Defender (1993+). Manual — part 28

RO.1014

RO274401

ENGINE

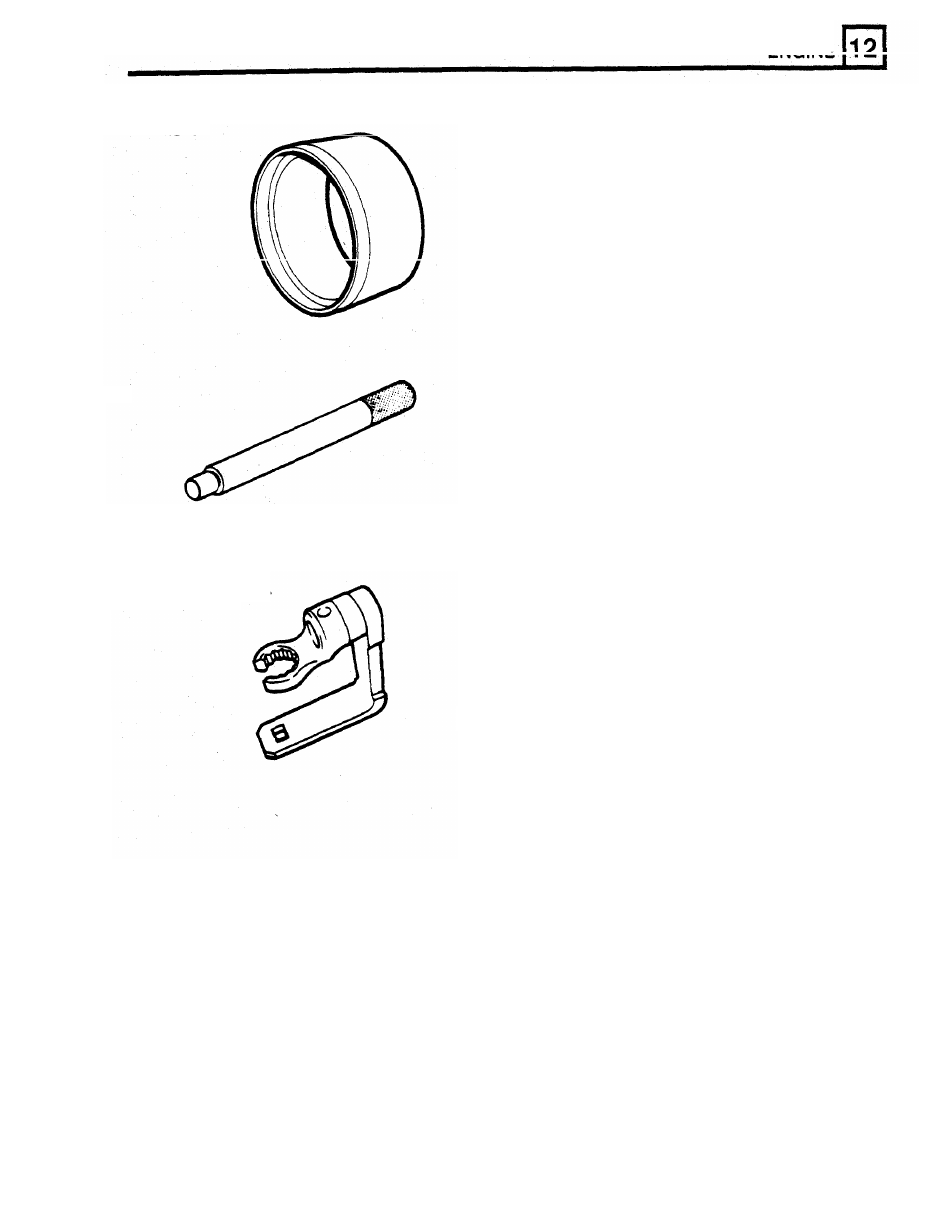

LRT-12-010

Crankshaft rear seal sleeve

RO1014

LRT-12-037

Drift for valve guide removal

-

intake and

RO274401A

exhaust

LRT-12-047

Torque adaptor lambda sensor

LST134

LST134

EMISSION CONTROL

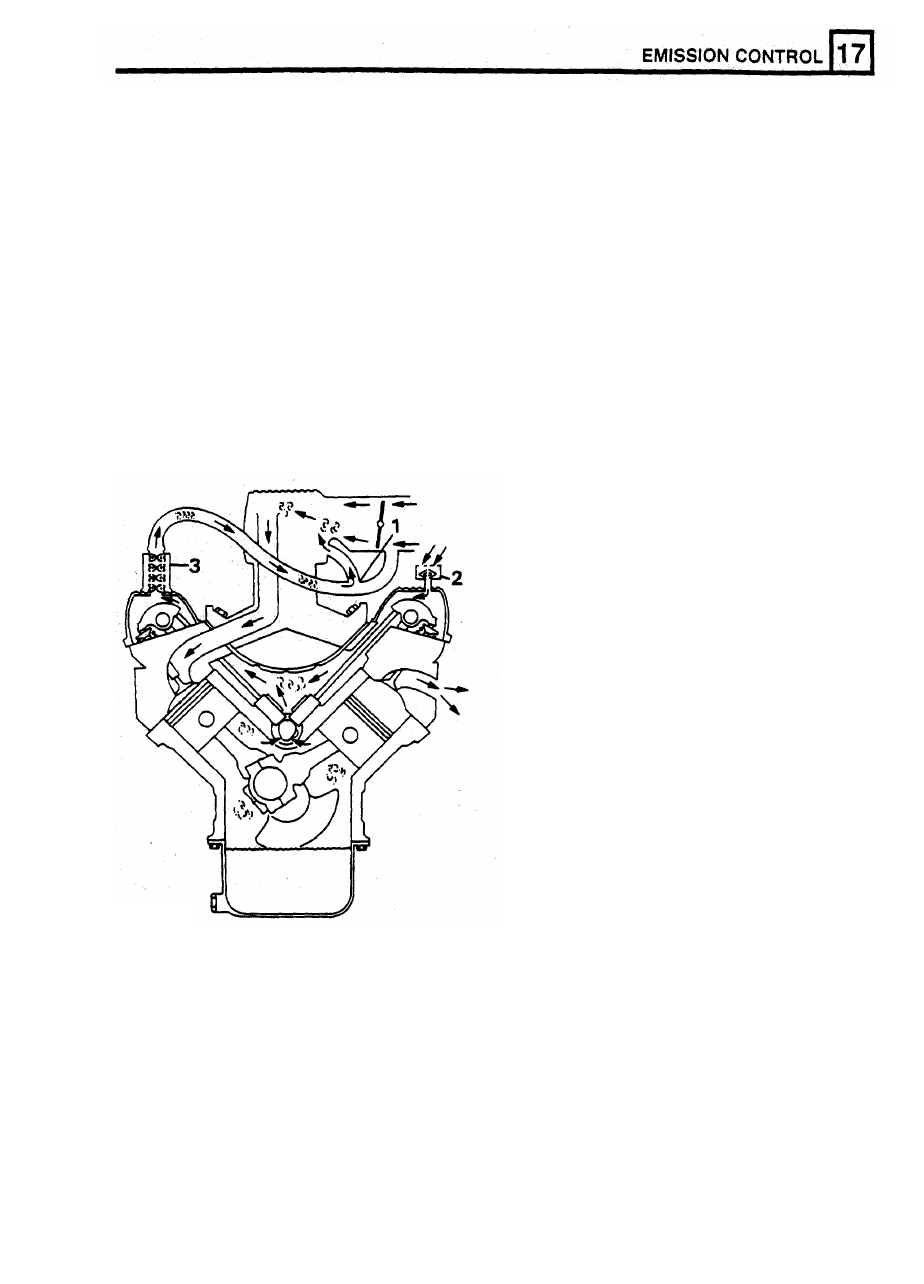

The purpose

of

the crankcase ventilation system is

to

ensure that any noxious gas generated in the

Three systems are used to control the vehicle

engine crankcase

is

rendered harmless by burning in

atmospheric emissions these are:

the combustion chambers as follows:

Oil laden noxious gas in the engine crankcase is

Engine crankcase fume emissions.

drawn through an oil separator

3

located on the right

Fuel tank Evaporative emissions

cylinder head rocker cover, where the oil is

Engine exhaust gas emissions.

separated and returned to the stump. The gas flows

through a restrictor

in

the three way connection

1

Crankcase ventilation system

and into the inlet plenum chamber where it drawn

into the combustion chambers and burned. The

The crankcase ventilation system which is an

volume of fresh air which

is

drawn from the

integral part of the air supply

to

the engine

atmospheric side

of

the throttle butterfly to mix with

combustion chambers, is often overlooked when

the gas, depends on the position

of

the throttle and

diagnosing

problems

associated

with

engine

the engine speed.

performance.

A

blocked ventilation pipe or filter or

excessive air leak into the inlet system through a

The air filter

2

fitted

to

the left cylinder head rocker

damaged pipe or leaking gasket can effect the

cover, must be maintained in clean condition to

mixture, performance and economy of the engine.

ensure sufficient air enters the crankcase under

varying throttle openings and manifold depression, to

prevent excessive crankcase pressure or depression

developing.

1

Three way connector

2

Air filter

3 Oil separator

REISSUED:

FEB

1993

1

RR3534M

E MISSION

CONTROL

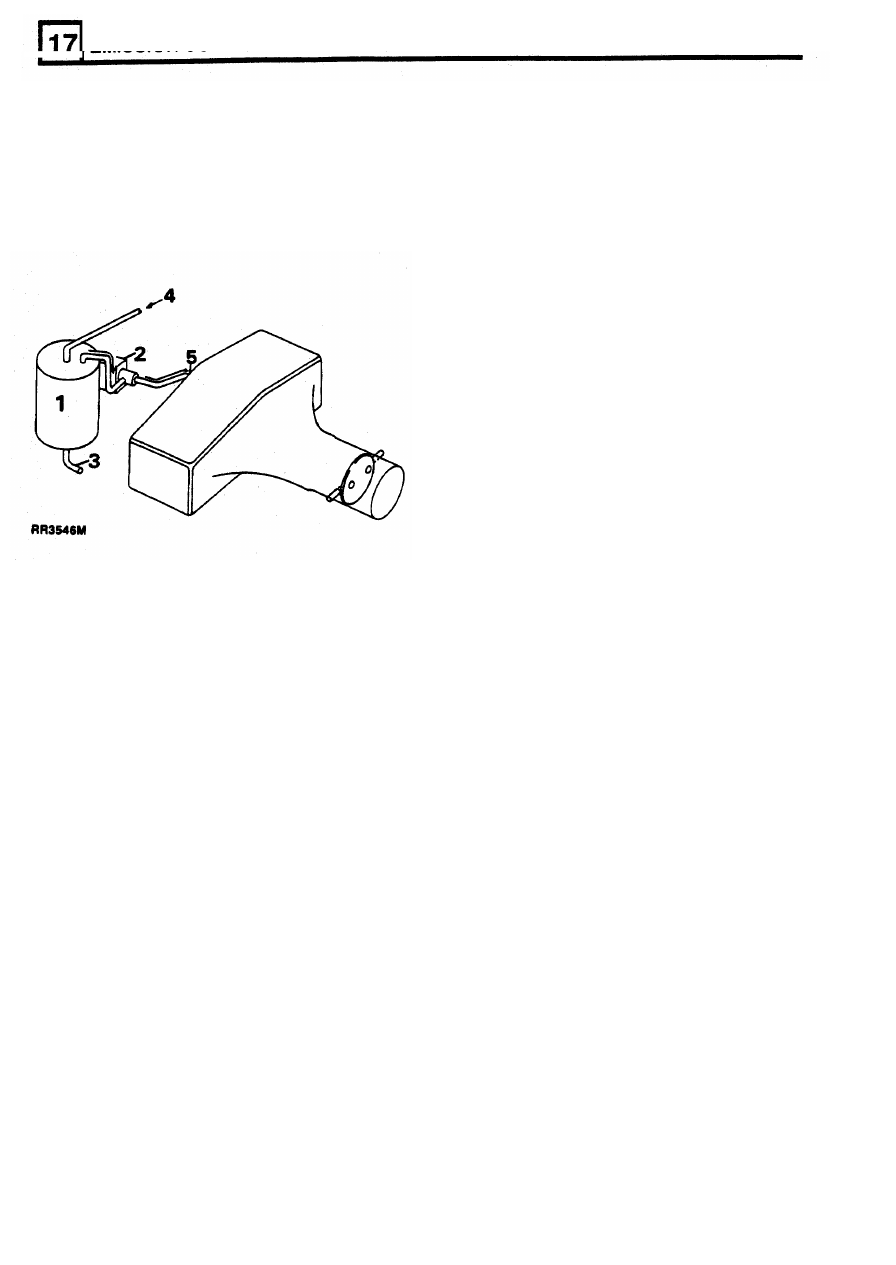

EVAPORATIVE EMISSION CONTROL

The opening of the purge valve (2), which

I

S

controlled by the MFI ECM occurs when the

Fuel tank evaporative control

following conditions prevail:

The specification for certain countries requires the

When the engine is running at speeds above

recycling

of

petrol evaporation from the fuel tank. For

1700 rev/min and temperatures above 54°C the ECM

these countries only, a charcoal canister and purge

will hold open the purge valve as necessary.

valve are installed in the engine compartment.

At

speeds below 1700 rev/min the ECM will only

pulse the purge valve open for short periods.

While the purge valve (2) is open, engine depression

draws air through vent

(3)

and fuel tank fumes via

(4)

into the engine combustion chambers, where they

are burned. Air entering at (3), passes through the

charcoal, where any accumulation of condensed fuel

is also extracted and burned in the engine.

A permanent leakage of air into the plenum

chamber through the purge system will effect

engine performance.

Fuel tank evaporative control system

The system consists of a fuel separator/expansion

tank located at a higher level than the fuel tank,

between the inner body side and the right rear

fender. The tank is vented to atmosphere through

a

relief valve and is connected

to the fuel tank and the

charcoal canister purge system in the engine

Evaporative purge system

1

Charcoal canister

compartment.

2

Purge valve

3

Charcoal canister air vent

4. Fuel purge connecion from

separator/expansion tank

5

Plenum chamber connection

Operation

When the engine is not running, the purge valve

(2)

seals the plenum

chamber

connection

(5).

Any

vapour

entering

the

canister

at

(4)

from

separator/expansion tank, is condensed by the air

entering at

(3)

which is then

absorbed

by the

charcoal.

2

REISSUED: FEB 1993

Operation

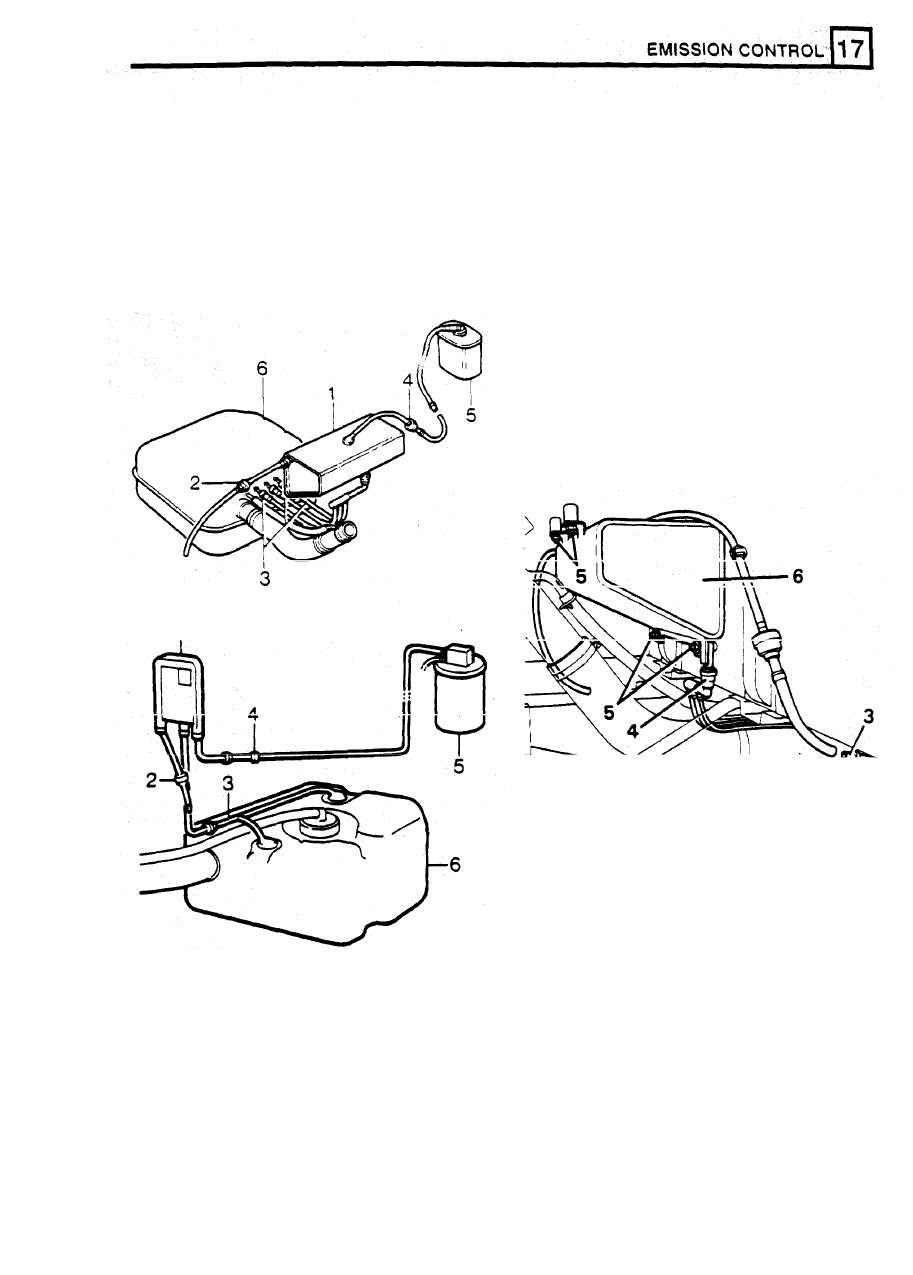

FUEL EXPANSION TANK

As

the temperature rises, fuel vapour in the fuel tank

IS

allowed

to

vent into the separator/expansion tank

(1)

via three pipes and a manifold connector

(3).

Any

vapour which condenses into liquid fuel drains

WARNING:

Ensure all necessay precautions are

through pipe

(6)

back into the main fuel tank and

taken against spillage of fuel when disconnecting

residual vapour is dealt with by the purge system

expansion tank hoses.

connection

(4)

in the engine compartment.

The atmosphere relief valve

(2)

will only open if a

DEFENDER 110

blockage occurs in the charcoal canister

or

purge

system.

Remove

The fuel expansion tank is located under the wheel

arch of the right rear fender.

1.

Loosen fuel tank filler cap

to

release any

2.

Disconnect battery negative lead.

3.

Disconnect pipe connection at joint under

chassis member.

4.

Disconnect evaporative control pipes. Use

LRS-19-002, press down on collet and pull

connector.

pressure in tank.

ST3416M

Defender 110

ST3417M

ST3460M

5.

Remove

four nuts

and remove expansion

tank.

Refit

6.

Reverse removal instructions.

Defender 90

Fuel tank evaporative control system

1

Fuel

expansion tank

2 Relief

valve

to

atmosphere

3

Fuel tank vent

4

Relief valve to charcoal canister

5

Charcoal Canister

in

engine compartment

6

Fuel tank

REVISED:

OCT

1993

3

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст