Defender (1993+). Manual — part 18

ENGINE

ENGINE REMOVAL

NOTE: Release bolts securing compressor

mounting bracket to engine and remove bracket

Remove

to enable temporary lifting eye ETC

5964

to be

fitted.

Secure lifting eye to mounting bracket

1.

Park vehicle on level ground and apply park

fixing points with suitable bolts of equivalent

brake.

size, pitch and thread. Leave lifting eye attached

2.

Depressurize fuel system, see Depressurise

until engine is reinstalled in vehicle.

fuel system.

3.

Remove bonnet, see CHASSIS AND BODY.

15.

Place drain tray underneath vehicle.

4. Disconnect battery.

16. Disconnect hose from reservoir

to

power

5.

Remove radiator/oil coolers.

steering pump. Secure hose end above level

6.

Place an absorbent cloth around fuel feed

of fluid reservoir

to

avoid unnecessary

loss of

hose at fuel rail and release compression nut.

fluid.

Remove feed hose from rail, seal end of pipes

17.

Disconnect power steering pump

to

power

with masking tape

to

prevent ingress of dirt.

steering box hose. Seal hose and pump

7.

Release fuel return hose clamp and remove

openings with masking tape

to

prevent ingress

hose from pressure regulator, seal both

of dirt. Wipe away any fluid spillage from

openings with masking tape

to

prevent ingress

chassis or steering box.

of dirt.

18.

Disconnect fuel temperature and coolant

8.

Remove vacuum hose from rear of regulator.

9.

Disconnect throttle cable from bracket.

Disconnect leads from coil.

temperature sensor multi-plugs.

10. Remove ram housing.

Identify

each

injector

multi-plug

for

11. Remove air flow sensor.

re-assembly and disconnect plugs from

12.

Remove air cleaner assembly.

injectors.

13.

Remove alternator, See alternator.

21.

Manoeuvre harness from behind fuel rails and

14.

Release air conditioning compressor from its

PIace to one side clear of engine assembly.

mounting and lay to one side. DO NOT

22.

Remove

two

clamps securing gearbox oil

discharge air conditioning system.

23.

Remove engine mounting fixings on both

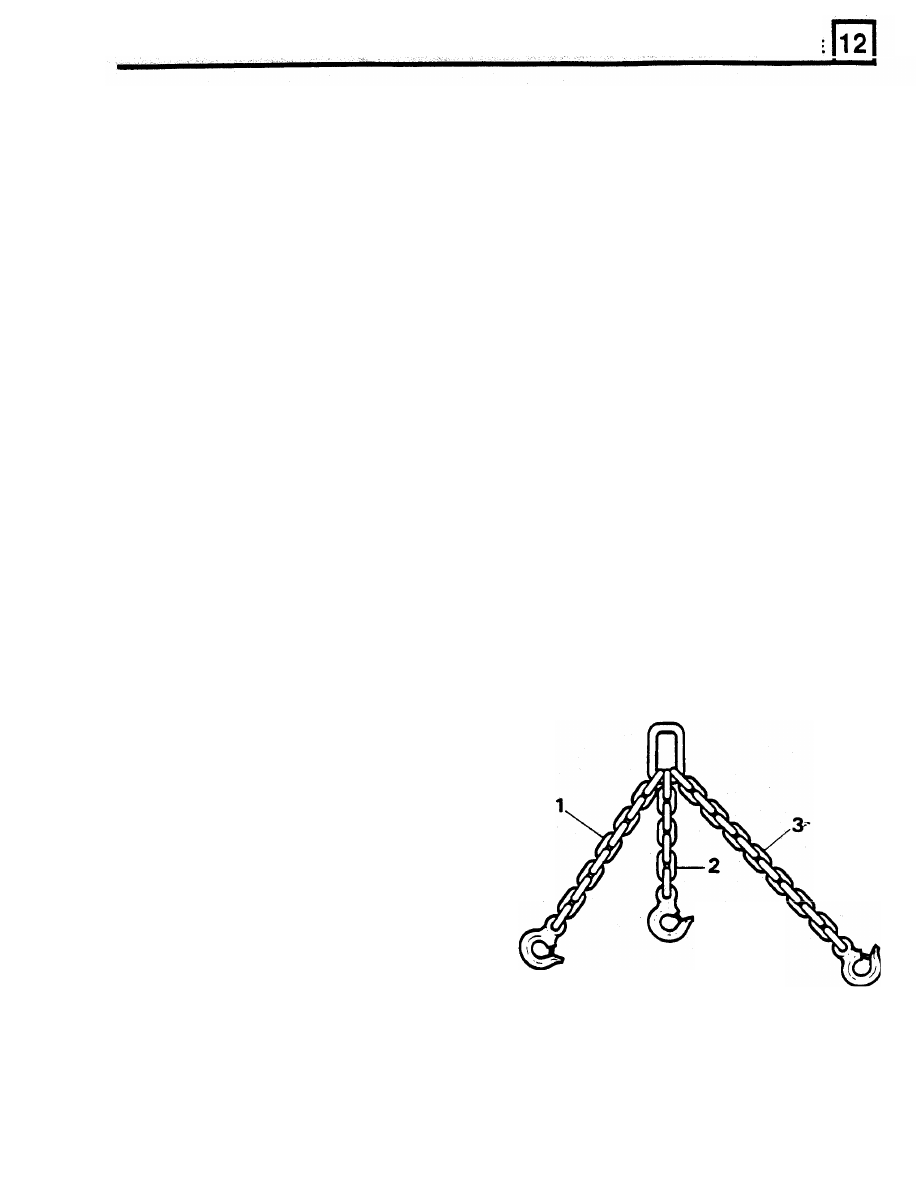

24. Fit lifting chains to engine lifting eyes as

cooler pipes

to

engine block.

sides of cylinder block.

shown in illustration

RR1780E.

RRl780E

1.

L/H

Front chain 356mm total overall length.

2.

R/H Front chain 330mm

total

overall length.

3.

R/H Rear chain 457mm total overall length

ENGINE

NOTE: All chain dimensions are measured from

end of lifting hook to end of last link i n chain.

Refit

43. Fit lifting chains

to

engine. Raise engine using

25. Fit chain lifting eye to a suitable engine hoist.

hoist.

Raise hoist high enough to enable engine

44. Lower engine into engine compartment.

mountings to be removed, and withdraw

Ensure all components are clear of engine

rubber mountings.

assembly.

26. Lower hoist until engine rests securely on

45. Lower engine into position. Locate primary

engine mounting brackets. Remove lifting

pinion into clutch. Engage bell housing

chains and hoist.

dowels.

27. Disconnect two heater hoses located on top of

right hand rocker cover.

47. Remove jack and lower hoist until engine

28. Remove ground strap from rear of left hand

cylinder head. DO NOT remove from retaining

48. Fit top two bell housing securing bolts.

clip.

Tighten to 40 Nm.

29. Remove all electrical harnesses from retaining

clips at rear of engine.

49. Fit remaining bell housing to cylinder block

30. Remove transmission breather pipes from

bolts, and tighten to 40 Nm.

retaining clip on rear lifting eye.

50. Fit new gasket and refit bottom cover, tighten

31. Remove top two bolts securing bell housing to

bolts to 9 Nm.

cylinder block.

51. Fit new exhaust flange gaskets, fit exhaust to

32. Raise front of vehicle, lower vehicle on to axle

manifold.

stands.

52. Refit all harnesses, ground straps breather

33. Remove bell housing bottom cover. Remove

pipes and hoses at rear of engine.

gasket from bell housing face.

53. Raise engine and refit engine mounting

34. Remove nuts securing exhaust downpipes to

rubbers, tighten nuts to 20 Nm.

manifolds, remove heat shield from right hand

54. Remove temporary lifting eye ETC 5964 and

side downpipe.

reverse instructions 1 to 23, ensuring that all

35. Remove electrical leads from starter motor

electrical plugs and harnesses are fitted in

solenoid. Disconnect multi-plug from oil level

correct locations.

sensor on side of sump, if fitted.

36. Remove remaining bell housing to cylinder

block bolts.

37. Remove starter motor ground strap from

chassis.

38. Remove stands and lower vehicle.

39. Position hydraulic trolley jack under bell

housing to support gearbox when engine and

gearbox are separated.

40. Fit lifting chains to engine. Carefully raise

hoist a little, ease engine and gearbox apart,

steady engine on hoist.

41. Ensure no components remain that will

Prevent engine being removed.

42. S l o w l y raise engine clear of engine

compartment. Move engine away from vehicle

and place on a suitable engine stand.

46. Fit two bolts and partially tighten.

rests securely

on engine mounting brackets.

ENGINE

ENGINE

-

DISMANTLE AND OVERHAUL

Remove engine from vehicle, see engine removal

and clean exterior. For safe and efficient working

secure engine to an approved engine stand. Drain

engine oil into a suitable container.

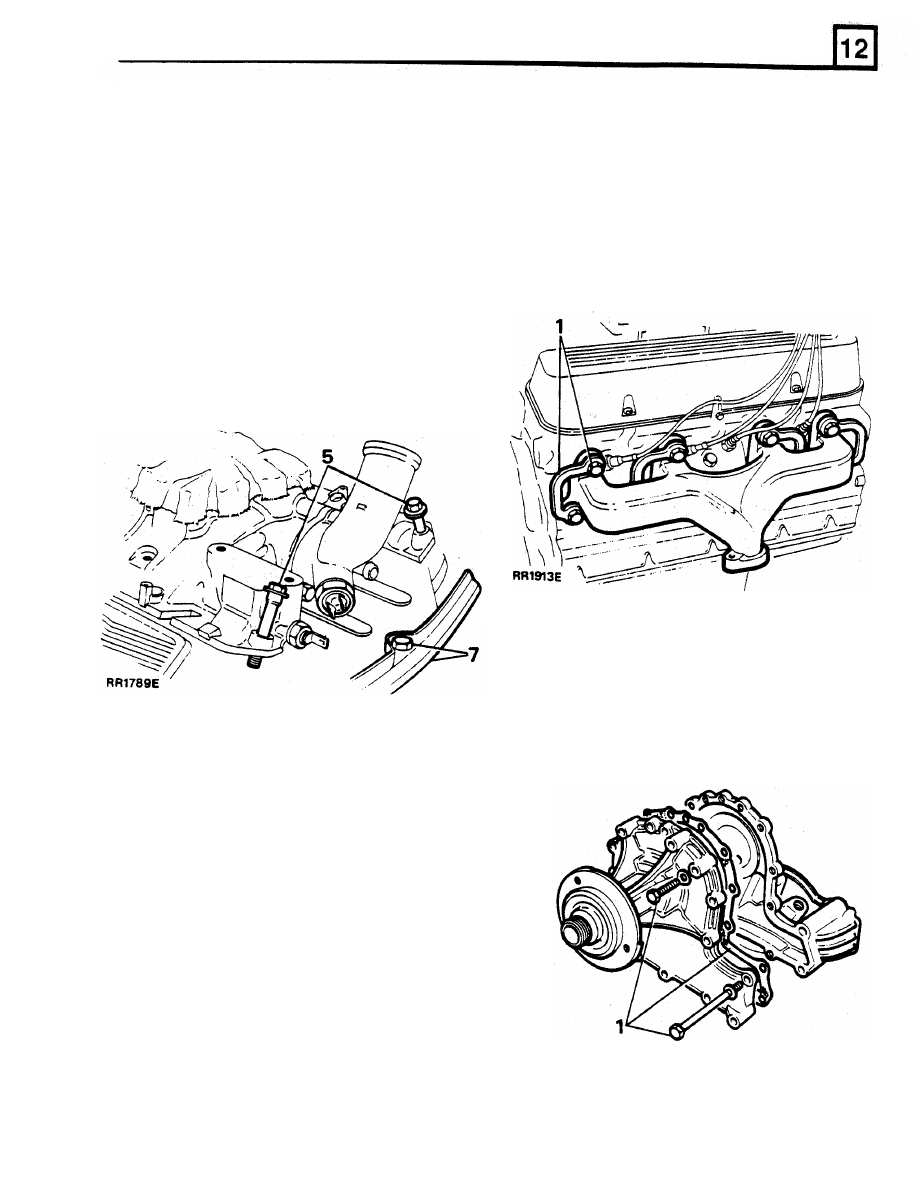

Remove intake manifold

6.

Lift intake manifold from cylinder heads.

7. Remove surplus coolant, remove gasket

clamp bolts, remove clamps.

8. Lift off gasket and seals.

Remove exhaust manifolds

1.

Bend back lock tabs, remove eight bolts

securing

each

manifold, and

withdraw

1.

Release hose clamp at water pump

manifolds and gaskets.

2. Detach retaining clips from top of injectors.

3. Remove four bolts securing fuel rail to

manifold.

4.

Withdraw fuel rail and injectors.

5.

Evenly loosen and remove twelve bolts

securing intake manifold to cylinder heads.

Remove water pump

1.

Remove fifteen bolts, pump and joint washer.

NOTE: The water pump is not serviceable. II

n

event

of failure, fit a new water pump assembly.

RR1794E

ENGINE

REMOVE AND OVERHAUL

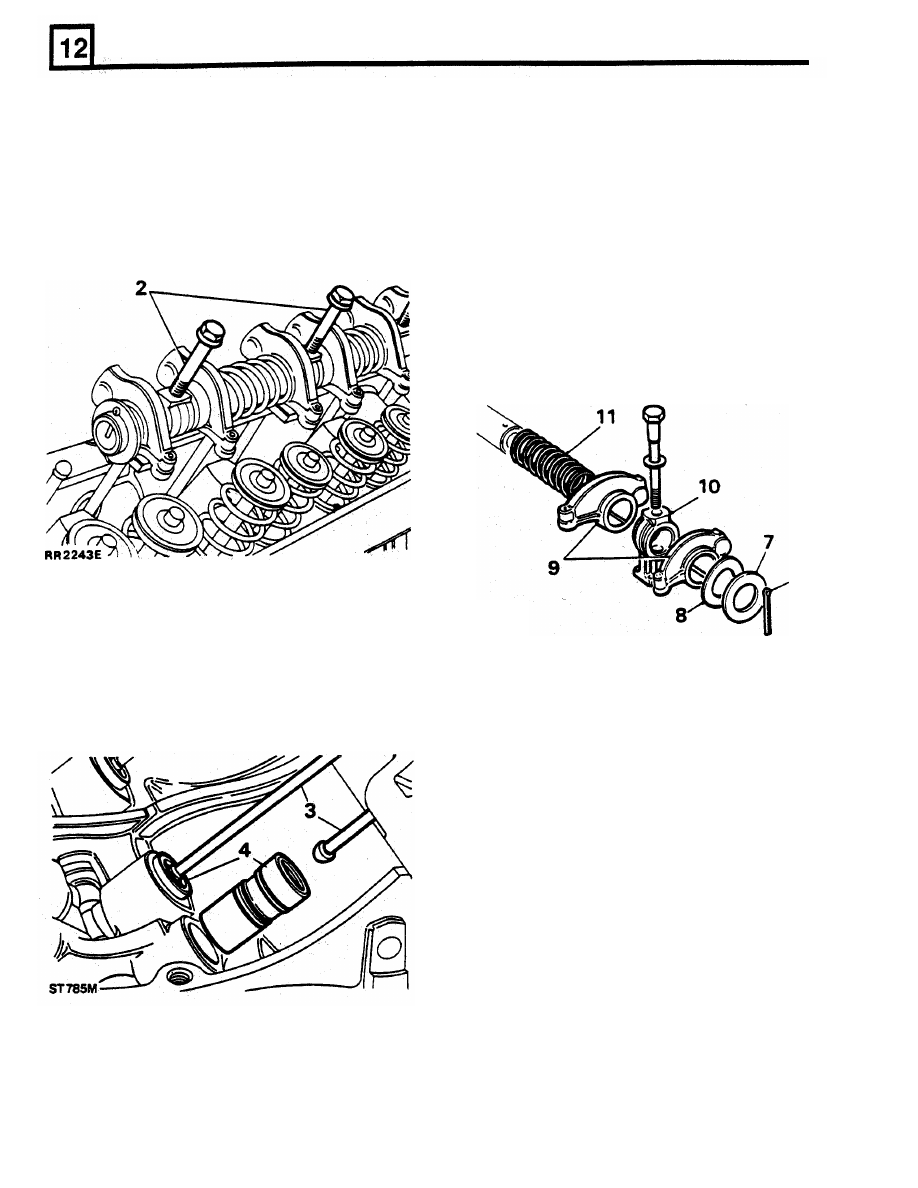

ROCKER SHAFTS

Dismantle rocker shafts

AND VALVE GEAR

5.

Remove split pin from one end

of rocker shaft.

1. Remove spark plug leads

from spark plugs

6. Withdraw following components and retain in

and retaining clips. Release four screws and

correct sequence for re-assembly:

lift

off rocker covers.

7.

A plain washer.

2. Remove four rocker shaft retaining

bolts

and

8.

A wave washer.

lift

off assembly.

9.

Rocker arms.

10. Brackets.

11. Springs.

12. Examine each component for wear, in

particular rockers and shafts. Discard weak or

broken springs.

3. Withdraw pushrods and retain in sequence

removed.

4. Remove hydraulic tappets. Retain with their

respective pushrods.

If

a tappet cannot be

removed leave in position until camshaft is

removed.

Inspect tappets and

pushrods

13. Hydraulic tappet: inspect inner and outer

surfaces of body for blow holes and scoring.

Fit a new hydraulic tappet

if

body is roughly

scored or grooved,

or

has a blow hole

extending through wall in a position to permit

oil leakage from lower chamber.

14. The prominent wear pattern

just above lower

end of body should not

be considered a

defect unless it is definitely grooved or scored.

It is caused by side thrust

of

cam against

body while tappet

I

S

moving vertically in its

bore.

15. Inspect cam contact surface of tappets. Fit

new tappets

if

surface

is

excessively worn

or

damaged.

16. A hydraulic tappet body that has been rotating

will have a round wear pattern. A non-rotatlng

tappet body will have a square wear pattern

with a very slight depression near centre.

5

ST787M

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст