Mazda Training manual — part 6

Powertrain Engines

Balancer Shaft Unit

•

The balancer shafts minimize the engine vibrations by rotating at twice the speed of the

crankshaft.

•

The balancer shaft unit features a two-piece housing, which is fixed to the cylinder block

by four bolts.

NOTE: The balancer shaft unit cannot be repaired due to its precise interior construction, i.e.

it must be replaced as a complete unit.

•

If the cylinder block, crankshaft, crankshaft main bearing, or balancer shaft unit have

been replaced, the backlash between the drive gear of the crankshaft and the driven

gear of the balancer shaft unit must be adjusted using shims (refer to the workshop

manual for details).

L1001.4_01006

1

Adjustment shim

6

Counter weights

2

Engraved identification mark

7

Balancer shaft unit housing

3

Drive gear

8

Engine front side

4 Balancer

shaft

no.2

9 Crankshaft

5

Balancer shaft no.1 with driven gear

Curriculum Training

01-11

Engines Powertrain

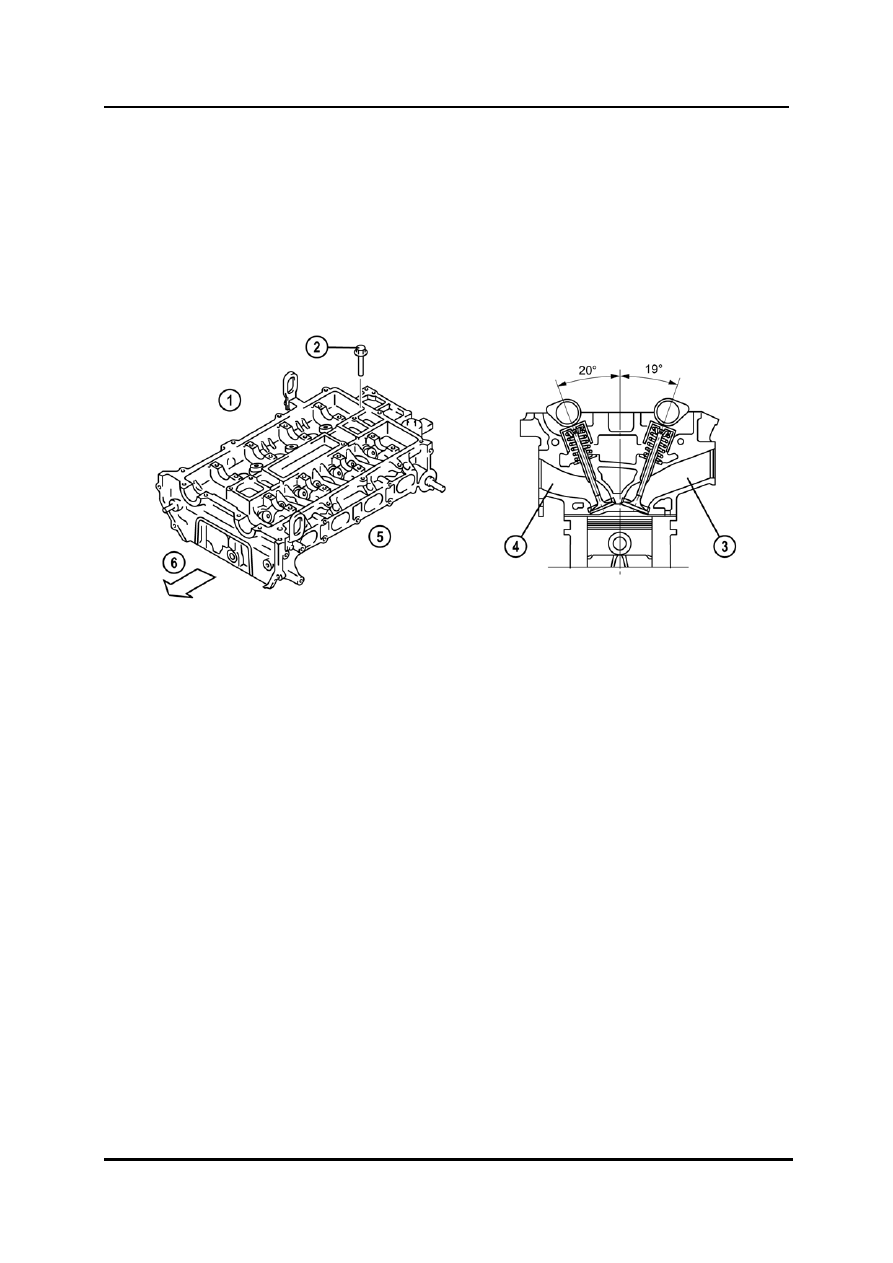

Cylinder Head

•

The cylinder head is a conventional construction with separate camshaft bearing caps.

•

The cylinder head bolts are torque-to-yield bolts, which must be tightened in several

stages (refer to the workshop manual for details).

NOTE: The cylinder head bolts must not be re-used if their length exceeds the specification

(refer to the workshop manual for details).

L1001.4_01007

1

Exhaust side

4

Exhaust port

2

Cylinder head bolt

5

Intake side

3

Intake port

6

Engine front side

01-12 Curriculum

Training

Powertrain Engines

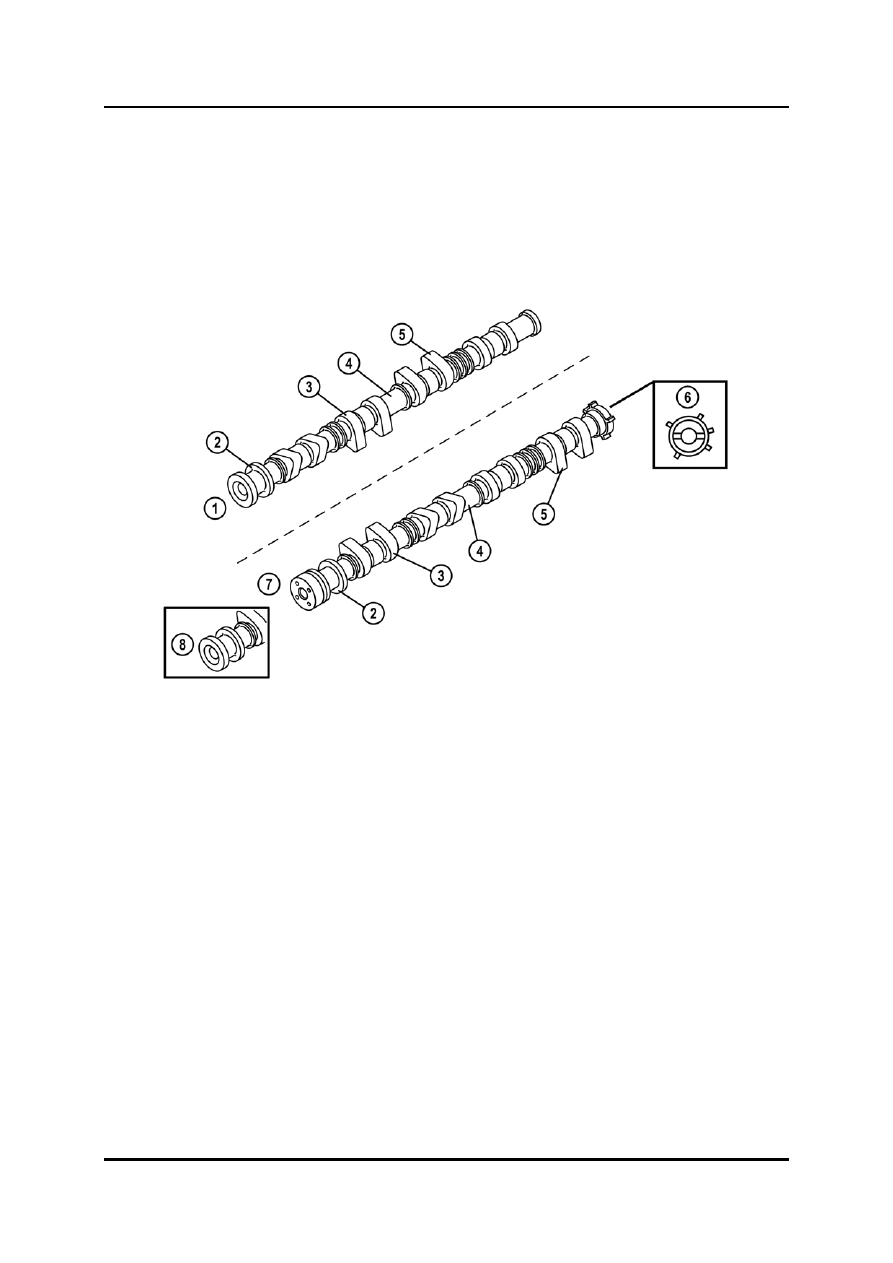

Camshafts

•

The camshafts feature no key for the installation of the camshaft sprockets, i.e. solely

the clamping force of the lock bolt secures the sprocket on the camshaft.

•

The intake camshaft of the LF and L3 engine is equipped with an oil line supplying oil to

the camshaft actuator of the variable valve timing system.

•

The intake camshaft has a pulse wheel for the CMP (Camshaft Position) sensor signals.

L1001.4_01008

1

Exhaust camshaft

5

Cam nose

2

Thrust collar

6

Pulse wheel for CMP sensor

3

Cam heel

7

Intake camshaft

(with variable valve timing system)

4

Cam journal

8

Intake camshaft front end (without

variable valve timing system)

Curriculum Training

01-13

Engines Powertrain

Valve Actuation

•

The camshafts actuate the valves via mechanical bucket tappets without adjustment

shims.

•

The valve clearance is adjusted by the different thickness of the bucket tappets. The

tappet thickness can be determined by the engraved number (e.g. number “402” means

a thickness of 3.402 mm). In order to replace the tappets the camshafts have to be

removed (refer to the workshop manual for details).

•

The valve clearance has to be audibly inspected (and if noisy adjusted) every 120,000

km.

L1001.4_01009

1 Camshaft

4 Tappet

thickness

2 Tappet

cross-sectional

view

5

Valve stem contact surface

3

Cam lobe contact surface

6

Bucket tappet

01-14 Curriculum

Training

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст