Defender (1993+). Manual — part 10

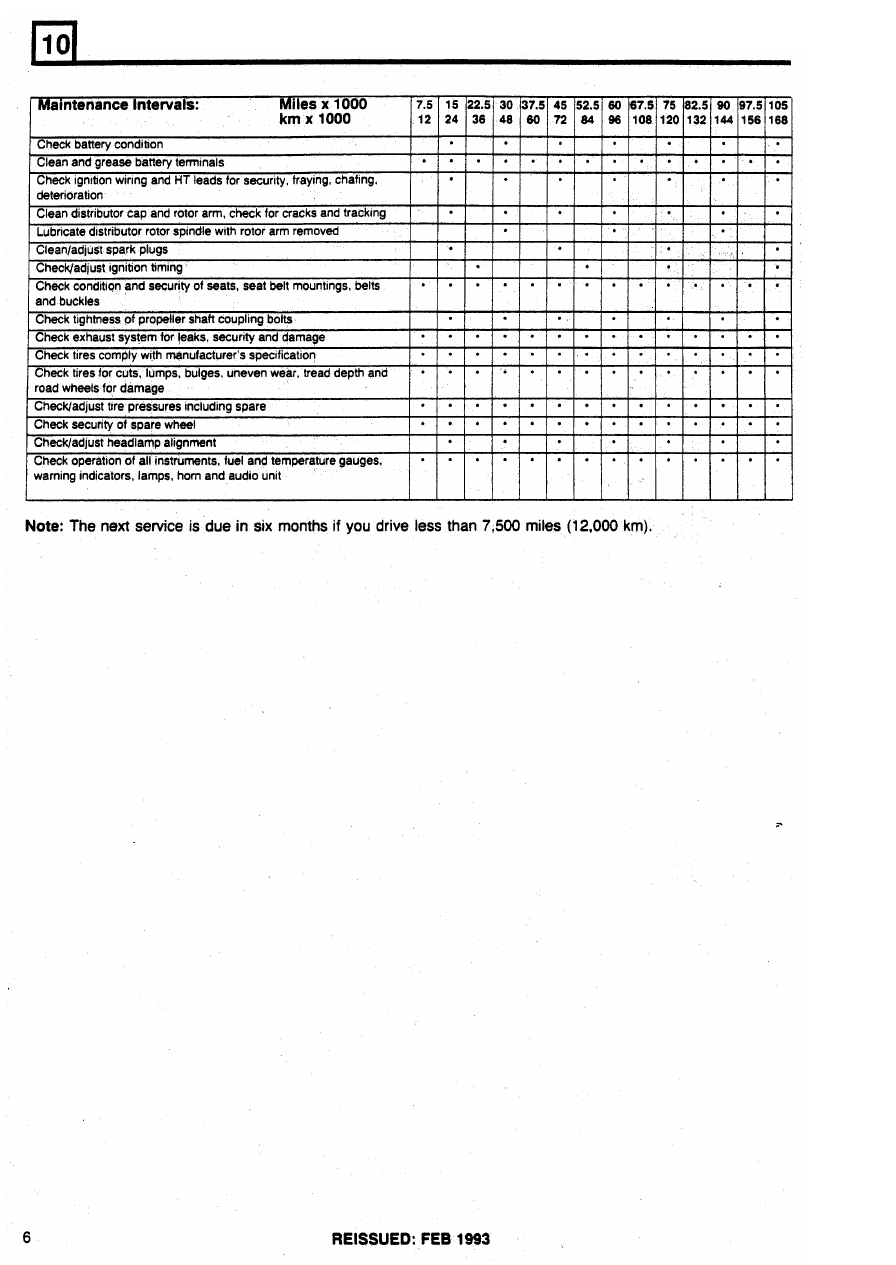

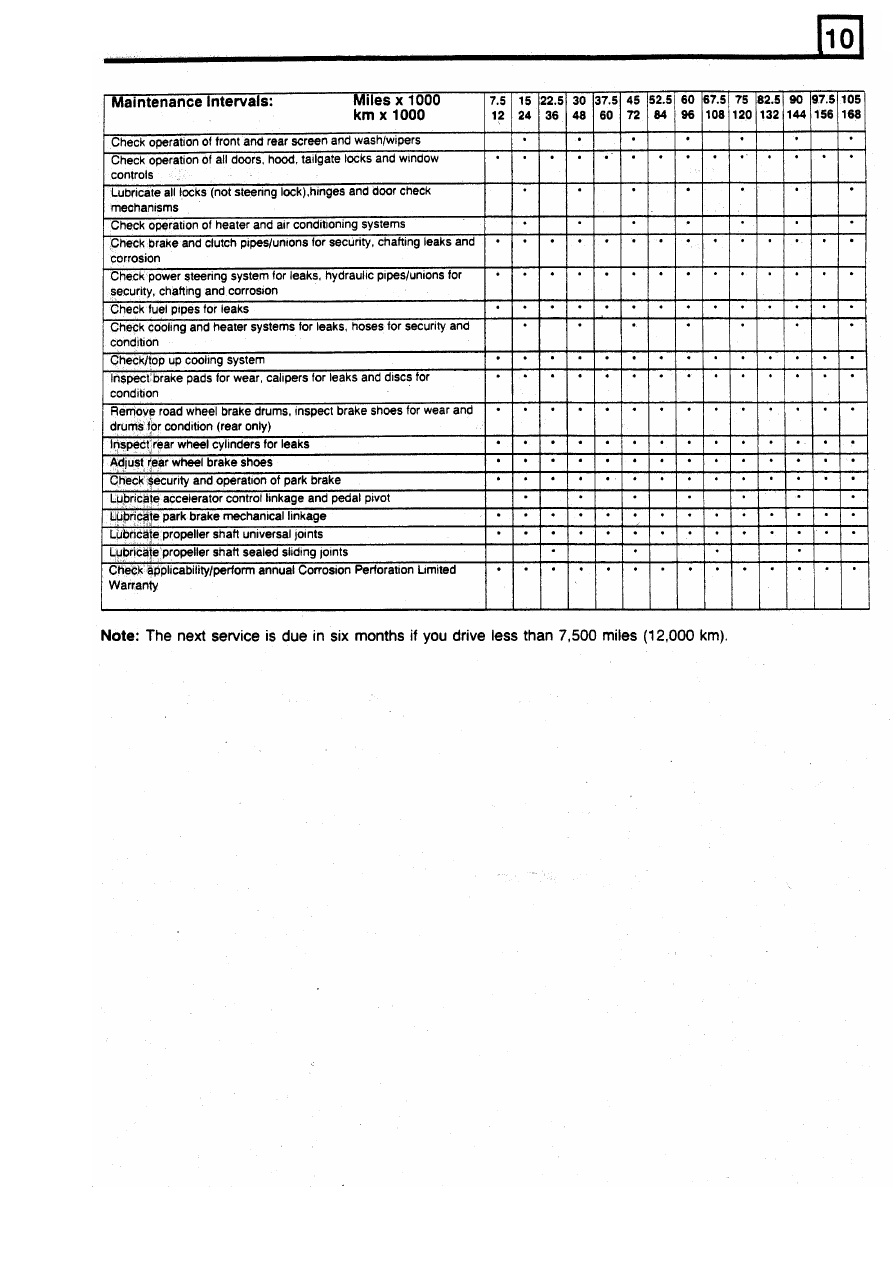

MAINTENANCE

MAINTENANCE

REISSUED: FEB

1993

7

MAINTENANCE

It is recommended that:

At

15,000 mile (24,000 km) intervals or every 18 months, whichever is the sooner, the hydraulic brake and

clutch fluid should be completely renewed.

At

37,500 mile (60,000 km) intervals or every 3 years, which ever is the sooner, all hydraulic brake and fluid,

seals and flexible hoses should be renewed, all working surfaces of the master cylinder, wheel cylinders and

caliper cylinders should be examined and renewed where necessary.

At

37,500 mile (60,000 km) intervals remove all suspension dampers, test for correct operation, refit or renew

as necessary.

At

two

year intervals or at the onset of the second winter, the cooling system should be drained, flushed and

refilled with the required water and anti-freeze solution.

The battery electrolyte level should be checked and topped up if required

once a year in tropical and sub-tropical climates

once every three years in temperate climates.

NOTE: Climatic and operating conditions affect maintenance intervals to

a

large extent: in many cases,

therefore, the determination of such intervals must be left to the good judgement of the owner or to

advice from an Authorised Dealer but the recommendations

will serve as a firm basis for maintenance

work.

Vehicles operating under arduous conditions will require more frequent servicing, therefore, at a minimum, the

Maintenance intervals should be reduced by half.

For low mileage vehicles it is recommended that the maintenance is carried out at

6

months intervals.

The owner need not perform recommended maintenance

in

order

to

maintain the emission warranty or

manufacturer recall liability.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous conditions

or

on dusty, wet or muddy terrain, more frequent

attention should

be

paid to all servicing requirements.

ADDITIONAL DAILY O R WEEKLY ATTENTION DEPENDING ON OPERATING CONDITIONS:

Check/top-up transfer box

oil.

Check steering rubber boots for security and condition. Renew

if

damaged.

Check brake fluid level: consult your Dealer if any fluid loss

is

suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft grease points and front sliding joint. Under tropical or severe conditions,

particularly where sand

is

encountered, the sliding joints must

be

lubricated very frequently

to

prevent ingress

of abrasive material.

Every week and every maintenance inspection check tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre pressures should

be

checked much more frequently, even to

the extent of a daily check.

MONTHLY

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months or as necessary.

8

REISSUED: FEB 1993

MAINTENANCE

LUBRlCATlON

5.

Clean the outside of the oil filler cap, remove

it

from the rocker cover and clean the inside.

This first part of the maintenance section covers

6.

Pour in the correct quantity of new oil of the

renewal of lubricating oils for the major units of the

correct grade from a sealed container to the

vehicle

and

other

components

that

require

high mark on the dipstick and firmly replace

lubrication, as detailed in the 'MAINTENANCE

the filler cap. Reconnect the battery.

SCHEDULES'

.

Refer to 'SECTION 09' for

capacities and recommended lubricants.

Vehicles operating under severe conditions of dust,

sand, mud and water should have the oils changed

CAUTION: The engine oil filter must not be

and lubrication carried out at more frequent intervals

removed whilst the sump is empty, otherwise the

than that recommended in the maintenance

oil pump may have to be primed.

schedules.

Draining of used oil should take place after a run

1.

Place an oil tray under the engine.

when the oil is warm. Always clean the drain and

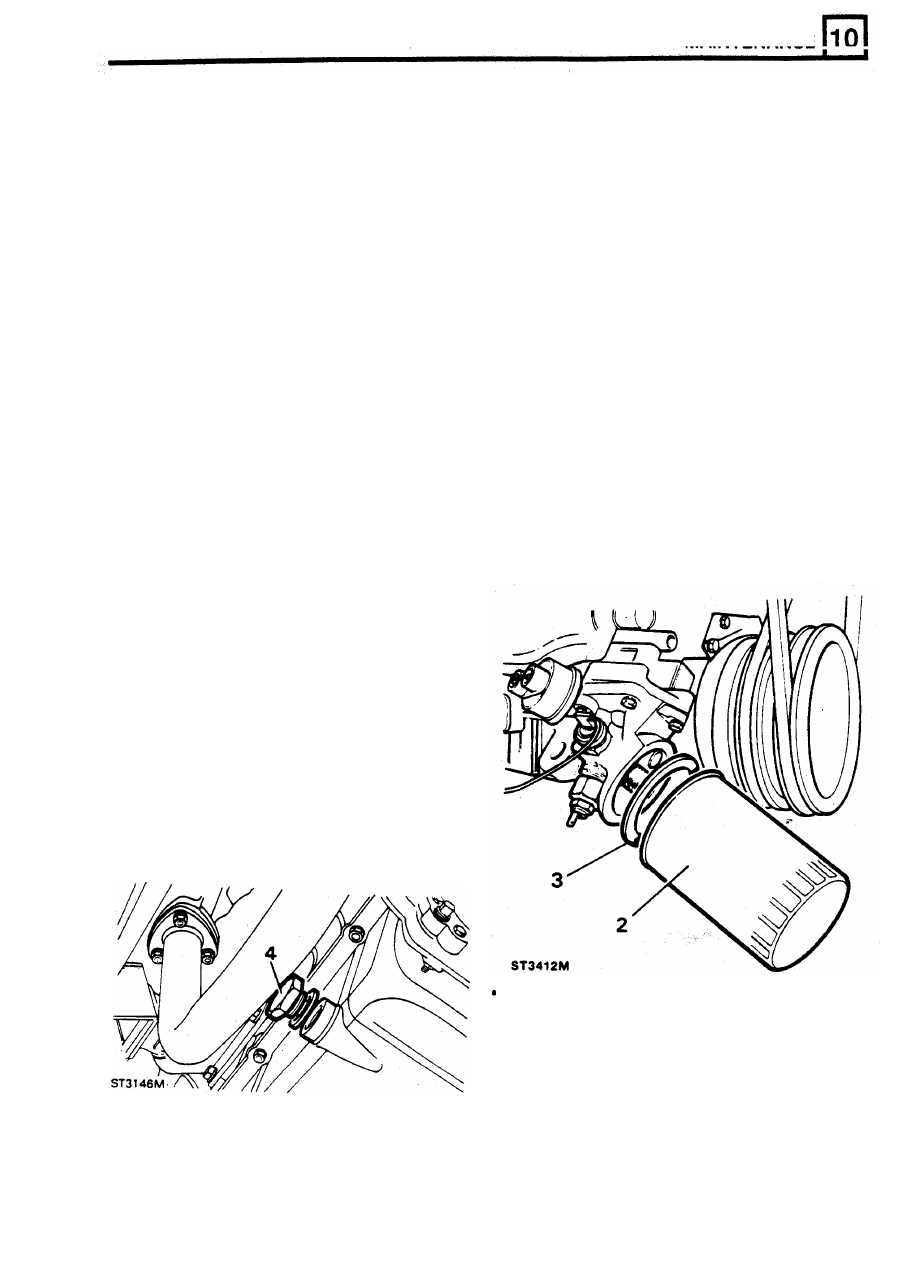

2.

Unscrew the filter anti-clockwise, using a strap

filler-level plugs before removing. In the interests of

spanner as necessary.

safety disconnect the vehicle battery

to

prevent the

3.

Smear a little clean engine oil on the rubber

engine being started and the vehicle moved

washer of the new filter, and half fill with fresh

inadvertently, while oil changing is taking place.

oil. Then screw the filter on clockwise until the

Allow as much time as possible for the oil to drain

rubber sealing ring touches the machined

completely except where blown sand

or

dirt can

face, then tighten a further half turn by hand

enter the drain holes.

In

these conditions clean and

only. Do not overtighten.

refit the drain plugs immediately the main bulk of oil

4.

Run the engine and check for leaks from the

has drained.

filter. Stop the engine, allow the oil

to

run

Where possible, always refill with oil of the make

back into the sump for a few minutes, then

and specification recommended in the lubrication

check the oil level again and top up if

charts and from sealed containers.

necessary.

WARNING: See ENGINE OILS under POISONOUS

RENEW OIL FILTER

SUBSTANCES - SECTION 01. INTRODUCTION.

RENEW ENGINE OIL

Drain and refill engine

1.

Drive vehicle to level ground.

2.

Run the engine to warm the oil; switch

off

the

ignition and disconnect the battery for safety.

3.

Place an oil tray under the drain plug.

4.

Remove the drain plug in the bottom

of

the

sump. Allow oil

to

drain away completely and

replace the plug and tighten to the correct

torque.

REISSUED: FEB 1993

9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст