Acura TL (1995-1998) body repair. Manual — part 7

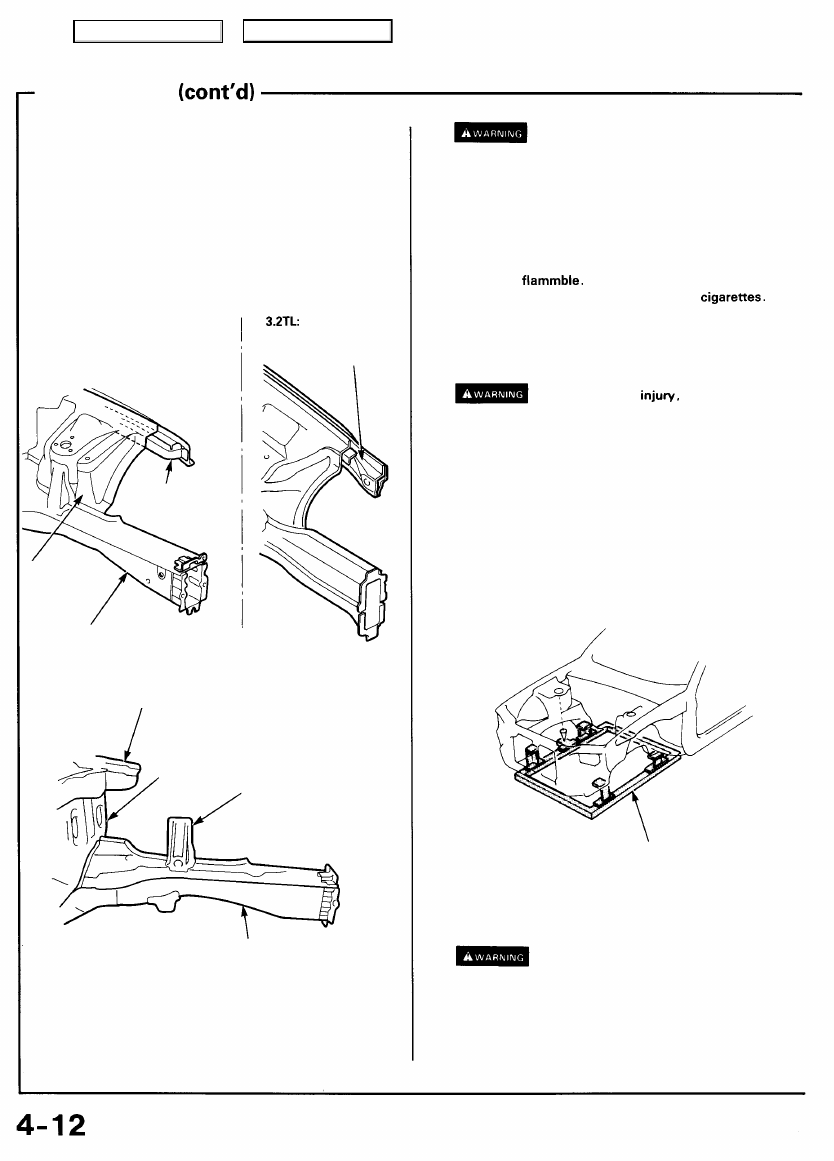

3.2TL:

Main Menu

Table of Contents

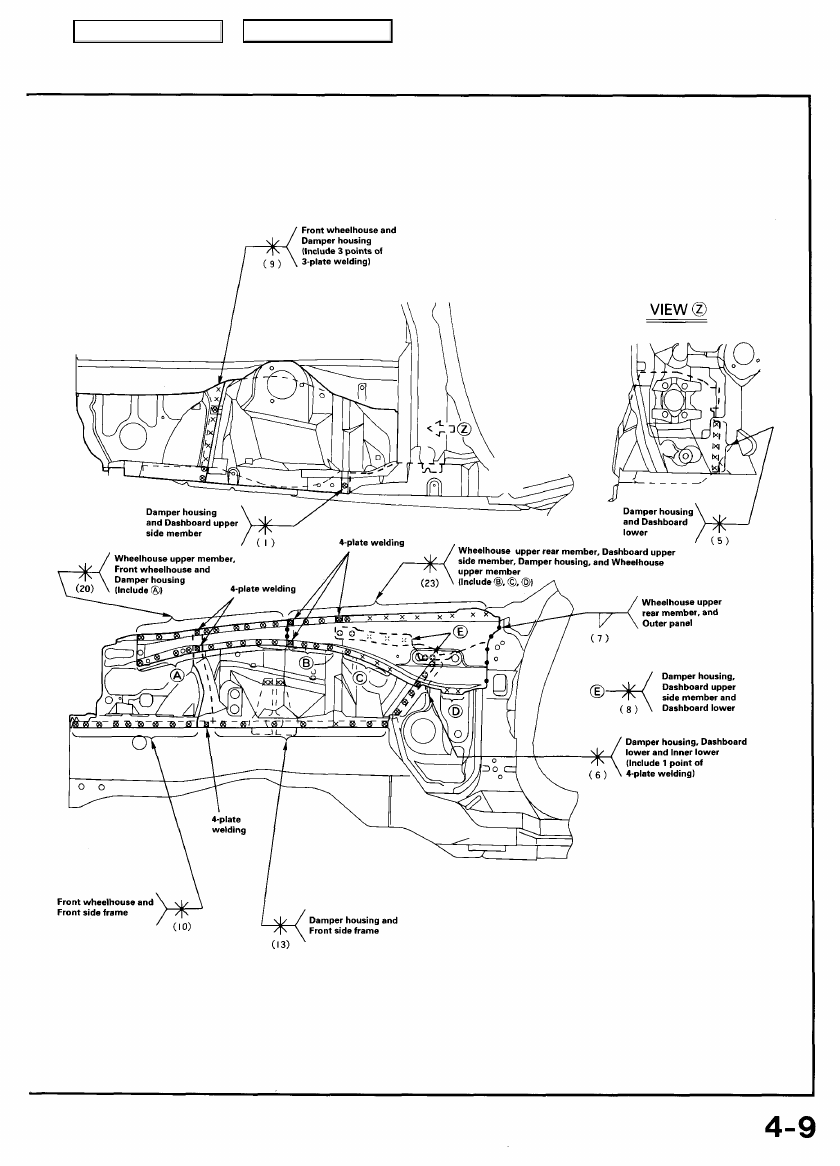

Front Wheelhouse/Damper Housing

Replacement

1. Remove the related parts.

• Parts to be removed when removing the front bulk-

head

• Parts on passenger side of lower dashboard which

are especially flammable

• Electrical accessories in engine compartment and

wire harnesses.

NOTE: See the 95-96 Acura 2.5TL & 96 Acura 3.2TL

Service Manuals, for removal and installation of the

engine, front suspension and brakes.

2. Pull out and straighten the damaged area to approxi-

mately the original shape.

• Attach the car to the frame straightener by tighten-

ing the underbody clamps at the horizontal pinch

weld points.

NOTE: Refer to the 95-96 Acura 2.5TL & 96 Acura 3.2TL

Service Manuals for safety stand location points.

• Before cutting off the damaged sections, pull them

out so that they are restored to the original shape.

• Do not pull out more than necessary.

• Pull out and straighten the damaged area of the

lower dashboard, front pillar, and other parts.

• After pulling, check the damper housing position

using the body dimensional drawings (see

).

NOTE: Check the condition of the door and hinges.

3. Peel off the undercoat.

Heat the undercoat at the weld areas of the wheelhouse

and front side frame with a gas torch, and peel off the

undercoat with a metal spatula.

4. Cut and pry off the front wheelhouse and damper

housing.

-1. When replacing the front wheelhouse only.

• Center punch around the spot weld imprints on the

front side frame and damper housing.

• Drill holes in the center punched areas using a spot

cutter.

• Using a chisel, pry off the welded flange.

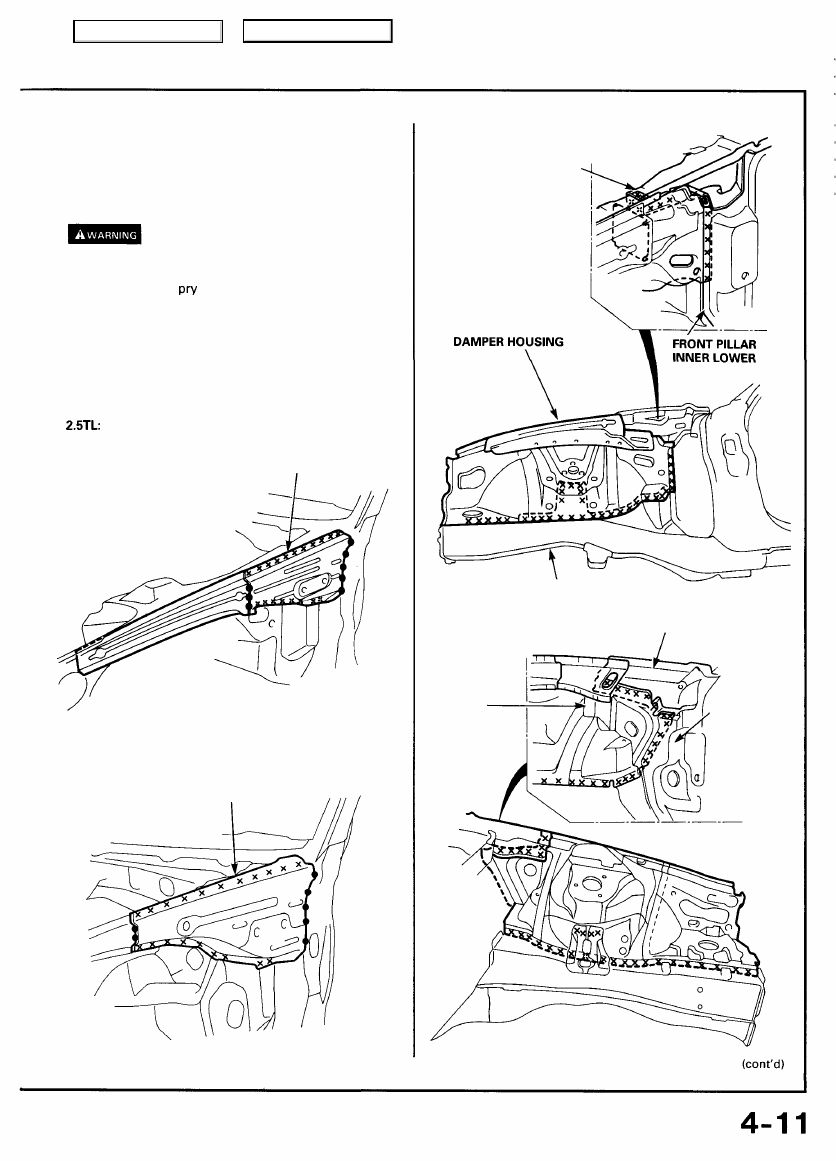

2.5TL:

FRONT WHEELHOUSE

3.2TL:

FRONT WHEELHOUSE

Main Menu

Table of Contents

-2. Replace the damper housing with the front

wheelhouse.

• Remove the wheelhouse upper rear member.

• Remove the MIG weld flange with a disc sander.

To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting or grinding.

• Using a chisel,

off the welded flange form the

front pillar and damper housing.

NOTE: Remove the wheelhouse upper rear member

carefully so they can be reused.

3.2TL:

WHEELHOUSE UPPER

REAR MEMBER

WHEELHOUSE UPPER

REAR MEMBER

2.5TL:

DASHBOARD

UPPER SIDE

MEMBER

3.2TL:

DAMPER

HOUSING

FRONT SIDE FRAME

DASHBOARD UPPER SIDE MEMBER

FRONT PILLAR

INNER LOWER

Main Menu

Table of Contents

Front wheelhouse/Damper housing

Replacement

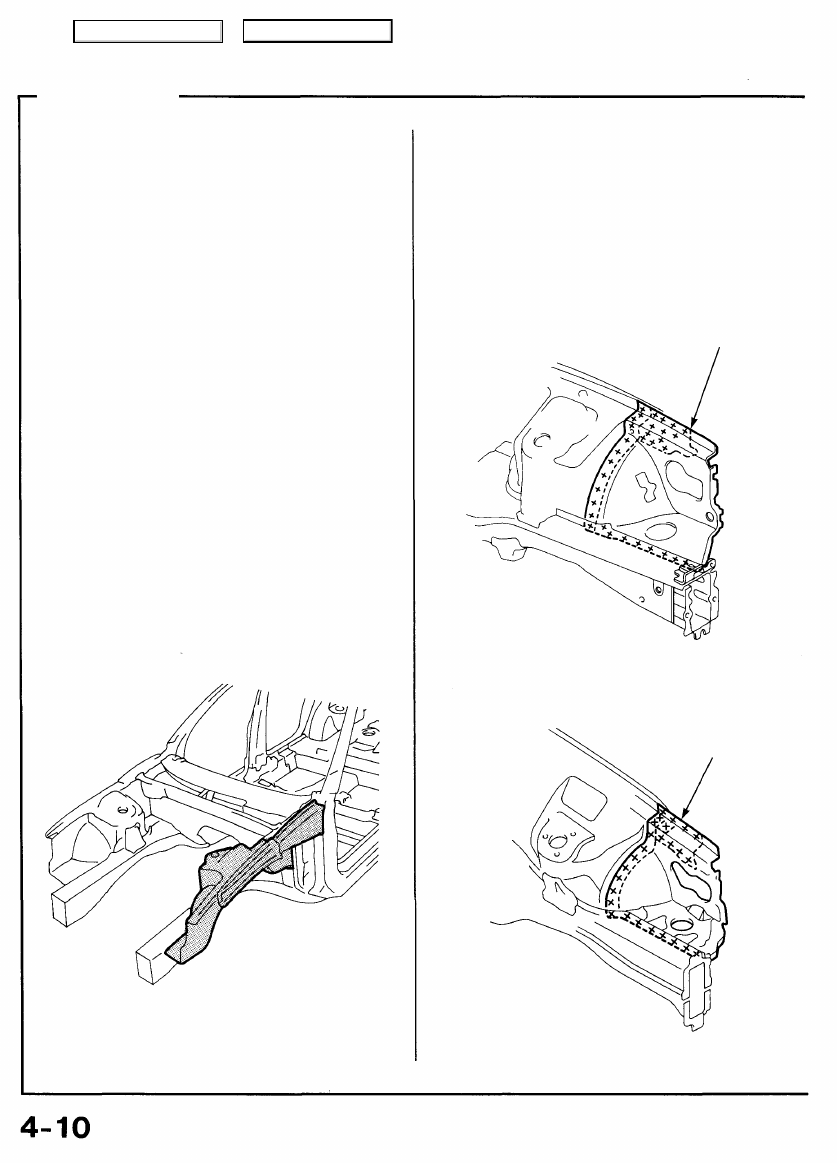

5. Mold the related parts.

• Level and finish the burrs left on the welding

surfaces with a sander.

• Fill all drilled holes by MIG or gas welding.

Use a hammer and dolly to even out the welded areas of

the lower dashboard, front side frame and dashboard

upper side member.

2.5TL:

WHEELHOUSE UPPER

MEMBER DIAGONAL

WHEELHOUSE

UPPER

EXTENSION

FRONT SIDE FRAME

DASHBOARD UPPER

SIDE MEMBER

DASHBOARD LOWER

DAMPER STIFFENER

FRONT SIDE FRAME

6. Set the new front wheelhouse and damper housing.

• Apply body paint to both sides of the new front

wheelhouse and damper housing.

• See Paint Repair section.

• Ventilate when spraying paint. Most paint

contains substances that are harmful if inhaled

or swallowed. Read the paint label before

opening the paint container.

• Avoid contact with skin. Wear an approved

respirator, gloves, eye protection and appropriate

clothing when painting.

• Paint is

Store it in a safe place, and

keep it away from sparks, flames or

• Remove the undercoat from both sides of the weld-

ing section and expose the steel plate using a disc

sander.

To prevent eye

wear goggles

or safety glasses whenever sanding, cutting or

grinding.

• Clamp to the front side frame with vise-grips and

squill vises.

NOTE: Apply the spot sealer to the welding surface

when spot welding.

• Clamp the front bulkhead with vise-grips.

• Measure the front compartment diagonally.

NOTE: Use of a positioning jig is recommended (see

page

).

POSITIONING JIG

• Spot weld several points in the clamped sections, and

temporarily attach the front wheelhouse and damper

housing.

To prevent eye injury and burns

when welding, wear an approved welding helmet,

gloves and safety shoes.

7. Check the dimensions, temporarily install the hood, front

fender and headlight, and check for differences in level

and clearance.

DAMPER

HOUSING

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст