Defender (1993+). Manual — part 13

CLEAN PLENUM CHAMBER VENTILATION

7 . Any remaining consolidated matter can

be

PASSAGEWAY

dislodged using a piece of soft bent

wire

or

a

pipe cleaner. Finally the passageway must

The cleaning of the plenum chamber ventilation

again be blown out to remove any remaining

passageway can be carried out without removing the

debris.

plenum chamber from the ram housing.

8.

Remove the small

'T'

piece between the

crankcase ventilation hoses and check that

it

CAUTION:

Care must be taken to prevent debris

is free from blockages, clean as necessary

from the passageway passing beyond the throttle

9.

Refit the ‘T’ piece and hoses, tighten the hose

valve disc.

clamps securely.

WARNING:

Safety glasses must

be

worn when

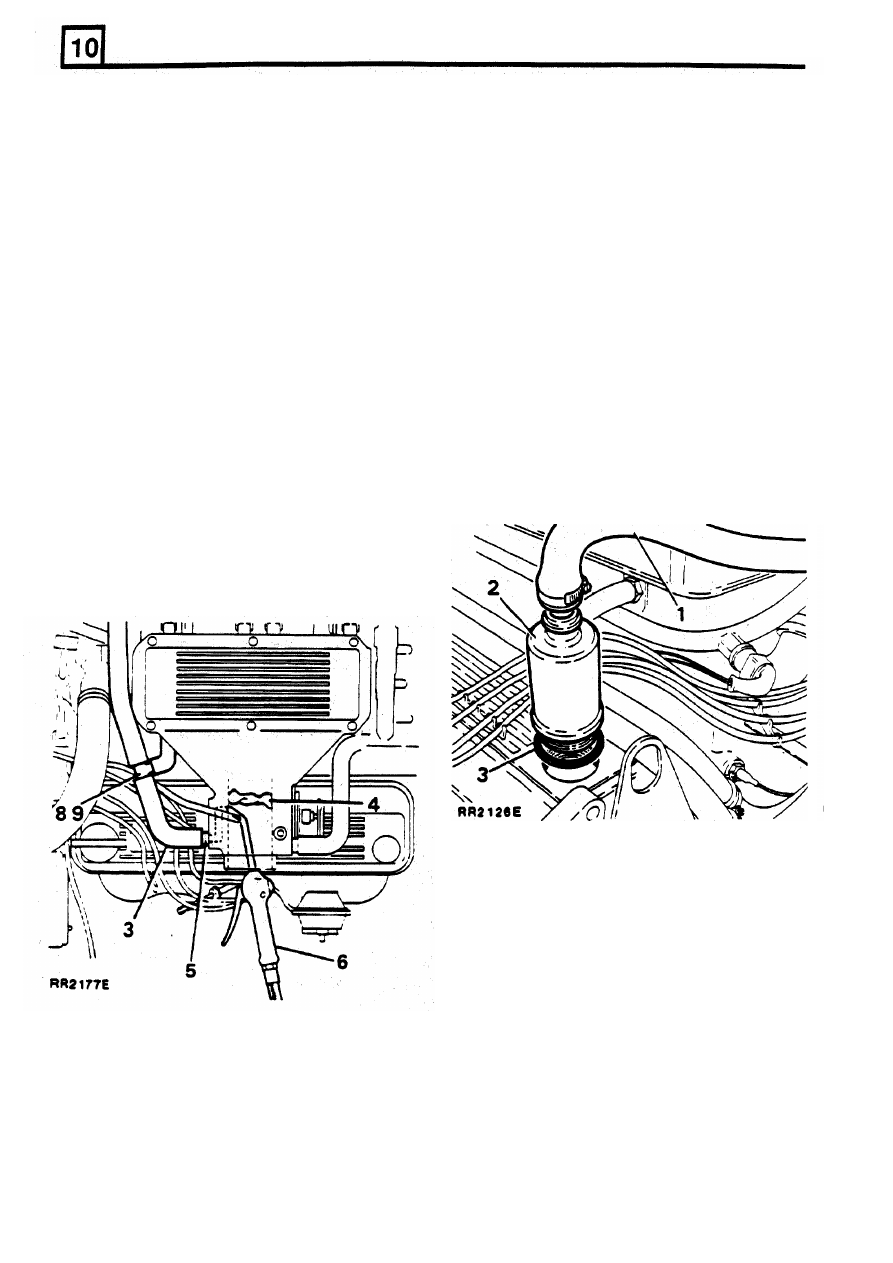

CLEAN POSITIVE CRANKCASE VENTILATION

performing this operation. Ensure that debris

is

not blown into the atmosphere which could be

harmful to other personnel within the vicinity.

1.

Release the hose clamp and pull the hose off

the canister.

1.

Disconnect the battery negative terminal.

2.

Unscrew the canister and remove if from the

2.

Release the hose clamp and remove the hose

rocker cover.

from the plenum chamber inlet neck.

3.

Remove the large

'O'

ring from the threaded

3.

Remove the crankcase ventilation hose from

end

of

the canister.

the side of the plenum chamber.

4.

Visually

inspect

the condition

of

the wire

4.

Insert a piece of lint free cloth down the

screen within the canister, if

in

poor condition

throttle valve bore to prevent debris passing

fit a new assembly, if in an acceptable

beyond the throttle valve.

5.

Place a cloth over the tube protruding from

the side

of

the plenum from which the

ventilation hose was removed to prevent

debris from the passageway being blown into

the atmosphere.

BREATHER FILTER

condition clean the screen as follows:

5.

Immerse the canister in

a

small amount

of

solvent and allow

time

tor the solvent

10

dissolve and loosen

any

engine fume debris

within the canister.

6.

Remove canister from solvent bath and allow

to dry out in still air.

WARNING:

Do not use a compressed air line to

remove any remaining solvent or particles of

debris within the canister as this could cause fire

or personal injury.

Refitting the breather/filter

6.

Use a compressed air

line

with a slim bent

nozzle to enable the passageway to be

cleaned out from

within

the throttle valve bore.

7

8.

Screw the canister into the rocker cover hand

9.

Refit hose and tighten hose clamp securely

Fit a new rubber

'0'

ring.

tight only.

I

18

RE-ISSUED: FEB 1993

MAINTENANCE

RR2171E

MAINTENANCE

RR1876E

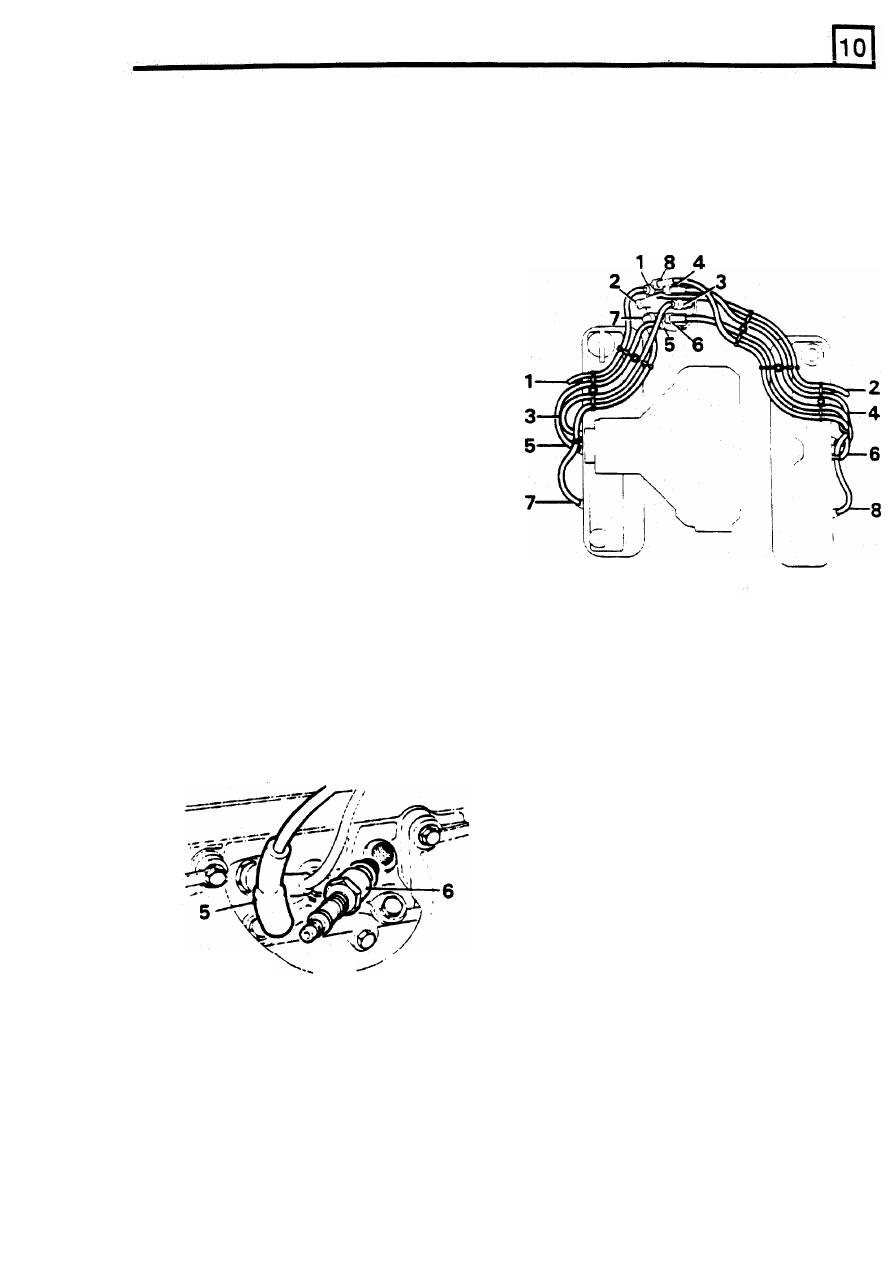

GENERAL MAINTENANCE AND ADJUSTMENTS

CHECK/ADJUST OPERATION

OF

ALL WASHERS

9.

Ensure that replacement H.T. leads are

AND TOP-UP RESERVOIR

refitted in their spacing cleats in accordance

with the correct layout illustrated.

Failure

to

observe this instruction may result

in cross-firing between two closely fitted leads

which are consecutive in the firing order.

Fitting H.T.

leads

1.

Check the operation of windscreen, tailgate

and headlamp washers.

2.

Adjust jets

if

necessary by inserting a needle

or

very fine sharp implement into the jet orifice

and maneuvering

to

alter the jet direction.

3.

Unclip the reservoir cap.

4.

Top up reservoir to within 25mm

(1

in) below

the bottom of the filler neck.

Use a screen washer soIvent/anti-freeze in the

reservoir, this will assist in removing mud,

flies and road film and protect against

freezing.

IGNITION

Spark plugs

1.

Take great care when fitting spark plugs not

to cross-thread the plug, otherwise costly

damage to the cylinder head will result.

2. Check or replace the spark plugs as

applicable.

3.

It is important that only the correct type

of

spark plugs are used

for

replacements.

4.

Incorrect grades

of

plugs may lead

to

piston

overheating and engine failure.

To remove spark plugs proceed as

follows:

5.

Disconnect the battery negative lead and

remove the leads

from

the

spark plugs.

6. Remove the' plugs

and

washers.

7.

Set

the electrode gap to the recommended

clearance.

8.

When pushing the leads onto the plugs,

ensure that the shrouds are firmly seated on

the plugs.

RE-ISSUED:

FEB

1993

19

MAINTENANCE

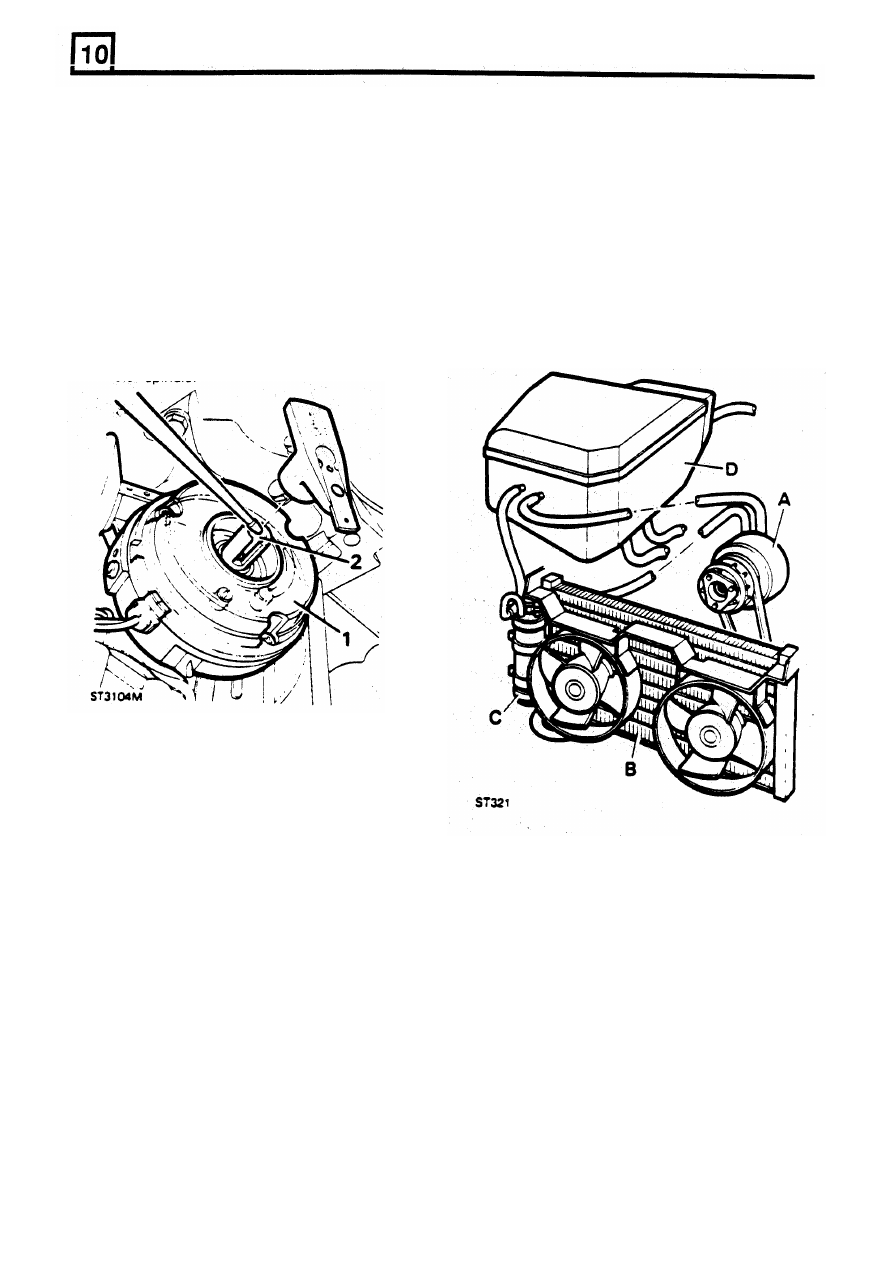

CLEAN AND LUBRICATE V8 ENGINE

AIR CONDITIONING SYSTEM DEFENDER 110

ELECTRONIC DISTRIBUTOR every 40,000 km

(24,000 miles)

The air conditioning system operates in conjunction

with

the vehicle heater

to

provide dried cooled

WARNING:

The electronic

ignition

System

recirculated or fresh air to the vehicle interior

involves very high voltages.

Inexperienced

The system consists

of

the following units which

personnel and wearers of medical pacemaker

should be examined at the same mileage intervals

devices should not be allowed near any part

of

as the heater system:

the high tension circuit.

1.

Remove the distributor cap and rotor arm and

wipe inside with a nap-free cloth.

Do

not

disturb the clear plastic insulating cover which

protects

the magnetic pick-up module.

2.

Apply three drops

of

clean engine oil to the

rotor spindle

A.

Engine mounted compressor.

B. Condenser in front of the radiator.

C.

A

receiver/drier in front

of

and to the right of

the condenser.

D.

Evaporator/heater unit in engine compartment

3.

Fit the rotor arm and distributor cap and

ensure that the

cap

is property located and

secured with the

two

clips.

1.

Compressor: Check the pipe connections tor

leakage and the hoses tor swelling Check

that the drive belt is correctly tensioned

2. Condenser: Using an air line. or a water

hose, dean the exterior of the condenser

matrix. Check the pipe Connections for signs

of leakage.

20

REVISED

OCT

1993

ST3150M

MAINTENANCE

3.

Receiver/drier: Check the pipe connections

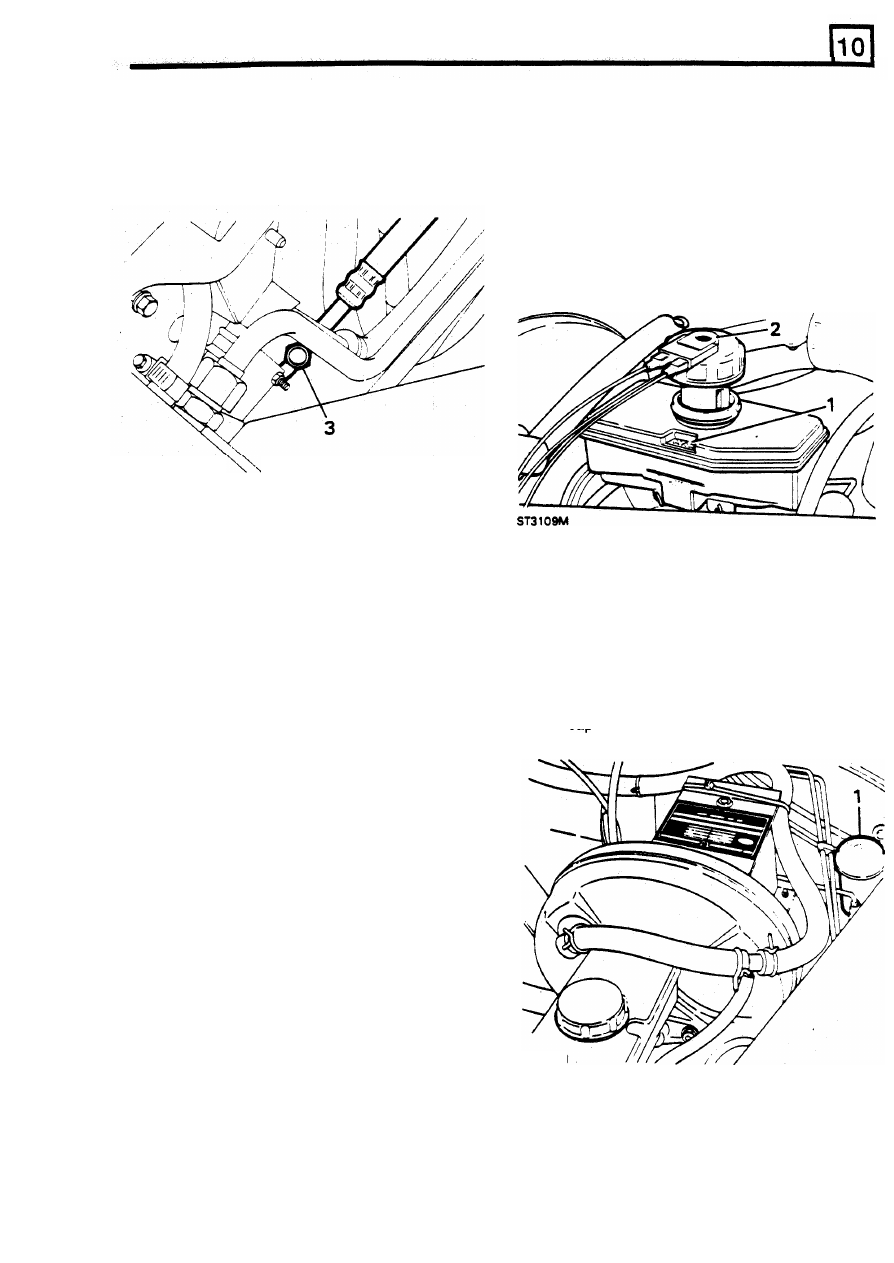

CHECK BRAKE FLUID RESERVOIR

for signs of leakage. Examine the sight glass

while the system is operating and

if

bubbles

are present

it

indicates that the system is

contaminated

with

air or water and

will

require

purging.

reservoir.

1.

Check the fluid level in the fluid reservoir

by

observing the level in relation

to

the 'MIN’

or

'MAX'

marks on the side of the translucent

2. If

the level is below the 'MAX' mark clean the

outside of the filler cap and top-up with new.

clean fluid from a sealed container.

Use

only

fluid recommended in

'SECTION 09'.

Refit the

cap.

4.

Evaporator: Examine the pipe connections for

leaks.

WARNING:

The air conditioning system

is

filled

at high pressure with a potentially toxic material.

If any repair or servicing work

is

necessary

following the above inspections, it

must

only

be

carried

out

by a qualified air conditioning

on the side

of

the

reservoir.

engineer who must wear protective goggles and

follow the WARNINGS and CAUTIONS given

in

SECTION 82.

CHECK

C

L

U

TCH

F

LU

I

D RESERVOIR

1.

Clean and remove the reservoir cap and

observe the fluid level in relation to the marks

2.

Top-up if necessary with new, clean fluid

from

a sealed container and

of

a recommended

specification -

see

'SECTION 09'.

Refit

the

cap.

21

RE-ISSUED:

FEB

1993

21

ST3141M

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст