Acura RL (1996-2004 year). Manual — part 318

Ignition System

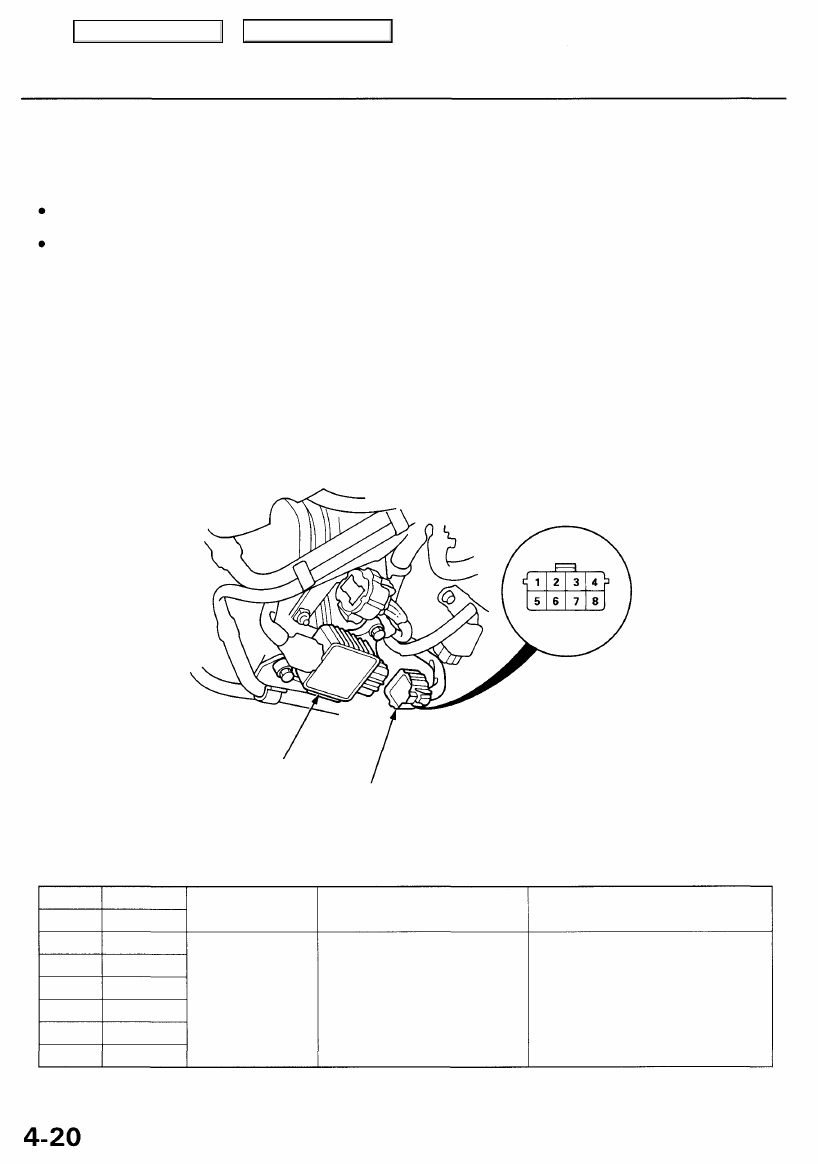

Ignition Control Module (ICM) Input Test

if the malfunction indicator lamp (MIL) blinks. Disconnect the 8P connector from the ignition control

module (ICM). Inspect the connector and socket terminals to be sure they are all making good contact.

If any terminals are bent, loose or corroded, repair them as necessary, and recheck the system.

If the terminals look OK, make the following input tests at the connector.

— If any test indicates a problem, find and correct the cause, then recheck the system.

— If all the input tests prove OK, the ICM must be faulty; replace it.

Wire side of

female terminals

ICM

8P CONNECTOR

Trml

Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

2

7

4

3

1

8

6

5

BLK

3

BLK

4

WHT

1

WHT/GRN

WHT/BLK

WHT/BLU

RED/GRN

WHT/RED

Under all

conditions

Ignition switch ON

(ID

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery

voltage.

• Poor ground (G151)

• An open in the wire

• Blown 30 A fuse in the under-dash

fuse/relay box

• Faulty ignition coil

• An open in the wire

Main Menu

Table of Contents

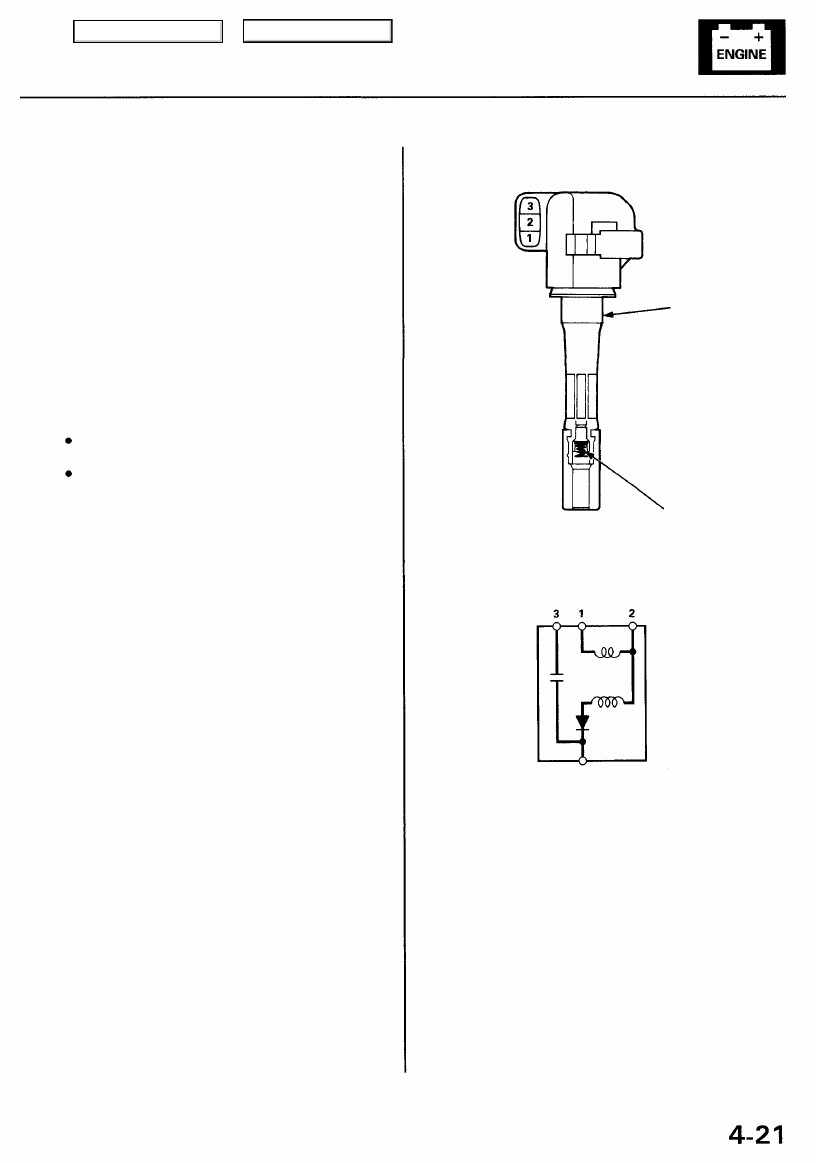

Ignition Coil Test

1. Turn the ignition switch OFF.

2. Remove the strut brace, then remove the engine

3. Remove the ignition coil.

4. Using an ohmmeter, measure resistance between

the terminals. Replace the coil if the resistance is

not within specification.

NOTE: Resistance will vary with the coil tempera-

ture; specification is at 77°F (25°C).

Primary Winding Resistance

(between the No. 1 and No. 2 terminals)

0.9- 1.1 ohms

If the resistance is not within specification,

replace the coil.

If the resistance is OK, but other troubleshooting

doesn't reveal the cause of the problem, substi-

tute a known-good ignition coil and check engine

operation again.

If the engine then runs OK, replace the original

coil.

Terminal

side of male

terminals

IGNITION

COIL

SECONDARY

WINDING

TERMINAL

SECONDARY

WINDING

TERMINAL

Main Menu

Table of Contents

Ignition System

Spark Plug Inspection

1. Inspect the electrodes and ceramic insulator for:

Worn or deformed

electrodes

Damaged

gasket

Cracked

insulator

Improper gap

Oil-fouling

Carbon deposits

Cracked center

electrode insulator

Burned or worn electrodes may be caused by:

Advanced ignition timing

Loose spark plug

Plug heat range too hot

Insufficient cooling

Fouled plug may be caused by:

Retarded ignition timing

Oil in combustion chamber

Incorrect spark plug gap

Plug heat range too cold

Excessive idling/low speed running

Clogged air cleaner element

Deteriorated ignition coil or ignition wires

2.

Do not adjust the gap of platinum tip plugs; replace

the spark plug if the gap is out of specification or if

the center electrode is rounded.

Electrode Gap:

Standard

Service Limit

1.1 mm (0.043 in)

1.3 mm (0.051 in)

Platinum tip plug:

Do not adjust the gap;

replace the spark plug if the

gap is out of specification or

if the center electrode is

rounded.

3. Replace the plug at the specified interval, or if the

center electrode is rounded as shown below:

ROUNDED ELECTRODE

NOTE: Use only the spark plugs listed below.

Spark Plugs

PFR5L-11 (NGK)

PK16PR-L11 (DENSO)

4.

Apply a small quantity of anti-seize compound to

the plug threads, and screw the plugs into the cylin-

der head finger-tight. Then torque them to 18 N-m

(1.8 kgf-m, 13 Ibf-ft).

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст