Defender (1993+). Manual — part 82

BRAKING

SYSTEM

20. The shoes in the wheel cylinder piston slots

2.

Disconnect the propeller shaft from the output

and lever the opposite ends into the pivot

flange.

block.

3.

Remove the two screws and withdraw the

21. Operate the snail cams

to

check that the

brake drum. Skim if excessively scored or

shoes respond.

oval.

22. Connect the brake fluid pipe to the wheel

4. Remove the split pin and clevis pin connecting

cylinder.

23. Fit the brake drum and secure with the single

5.

Remove the brake shoes complete with

screw.

pull-off springs. Note position of springs in

24. Adjust each brake shoe independently as

relation to the shoes.

follows:

turn one adjuster until the shoe is

6. Remove the four bolts securing back-plate to

locked

against

the

drum.

Back

off

transfer box and withdraw the back-plate

approximately

two

serrations of the snail cam

complete with oil catcher.

so

that the drum revolves freely.

25. Repeat instruction 24 on the second shoe and

carry out the same procedure for the opposite

brake.

1.

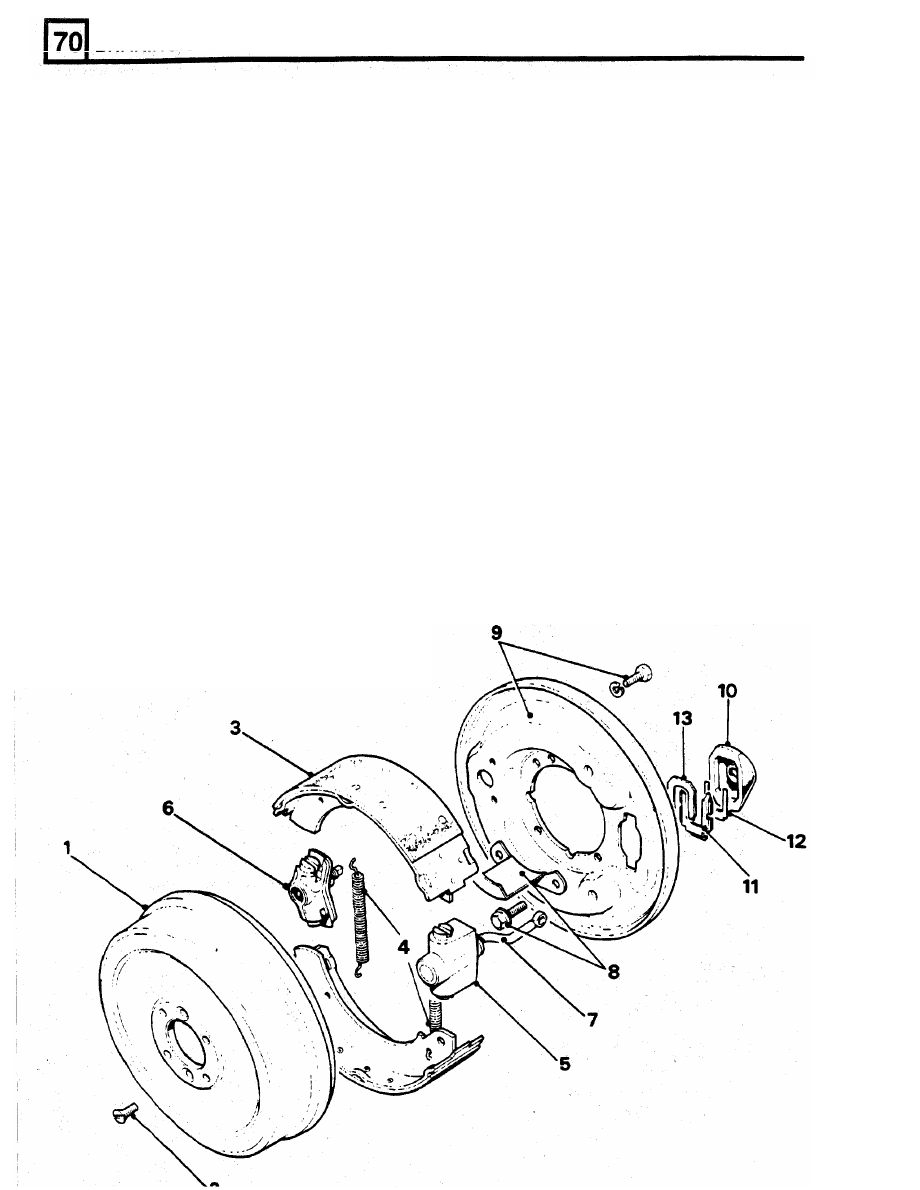

Brake drum.

26. Bleed the brakes.

2. Brake drum retaining screws

27. Fit the road wheels, remove the axle stands

3. Brake shoes.

4. Brake shoes pull-off springs.

6.

Adjuster assembly.

8. Oil catcher.

9. Back plate and retaining bolts.

10. Dust cover.

the drawlink to the actuating lever.

KEY

TO

TRANSMISSION BRAKE

and finally tighten the road wheel nuts to the

correct torque.

5.

Expander assembly.

OVERHAUL TRANSMISSION BRAKE

7. Draw link.

WARNING:

Do

not use an air line to remove dust

from the brake assembly. Asbestos dust from the

brake linings can

be

a serious health risk, if

11. Locking plate.

inhaled.

12. Packing plate.

DISMANTLING

13.

Spring plate.

1.

Disconnect the battery and chock the road

wheels for safety.

BRAKING SYSTEM

Remove and overhaul expander assembly

7.

Remove the rubber dust cover.

8.

Remove the expander and draw link.

9. Remove the retainer spring plate.

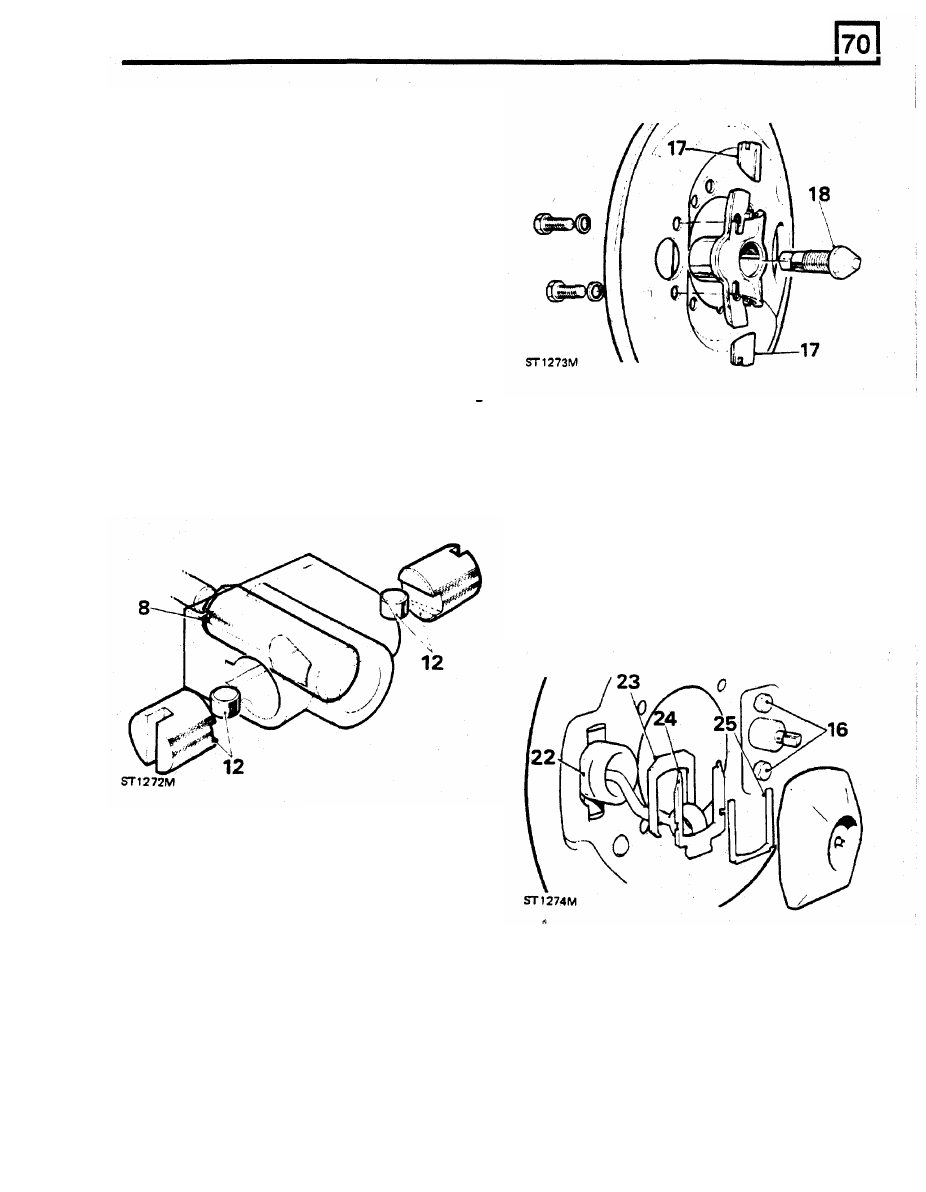

10. TDO106,254,254 Remove the locking plate.

11. Remove the packing plate and withdraw the

expander assembly from the back-plate.

12. Remove the two plungers and rollers.

13. Clean all parts in Girling cleaning fluid and

allow to dry. Examine the components for

wear and discard if unsatisfactory.

Assemble expander assembly

14. Grease and fit the expander and drawlink.

15. Grease and fit the plungers and rollers noting

that the highest end o f the ramp on the

plungers is fitted towards the back-plate.

Secure the assembly band to

one side for assembly

to

back-plate.

ASSEMBLE

NOTE:

If

the brake linings are oil-soaked check

prevent the plungers falling out and place to

and if

necessary renew the

output shaftoil

seal.

22. Position the expander assembly on the inside

of

the back-plate and secure with the following

plates at the rear of the back-plate.

23. Locking plate.

24. Retaining plate.

25. Packing plate.

26. Fit the rubber dust cover.

Remove and overhaul adjuster assembly

16.

Remove the two bolts and withdraw the

adjuster assembly from

the

back-plate.

17.

Remove the plungers.

18. Screw the adjuster cone inwards

to

remove

from the housing.

discard any unsatisfactory components.

19. Clean the parts in Girling cleaning fluid and

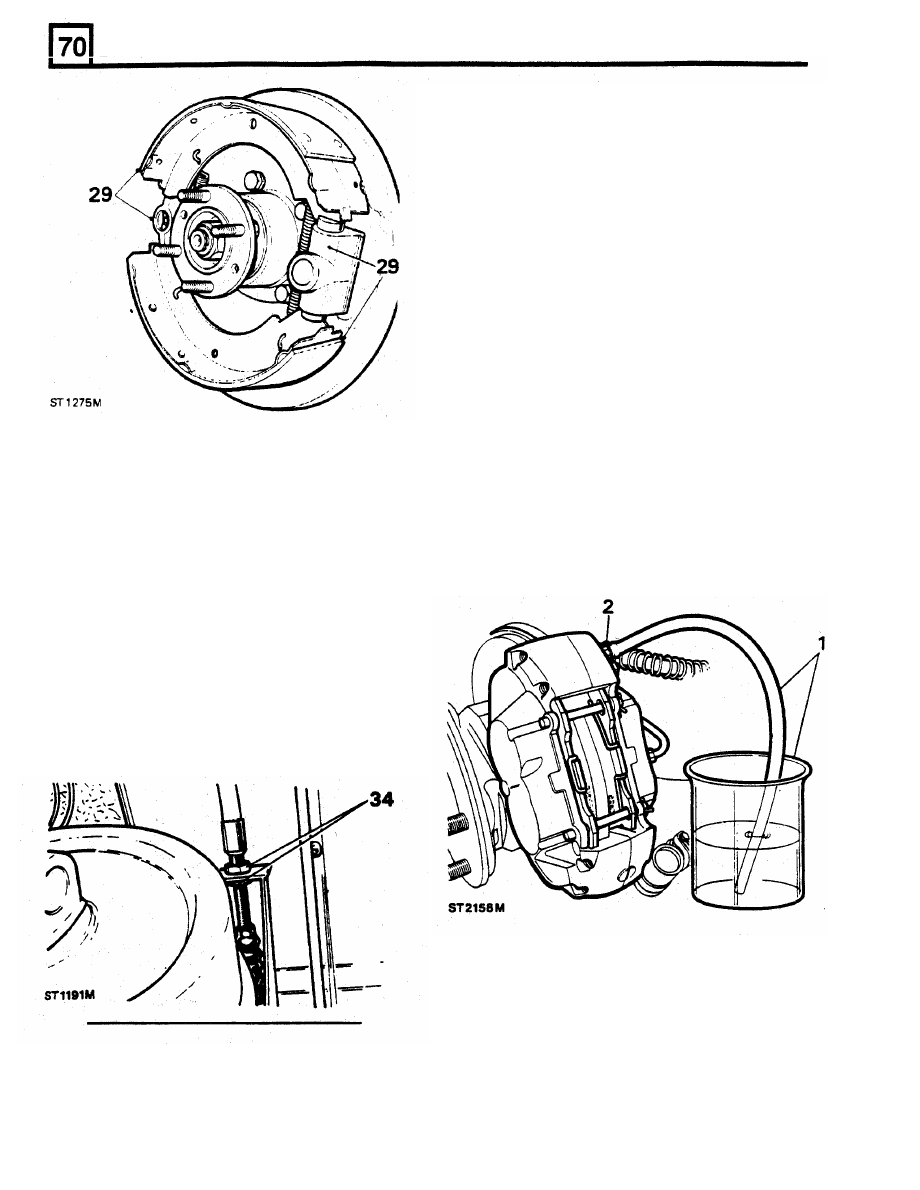

27. Fit the adjuster assembly to the back-plate

with the two bolts but do not fully tighten at

this stage.

28. Fit the back-plate assembly and mud shield to

the transfer box with the four bolts and tighten

to

the correct torque.

and

fit

to

the back-plate. Note that the fully

lined end of the lower shoe must be toward

the expander assembly and the fully lined end

of the upper shoe towards the adjuster

assembly.

Assemble adjuster assembly

20. Grease and screw in the adjuster cone.

the chamfered ends with the adjuster cone.

Note that the two plungers are identical and

can be fitted to either bore. Secure the

assembly with a rubber band

to

prevent the

plungers falling out.

21. Grease and

fit

the adjuster plungers and align

29. Fit new pull-off springs to relined brake shoes

BRAKING

SYSTEM

BLEEDING

THE

BRAKES

Primed

System

Bleed the front brakes first starting with the wheel

nearest to the master cylinder.

1.

Attach a rubber tube to the bleed screw and

immerse the other end in a glass jar

containing

a

quantity

of

clean,

new

recommended brake fluid.

2.

Check that the fluid reservoir is full

to

the

maximum mark.

3. Unscrew the bleed screw approximately

half-a-turn, enough to allow fluid to be

pumped out.

Do

not open the screw too far or

air will be drawn back into the system around

the threads.

4. Smartly depress the foot pedal, pause and

30.

Fit

the brake drum and secure with the

two

then allow the pedal to rapidly return, pause

screws.

again before repeating the procedure.

31.

Connect the expander drawlink to the

5.

Continue with the above sequence until all air

actuating lever with a new clevis pin, washer

bubbles cease whilst ensuring that the

and split pin.

reservoir is kept topped-up.

32. Turn the adjuster cone fully in and tighten the

6. Close the bleed screw immediately after the

two

retaining bolts left slack in instruction 27.

last down stroke, whilst the pedal

is

33. Slacken off the adjuster two 'clicks' and firmly

depressed.

apply the hand lever to centralise the shoes.

The drum should then rotate freely after

releasing the hand lever.

34. Adjust the handbrake cable

to

give the pawl

two

'clicks'

free

movement on the ratchet

before the third 'click' fully expands the shoes

against the drum.

35. Connect the propeller shaft and evenly tighten

the retaining nuts to the correct torque.

36. Remove chocks

from

wheels and connect the

battery.

Unprimed System

To bleed a replacement master cylinder or a fully

drained system.

7.

Top up the fluid reservoir to the maximum

mark.

8.

Open a bleed screw in both circuits and allow

fluid to prime both circuits of the master

cylinder by gravity for approximately five

minutes, then bleed as for a primed system.

4.

Remove the two bolts securing brake caliper

to

the swivel housing and withdraw the

caliper

.

BRAKING

SYSTEM

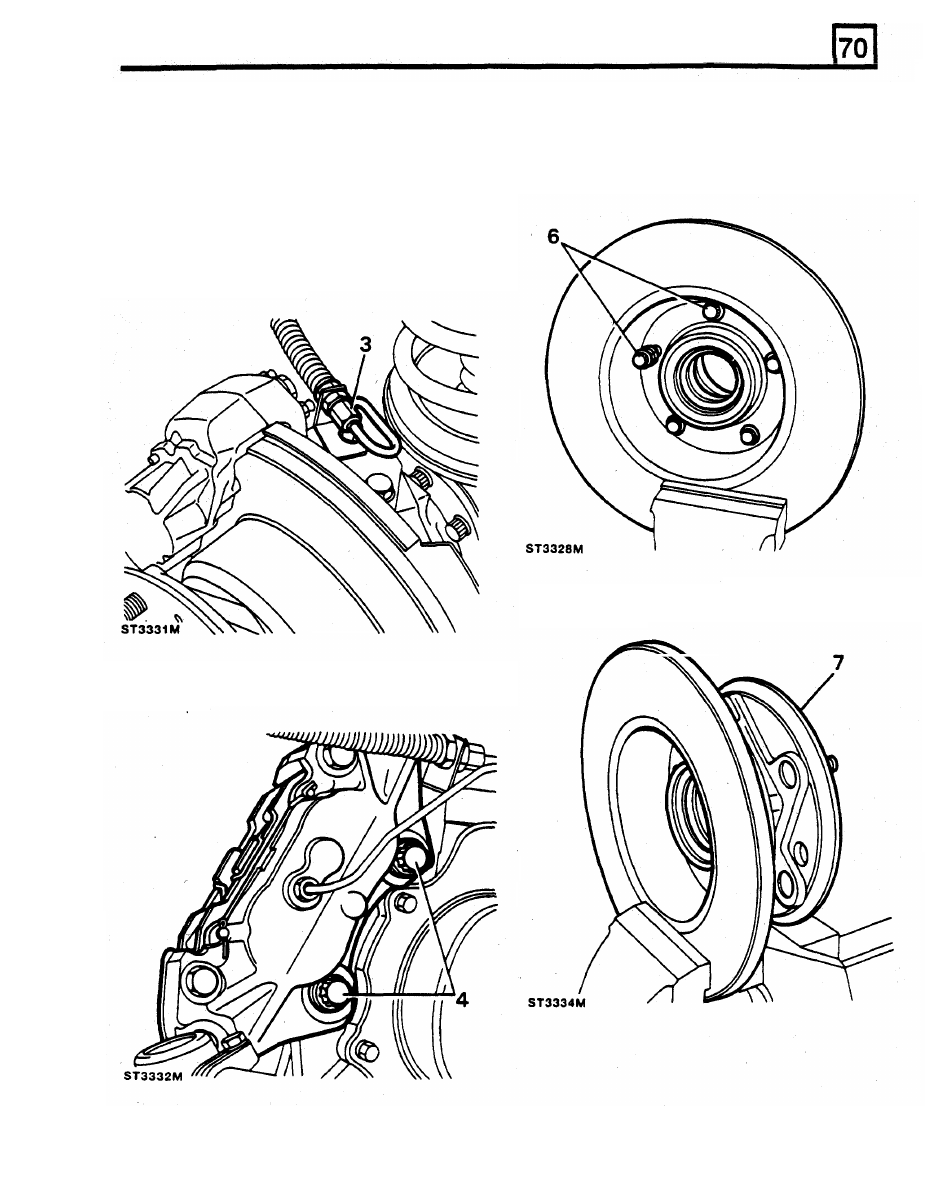

RENEWING FRONT BRAKE DISCS

5.

Remove the front hub complete with brake

disc by following instructions 6 to

14

in

Removing

SECTION

54 for

front hub

overhaul.

6. Remove the five bolts

to

separate the disc

1.

Disconnect the battery.

from the hub.

2.

Jack-up vehicle, lower on to axle stands and

remove road wheels.

3.

Disconnect the brake pipe union from the

jump hose at the swivel housing bracket.

Cover pipe to prevent entry

of

dirt.

7.

The hub

will

require tapping with

a

mallet

to

finally release it from the disc.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст