Defender (1993+). Manual — part 81

BRAKING SYSTEM

REMOVE AND OVERHAUL BRAKE CALIPERS

Special tool:

18G672 - LRT-70-500 - Piston clamp

Remove caliper

1.

Slacken the wheel retaining nuts, jack-up the

vehicle, lower onto axle stands and remove

the wheels.

2.

Expose the brake flexible hose by moving the

coiled protective covering and clamp the hose.

Disconnect the hose from the caliper.

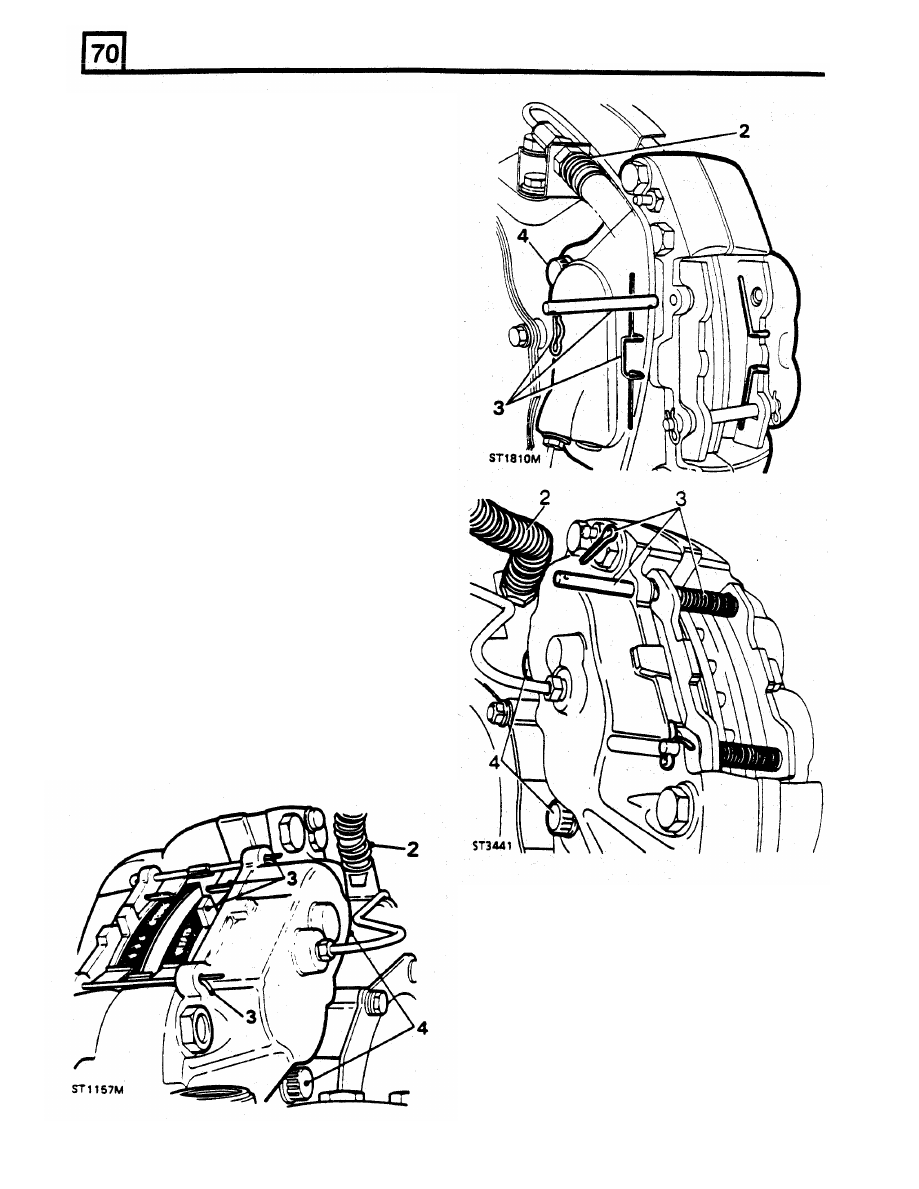

NOTE: Three different methods of retaining the

brake pads are used. Each type is listed

below

and shown

in

the illustrations referred to:

Type A

-

Plate anti-rattle springs

-

Fig. ST1157M.

Type

B

-

Wire anti-rattle springs

-

Fig. ST1810M.

Type C

-

Coil anti-rattle springs

-

Fig. ST3441

3. Removing

friction

pads

-

plate

type

anti-rattle springs

Straighten the splayed ends

of

the pad

retaining pins and withdraw the pins. Collect

the anti-rattle springs and withdraw the pads.

If

the same pads are to

be

refitted, identify

them for assembly

to

their original locations.

Removing friction

pads

-

wire

or

coil

anti-rattle springs

Remove the

four

spring clips or split cotters

and remove the retaining pins. Withdraw me

friction pads. If the same pads are to be

refitted, identify them

for

assembly to their

original locations.

4.

Remove the

two

bolts

and withdraw the

caliper from the vehicle.

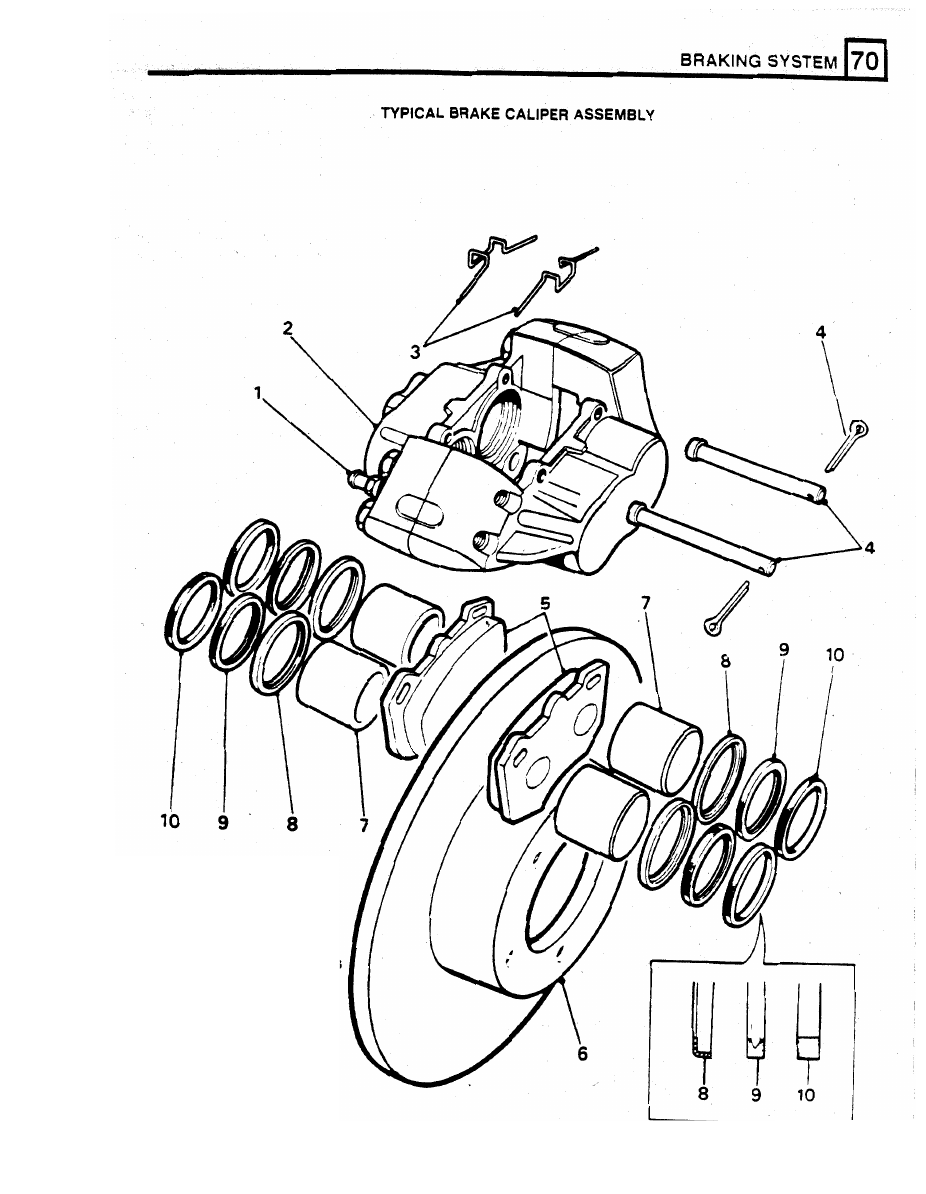

KEY TO

CALIPER

1. Bleed screw

2

Caliper

3. Hold down springs.

4.

Retaining pins and clips

5. Friction pads.

6. Brake disc.

7. Piston.

8. Wiper seal retainer.

9. Wiper seal.

or split pins.

10. Fluid seal.

ST2721M

BRAKING SYSTEM

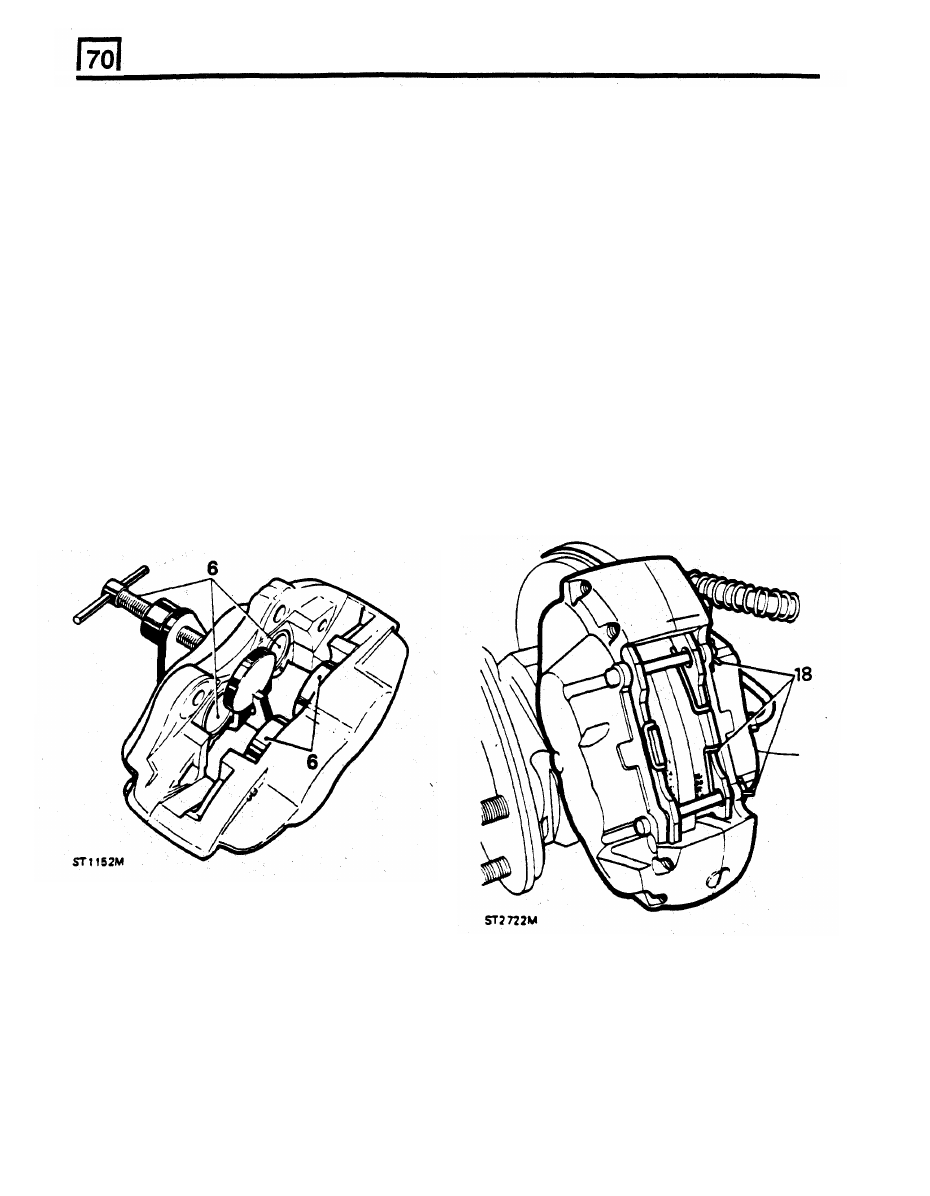

Slide the assembly, seal first, over the

Do not separate the caliper halves.

protruding piston and into the bore recess

Remove the piston clamp from the mounting

half and use the clamp to press home

the

seal retainer and piston.

5.

Clean the outer surfaces of the caliper with

methylated spirit.

6.

Using special tool

18G672,

clamp the pistons

in the mounting half of the caliper and gently,

keeping fingers clear, and with CAUTION,

Mounting-half pistons

apply air pressure

to

the fluid inlet port to

expel the rim half pistons. Since

it

is unlikely

that both pistons will expel at the same time,

regulate the rate with a suitable piece of

to

13.

timber between the appropriate piston and

caliper.

7 .

Finally, remove the pistons keeping them

15.

Fit the caliper to the axle and secure with the

identified with their respective bores.

two

bolts tightening evenly to the correct

8.

Remove the wiper seal retainer by inserting a

torque,

see

data.

blunt screw driver between the retainer and

16.

Connect the brake flexible hose to the caliper

the seal and prise the retainer carefully from

and remove the hose clamp.

the mouth of the bore.

17.

Lightly Smear the back and edges

of

the pads

9.

Taking care not to damage the seal grooves,

with

disc brake lubricant carefully avoiding the

extract the wiper seal and fluid seal.

friction material.

10.

Clean the bores, pistons and particularly the

18.

Fit the

friction

pads and secure using new

seal grooves

with

clean brake fluid or

pins and split pins and anti-rattle springs.

methylated spirit only. If the caliper or pistons

Splay the ends

of

the early type retaining

are corroded

or

if

their condition is not

perfect

pins.

the parts

must

be

renewed.

14.

Clamp the rim-half pistons and carry out the

same procedure as for removing and fitting

the rim half pistons and seals, instructions

6

Fit calipers and pads to vehicle

Assemble

rim-half

pistons

1 1 .

Coat a

new

fluid seal with Lockheed disc

brake lubricant. Ease the seal into the groove

in the bore using only the fingers and ensure

that

it

is properly seated. The fluid seal and

the groove are not the same in section

so

that

when

the seal is seated

it

feels proud to the

touch at the edge furthest away

from

the

mouth

of

me bore.

12.

Smear the appropriate piston with hydraulic

brake lubricant and insert

it

squarely into the

bore by hand only.

Do

not

tilt

the

piston

during insertion and leave approximately

-

mm

projecting from the bore.

13.

Coat a new wiper seal with hydraulic brake

lubricant and fit it to a new seal retainer.

19. Bleed the brake hydraulic system as

described later

in

this section.

28.

When the

foregoing

instructions have been

completed on both calipers, depress the brake

pedal

firmly

several times to locate the friction

pads.

21.

Fit the road wheels, remove the axle stands

and finally tighten the road wheel nuts, see

data.

22.

Road test the vehicle. remembering

that if

new

friction

pads have been

fitted

they are not

‘bedded

- in' and may take several hundred

miles before the brakes are at maximum

efficiency.

BRAKING

SYSTEM

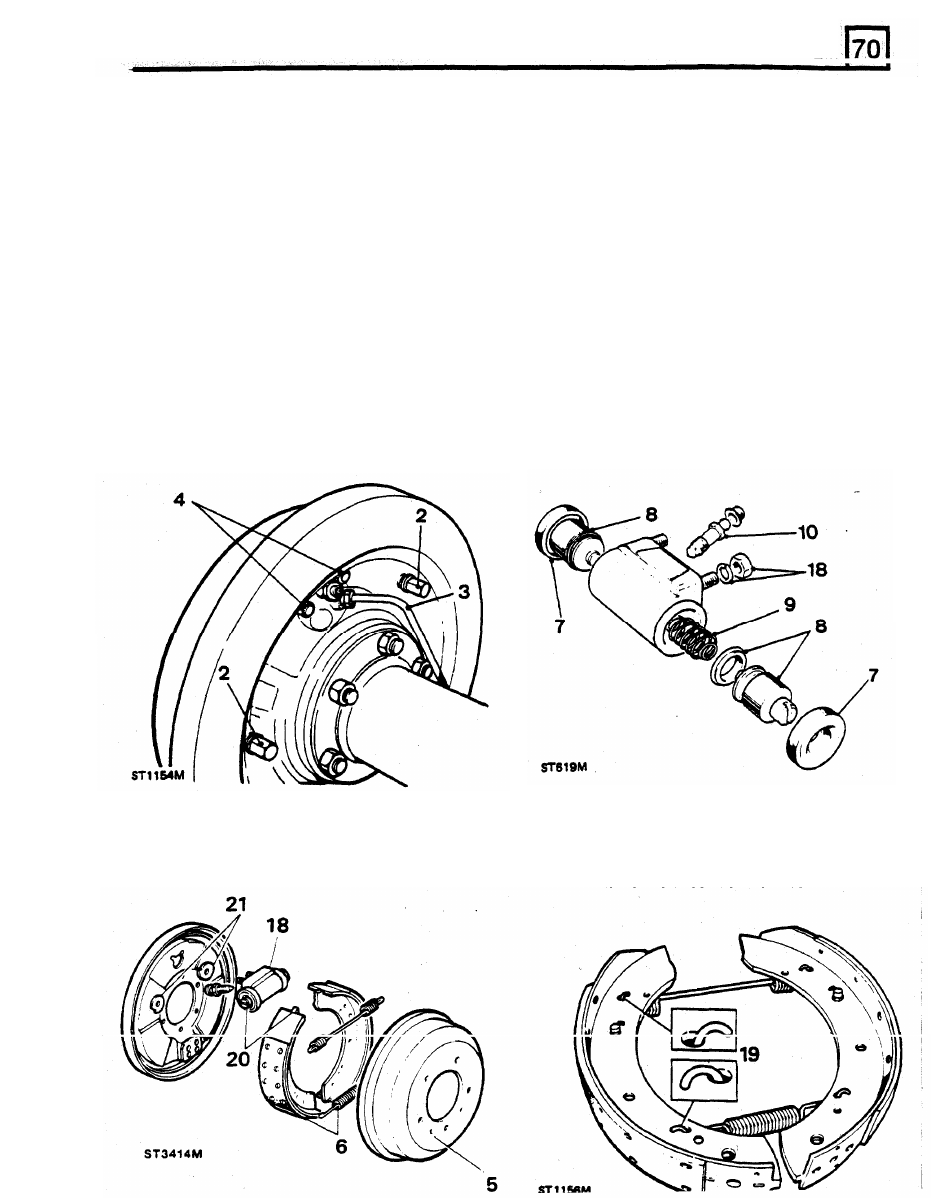

OVERHAUL REAR BRAKES - 110 models

DISMANTLING

7 . Remove the two dust covers.

WARNING:

Do

not use an air line to blow

dust

from the brake assemblies - asbestos dust from

brake linings can be a serious health

risk

if

11.

Clean components with Girling cleaning fluid

inhaled.

and allow to dry.

12.

Examine the cylinder

and pistons for

1.

Slacken the road wheel nuts, jack-up the

corrosion, scores and wear. Renew any

component that is not satisfactory or replace

complete cylinder assembly.

2.

Slacken the two brake shoe adjusters on the

13.

Fit new seals to the pistons noting that the

brake drum.

14. Lubricate the pistons with new clean Girling

3. Disconnect the brake fluid pipe to the wheel

ingress of dirt.

16. Fit the dust covers.

4. Remove the two retaining nuts and withdraw

the wheel cylinder

from

the back-plate.

Dismantle and overhaul wheel cylinder

8.

Withdraw the pistons and discard seals.

9.

Remove the spring.

10.

Remove the bleed screw.

vehicle, lower onto axle stands and remove

the road wheels.

rear of the back-plate to assist removal of

seal lip is towards the cylinder.

brake fluid.

cylinder and cover the pipe end to prevent

15.

17. Fit the bleed screw and tighten to 0,5 to

0,8

kgf

m.

Fit the spring between the

two

pistons.

Assembling rear brake

5. Remove the single retaining screw and

18.

Fit the wheel cylinder to the back-plate and

6

*

Assemble new brake shoe pull-off springs to

secure with the two nuts and spring washers.

relined brake s h o e s as illustrated.

withdraw the brake drum.

position of the pull-off springs.

Lever off the brake shoes whilst noting the

19.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст