Defender (1993+). Manual — part 39

CLUTCH

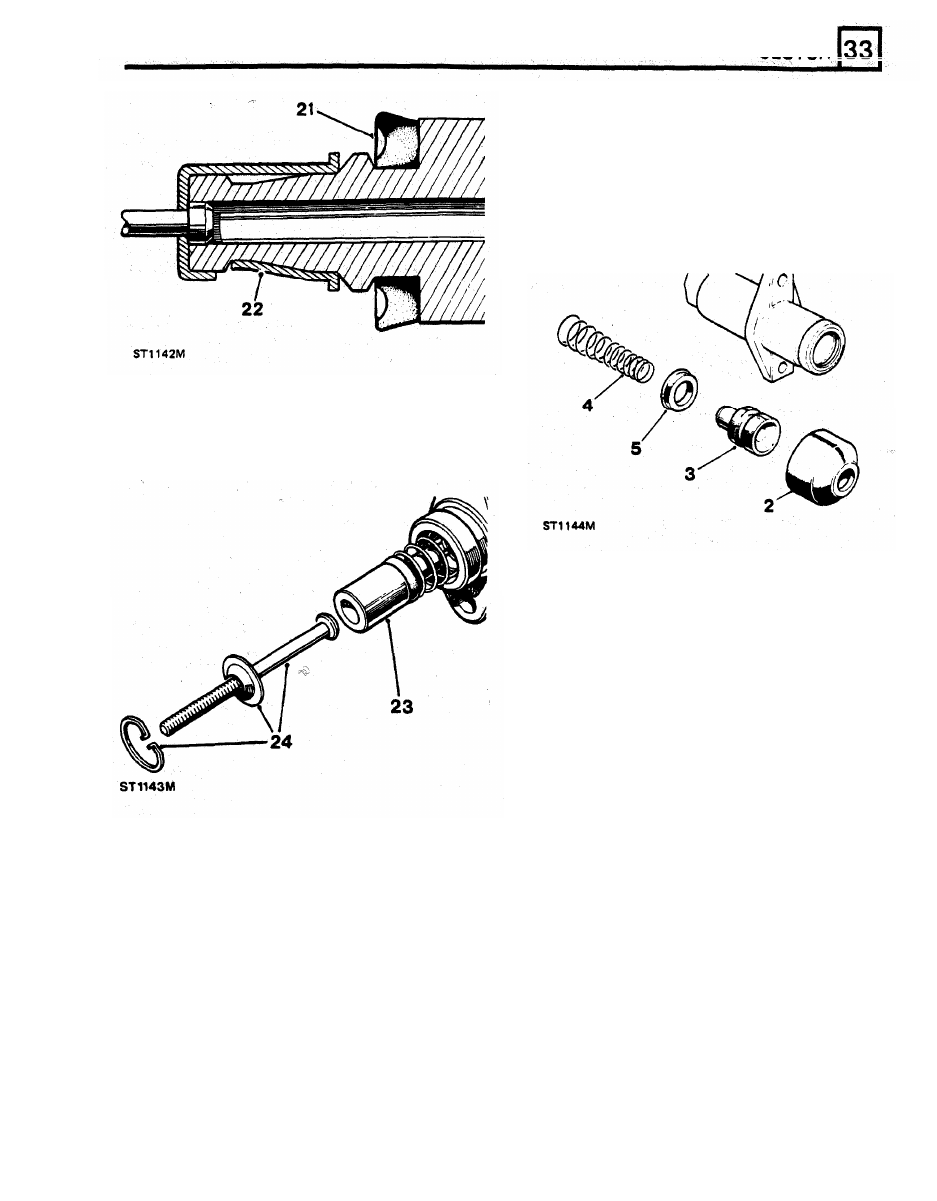

OVERHAUL SLAVE CYLlNDER

Dismantle

1

.

Remove the slave cylinder

from

the vehicle.

3.

Expel the piston assembly, applying low

4.

Withdraw

the

spring.

2.

Withdraw the dust cover.

I

pressure air to the fluid inlet.

5. Prise

off the seal from the piston.

I

23.

Smear the piston with rubber grease and

insert the assembly, valve end first, into the

cylinder.

24.

Fit the push-rod, retaining washer and circlip.

Inspection

6.

Clean all components with cleaning fluid and

allow

to

dry.

7.

Examine the cylinder bore and piston, ensure

that they are smooth to the touch with no

corrosion, score marks or ridges.

If

there

is

any doubt, fit new replacement.

8.

The seal should be replaced with a new

I

component.

Assemble

9.

Smear the seal with rubber grease and the

remaining internal items with brake and clutch

fluid.

10.

Fit the seal, large diameter last,

to

the piston.

11.

Locate the conical spring, small diameter first,

over the front end of the piston.

12.

Smear the piston with rubber grease and

I

insert the assembly, spring end first, into the

cylinder.

13.

Fill the dust cover with rubber grease and

fit

the cover

to

the cylinder.

CLUTCH

CLUTCH PEDAL AND

MASTER CYLINDER

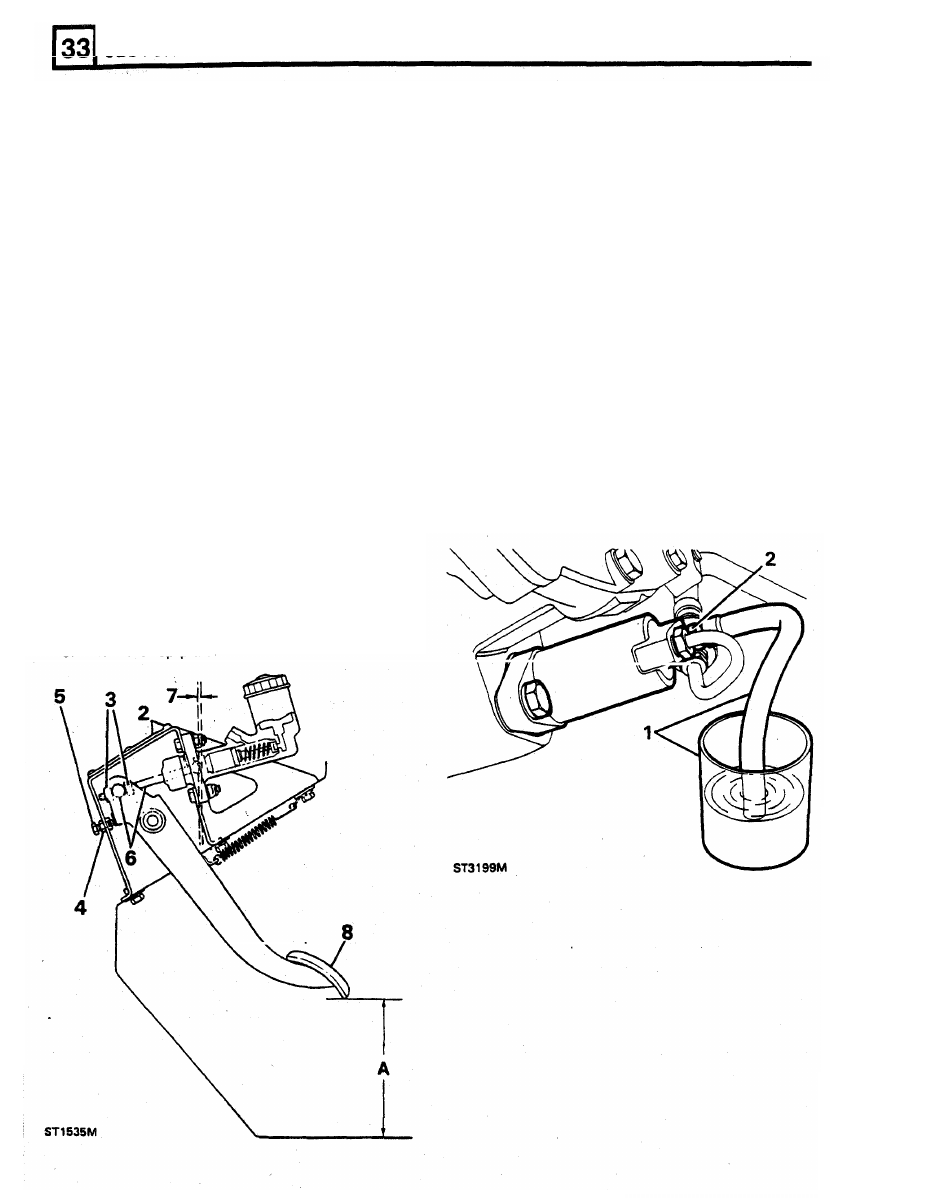

BLEED CLUTCH HYDRAULIC SYSTEM

ADJUSTMENT

When the gearbox and bell housing assembly has

been fitted

to

the vehicle the hydraulic clutch release

system must be bled

to

expel air,

NOTE: During the following procedure, keep the

fluid reservoir topped-up to avoid introducing air

Adjust

into the system. Use only the fluid recommended

in the Lubrication chart. Use only new fluid from

2.

Withdraw the six screws and remove the top

a sealed container.

plate.

3.

Slacken master cylinder push-rod locknuts to

1.

Attach a length of suitable tubing

to

the slave

provide free movement

of

the push-rod

cylinder bleed screw and immerse

the

free

through the pedal trunnion.

end of the tube in a glass jar containing new

4.

Slacken the adjustment screw locknut.

clutch fluid.

5.

To increase the pedal height, turn the

2. Slacken the bleed screw and depress the

adjustment screw anti-clockwise. To reduce

clutch pedal, pausing at the end

of each

turn clockwise.

stroke, until the fluid issuing from the tubing is

When correct tighten the locknut.

free of air with the tube free end below the

6.

To adjust the master cylinder push-rod, check

surface

of

the fluid in the container. Whilst

that the push-rod has free-play through the

holding the clutch pedal down and with the

trunnion.

free end of the tube below the fluid, tighten

7.

Adjust

the

locknuts

until the push-rod has

1,5

the bleed screw.

mm free-play between the push-rod and

master cylinder. When correct tighten the

locknuts.

8.

Check that there

is

6

mm free movement of

the pedal at the pad.

If

necessary re-adjust

the push-rod.

9. Refit the top plate.

1.

The correct height for the clutch pedal from

the floor of the footwell, without a mat,

to

the

lower edge of the pedal is

140

mm, dimension

A'.

CLUTCH

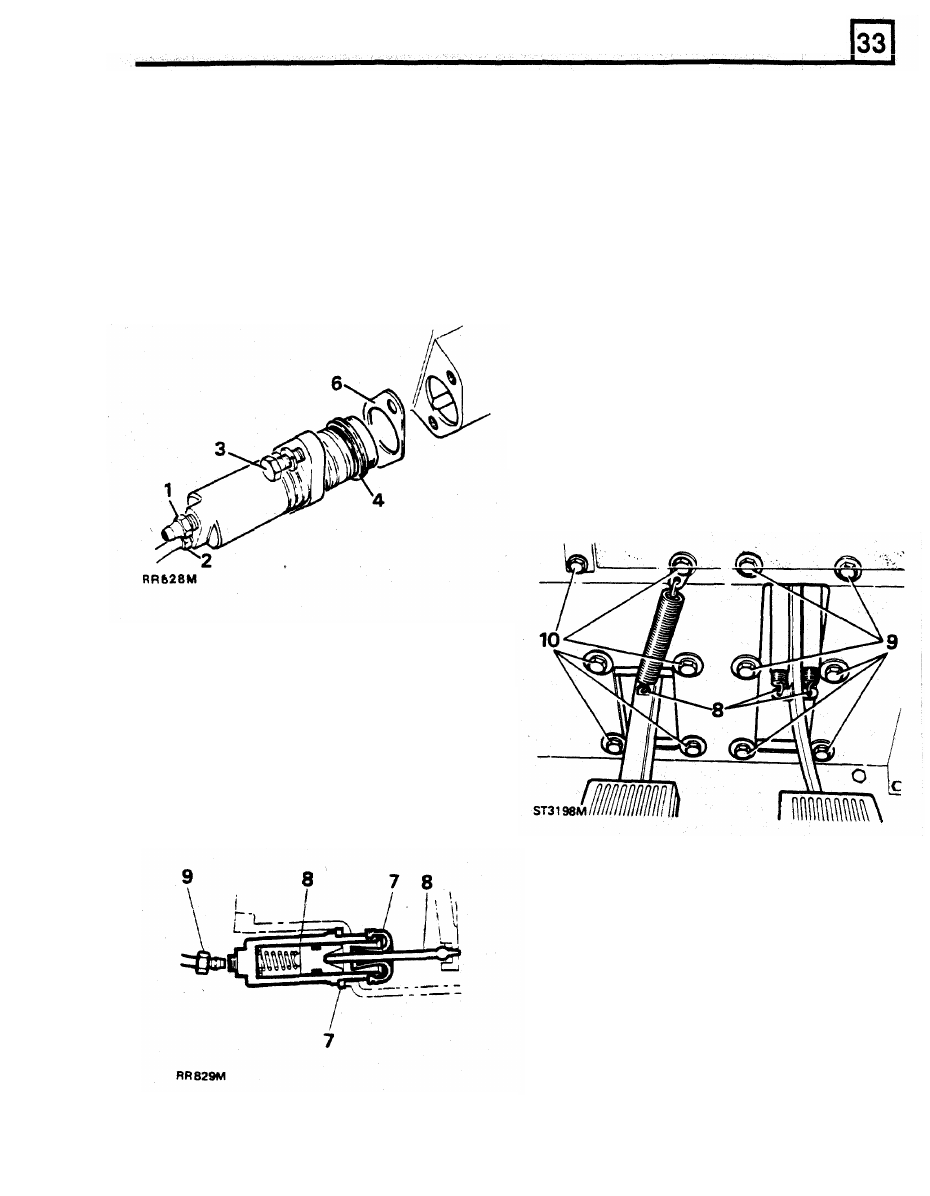

RENEW CLUTCH SLAVE CYLINDER

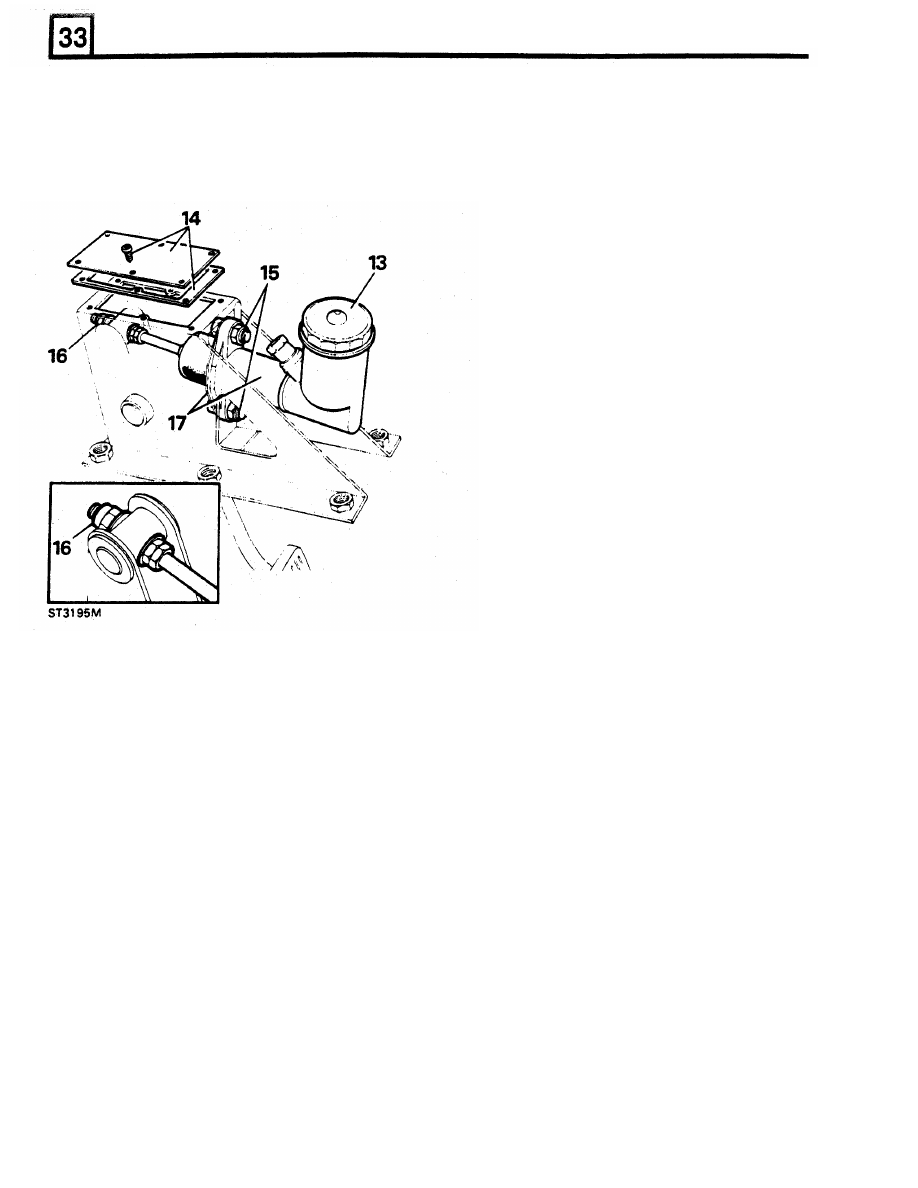

RENEW CLUTCH MASTER CYLINDER

Left hand drive vehicles

To Remove

1.

Evacuate clutch system fluid at slave cylinder

2. Remove the bonnet.

2. Disconnect fluid pipe.

cylinder

to

the the servo.

3. Remove

two

securing bolts and withdraw

4.

Carefully ease the master cylinder away from

the servo without imposing any strain upon

the brake fluid pipes.

4.

If

dust cover is not withdrawn with slave

5. Disconnect the vacuum hose from the servo

and move aside.

6.

Disconnect

the two

brake lamp lucars.

7.

From inside the vehicle, remove the fibre

board closing panel above the pedals.

8.

Release the two return springs from the brake

pedal and single spring from the clutch pedal.

9.

Remove the six bolts securing the brake pedal

box to the bulkhead and carefully withdraw

the pedal box with the servo sufficiently to

allow clearance for the clutch master cylinder

and pedal box

to

be withdrawn.

10.

Remove the

SIX

bolts securing the clutch

pedal box

to

the bulkhead.

bleed valve.

3.

Remove the

two

nuts securing the master

slave cylinder and backing plate.

cylinder, withdraw it from bell housing.

To Refit

5.

Withdraw dust cover and backing plate from

slave cylinder.

6. Coat both sides of backing plate with Hylomar

P232M waterproof jointing compound.

7.

Locate backing plate and dust cover in

position on slave cylinder.

8.

Fit slave cylinder, engaging push rod through

centre of dust cover and with bleed screw

uppermost.

9.

Reconnect fluid pipe.

11.

Release the hydraulic pipe from the dutch

master cylinder and cover the end.

12. Remove the clutch pedal and master cylinder

assembly from the vehicle.

13. Remove the reservoir cap and discard the

fluid.

14. Remove the six screws and lift-off the pedal

box top cover and gasket.

15. Remove the two nuts and bolts that secure.

the master cylinder to the pedal box:

16. Remove the nut and washer from the end of

the master cylinder push rod.

17. Withdraw the master cylinder and steel

gasket.

18. Fit the two locknuts and plain washer to the

10. Replenish and bleed clutch system.

11. Check for fluid leaks with pedal depressed

push-rod.

and also with system at rest.

1. Disconnect the battery.

CLUTCH

Refitting

19.

Fit

the master cylinder and steel gasket

to

the

pedal box and insert the push-rod through the

bush and trunnion and loosely fit

the

single

nut

to

the end of the push-rod.

20.

Secure the master cylinder with the two nuts

and bolts to the pedal box.

21. Fit the pedal box to the bulkhead resealing

with Bostic adhesive and secure with the six

bolts.

22. Check the clutch pedal height and free-play,

adjust if necessary. Tighten the push-rod end

nut. Connect the return spring to the pedal.

23. Fit the pedal box top cover with a new gasket

and secure with the six screws.

24. Connect the fluid pipe to the master cylinder.

25. Fit the brake servo and pedal box assembly,

reseal with Bostic adhesive and secure with

the six bolts.

26.

Connect the return springs to the pedal.

27.

Fit the brake master cylinder to the servo and

tighten the two nuts,

28. Fit the fibre board closing panel.

29. Connect the stop lamp lucars.

30. Attach the three way pipe union bracket to the

servo ('90' models).

31. Connect the vacuum hose to the servo.

32. Fill the clutch master cylinder with new fluid

from

a

sealed

container

of

the

recommmended grade to the level mark on

the side of the reservoir.

33. Bleed the clutch hydraulic system and fit the

reservoir cap.

34. Connect the battery, fit the bonnet and road

test the vehicle.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст