Defender (1993+). Manual — part 99

ELECTRICAL EQUIPMENT

TEST 7 :

Visual and

HT Cable Checks

Examine:

Should be:

1.

Distributor Cover

Clean, dry, no tracking

2.

Coil Top

Clean, dry, no tracking

3.

HT Cable Insulation

Must not be cracked

4.

HT Cable Continuity

Must not be open

5.

Sparking Plugs

Clean, dry, and set to

marks

marks

chafed

or

perished

circuit

correct gap.

NOTE:

1.

Reluctor

Must not foul pick-up

2.

Rotor and Flash

Must

not be cracked

or leads

or

show signs

of

tracking marks.

8

REISSUED:

FEB

1993

ELECTRICAL EQUIPMENT

ALTERNATOR - TYPE A127

BATTERY

Remove and refit

Removal

WARNING: During battery removal or before

carrying out any repairs or maintenance to

1.

Disconnect battery ground lead.

electrical components always disconnect the

2 .

Disconnect the electrical leads from the

battery negative lead first. If the positive lead is

alternator.

disconnected with the negative lead in place,

3.

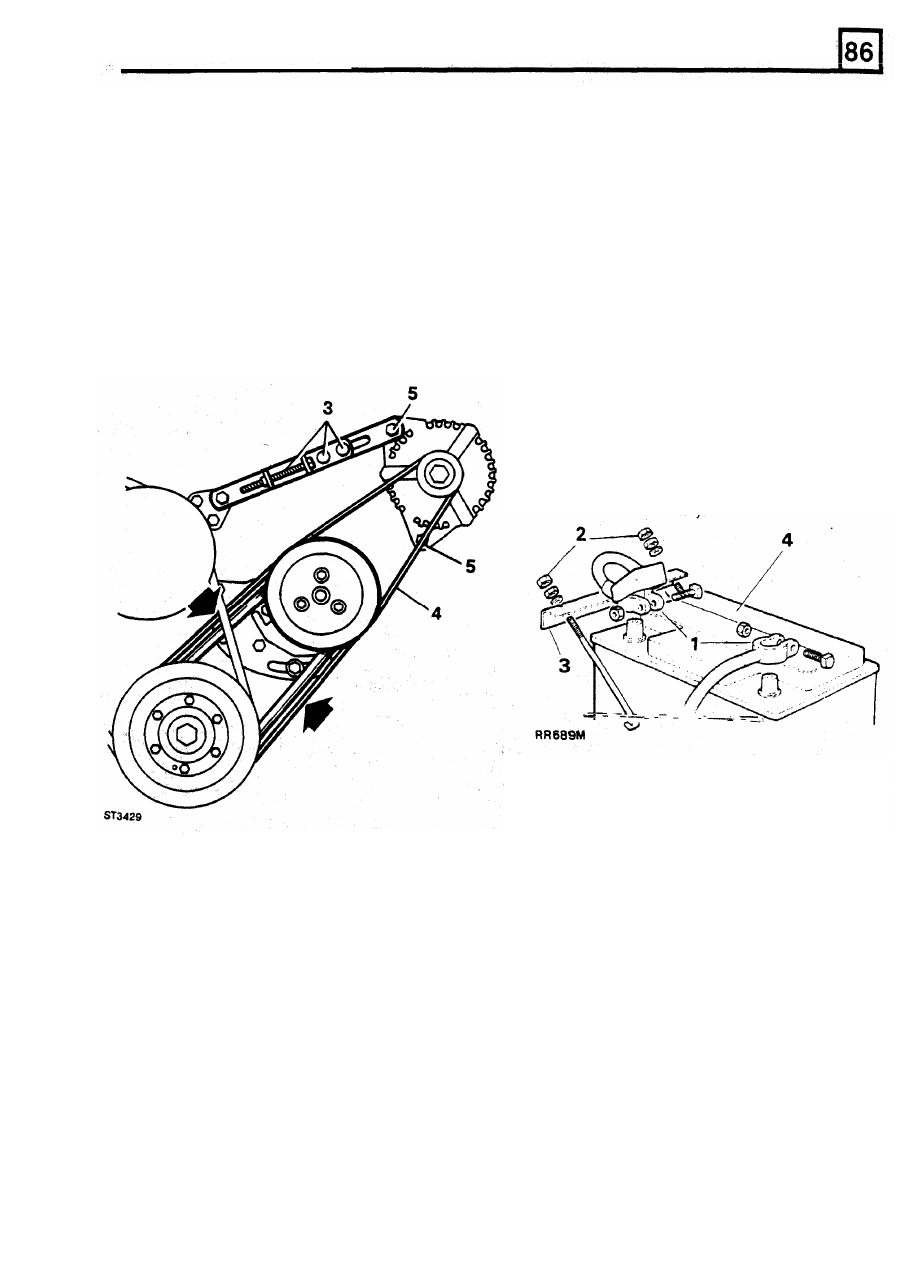

Slacken the two tensioner nuts and rotate the

accidental contact of the wrench to any

tensioner screw anti-clockwise to slacken the

grounded metal part could cause a severe spark,

belt tension.

possibly resulting in personal injury. Upon

4.

Remove the belt.

installation of the battery the positive lead

5.

Remove the two securing bolts and withdraw

the alternator from the engine.

Remove and refit

should

be

connected first.

Removing

1.

Disconnect battery ground lead followed by

2. Release the four nuts securing the battery

3.

Remove the bracket from the studs.

4. Remove the battery

the disconnection of the positive lead.

bracket in position.

Refitting

5.

Reverse the removal procedure.

Refit

NOTE: Coat the battery clamps

and

terminals

with petroleum jelly before

refitting.

6. Position n the alternator on

the

engine and fit

7 .

Adjust

the

drive

belt

tension,

see

8.

Connect the electrical leads

to

the alternator

the securing bolts.

MAINTENANCE.

and connect the battery.

REISSUED:

FEB

1993

9

ELECTRICAL EQUIPMENT

STARTER

MOTOR - Type

M78R

Overhaul

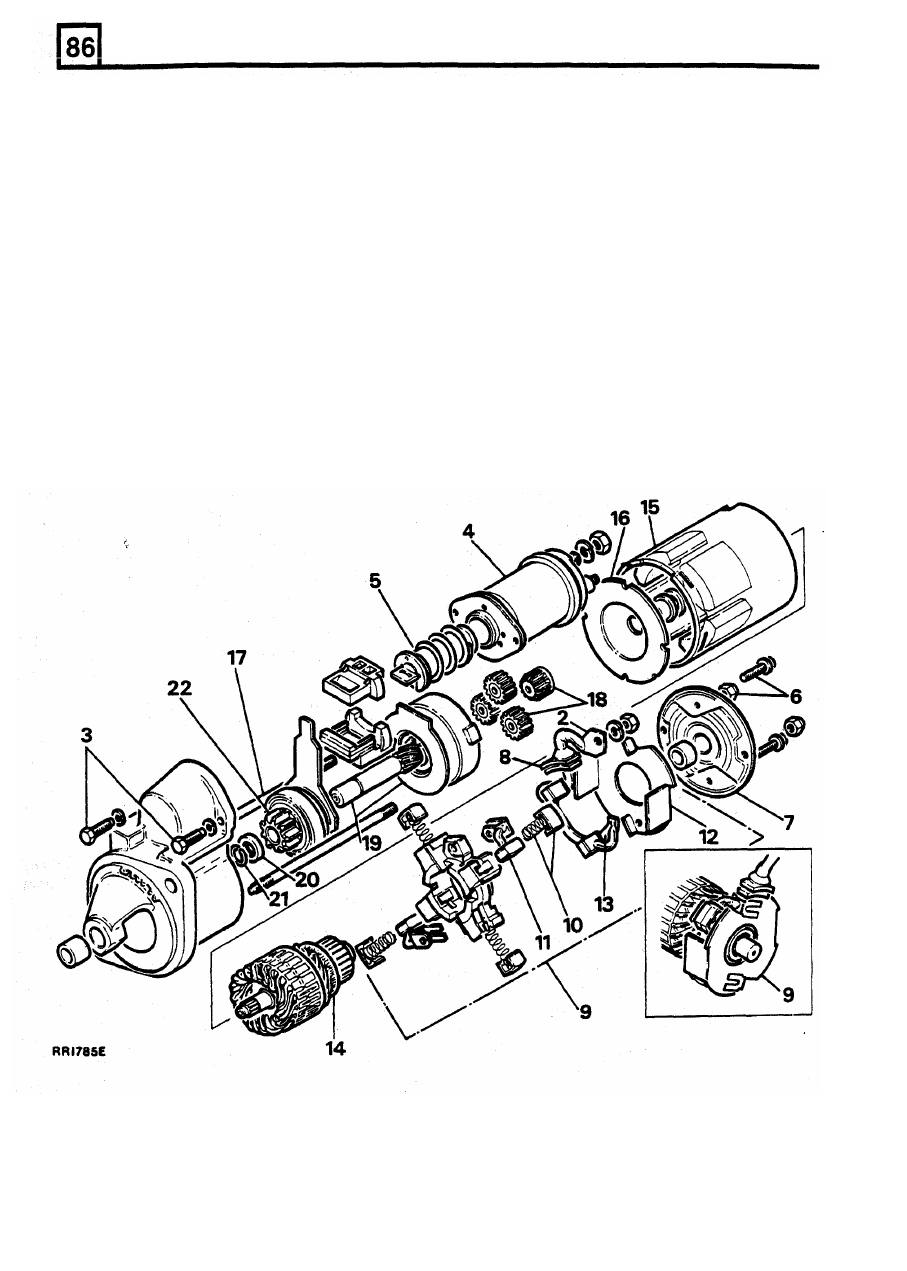

Dismantling

1.

Remove the starter motor.

13. Withdraw the brushes and bus bar.

2. Remove the braid between the starter and the

solenoid terminal.

15.

Remove the yoke.

3. Remove the solenoid fixing screws.

16. Remove the intermediate bracket.

4.

Withdraw the solenoid body.

17. Loosen and remove the through bolts from the

5.

Lift and remove the solenoid plunger.

drive end bracket.

6.

Remove two nuts and two screws from the

commutator end bracket.

7.

Remove the commutator end bracket.

8. Remove the grommet from the yoke.

9.

Lift the brushbox assembly clear of the

jump ring back towards the drive.

armature.

21.

Prise the jump ring from its locating groove.

14. Remove the armature from the yoke.

18. Remove the sun and planet gears.

19. Push out the drive shaft sprocket assembly

from the drive end bracket.

20.

Carefully tap the thrust collar

from

over the

10. Remove the brush springs.

22.

Remove the drive assembly from the drive

11. Unclip and remove the earth brushes.

shaft.

12.

Remove the insulating plate.

10

REISSUED: FEB 1993

ELECTRICAL EQUIPMENT

Inspecting

Solenoid

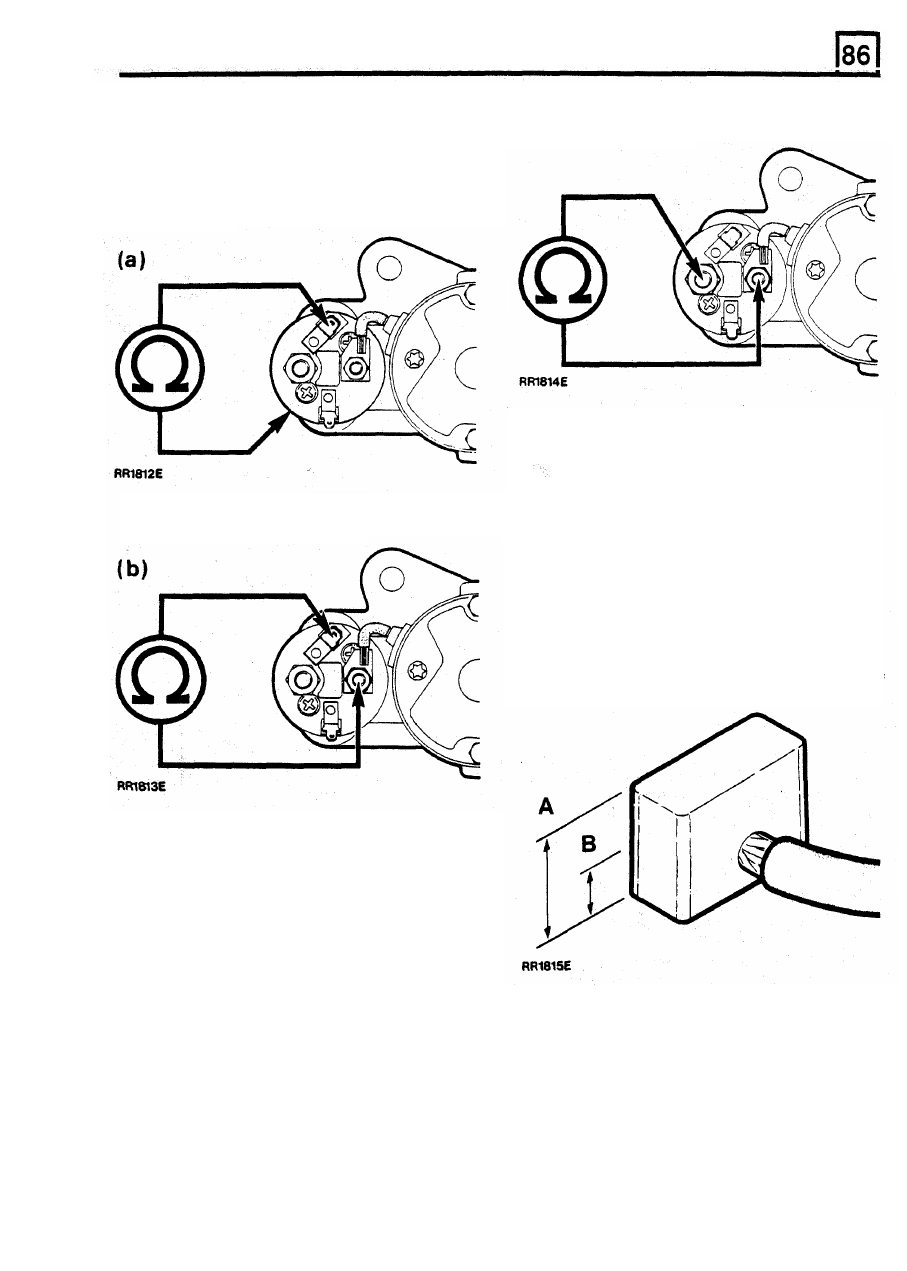

Solenoid plunger removed, ohmmeter should read

infinity.

23. Check the continuity and resistance value

of

windings by connecting an ohmmeter as

shown.

Solenoid plunger operated by hand, ohmmeter

should read zero.

If

test results are unsatisfactory, replace the

solenoid.

If

results are correct proceed to 25.

(a) Resistance value should be: 1.074 ± 0.035

ohms

25. Check operation of spring for freedom of

movement.

Brush gear

26. Check brush springs and ensure that the

brushes move freely in their holders.

Clean the brushes with a petrol moistened cloth, if

required.

(b) Resistance value should be: 0.298

±

0.015

ohms

If

test results are unsatisfactory replace the solenoid.

If

results are correct proceed to 24.

24. Check the contacts by

connecting an

ohmmeter as shown.

Brush length new, Dimension A is 9 mm.

Minimum brush length, Dimension B is 3.5

mm.

REISSUED: FEB

1993

11

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст