Defender. Manual — part 272

Handles, Locks, Latches and Entry Systems - Taildoor Lock Cylinder

Removal and Installation

Removal

1. Remove the taildoor trim panel.

For additional information, refer to:

Taildoor Trim Panel

(501-

05 Interior Trim and Ornamentation, Removal and

Installation).

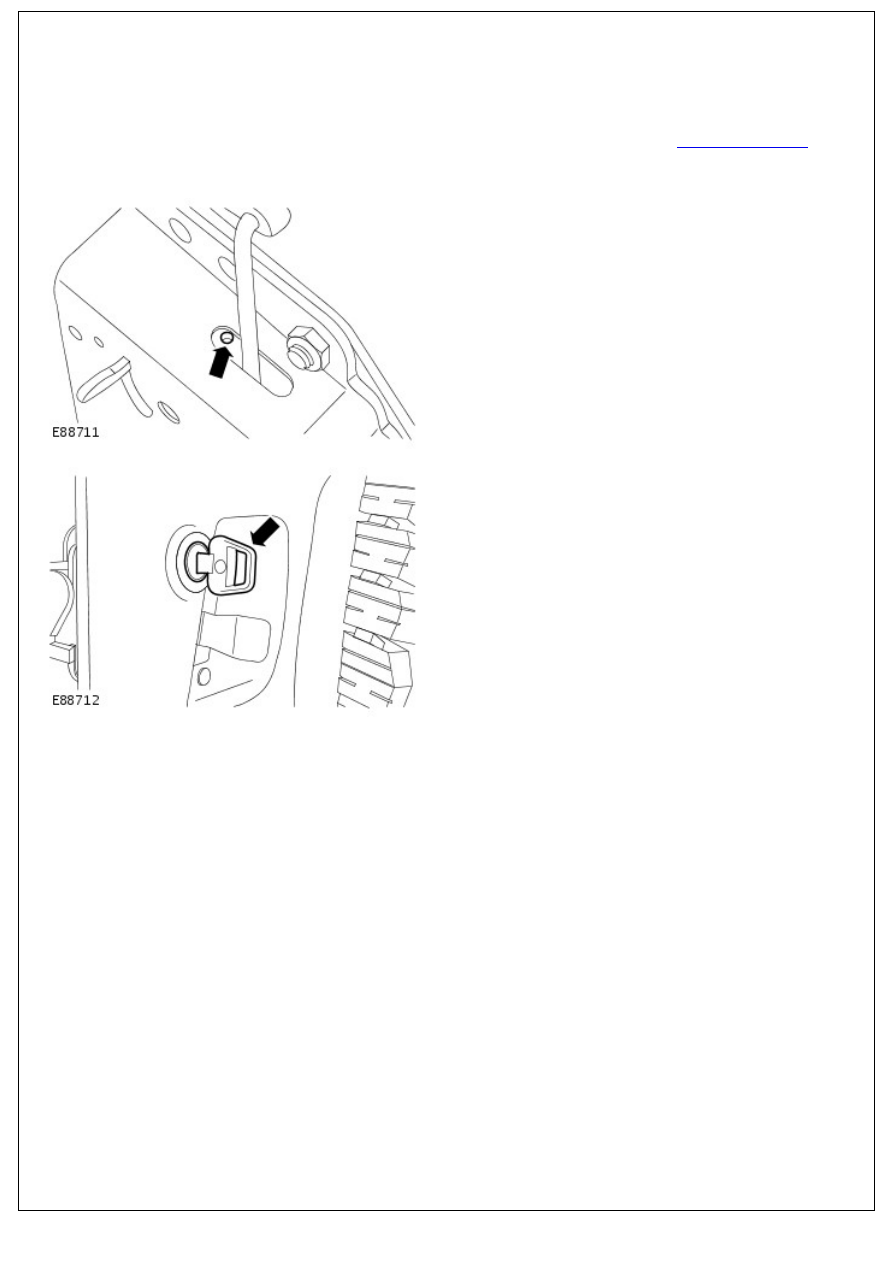

2. NOTE: Make sure the latch is in the locked position.

Using a suitable tool release the lock cylinder.

3. Insert the key and remove the lock cylinder.

Installation

1. To install, reverse the removal procedure.

Handles, Locks, Latches and Entry Systems - Taildoor Lock Motor

Removal and Installation

Removal

1. Remove tail door trim panel.

For additional information, refer to:

Taildoor Trim Panel

(501-

05 Interior Trim and Ornamentation, Removal and

Installation).

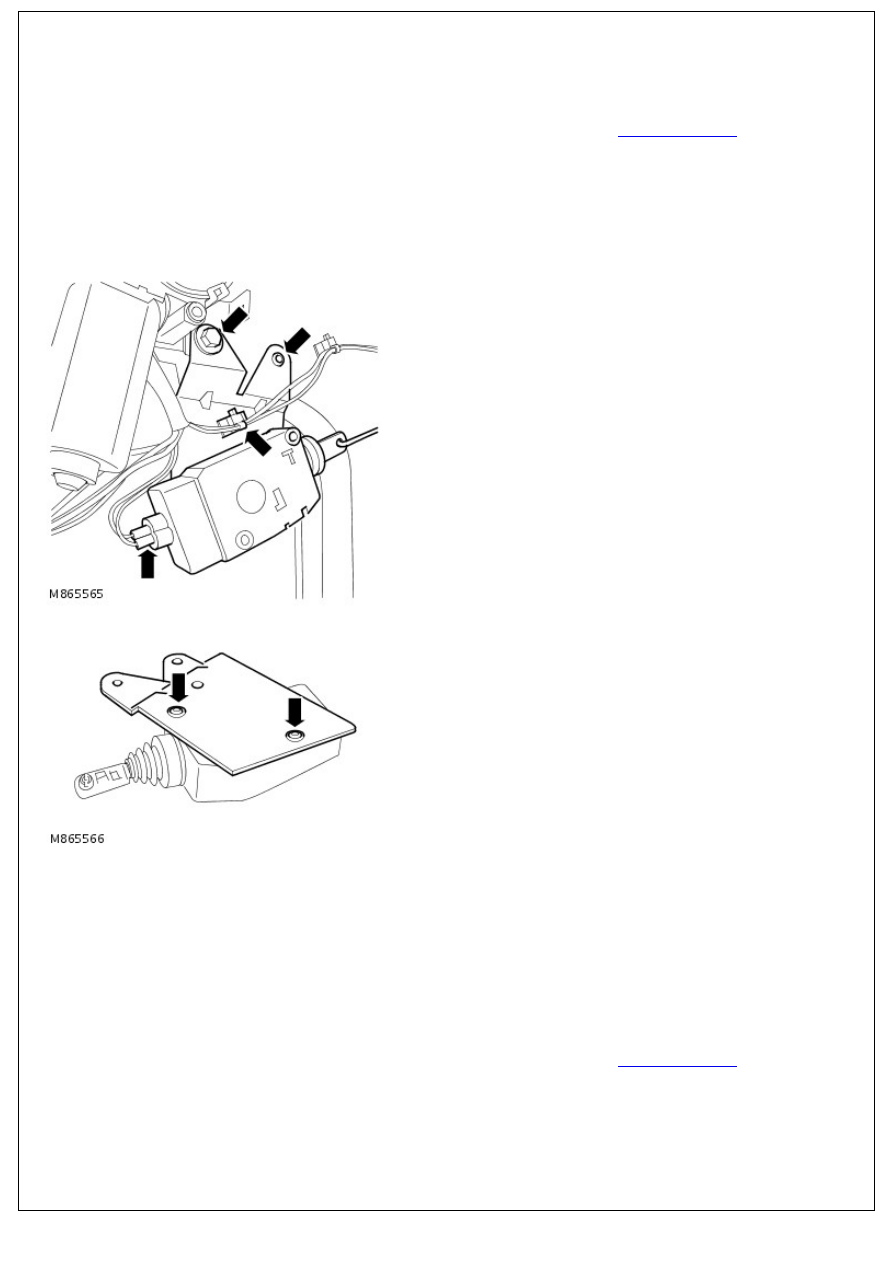

2. Disconnect multiplug from taildoor lock motor.

3. Remove bolt and screw securing taildoor lock motor to

taildoor.

4. Release clip securing harness to taildoor lock motor

mounting bracket.

5. Remove taildoor lock motor assembly from operating rod.

6. Remove 2 screws securing taildoor lock motor to mounting

bracket.

Installation

1. Install taildoor lock motor to mounting bracket and secure

with screws.

2. Connect operating rod to taildoor lock motor.

3. Install taildoor lock motor to door, fit screw and tighten bolt

to 6 Nm (4 lbf.ft).

4. Position harness to taildoor lock motor mounting bracket and

secure with clip.

5. Connect multiplug to taildoor lock motor.

6. Install taildoor trim panel.

For additional information, refer to:

Taildoor Trim Panel

(501-

05 Interior Trim and Ornamentation, Removal and

Installation).

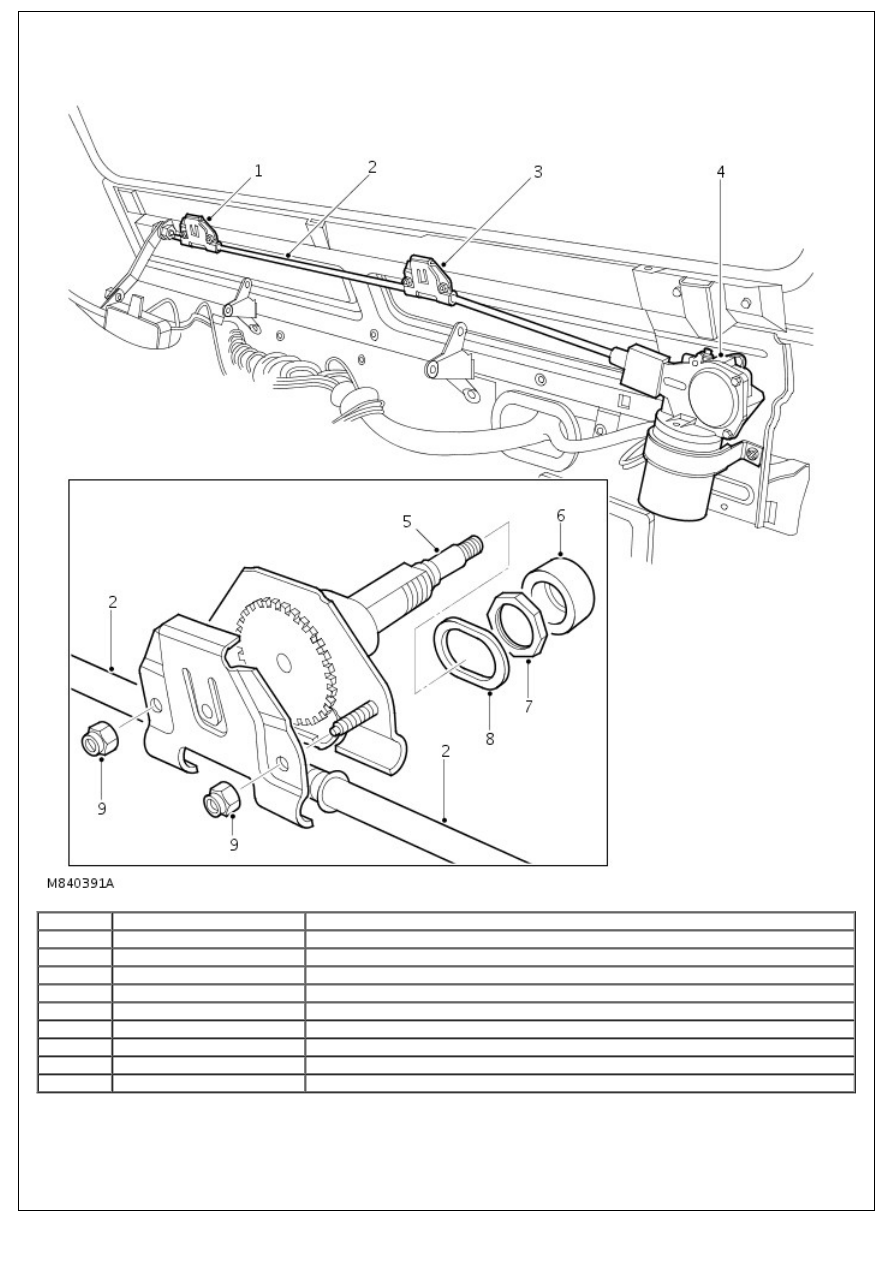

Wipers and Washers - Wipers and Washers

Description and Operation

Item

Part Number

Description

1.

-

LH wheelbox

2.

-

Cable

3.

-

RH wheelbox

4.

-

Wiper motor

5.

-

Spindle with DIN taper arm attachment

6.

-

Spacer

7.

-

Locknut

8.

-

Seal

9.

-

Locknuts

WINDSCREEN WIPERS

Although windscreen wiper functionality remains the same, the mechanical architecture has undergone significant

changes, for 2002 Model year. The body structure has undergone some minor changes to house the revised wiper

linkage.

A modified wiper motor is introduced which is balanced to reduce operation noise. The brush plate is fitted with

capacitors to reduce radio interference and a thermal cut-out is introduced to prevent motor burnout. The motor also

contains a new park switch which also reduces operation noise. A common motor is now used on both LHD and RHD

variants.

The motor is repositioned on the bulkhead which allows a straighter drive cable run. The straighter run reduces load on

the cable allowing a stiffer cable to be used. The stiffer cable and the incorporation of a reduced friction material

reduces torsion wind-up of the cable and results in smoother wiper operation and a reduction of blade over travel.

New, larger wheel boxes are fitted in an inverted position from the previous installation. The bulkhead mounting holes

are larger with flats for positive location of the wheel box spindle. The wheel boxes now feature a 40 tooth gear ratio in

lieu of a 32 tooth gear. This reduces backlash and load and further reduces blade over travel. The wheel box casings

are secured with locknuts.

The wheel box spindles now have a splined DIN taper fitting for the new wiper arms which are secured on the spindle

with an M8 nut. The taper improves arm retention.

A new grease is introduced which improves wiper operation at very low temperatures.

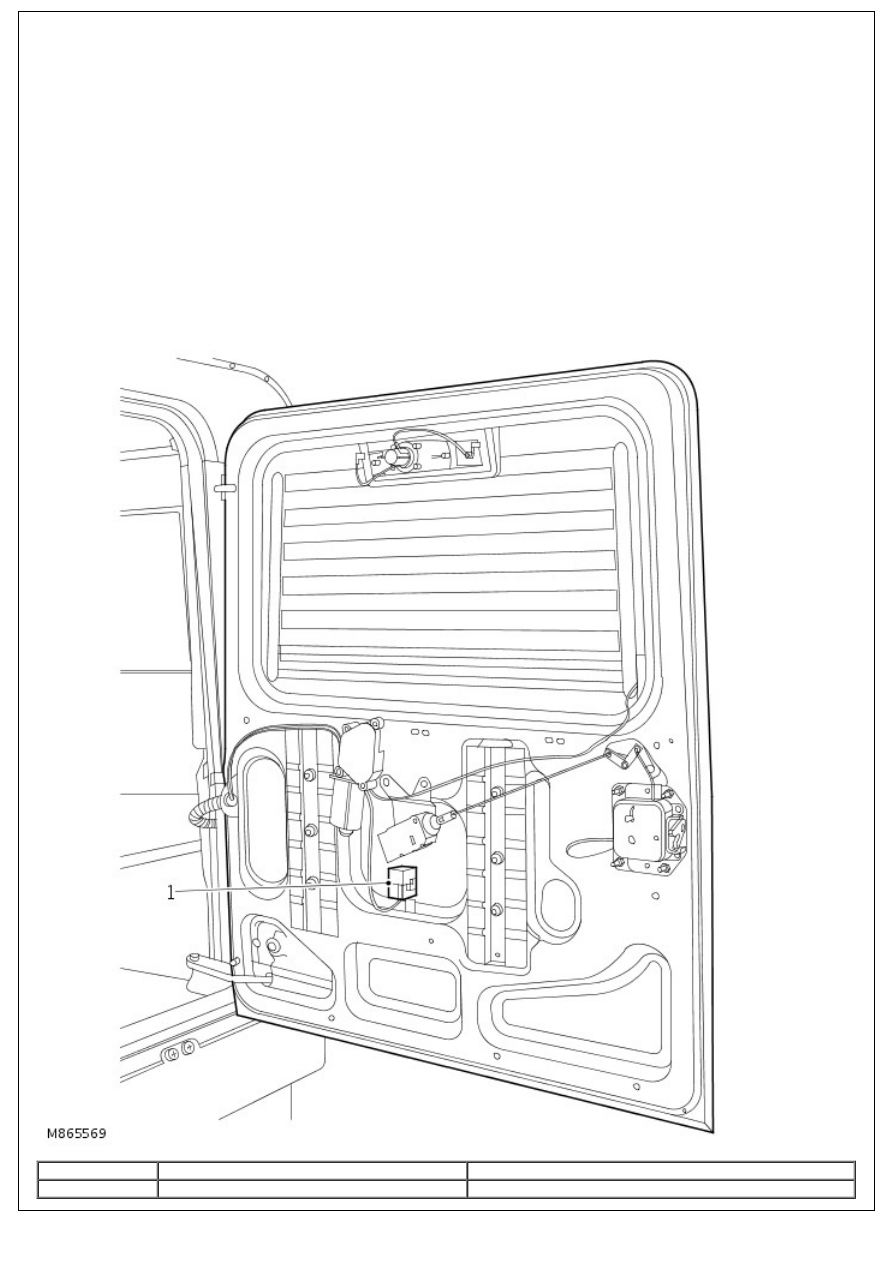

REAR WIPER

Item

Part Number

Description

1.

-

Rear wiper relay

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст