Defender (1993+). Manual — part 62

REAR AXLE AND FINAL DRIVE

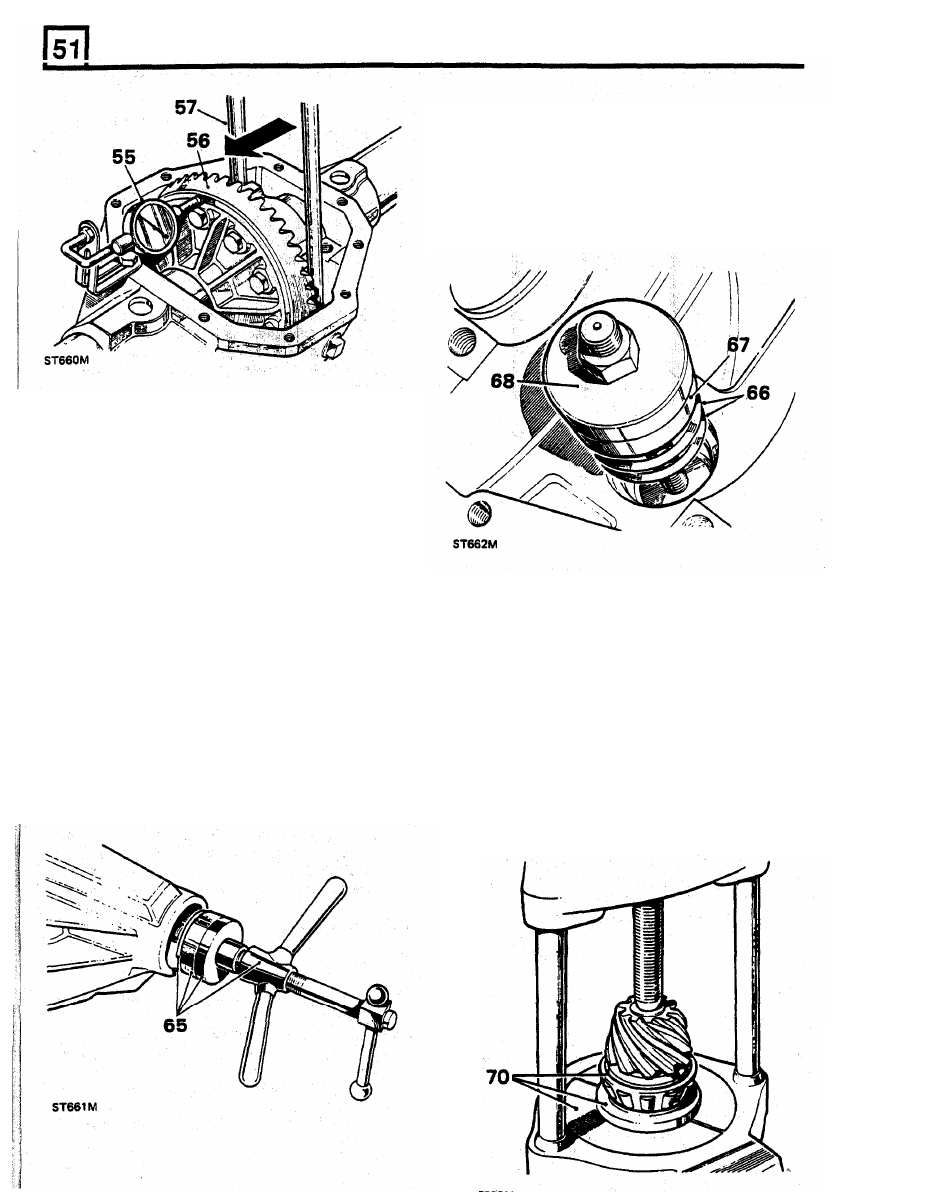

66. Place the selected shim washers on

to

the

inner bearing cup seating.

67. Position the inner bearing cup in

the

casing.

68. Position the inner bearing replacer 18G

11

22

G

detail

1,

onto 18G 1122 and secure with

the fixing nut.

69.

Hold still the centre

screw and turn the

butterfly lever

to draw in the bearing cups.

61. Add 0,127 mm, for bearing pre-load, to the

total noted in the preceding instruction. The

sum is then equal to the nominal value of

shims required for the differential bearings:

Shims are available in the range 0,07 mm,

0,12 mm, 0,25 mm and

0,76

mm. Select the

total value of shims required.

62. Remove the differential unit and bearings and

place aside.

Do not fit the shim washers until

the

subsequent 'Differential backlash' checks

have been made, instructions 96 to 102.

70. Press the inner bearing cone onto the drive

pinion using 18G

47

BK, details 1 and 2 and

press

MS

47.

71. Position the pinion and bearing in the casing;

omit the collapsible spacer at this stage.

72. Fit the outer bearing cone onto the pinion.

73. Fit the coupling flange and plain washer and

loosely fit the flange nut.

74. Tighten the coupling flange locknut to remove

end-float from the pinion.

75. Rotate the pinion to settle the bearings and

slowly

tighten the flange locknut. Use a spring

balance to obtain a torque resistance of 9,25

to 13,8 kgf cm. to rotate the pinion.

Fit drive pinion

63.

Select shim washers

of

the same thickness

value as those removed from under the pinion

inner cup, instruction 35, and place ready for

fitting,

64. Position the outer bearing replacer

18G 1122

G detail 2, and the outer bearing cup en the

press tool 18G 1 122.

65.

Locate the assembly into the pinion housing

nose.

REAR

AXLE AND

FINAL DRIVE

Drive pinion

markings

81. Remove the keep disc from the magnetized

base

of

dial gauge tool

18G191

76. Check that the serial number marked on the

82.

Place the dial gauge and setting gauge

pinion end face matches that marked on the

18G191P or 18G191-4 on a

fiat

surface and

crown wheel.

zero the dial gauge

stylus

on to

the setting

77.

The markings on the end face adjacent to the

gauge.

serial number are

of

no significance during

83.

Position the dial gauge centrally on the pinion

servicing.

end face

with

the stylus registering on the

78.

The figure marked on the end face opposite to

lowest point on one differential bearing

bore.

the serial number indicates, in thousandths

of

Note the dial gauge deviation from the zeroed

an

inch, the deviation

from nominal required to

correctly set the pinion. A pinion marked plus

84.

Repeat on the other bearing bore. Add

(+) must be set below nominal, a minus

(-)

together the readings, then halve the sum to

pinion must be set above nominal. An

obtain the mean reading. Note whether

the

unmarked pinion must be set at nominal.

stylus has moved up

or

down

from

the zeroed

setting.

setting.

79.

The nominal setting dimension is represented

by the setting gauge block 18G191P or

Example 1

18G 191 -4, which is referenced from the pinion

end face

to the bottom radius

of

the

Reading obtained L H side

+

0.006in

differential bearing bore. The latter gauge

I

S

Reading obtained R H side

- 0.003in

illustrated following instruction

85.

Add

+

0.006in

- 0.003in

+

0.003in

Divide by 2 (0.003in divided by 2)=

0.0015in

Therefore subtract

0.0015in

from the shim thickness

behind

the pinion inner bearing track

Example 2

Reading obtained

L H side

+

0.006in

Reading obtained

R H side

- 0.008in

Add

+

0.006in

- 0.008in

- 0.002in

Drive pinion adjustment

I

80.

Ensure that the pinion end face is free of

raised burrs around the etched markings.

Divide by

2

(0.002in divided by

2)= 0.001in

Therefore add

0.001in from

the shim thickness

behind the pinion inner bearing

track

REAR AXLE

AND FINAL DRIVE

85. Where the stylus has moved down (85a), the

86. Before adjusting the shim thickness, check the

amount is equivalent

to

the thickness of shims

pinion face marking and

if

it

has a plus

(+)

that must be removed from under the pinion

figure, subtract that from the shim thickness

inner cup

to

bring the pinion down

to

the

figure obtained in the previous instruction

nominal position. Where the stylus has moved

Alternatively

if

the pinion has a minus

( - )

up (85b), the amount

IS

equivalent

to

the

figure, add the amount

to

the shim thickness

additional thickness of shims required

to

bring

figure.

the pinion up

to

the nominal position.

87. Adjust the shim thickness under the pinion

inner cup as necessary, by the amount

Illustration

A.

Using setting gauge 18G191P.

determined in instructions

85

and

86.

88. Recheck the pinion height setting instructions

illustration

B.

Using

universal

setting

block

82

to

84. If

the setting is correct, the mean

18G

191

-4.

This setting block has three setting

reading on the dial gauge

will

agree

with

the

heights as follows:

figure marked on the pinion end face

For

example, with an end face marking of +3, the

39.50 mm Rationalised axle

dial gauge reading should indicate that the

38.10 mm Pre-Rationalised axle

pinion is 0.003 in

(0.0762

mm) below nominal.

30.93 mm Salisbury axle

89. When the pinion setting is satisfactory,

temporarily remove the pinion outer bearing.

Ensure that the height marked

30.93

mm is used for

this differential.

90. Fit a new collapsible bearing spacer, flared

end outward, to the drive pinion and refit the

outer bearing.

91. Fit the pinion oil slinger.

92. Fit the oil seal gasket.

REAR AXLE

AND FINAL

DRIVE

93.

Fit the pinion oil seal, lipped side first, using

general purpose grease or, where available, a

molybdenum disulphide based grease on the

seal lip, using

RO

1008 to drift in the seal.

94.

Fit the coupling flange and plain washer and

loosely

fit

a new flange nut. Secure

18G 1205

to

the coupling flange, using slave fixings.

95. Alternately tighten the flange nut and check

the drive pinion resistance to r

following figures are achieved, as applicable:

a. Assemblies

re-using

original

pinion

bearings: 17,3 to 34,3 kgf cm.

b. Assemblies with new pinion bearings: 34,5

to 46,0

kgf cm.

NOTE: Once the bearing spacer has started to

collapse the torque resistance build-up is rapid,

therefore check frequently, using a spring

102. Fit the shim value determined in instruction

101, taking the shims from the pack

balance, to ensure the correct figures are not

previously determined during 'Differential

exceeded, otherwise a new collapsible bearing

bearing adjustment' checks, instructions 57 to

spacer

will

be required.

62

18G 47 BL details 1 and

2,

using press NS

47 and 18G 134

DP.

103. Fit the remaining shims

from

instruction

101

to

the opposite side of the differential, using 18G

47

BL

details 1 and 2, press MS 47 and 18G

134 DP.

104. Fit the differential unit with shims and

bearings to the axle casing, using the axle

spreader 18G 131

C

with pegs 18G 131 F.

105. Remove the axle spreader.

106. Fit the bearing caps in their correct position,

referring

to

the relationship markings on the

caps and on the axle casing.

107. Tighten the bearing caps fixings to 126 to 142

Nm.

108. Mount a dial gauge

on

the axle casing

with

the stylus resting on a crown wheel tooth.

Differential backlash

checks

96. Pick up the differential unit as left after

instruction 52.

97. Fit the differential unit and lever the unit away

from the drive pinion until the opposite bearing

cup is seated against the housing. Do not tilt

the unit.

98. Install a dial gauge on the casing with its

stylus resting on the back face of the crown

wheel. Zero the gauge.

99. Lever the differential unit to engage the crown

wheel teeth in full mesh with the drive pinion

teeth. Do not tilt the unit.

100. Note the total reading obtained on the dial

gauge.

correct crown wheel backlash when fitted. The

result indicates the value of shimming to be

fitted between the differential case and the

bearing cone at the crown wheel side of the

differential.

101. From this figure subtract 0.010 in to obtain

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст