N·m

6.0 ± 1.0 N·m

12

Removal steps

1.

Air cleaner intake duct

2.

Air cleaner air flow sensor

connector

3.

Air cleaner air flow sensor, air

cleaner cover assembly

4.

Air cleaner air flow sensor

5.

Air cleaner cover

6.

Air cleaner element

7.

Breather hose

8.

Air cleaner body assembly

9.

Clip

10. Engine air intake hose

11. Breather hose connection

>>

B

12. Air by-pass valve connection

>>

A

13. Engine air intake hose

Removal steps (Continued)

Main

Index

Group

TOC

AIR CLEANER

INTAKE AND EXHAUST

15-7

INSTALLATION SERVICE POINTS

>>A<< ENGINE AIR INTAKE HOSE

INSTALLATION

AC600111AE

Engine

air intake hose

Mating mark

(green)

Nipple

Turbocharger

assembly

Install by aligning the mating mark (green) on the

engine air intake hose with the nipple on the turbo-

charger assembly.

>>B<< AIR BY-PASS VALVE

CONNECTION

AC600112AB

Air by-pass valve

Engine

air intake hose

Mating mark

(white)

Mating mark

Install by aligning the mating mark (white) on the air

by-pass valve and the mating mark on the engine air

intake hose.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст