Defender (1993+). Manual — part 23

ST828M

ENGINE

Crankshaft dimensions-millimetre

Cranks

haft

Diameter

'12'

Width '13'

Diameter

'1 4'

Grade

Standard

58.400-58.412

26.975-27.026

50.800-50.812

0.254

U/S

58.146-58.158

26.975-27.026

50.546-50.558

0.508 U/S

57.892-57.904

27.229-27.280

50.292-50.304

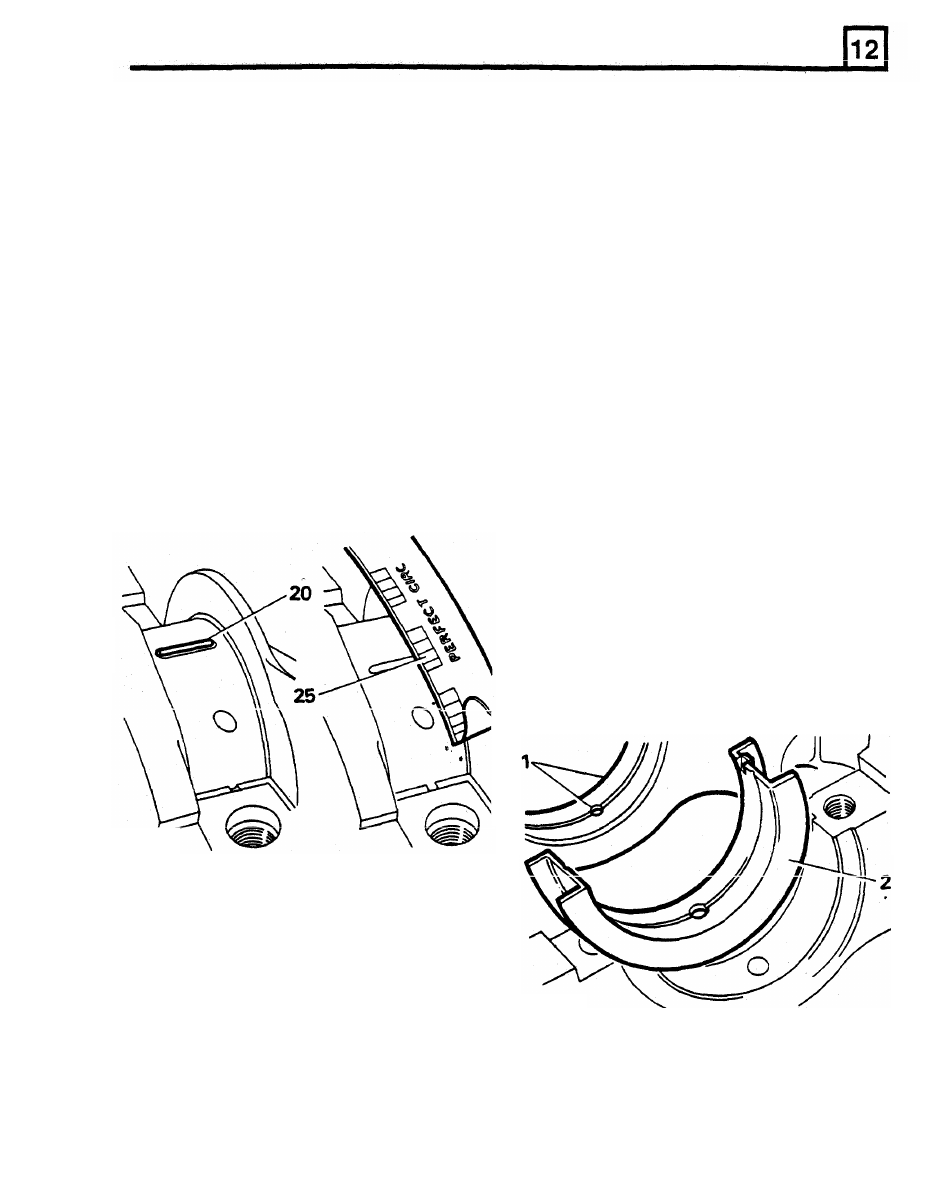

Check main bearing clearance

26. Graduation most closely corresponding

to

width

of

Plastigauge indicates

bearing

16. Remove oil seals from cylinder block and rear

clearance.

main bearing cap.

27. Correct bearing clearance with new

or

17. Locate upper main bearing shells (with oil

overhauled components is 0.023 to 0.065

mm.

hole and oil grooves) into cylinder block.

28.

If

correct clearance is not obtained initially,

18. Locate flanged upper centre main bearing

select a suitable bearing to give required

shell.

clearance.

19. Place crankshaft in position on bearings.

29. Wipe

off Plastigauge with an oily rag.

Do

NOT

20. Place a piece

of Plastigauge across centre

of

crankshaft main bearing journals.

21. Locate lower shells into main bearing caps.

scrape

it

off.

30. Maintain bearing shells and caps in sets,

in

the correct sequence.

ASSEMBLING ENGINE

FIT CRANKSHAFT AND MAIN BEARINGS

1. Locate upper main bearing shells (with oil

holes and grooves) in cylinder block.

2. Locate the flanged upper centre main bearing

shell.

3.

Lubricate crankshaft main bearing journals

and bearing shells with clean engine

oil

and

lower crankshaft into position.

ST830M

22. Fit numbers one to four main bearing caps

and shells, tighten to 70 Nm.

23. Fit rear main bearing cap and shell and

tighten to 90 Nm.

Do

not allow crankshaft

to

rotate while Plastigauge is in use.

24. Remove main bearing caps and shells.

25. Using scale printed on Plastigauge packet,

measure flattened Plastigauge at widest point.

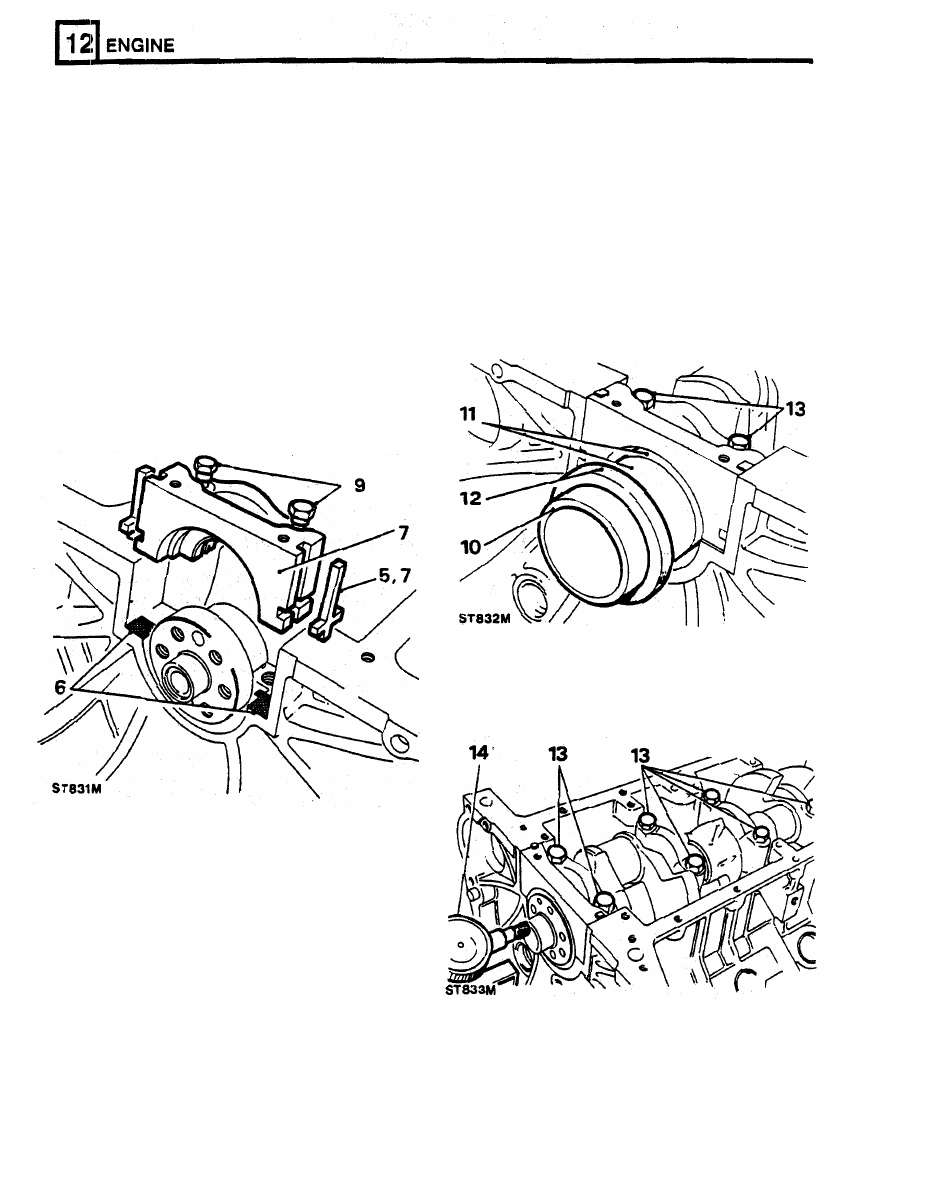

4.

Lubricate lower main bearing shells and fit

NOTE:

Lubricant coating must cover seal

numbers one

to

four main bearing caps and

guide outer surface completely to ensure

shells only, leave the fixing bolts finger-tight.

that oil seal lip is not turned back during

5. Fit

cross shaped side seals

to grooves each

assembly.

side of rear main bearing cap.

Do not cut side

Position oil seal,

lipped side towards the

seals,

they

must

protrude

1.5

mm

engine, o n to seal guide. Seal outside

approximately above bearing cap parting face.

diameter must

be clean and dry.

6.

Apply Hylomar SQ32M jointing compound to

rearmost half of rear main bearing cap parting

12. Push oil seal fully and squarely by hand into

face

or,

if

preferred, to equivalent area on

recess formed in cap and block until

it

cylinder block as illustrated.

contacts machined step

in recess.

7.

Lubricate bearing half and bearing cap side

Withdraw seal guide.

seals with clean engine oil.

8.

Carefully fit bearing cap assembly.

9.

Do not tighten fixings, but ensure that cap is

fully home and squarely seated on cylinder

block.

CAUTION: Do not handle oil seal lip, check

i t is not damaged and ensure that outside

diameter remains clean and dry.

10.

Position seal guide LRT-12-010 on crankshaft

flange.

11. Ensure that oil seal guide and crankshaft

guide and oil seal journal with clean engine

oil.

journal are scrupulously clean. Coat seal

CAUTION: Do not exceed 1,000 engine

rev/min for 15 seconds when first starting

engine, otherwise crankshaft rear oil seal

will be damaged.

13. Tighten cap bolts

to

correct torque, numbers

one

to four bearings

70

Nm, rear main

bearing

90

Nm.

14. Check crankshaft end-float, 0.10

to 0.20 mm.

ST834M

ENGINE

FIT CONNECTING

RODS

AND PISTONS

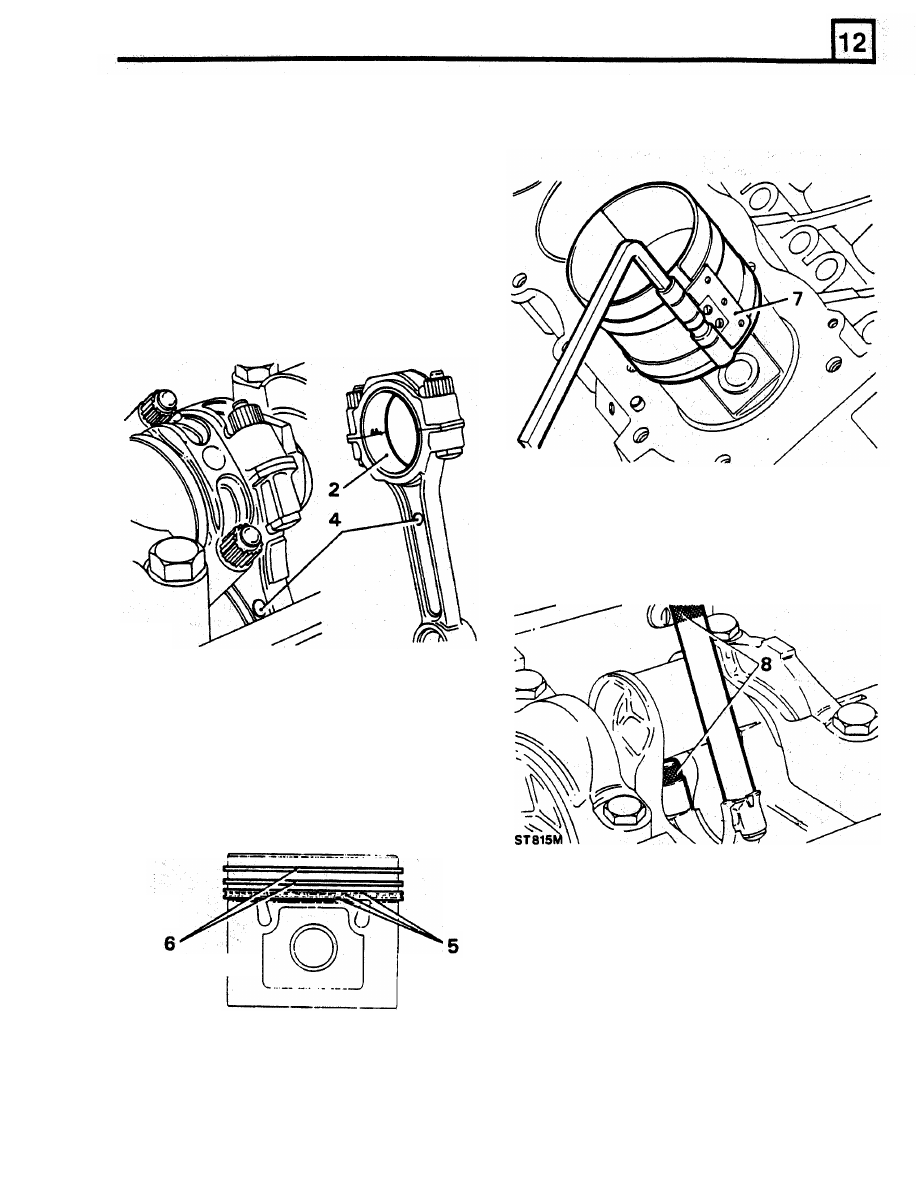

7 .

Using a piston ring compressor, locate piston

into cylinder bore, until piston crown

IS

just

below cylinder block top face.

1.

Locate applicable crankshaft journal at

B.D.C.

2,

Place bearing upper shell in connecting rod.

3.

Retain upper shell by screwing guide bolts

605351

onto connecting rods.

4.

Insert connecting rod and piston assembly into

respective bore, noting that domed shape

boss on connecting rod must face towards

front

of engine on right hand bank

of

cylinders

and towards rear on left hand bank. When

both connecting rods are fitted, bosses will

face inwards towards each other.

5.

Position oil control piston rings with ring gaps

all at one side, between piston pin and piston

thrust face. Space gaps in ring rails

approximately

25

mm

each side

of expander

ring joint.

6.

Position compression rings with ring gaps on

opposite sides of piston between piston pin

and piston thrust face.

9.

Place bearing lower shell in connecting rod

cap.

10.

Locate cap and shell onto connecting rod,

noting that rib on edge

of cap must be

towards front of engine on right hand bank of

cylinders and towards rear on left hand bank.

11.

Check that connecting rods move freely

sideways

on the

crankshaft.

Tightness

ST835M

indicates insufficient bearing clearance or

misaligned connecting rod.

I

ST836M

8.

Pull connecting rods

on to crankpins using the

guide bolts. Use extreme care

to

prevent

scratching crank pins.

ENGINE

RR1800E

12.

Check end-float between connecting-rods on

5.

Encircle sprockets with chain keeping timing

each crankshaft journal. Clearance limits:

0.15

to

0.37

mm.

13.

Tighten connecting rod nuts

to

the correct

torque, 50 Nm.

Fit

oil strainer and joint

washer.

marks aligned.

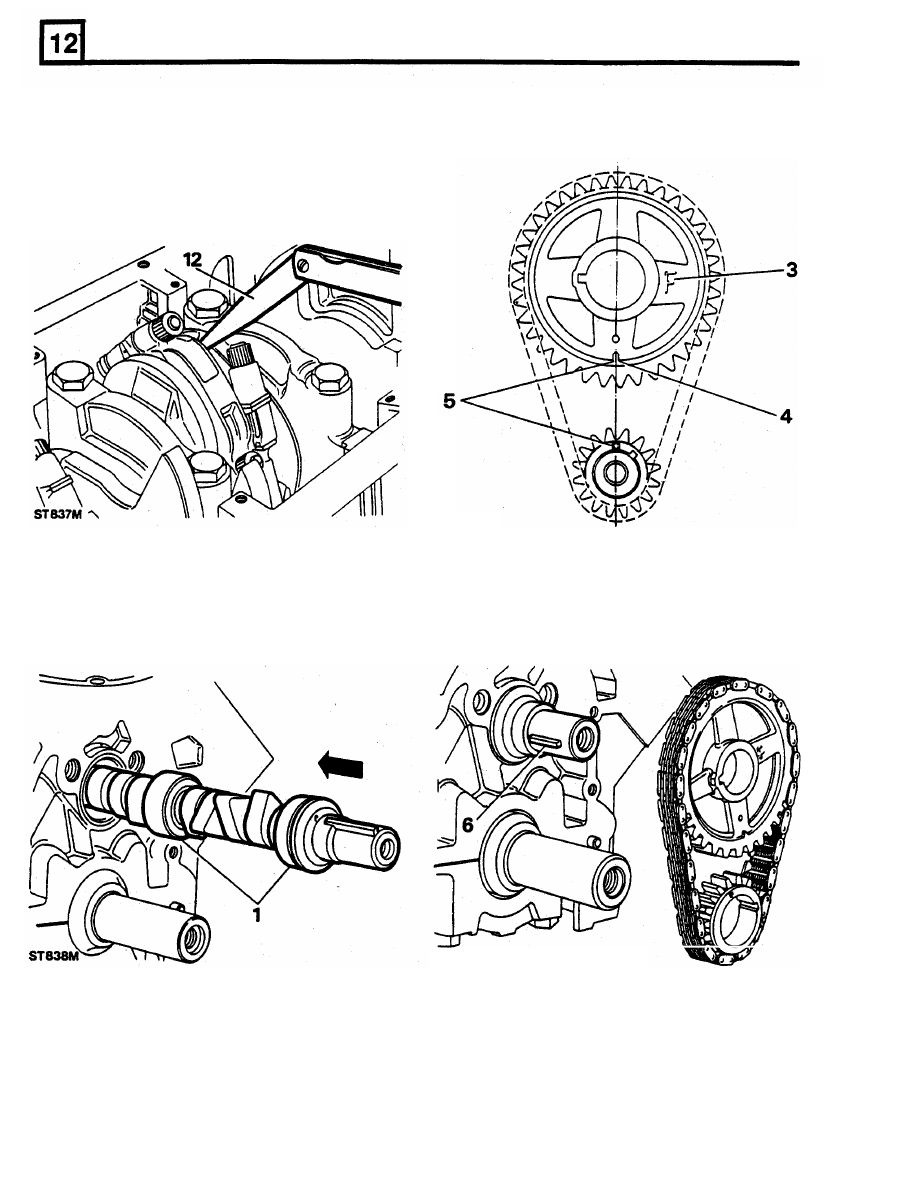

FIT CAMSHAFT

TIMING CHAIN AND SPROCKET

6.

Fit sprocket assembly to camshaft and

crankshaft key locations. Check that camshaft

1.

Lubricate camshaft journals and carefully

key is parallel to shaft axis

to ensure

adequate lubrication

of

distributor drive gear.

insert camshaft into cylinder block.

2.

Turn crankshaft

to bring number one piston

to

TDC

.

3.

Temporarily fit camshaft sprocket with marking

' F or

'FRONT' outward.

4.

Turn camshaft until mark on camshaft

sprocket is at six o'clock position, remove

sprocket without disturbing camshaft.

RR1801E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст