Defender (1993+). Manual — part 84

BRAKING

SYSTEM

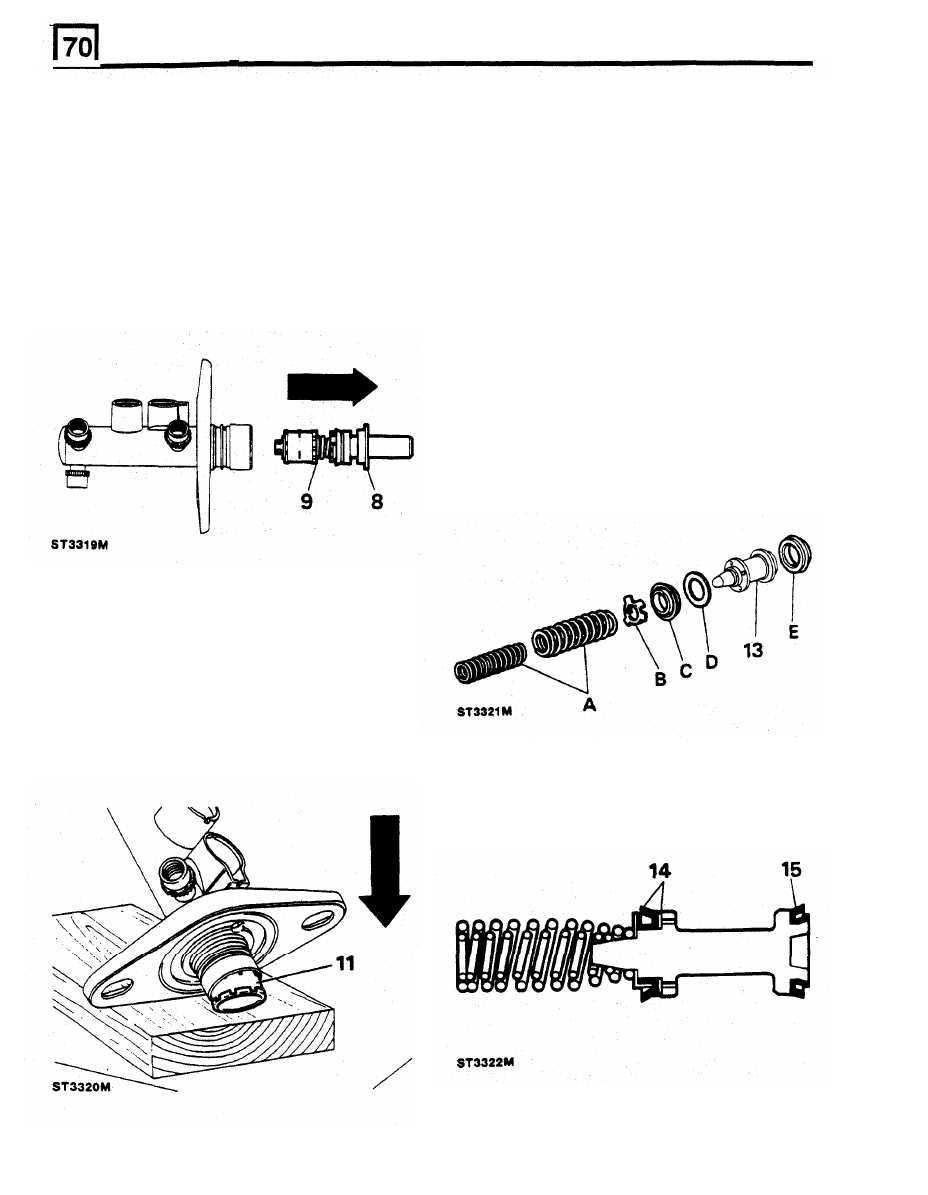

8. Remove the guide ring from the mouth of the

12.

Clean all parts with Girling cleaning fluid or

master cylinder which supports the primary

unused brake fluid and place the cleaned

plunger assembly and place to one side, this

parts on to a clean sheet of paper. Inspect the

component is not part

of

the master cylinder

cylinder bore and plungers for signs of

service kit and is to be refitted on assembly of

corrosion, ridges and score marks. Provided

the unit.

the working surfaces are in perfect condition,

9. Pull the primary plunger assembly

out

of the

new seals from a Girling Service repair kit

master cylinder.

may be used.

NOTE:

The primary plunger assembly cannot

be

broken down any further and is serviced as a

complete unit. Discard the assembly.

Renewing secondary plunger seals

secondary plunger and discard:

13.

Remove the following components from the

NOTE: A

small screwdriver with the end rounded

and polished is required to remove the

'L'

seal.

DO

NOT

damage the secondary plunger.

A.

Springs

B. Seal retainer

C.

Recuperating seal (primary cup)

D.

Washer

E. 'L'

seal

10.

The secondary plunger assembly will remain

at the bottom of the master cylinder bore, the

plunger can be easily expelled by tapping the

assembly on

a

piece

of

timber until the

plunger appears at the cylinder mouth,

carefully pull the plunger

out

of the master

cylinder.

11.

If

the swirl tube was not expelled at the same

time as the secondary plunger, repeat the

above operation

to

expel it from the bottom of

the master cylinder bore and discard.

14.

Coat the new seals in unused brake fluid and

firstly fit the 'L' seal to the plunger.

15.

Fit the washer followed by the recuperating

seal. Fit the seal retainer and springs, ensure

the springs are correctly seated.

BRAKING SYSTEM

RENEW BRAKE MASTER CYLINDER - Lucas

Fitting new master cylinder

Girling type 25,4 mm AS/AS

Removing

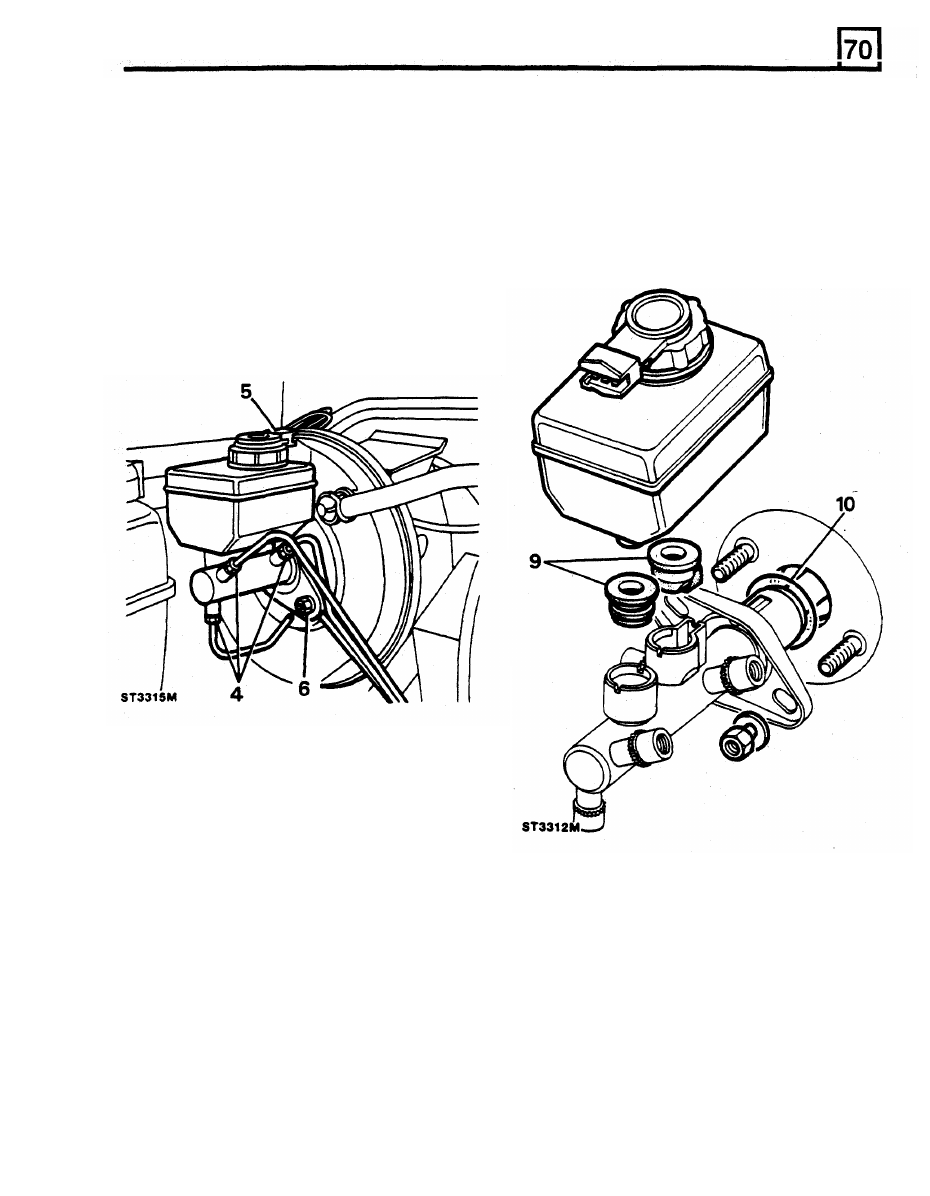

9.

Insert new reservoir seals in the master

cylinder ports and fit the reservoir by reversing

the removal method.

1.

Disconnect the battery.

10.

Ensure that the water ingress seal is in

2.

Place a container under the master cylinder to

position between master cylinder flange and

catch escaping brake fluid.

servo and fit master cylinder to servo and

3. Clean area round master cylinder ports.

secure with the two nuts tightening evenly

to

4.

Disconnect the pipes from master cylinder

the correct torque

11

to

17

Nm.

ports. Cover, not plug, the pipe ends to

prevent entry

of

dirt.

5.

Disconnect electrical leads from reservoir cap.

6.

Remove the two nuts securing master cylinder

to

servo and withdraw cylinder.

7 . Remove reservoir cap and drain fluid into

container for disposal.

WARNING:

Do

not use fluid drained or bled from

the system. Dispose

of

fluid as instructed in

SECTION

01

in a container marked

"Used

brake

fluid".

11.

Connect the brake pipes to the master

cylinder ports and tighten to 16 Nm.

12.

Fill the reservoir with the Correct grade

of

new

fluid, see

SECTION

09, taken

from a

sealed

container.

13. BIeed the brake system.

14.

Connect the battery and road test vehicle.

8 . The reservoir is a push fit in the master

cylinder and secured

by

seals. Carefully ease

the reservoir from the master cylinder by

rolling it from the seals, as illustrated in

Master Cylinder Overhaul. Note that the two

seals are different in size.

BRAKING SYSTEM

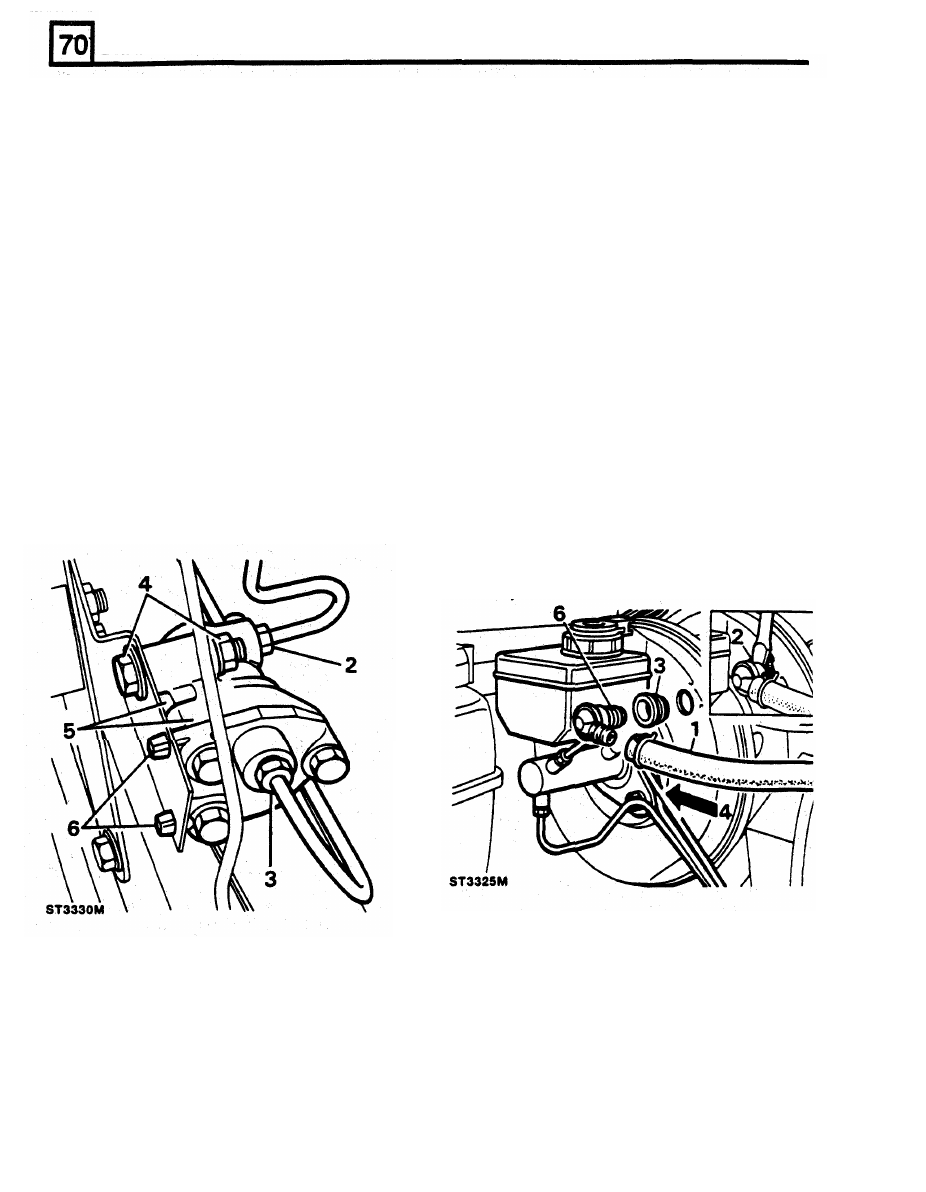

RENEW 'G' VALVE - where fitted

The

'G'

valve on both right-hand and left-hand drive

vehicles is situated on the right-hand side

of

the

chassis, within the engine compartment, attached to

1.

Disconnect the brake vacuum hose from the

a bracket, at the commencement of the front axle

servo non return valve.

arch.

2.

The valve is a push fit in the servo and to

remove it, carefully prise the valve out with

a

Removing

screwdriver blade between the valve and

grommet. Take care not

to

exert

too

much

1.

Disconnect the battery.

pressure on the vacuum chamber.

2.

Disconnect from the

'G'

valve the pipe union

3. Remove the rubber grommet but be careful

from

the master cylinder.

not to allow it t o fall into the vacuum chamber.

3.

Disconnect from the

'G'

valve the pipe union

4.

Check the valve for correct operation; it

to

the rear wheel cylinders.

should not be possible

to

pass air through into

4.

Remove the nut and bolt securing the 'G'

the servo in direction of arrow. Do not use

valve to the bracket.

compressed air.

5.

Release the valve from the bracket.

Fitting

6. Fit the

'G'

valve

to

the bracket locating the

lugs in the holes which are to ensure that the

valve is installed at the correct angle.

RENEW SERVO NON RETURN VALVE

Remove

NOTE: The illustration shows the latest valve

fitted to the

L.S.C.

80

servo but the principle of

removal and fitting is the same for earlier types.

Fitting new valve

5.

Fit the rubber grommet.

6.

Smear the ribs

of

the valve with Lucas Girling

grease

to

assist assembly, and push valve

fully home.

7. Connect the vacuum hose

to

the

valve.

8 . Road test vehicle.

7. Secure the valve to the bracket with the single

bolt and nut.

8. Connect the two pipes to the valve and

tighten to 16 Nm.

9. Bleed the brake hydraulic system and road

test the vehicle.

BRAKING SYSTEM

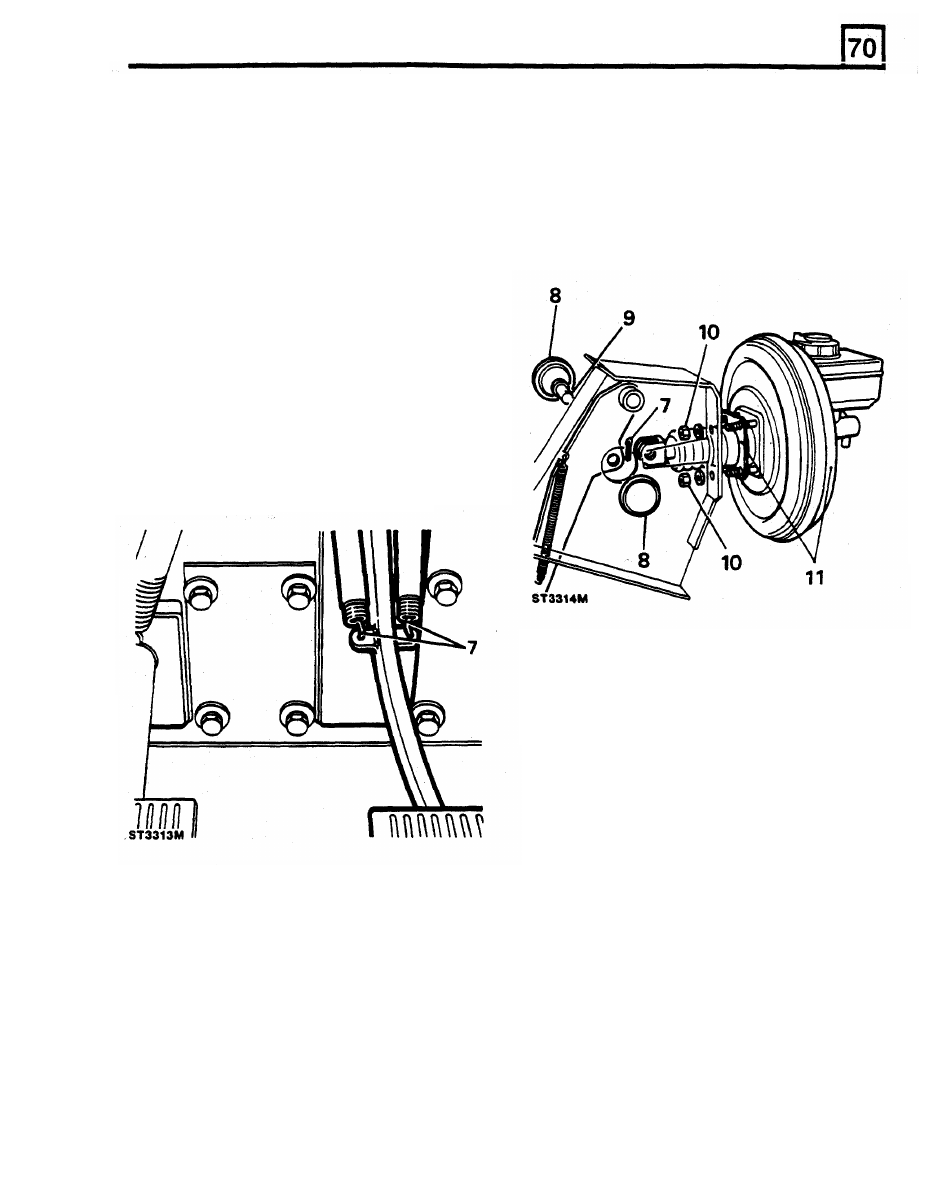

RENEW BRAKE SERVO

- L.S.C. 80

8.

Remove the

two

plugs from each side of the

pedal box.

Removing

9. Remove the split pin, washer and clevis pin

securing the servo push rod to the brake

1.

Disconnect the battery.

pedal.

2.

Disconnect the electrical leads from reservoir

10.

Remove the four nuts (two each side)

cap.

retaining the servo to the pedal box and

remove the servo and rubber washer from

NOTE: See operation for renewing the master

vehicle.

cylinder for the following instructions 3 to 6.

3.

Disconnect the vacuum hose from servo.

4.

Clean the master cylinder round the area of

the outlet ports.

5.

Remove the brake pipes from the master

cylinder and cover, not plug, each pipe as it is

released

to

prevent entry of dirt.

6. Remove the two nuts securing the master

cylinder to the servo and carefully remove the

master cylinder. Cover the ports to prevent

fluid

loss

and entry of dirt.

7. From inside the vehicle, release the two brake

pedal return springs.

Fitting servo

11.

Fit the servo and rubber washer to the pedal

box and secure with the four nuts. Tighten

evenly

to

the correct torque.

12. Connect the brake pedal to the servo with the

clevis pin and a new split pin.

A

washer was

fitted on earlier installations.

13.

Fit plugs to each side

of

pedal box.

14.

Attach the pedal return springs.

15.

Connect the vacuum hose to the servo non

return valve. Ensure that the hose is in good

condition.

16.

Fit the master cylinder to the servo and

secure with the

two

nuts. Tighten to the

correct torque.

17.

Fit the fluid pipes

to

the master cylinder and

tighten to 16 Nm.

18.

Top-up the reservoir with new fluid from a

sealed container and bleed the brake system.

19.

Connect the electrical leads to the reservoir

cap.

20.

Connect the battery and road test the vehicle.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст