Mazda Transaxle FN4A-EL. Manual — part 7

K1–20

AUTOMATIC TRANSAXLE

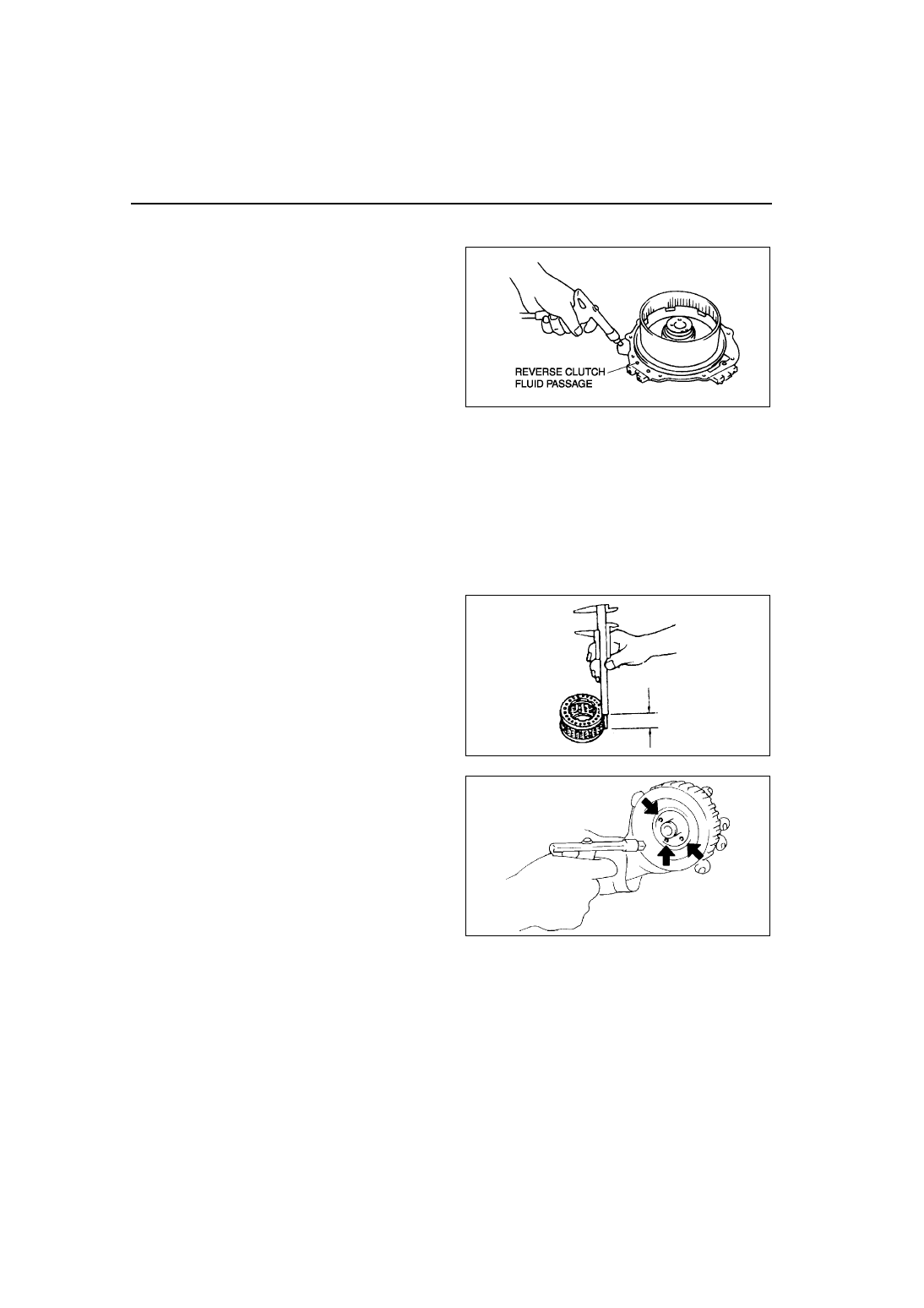

Reverse Piston Disassembly Note

1. Set the 2-4 brake drum onto the end cover.

2. Remove the reverse piston from the 2-4 brake

drum by applying compressed air through the

fluid passage.

Air pressure

392 kPa {4.0 kgf/cm

2

, 57 psi} max.

Assembly Procedure

1. Measure the facing thickness in three places and calculate the average value.

Drive plate part number: FN11 19 370

Standard: 1.60 mm {0.063 in}

Minimum: 1.45 mm {0.057 in}

Drive plate part number: FNE1 19 370

Standard: 2.55 mm {0.100 in}

Minimum: 2.40 mm {0.094 in}

2. If not within the specification, replace the drive plates.

3. Measure the free length of the spring and inspect

for deformation.

Spring free length

Standard: 17.0 mm {0.669 in}

Minimum: 15.0 mm {0.591 in}

4. If not within the specification, replace the spring

and retainer.

5. Verify that there is airflow when applying

compressed air through the fluid passage of 3-4

clutch drum.

Air pressure

392 kPa {4.0 kgf/cm

2

, 57 psi} max.

6. Replace the 3-4 clutch drum if damaged or

malfunctioning.

A6E5714A037

X3U517AC8

X3U517AC9

AUTOMATIC TRANSAXLE

K1–21

K1

7. Verify that there is airflow when applying

compressed air through the fluid passage of 2-4

brake drum.

Air pressure

392 kPa {4.0 kgf/cm

2

, 57 psi} max.

8. Replace the 2-4 brake drum if damaged or

malfunctioning.

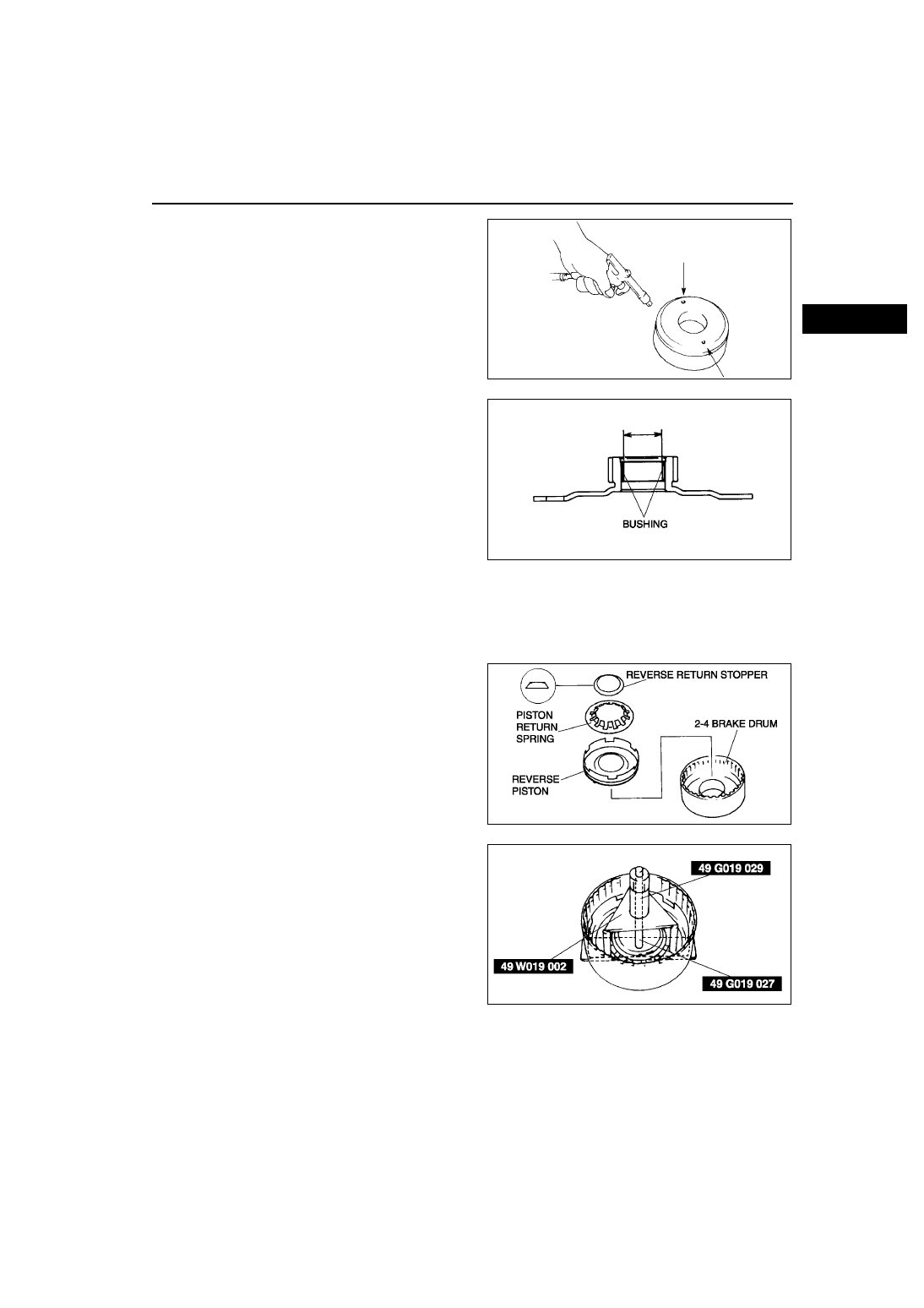

9. Measure the bushing of the rear sun gear.

Bushing inner diameter

Standard:

26.400—26.421 mm {1.03937—1.04019

in}

Maximum: 26.441 mm {1.04098 in}

10. If not as specified, replace the rear sun gear

plate.

11. Install the reverse clutch.

Caution

••••

Installing the reverse clutch piston may

damage its seal. Carefully install the reverse clutch piston by pushing evenly around the

circumference.

(1) Apply ATF to the circumference of the reverse clutch piston seal, and install the piston into the 2-4 brake

drum.

(2) Install the piston return spring and reverse

return stopper to the reverse piston.

(3) Install the snap ring and the SSTs to the 2-4

brake drum as shown.

Caution

••••

Depress the piston return spring only

enough to install the snap ring.

Overpressing will damage the piston

return spring assembly edges.

(4) Compress the piston return spring.

(5) Install the snap ring.

(6) Remove the SSTs.

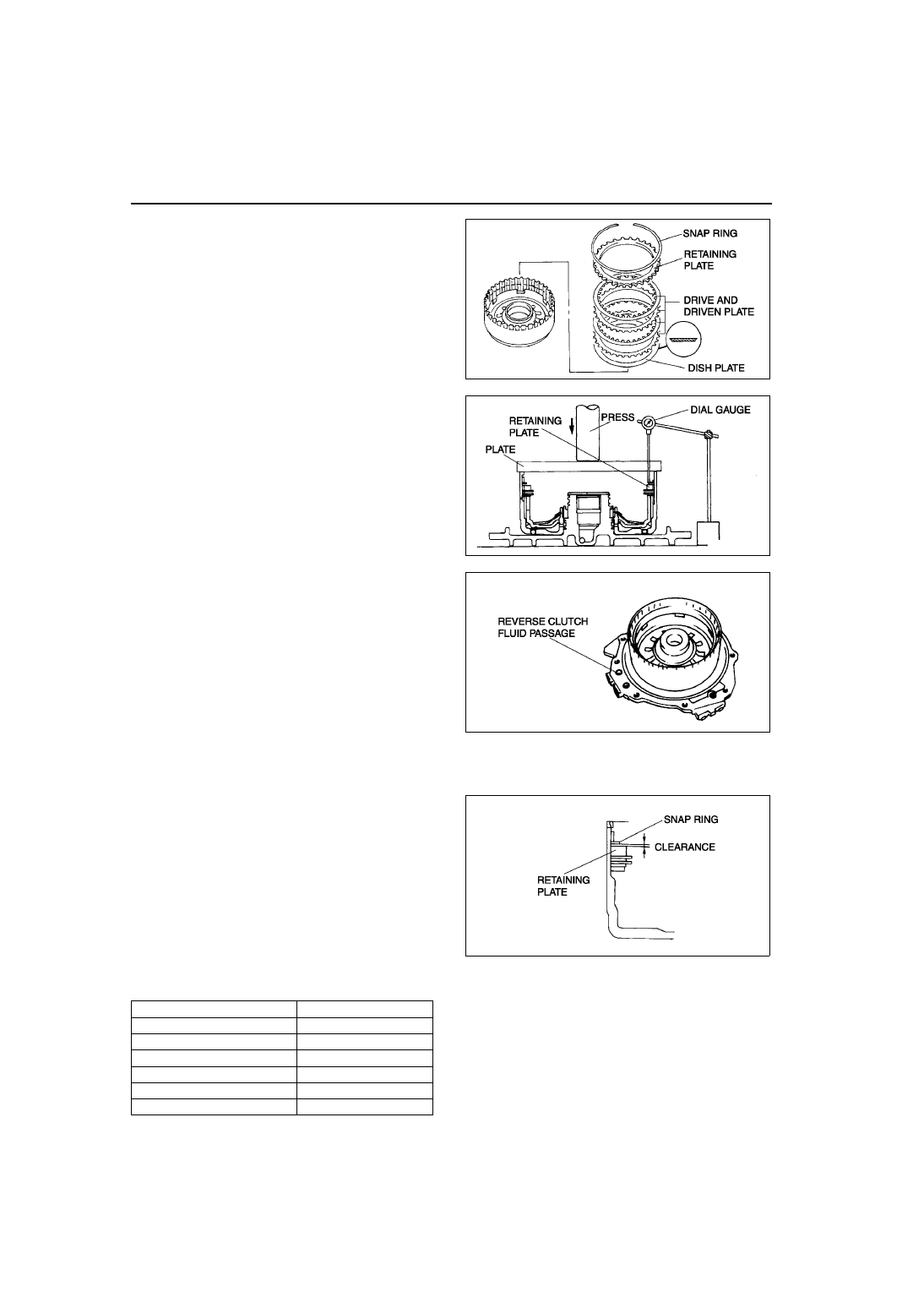

(7) Install the dish plate.

(8) Install the drive and driven plates in the

following order.

Driven-Drive-Driven-Drive

X3U517ACA

A6E5714A038

A6E5714A039

A6E5714A036

K1–22

AUTOMATIC TRANSAXLE

(9) Install the retaining plate.

12. Measure the reverse clutch clearance.

(1) Install the reverse clutch into the end cover,

and set the dial gauge.

(2) Secure the reverse clutch by lightly pressing

down with a press, etc.

(3) Apply compressed air to the part indicated in

the figure and let the reverse clutch piston

stroke three times.

Air pressure

392—441 kPa {4.0—4.5 kgf/cm

2

, 57—63 psi}

(4) Apply compressed air and operate the

reverse clutch piston. Read the value when

the indicator of the dial gauge stops.

(5) Release the compressed air and read the dial

gauge when the reverse clutch piston is not

operating.

(6) Calculate the reverse clutch clearance

according to the following formula:

step (4) value – step (5) value = Reverse clutch clearance.

(7) Measure the clearances at four locations (90

°

apart) by following the steps from (3) to (6).

Verify that the average value is within the

specification below.

Reverse clutch clearance

1.00—1.03 mm {0.039—0.051 in}

(8) If not as specified, remove the snap ring and

measure its thickness.

(9) Add the thickness to the average value

calculated in step (7), and select the snap ring

whose range includes the value.

Snap ring sizes

Range mm {in}

Snap ring sizes mm {in}

2.250—2.450 {0.089—0.096}

1.2 {0.047}

2.450—2.650 {0.096—0.104}

1.4 {0.055}

2.650—2.850 {0.104—0.112}

1.6 {0.063}

2.850—3.050 {0.112—0.120}

1.8 {0.071}

3.050—3.250 {0.120—0.128}

2.0 {0.079}

3.250—3.450 {0.128—0.136}

2.2 {0.087}

A6E5714A040

A6E5714A041

A6E5714A042

A6E5714A043

AUTOMATIC TRANSAXLE

K1–23

K1

(10)Install the selected snap ring and perform steps (2) to (7) again. Verify that the calculated value satisfies

the clearance specification.

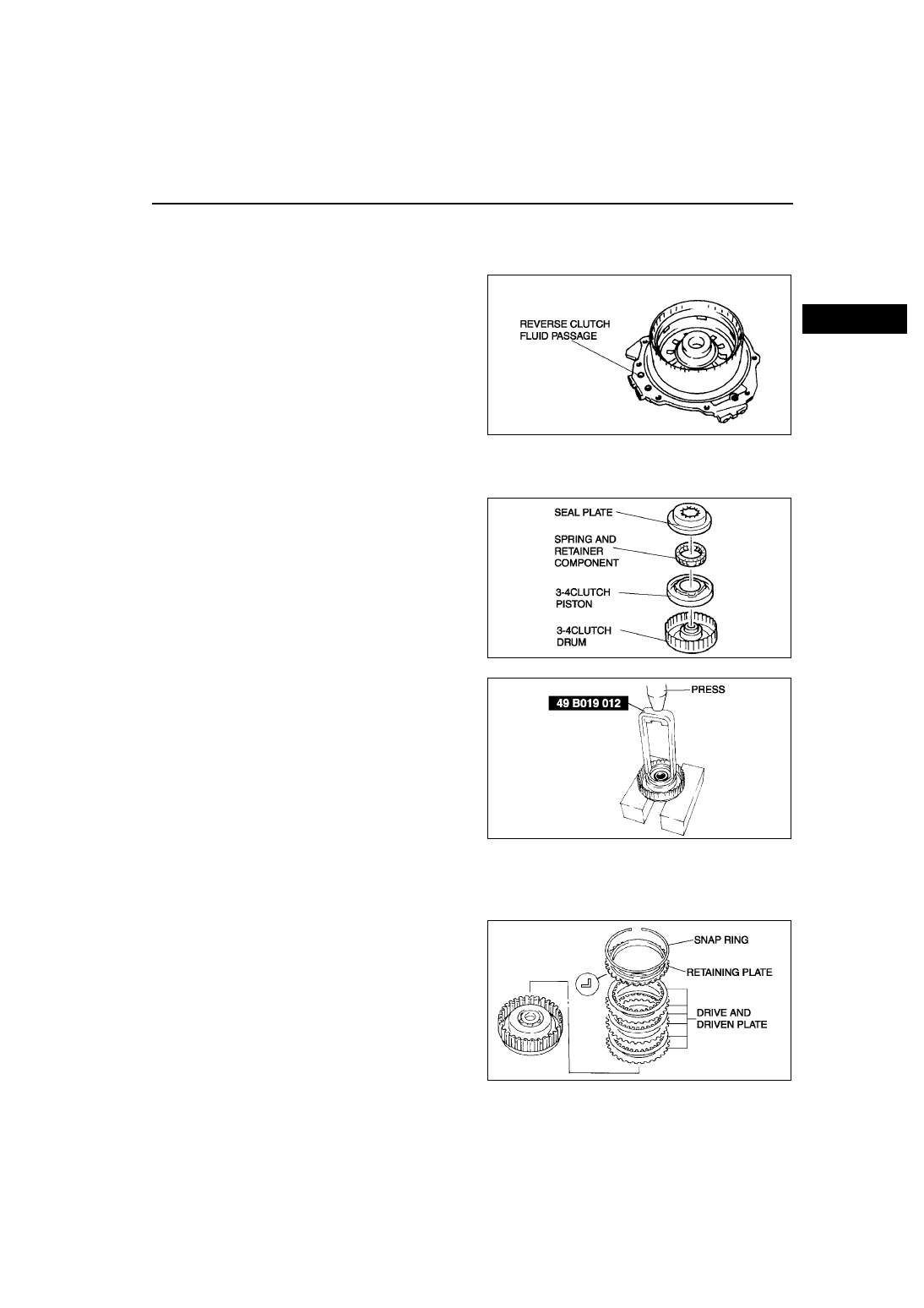

13. Inspect the reverse clutch operation.

(1) Install the 2-4 brake drum to the end cover.

(2) Inspect the reverse clutch operation by

applying compressed air as shown.

Air pressure

392—441 kPa {4.0—4.5 kgf/cm

2

, 57—63 psi}

14. Install the 3-4 clutch.

Caution

••••

Installing the 3-4 clutch piston may

damage its seal. Carefully install the 3-4

clutch piston by pushing evenly around

the circumference.

(1) Apply ATF to the circumference of the 3-4 clutch piston seal, and install the piston in to the 3-4 clutch drum.

(2) Install the spring and retainer.

(3) Apply ATF to the 3-4 seal plate, and install it

onto the 3-4 clutch drum.

(4) Install the SST as shown.

Caution

••••

Depress the 3-4 seal plate only enough to

install the snap ring. Overpressing will

damage the 3-4 seal plate assembly

edges.

(5) Compress the spring and retainer component

and 3-4 seal plate.

(6) Install the snap ring.

(7) Remove the SST.

(8) Install the drive and driven plates in the

following order.

Driven-Drive-Driven-Drive-Driven-Drive

(9) Install the retaining plate.

DRIVE PLATE PART NUMBER:FN11 19 370

A6E5714A042

A6E5714A044

A6E5714A045

A6E5714A046

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст