Mazda Training manual — part 5

Powertrain Engines

Cylinder Block

•

The cylinder block features a bearing support frame, in which the main bearing caps are

integrated. Cylinder block and bearing support frame are matched to each other, i.e. they

cannot be replaced separately. If one of the components exceeds the specification, the

cylinder block must be replaced as a complete unit.

•

The main bearing cap bolts are torque-to-yield bolts, which must be tightened in several

stages (refer to the workshop manual for details).

L1001.4_01002

1

Cylinder block

2

Bearing support frame

Curriculum Training

01-7

Engines Powertrain

Pistons

•

The piston skirt is coated to reduce friction between the piston and the cylinder.

•

Piston, piston pin and connecting rod are shrinkage fitted and cannot be disassembled. If

one of the components exceeds the specification, the piston/ connecting rod assembly

has to be replaced as a complete unit.

L1001.4_01003

1

Engine front side

3

Valve recesses

2

Arrow indicating the installation direction

01-8 Curriculum

Training

Powertrain Engines

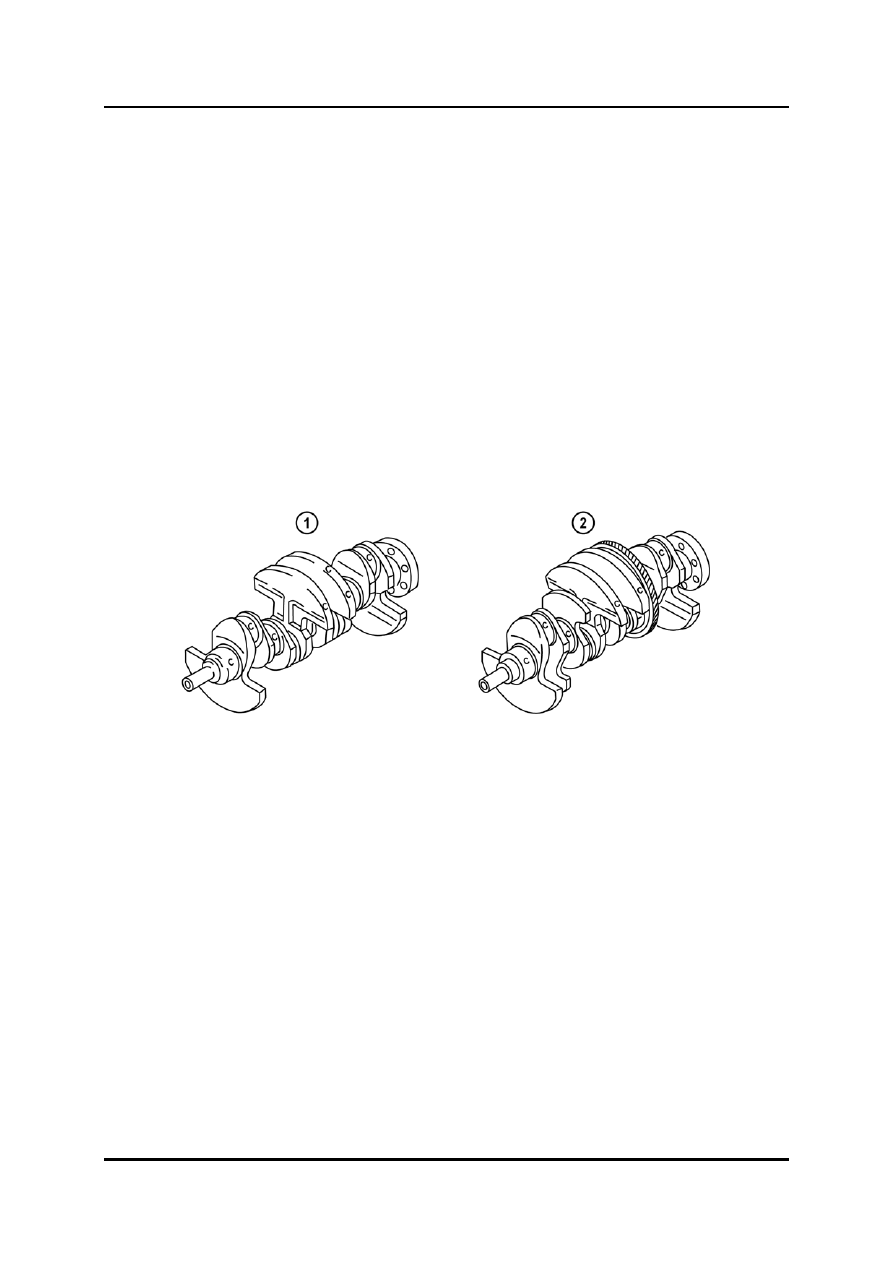

Crankshaft

•

The crankshaft for the L8 and LF engine has four counterweights, while the crankshaft

for the L3 engine has eight counterweights.

•

In addition, the crankshaft for the L3 engine is equipped with a drive gear for the

balancer shafts.

•

The crankshaft features no key for the installation of the crankshaft sprocket and the

crankshaft pulley, i.e. solely the clamping force of the lock bolt secures both components

on the crankshaft.

•

The crankshaft pulley has a pulse wheel for the CKP (Crankshaft Position) sensor

signals. For this reason, the crankshaft pulley must be fixed to the engine front cover

using a detent bolt (M6 x 1.0) before tightening the crankshaft pulley lock bolt.

•

The crankshaft pulley lock bolt is a torque-to-yield bolt, which must be tightened in

several stages (refer to the workshop manual for details).

NOTE: The crankshaft pulley lock bolt must not be re-used.

L1001.4_01004

1

Crankshaft (L8, LF engine)

2

Crankshaft (L3 engine)

Curriculum Training

01-9

Engines Powertrain

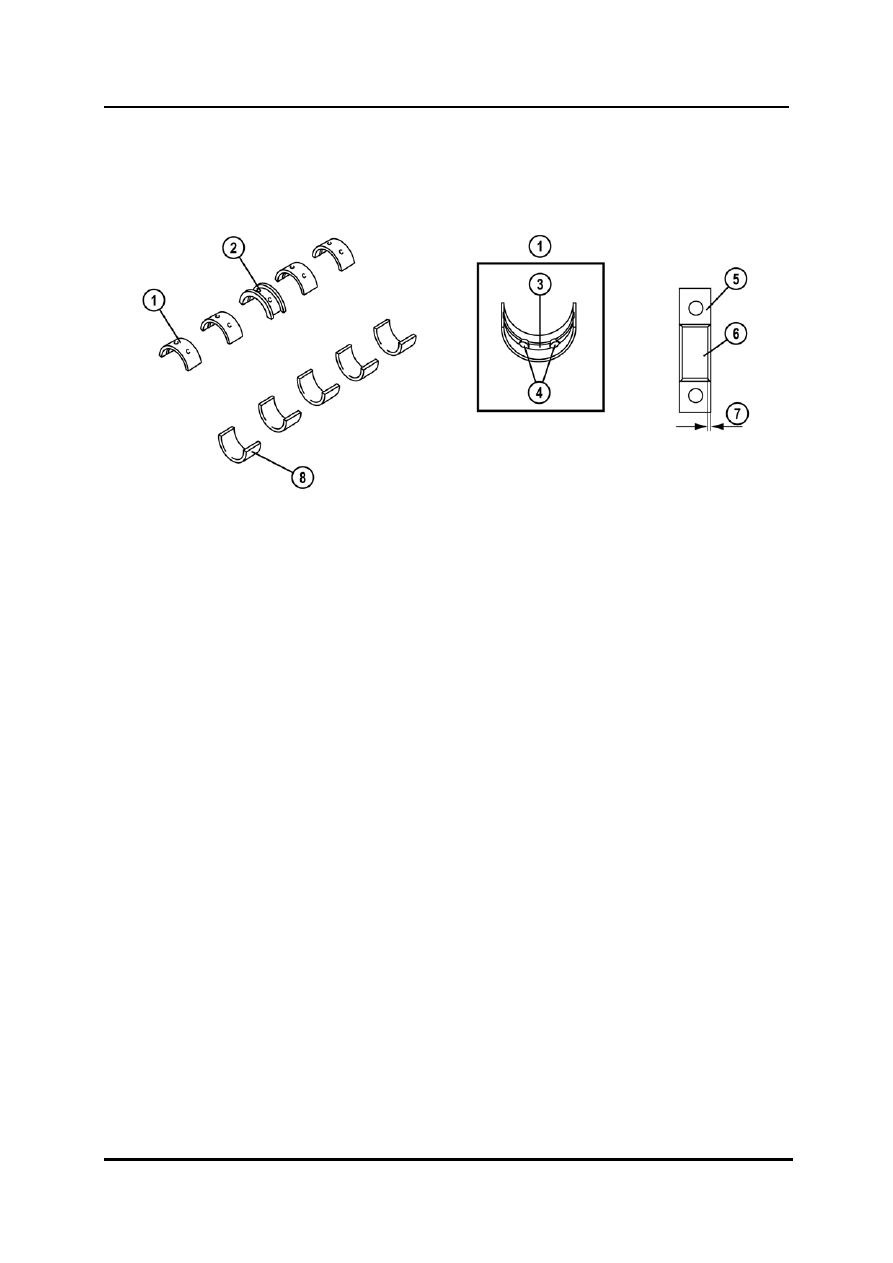

•

There is no positioning tab for locating the upper and lower bearing in the main journal.

For installing the main bearing shells (upper and lower), they have to be measured and

attached so that they are positioned in the center of the main bearing cap (refer to the

workshop manual for details).

L1001.4_01005

1

Upper main bearing shell

5

Main bearing cap

2

Thrust bearing

6

Main bearing shell

3

Upper main bearing oil groove

7

Specified measurement

4

Oil holes

8

Lower main bearing shell

01-10 Curriculum

Training

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст