Defender (1993+). Manual — part 20

RR751M

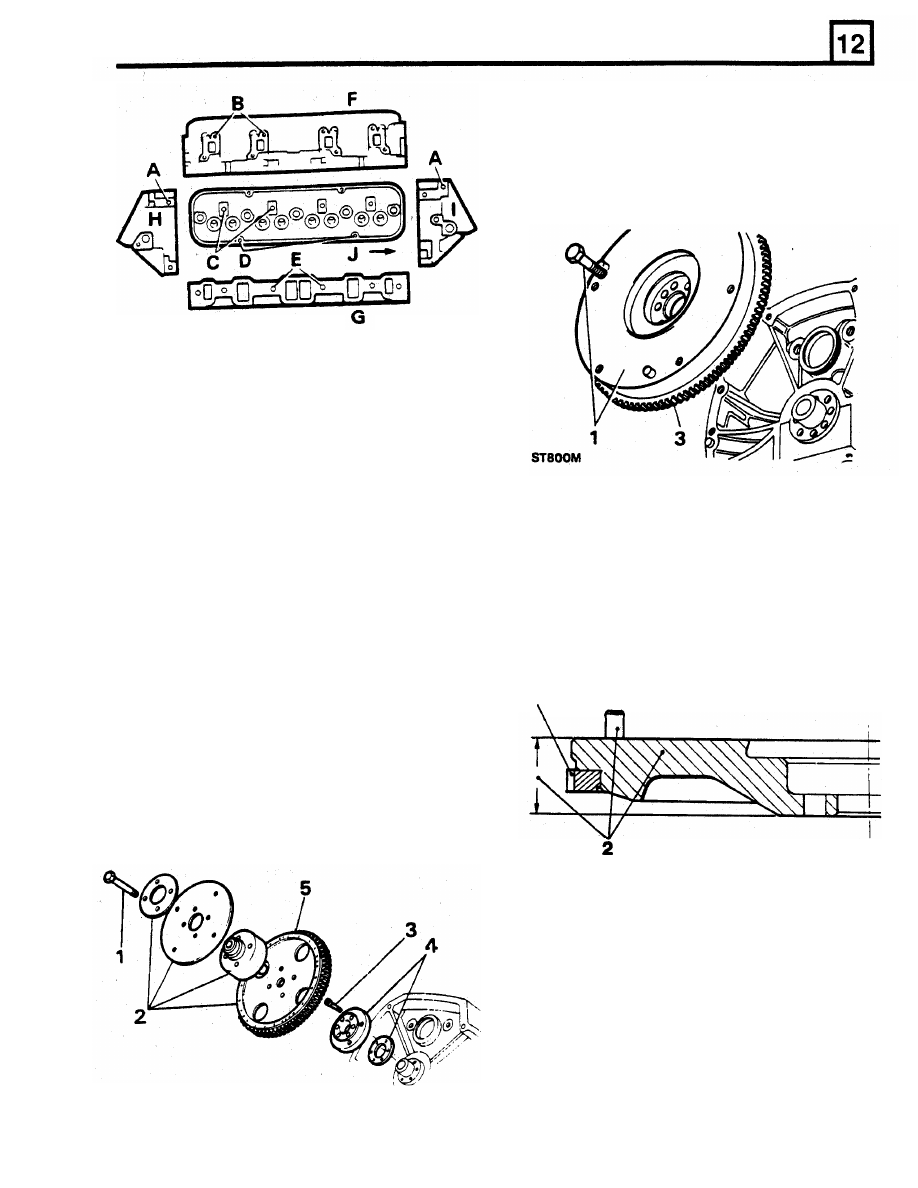

REMOVE AND OVERHAUL FLYWHEEL

1.

Remove retaining bolts and withdraw flywheel

from crankshaft.

NOTE: Right-hand cylinder head illustrated.

F

Exhaust manifold face

G

Intake manifold face

H

Front face

I

Rear face

J

Front of engine

REMOVE FLEXIBLE DRIVE PLATE AND RING

GEAR ASSEMBLY

2. Examine flywheel clutch face for cracks,

scores and overheating. The flywheel can be

NOTE:

Scribe

each

component

with

an

refaced provided m i n i m u m thickness does

identification line to enable re-assembly

in

not go below 39.93 mm

(1.572

in). Remove

original

position.

3. Examine ring gear for worn, chipped and

three dowels before machining.

1.

Remove four retaining bolts.

broken teeth. Renew as follows:

2.

Withdraw clamp ring, flexible drive plate, hub

aligner and ring gear assembly.

3. Remove six socket head bolts securing

crankshaft adaptor plate and shim to

crankshaft flange.

4.

Withdraw crankshaft adaptor plate and shim.

5.

Inspect ring gear assembly for distortion,

cracks, chipped or badly

worn teeth.

If

ring

gear

is in poor condition

fit

a new assembly.

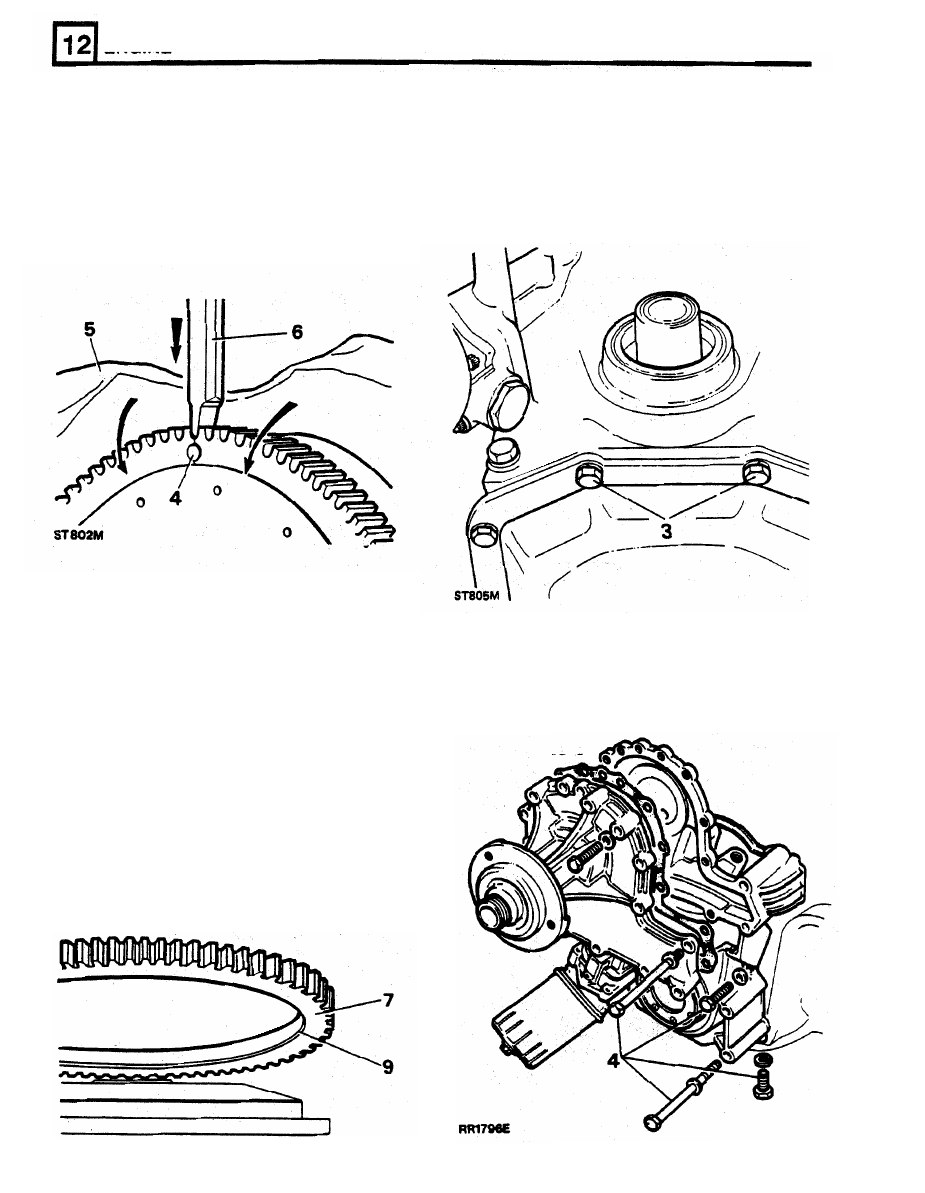

4.

Drill a

10

mm diameter hole axially between

roots of any tooth and inner diameter

of

starter ring sufficiently deep to weaken ring.

DO

NOT allow drill to enter flywheel.

RR1806E

ENGINE

3

ST803M

ENGINE

5.

Secure flywheel in a vice using

soft

jaws and

place a cloth over flywheel

to

protect operator

REMOVE TIMING GEAR

COVER

AND WATER

from flying fragments.

PUMP

WARNING: Take adequate precautions

1.

Place an oil drip-tray beneath timing cover,

against flying fragments when splitting

remove oil filter element.

ring gear.

2. Remove crankshaft pulley bolt and special

washer, withdraw pulley.

6.

Place a chisel as shown, strike it sharply

to

split starter ring gear.

7. Heat new ring gear uniformly to between

170

°

C and 175°C,

DO

NOT EXCEED higher

temperature.

8.

Place flywheel, clutch side down, on flat

3. Remove

two

bolts securing sump

to

bottom of

surface.

timing cover.

9.

Locate heated starter ring gear

in position on

4.

Remove timing cover bolts and withdraw

flywheel, with chamfered inner diameter

cover complete with

oil pump.

towards flywheel flange. If starter ring gear is

chamfered both sides, it can

be

fitted

either

way round.

10. Press starter ring gear

firmly against flange

until ring contracts sufficiently to grip flywheel.

11.

Allow flywheel to

cool

gradually.

DO

NOT

HASTEN cooling

in any way, distortion may

occur.

12.

Fit new clutch assembly location dowels to

flywheel.

ST804M

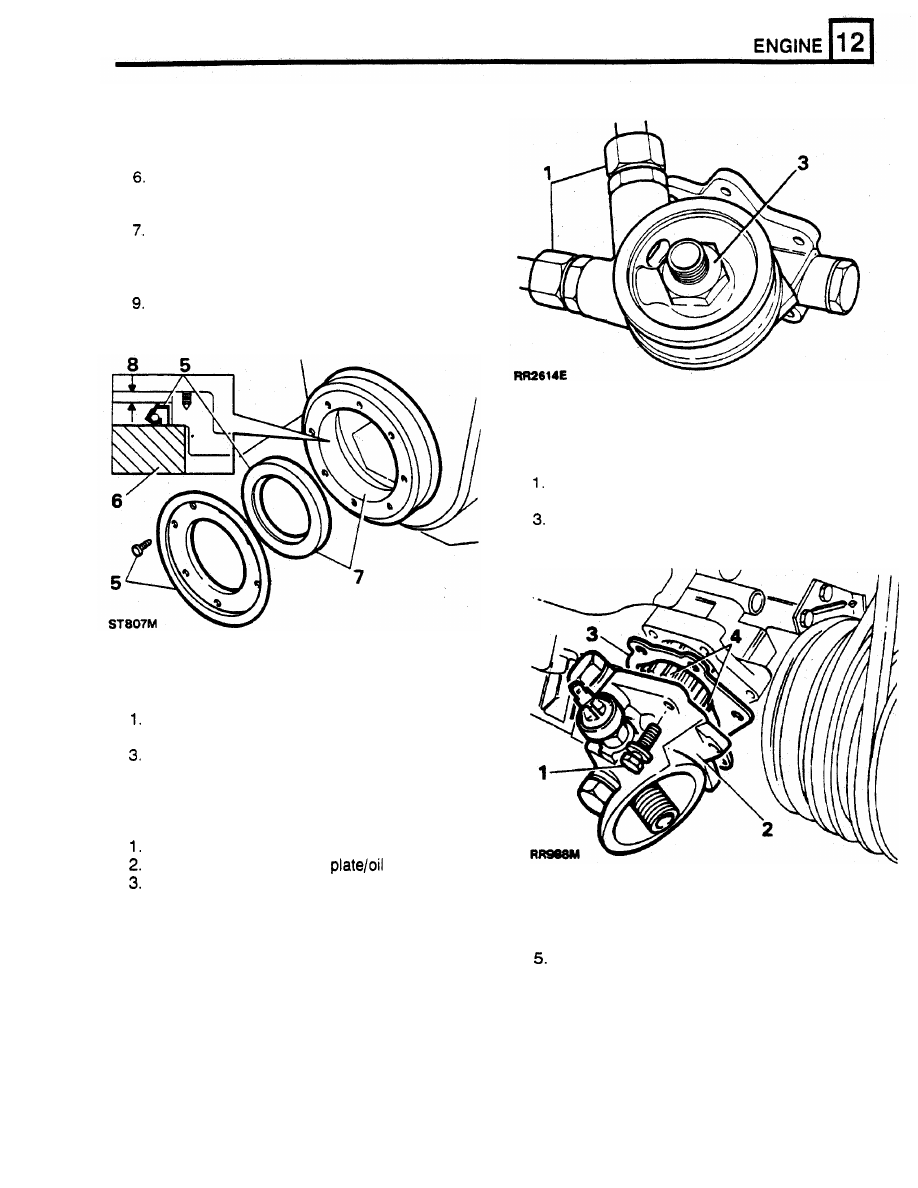

Fit new timing cover oil seal

5.

Remove seven drive screws and withdraw

mud shield and oil seal.

Position gear cover with front face uppermost

and underside supported across oil seal

housing bore on a suitable wooden block.

Enter

oil

seal, lip side leading, into housing

bore.

8.

Press in oil seal until plain face

is

approximately

1,5

mm below gear cover face.

Fit mud shield and securing screws.

REMOVE AND OVERHAUL OIL PUMP

Remove bolts from oil pump cover.

2. Withdraw oil pump cover.

Lift

off cover and remove gasket.

4.

Withdraw oil pump gears.

DISTRIBUTOR REMOVE

Release single nut securing distributor clamp.

2. Remove clamp, withdraw distributor.

If necessary overhaul distributor.

REMOVE ENGINE

OIL

COOLER ADAPTOR

PLATE

Remove both oil cooler pipes.

Mark position

of

adaptor

pump cover.

Remove centre fixing and withdraw adaptor

plate.

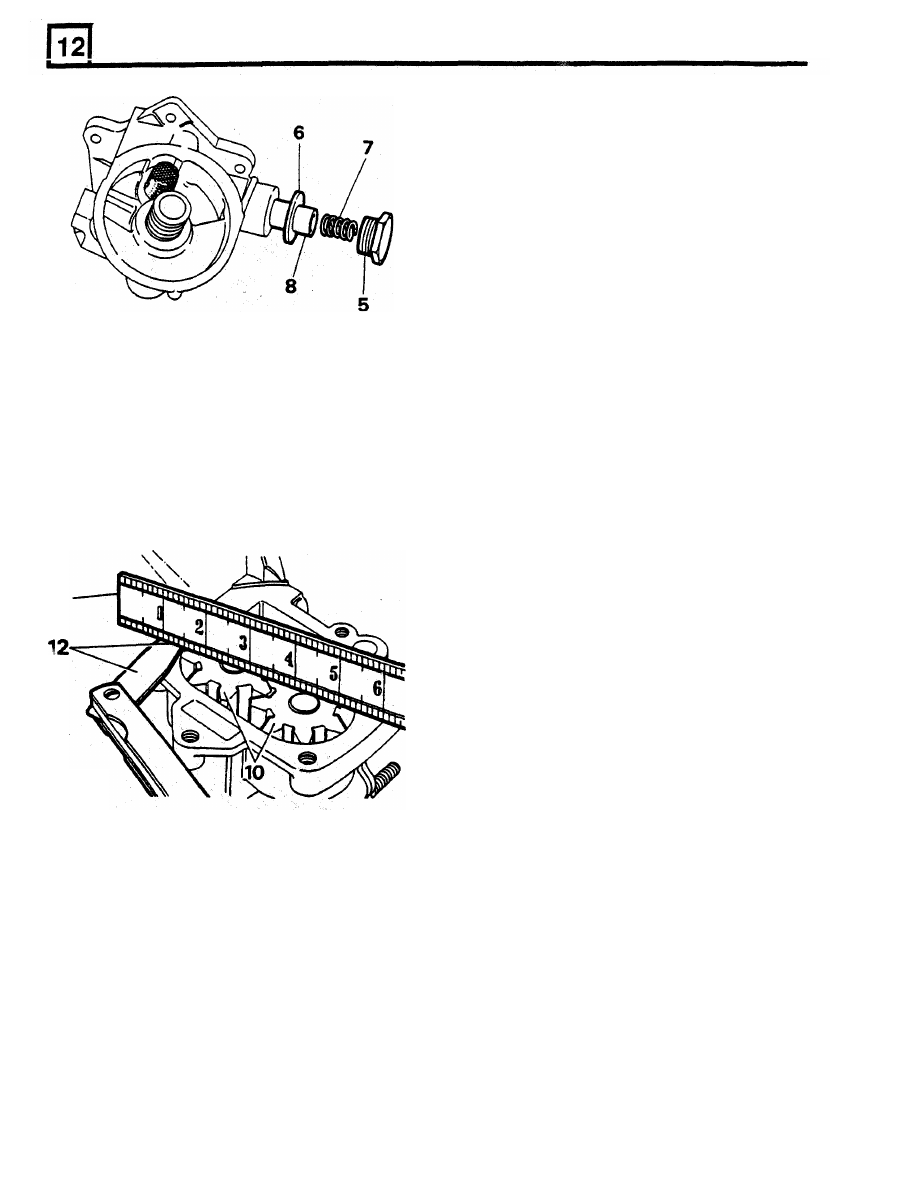

Dismantle pump

Refit

Unscrew plug from pressure relief valve.

4.

Reverse the removal procedure, lining

up

the

6.

Remove sealing washer from plug.

location marks to ensure pipe runs are

7.

Withdraw spnng from relief valve.

correct. Ensure the pipes and centre fixing are

tightened to the specified torque.

8.

Withdraw pressure relief valve.

ENGINE

ST809M

11

Assemble pump

17. Insert relief valve spring.

18.

Locate sealing washer on relief valve plug.

19.

Fit relief valve plug, tighten

to

40

-

47 Nm.

20. Fully pack oil pump gear housing with

Petroleum Jelly.

No other grease is suitable.

21. Fit oil pump gears ensuring that Petroleum

Jelly

is

forced into every cavity between teeth

of gears.

IMPORTANT: Unless pump is fully packed

with Petroleum Jelly

it

may not prime itself

when engine is started.

22. Place new gasket on oil pump cover.

23. Locate oil pump cover

in position.

24. Fit special fixing bolts and tighten to 13 Nm.

Examine pump

9.

Check

oil pump gears for wear/scoring.

10. Fit oil pump gears and shaft into front cover.

11. Place a straight edge across gears.

12. Check clearance between straight edge and

front cover.

lf

less than

0.05

mm, check front

cover gear recess for wear.

13.

Check

oil

pressure

relief

valve

for

wear/scoring.

14. Check sides of relief valve

spring for wear or

signs of collapse.

15. Clean wire screen filter for relief valve.

16.

Check relief valve is an easy slide

fit

with no

perceptible side movement in its bore.

ST810M

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст