Defender (1993+). Manual — part 61

REAR

AXLE AND FINAL DRIVE

REAR AXLE AND FINAL DRIVE

CAUTION:

To prevent permanent damage to the

gear carrier case,

it

must not

be

over-stretched.

Each flat on the turnbuckle

is numbered to

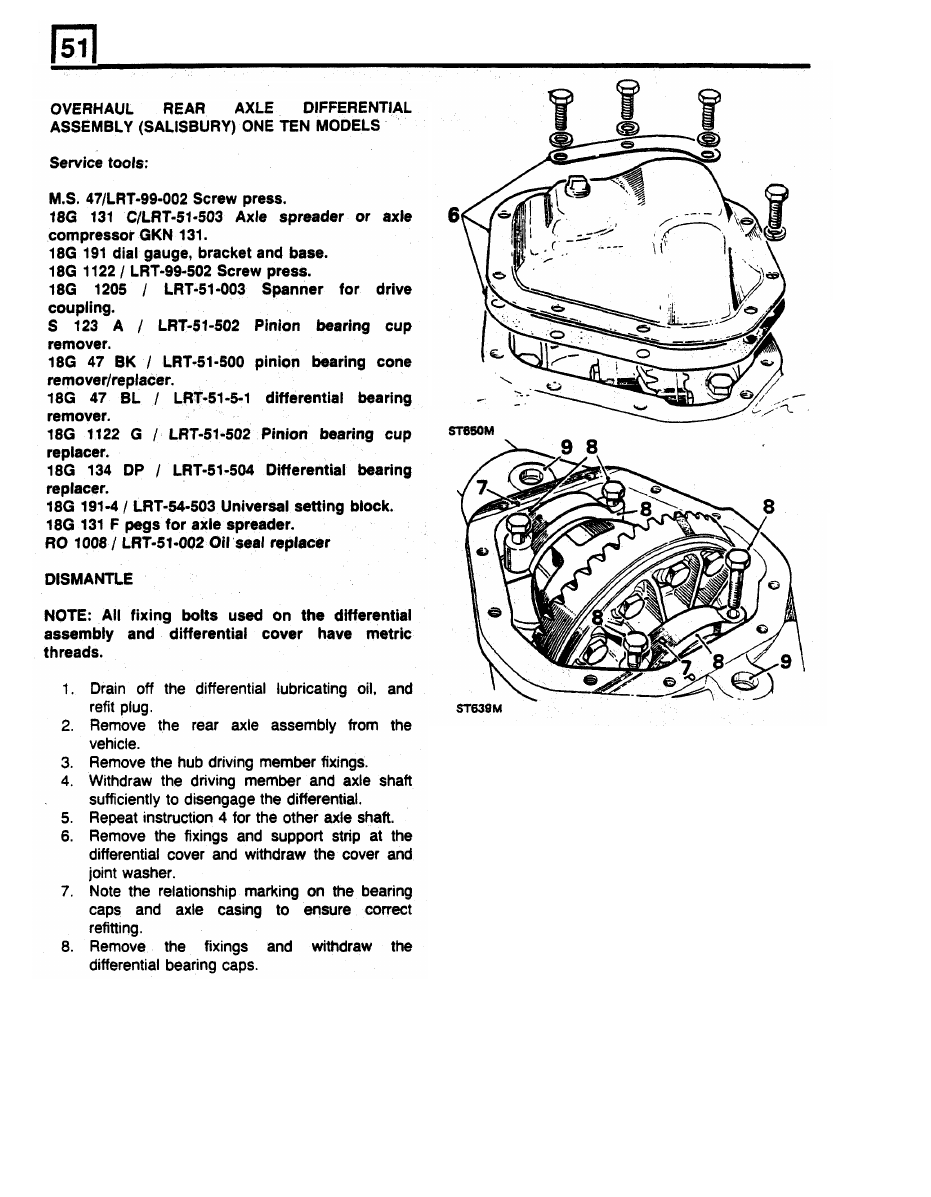

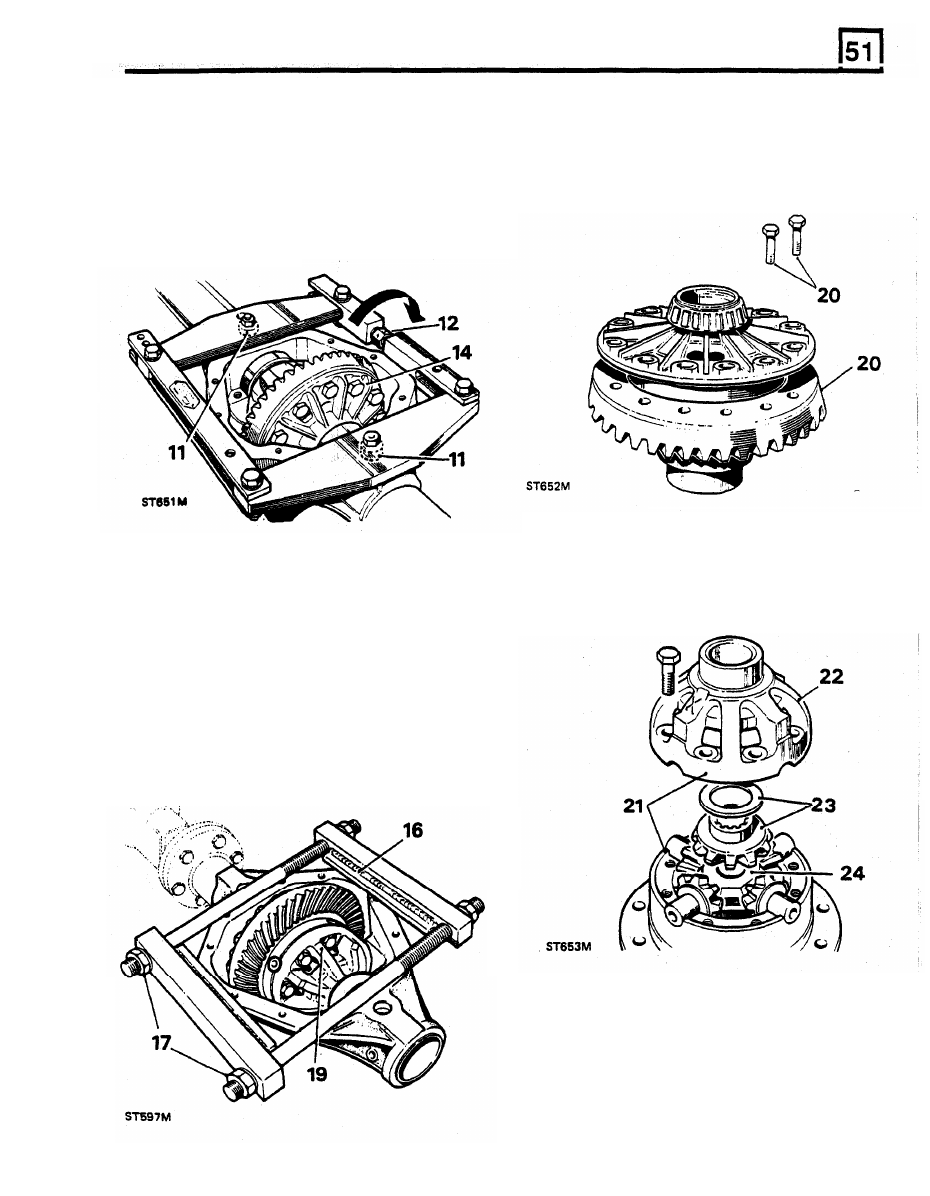

20. Add alignment marks between the crown

enable

a check to be made on the amount

wheel and the differential case for reassembly

turned. The maximum stretch permitted

is 0,30

purposes, then remove the fixings and

mm, equivalent to three flats.

Dismantle differential

withdraw the crown wheel.

15.

Ease off the adjuster and remove the

spreader.

21.

Note the alignment markings on the two

differential casings

to

ensure correct refitting,

then remove the fixings.

22.

Lift

off the upper case.

16.

Place the tool on to the differential casing, as

23. Withdraw the upper differential wheel and

thrust washer.

illustrated,

with

the weld seam uppermost.

Ensure that the plates rest squarely on the

differential machined surface and the end bars

butt against the edges of the casing.

17.

Tighten the adjusting nuts by hand only, until

all slack is taken up.

18.

Continue to tighten both nuts alternately with a

spanner, one flat at a time, to a maximum of

three flats.

19.

Carefully lever-out the differential assembly.

Using axle compressor GKN 131

24. Lift out the cross-shaft and pinions.

25. Withdraw the four dished thrust washers.

26. Withdraw the lower differential wheel and

thrust washer.

REAR

AXLE AND FINAL DRIVE

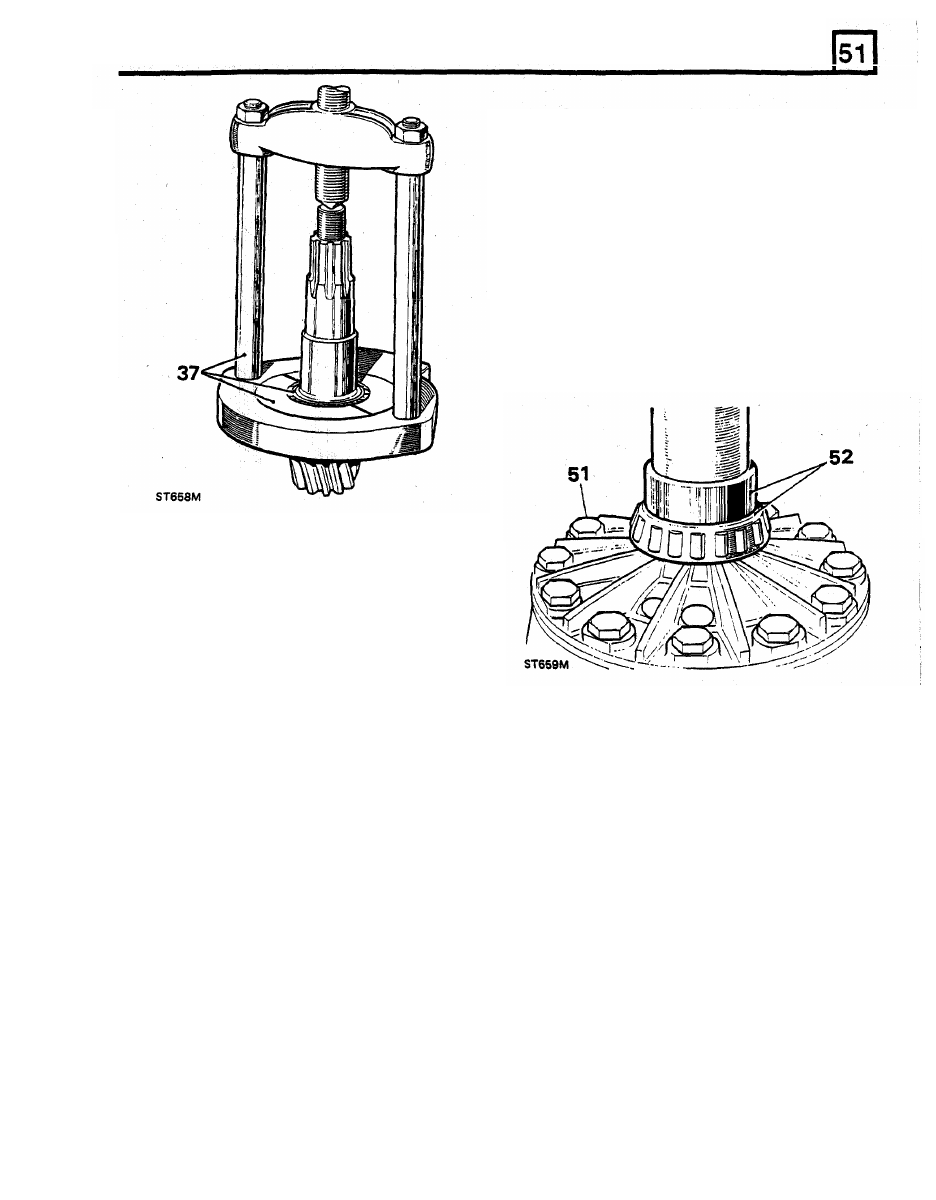

34. Withdraw the outer bearing cone.

27. Remove the differential bearing cones using

35. Extract the pinion inner bearing cup and shim

remover 18G 47 BL and adaptors 1 and 2 and

washers from the casing. Note the shim

press M.S. 47.

washer thickness using remover S 123 A.

28. Withdraw the shim washers fitted between the

36. Extract the pinion outer bearing cup from the

bearing cones and the differential casings.

casing using remover S 123 A.

37. Remove the inner bearing cone from the

pinion, using remover 18G 47 BK and press

M.S. 47.

Remove final drive pinion

29. Prevent the coupling flange from rotating and

remove the flange

locknut and plain washer

using tool 18G 1205.

30. Support the drive pinion and remove the

coupling flange by tapping with a hide

hammer.

31. Withdraw the drive pinion together with

the

inner bearing cone.

32. Withdraw and discard the collapsible bearing

spacer.

33.

Withdraw the oil seal, gasket and oil thrower.

R E A R

AXLE

AND

FINAL

DRIVE

50.

Secure the assembly with bolts using Loctite

'Studlock' grade CVX on the threads and

tighten evenly and diametrically to

89

to 101

Nm.

51.

Fit the crown wheel to the differential casing.

Use Loctite 'Studlock' grade

CVX on the fixing

bolt threads and tighten to

the correct torque.

52. Press on the differential roller bearing cones

less him washers, using 18G 134

DP, and

leave to one side until required for instruction

53. Fit the

bearing cups

to

the differential.

54. Fit the differential unit and bearings to the

gear

carrier casing,

and

rotate

unit

to

centralize the bearings. Do not

fit

the bearing

caps.

INSPECTION

38. Examine all components for obvious wear or

damage.

39. The bearing cones must be a press fit on their

locations, except the drive pinion flange and

bearing which is a slide fit.

40. The crown wheel and pinion are supplied as a

matched pair and must not be interchanged

A new crown wheel and pinion matched pair

may be fitted to an original gear carrier casing

if sound. The original crown wheel and pinion,

if sound, may be fitted into a replacement

casing.

41. The two parts of the differential unit casing

are matched and must not be replaced

separately.

42. Discard and renew all thrust washers.

43. Differential housings with worn thrust washer

seatings must be replaced as a pair.

44. Examine the differential case to crown wheel

joint face for burrs and damage which could

lead to crown wheel run-out when fitted.

separately.

55.

Position a suitable dial gauge indicator on the

casing with the stylus registering on the back

face of the crown wheel.

56.

Rotate the differential and check the total

indicated run-out on the crown wheel back

face. This must not exceed 0,05 mm. If

run-out is excessive, check the mating faces

for dirt and damage: if necessary, select a

new radial position for the crown wheel. When

satisfactory, continue with the following check.

Differential bearing adjustment

57.

Insert

two

levers between the casing and the

differential unit at one side.

ASSEMBLE

58.

Move the differential unit fully

to one side of

the casing; do not

tilt

the unit.

Assemble differential unit

59. Rotate the differential unit to settle the

bearings, continue to lever the differential to

the side, then zero the dial gauge indicator.

60. Lever the assembly

fully to

the other side

of

the casing, rotate the unit

to

settle the

45. Fit the differential lower wheel and thrust

washer to the differential case. See illustration

following instruction 23.

46.

Fit the dished thrust washers.

bearings, then note the

total

indicator reading.

47.

Fit the cross-shaft and pinions.

48.

Fit the differential upper wheel and thrust

washer.

49.

Fit the differential upper case lining-up the

96.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст