Defender (1993+). Manual — part 75

STEERING

Torque peak check

NOTE:

That the addition or subtraction of

a

0,07

The purpose of this check is

to

determine the point

mm shim will move the torque peak area by

at

which the rolling resistance is the greatest when

approximately one quarter of a turn of the input

the steering is turned from lock to lock. This

shaft.

resistance, which must be equally distributed, should

be when the sector shaft roller is positioned along

Shim washers are available from Land Rover

the centre portion of the worm approximately two

Parts and Equipment

in

the following sizes: 0,03

revolutions of the input shaft from either the left

or

mm, 0,07 mm, 0,12 mm and 0,24 mm.

right hand lock.

3. Having added or subtracted shims as

The correct position of the resistance depends upon

necessary, reassemble the steering box and

the amount of shimming behind the input shaft inner

check that the torque peak position

IS

now

bearing cup. Provided that the original shim pack

correct.

has been refitted, the torque peak position should be

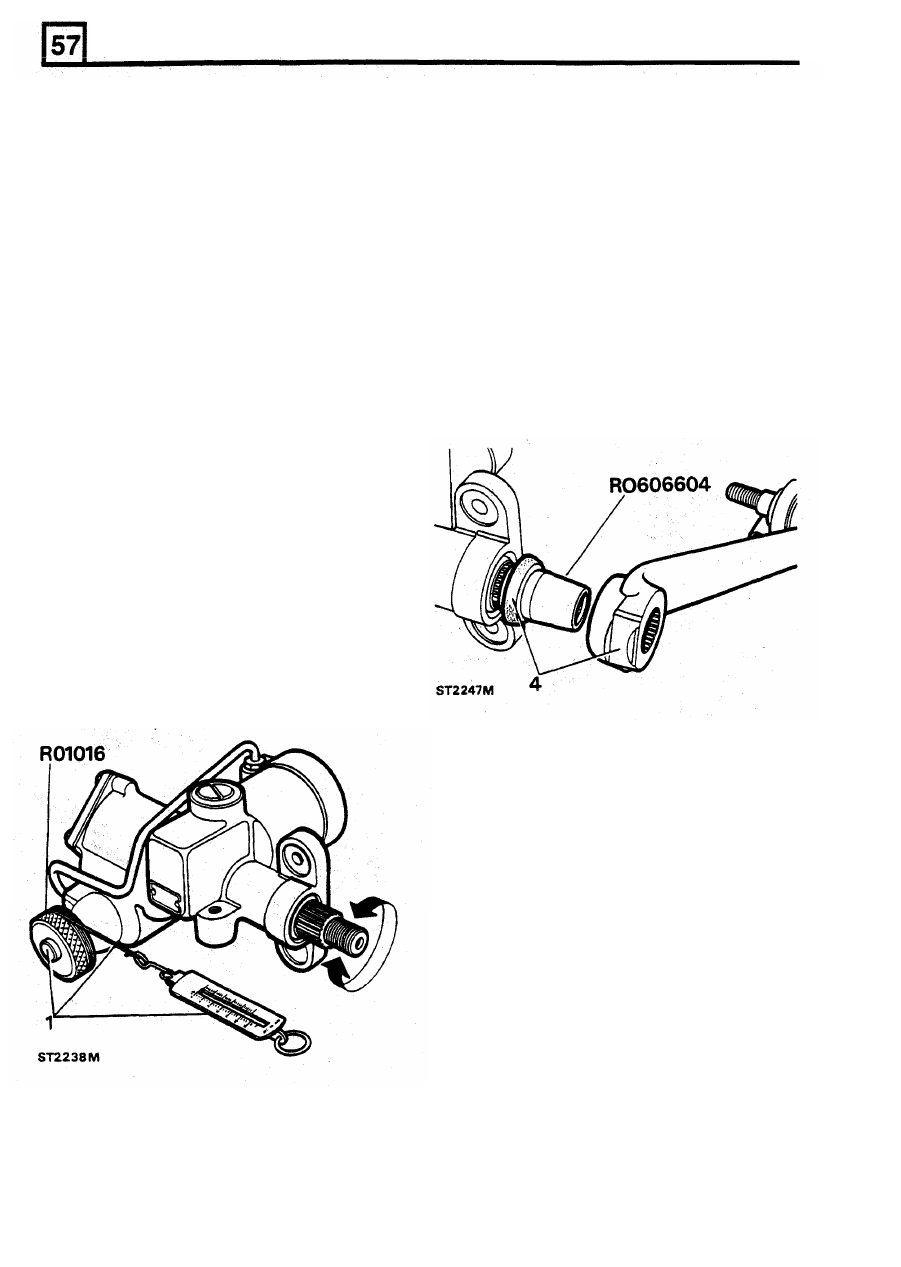

4.

Using seal saver

RO

606604, fit

a new outer

correct unless major components have been

dust seal over the sector shaft. Fit the drop

renewed. The procedure for checking and adjusting

arm

to

the sector shaft and a new lock

the torque peak is contained in the following

washer. Fit and tighten the retaining nut to the

instructions.

correct torque and bend the lock tab over a

flat of the nut.

1.

Attach the torque setting tool RO 1016 to the

input shaft and turn it fully anti-clockwise.

Wind cord round the tool and fasten a spring

balance to the free end

as

before. Turn the

input shaft by pulling the spring balance and

note the position where the highest figure is

obtained. If the highest figures are not

recorded along the middle portion of the travel

as explained above adjustment is necessary.

2.

Adjustment involves the dismantling of the

steering box and removal of the input shaft

inner bearing cup and shims. If the torque

peak (highest figure) occured before the

centre position, add shims

to

the pack.

Remove shims if the torque peak occurs after

the centre Position.

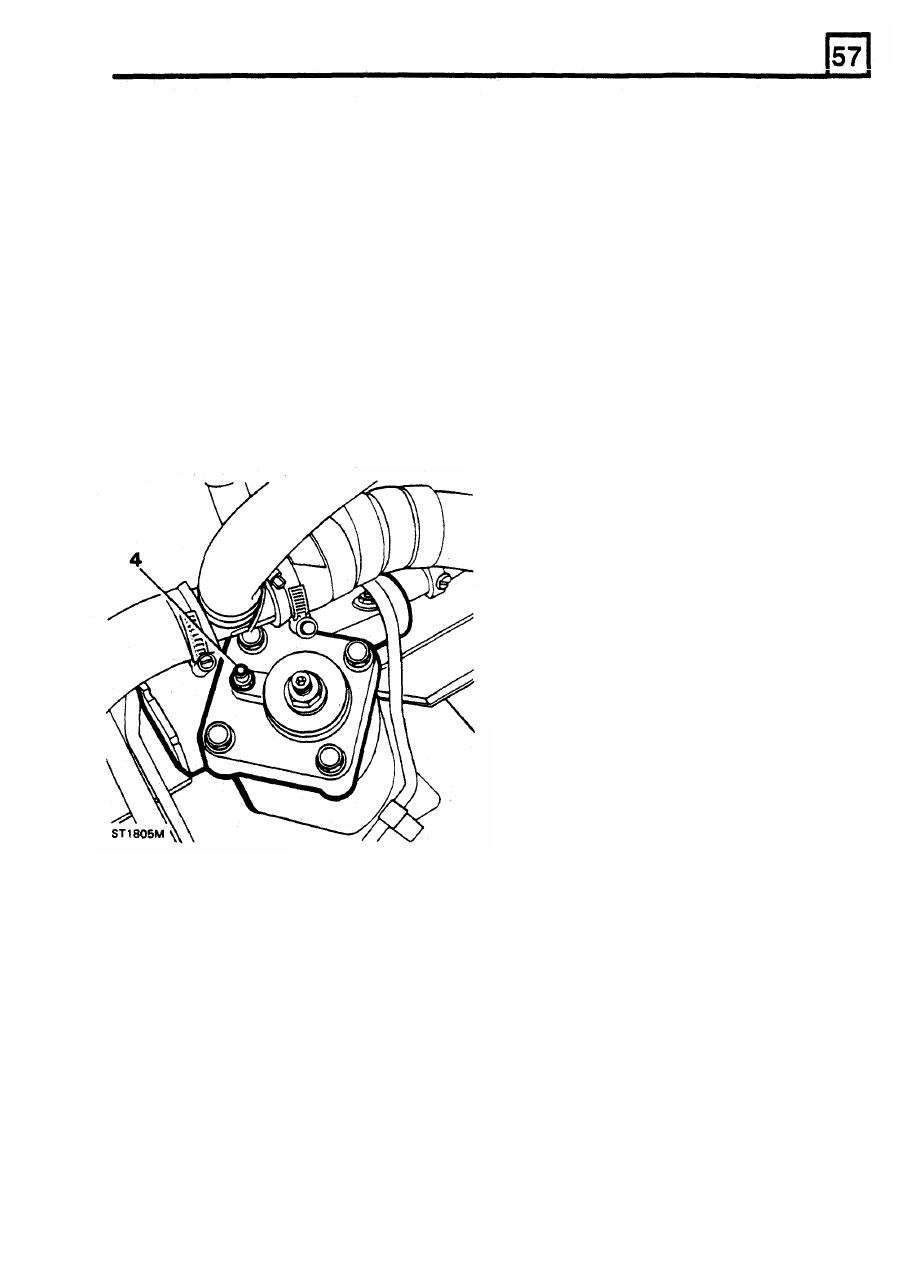

Fitting steering box to vehicle and testing

1.

Fit the steering box to the vehicle and

replenish the system with the correct make

and grade of fluid, For this information refer to

'RECOMMENDED

LUBRICANTS

AND

FLUIDS’

and bleeding the power steering

system.

2.

To

test the effectiveness

of

the

steering box

overhaul and the system

for

leaks, run the

engine and hold the steering hard on full lock

in both directions whilst a second person

checks for fluid leaks.

CAUTION:

Do not hold

the

steering on full lock

for more than thirty seconds in any one minute

t o avoid overheating the fluid and possibly

damaging the seals.

3. Finally road test the vehicle.

20

REISSUED: FEB 1993

STEERING

POWER

STEERING

SYSTEM

-

Adwest

Test

Lightweight box

If

there is

a

lack of power assistance for the steering

Bleed

the pressure of the hydraulic pump should be

checked first before renewing any components of the

system. The fault diagnosis chart should also be

1.

Fill the steering fluid reservoir

to

the mark on

the side of the reservoir with one of the

used to assist in tracing faults

in

the power steering.

recommended fluids.

2.

Start and run the engine until it attains normal

operating temperature.

3.

Check

and

correct the reservoir fluid level.

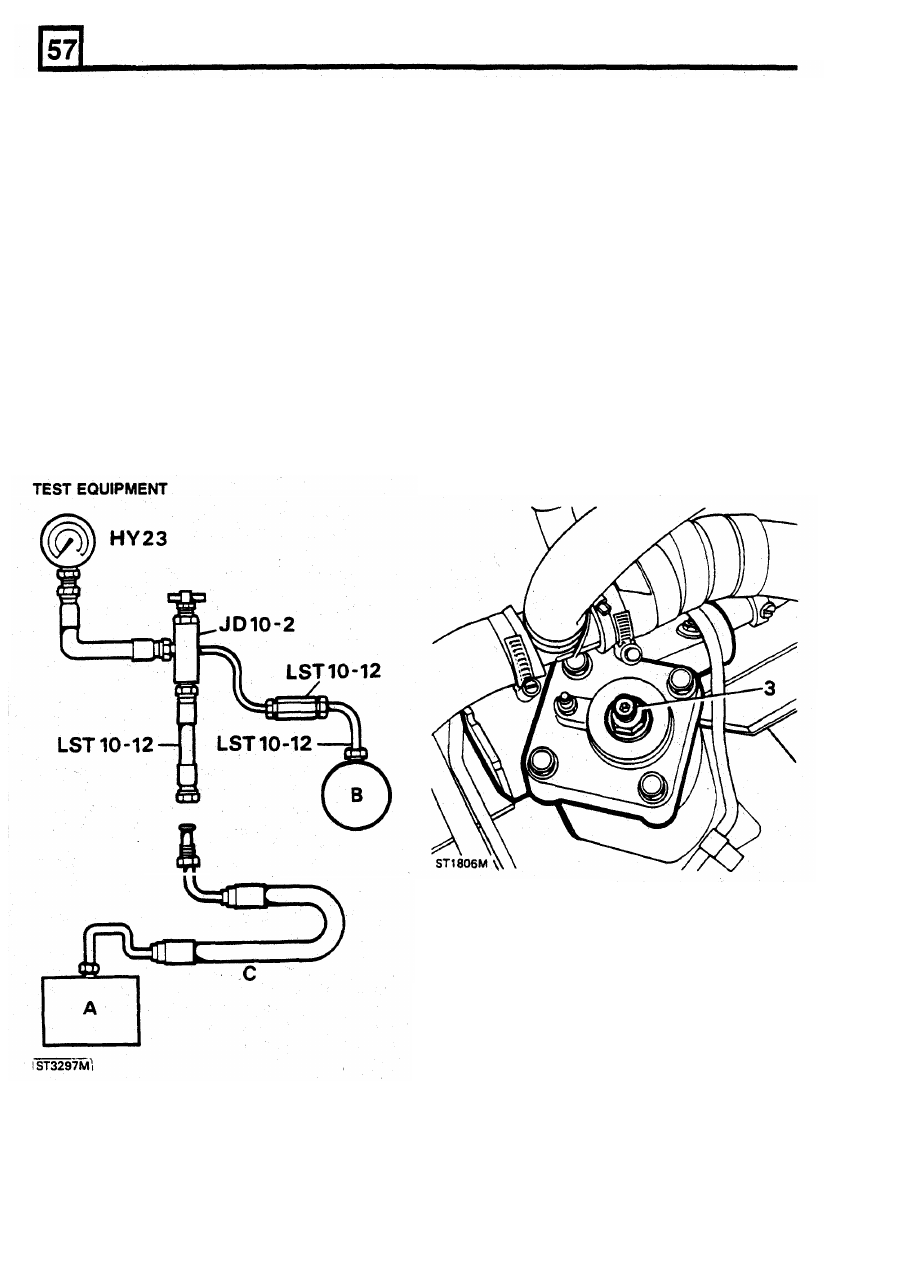

Procedure

1.

The hydraulic pressure test gauge is used for

testing the power steering system. This gauge

NOTE: During the carrying out

of

items

4,

5

and

is calibrated to read up

to

140 kgf/cm² and the

6, ensure that the steering reservoir is kept full.

normal pressure which may be expected

in

Do

not increase the engine

speed or move the

the power steering system

is

77

kgflcm².

steering wheel.

2. Under certain fault conditions of the hydraulic

pump it

is

possible to obtain pressures up to

4. Run the engine at idle speed, slacken the

105

kgf/cm². Therefore,

it

is

important to

realise that the pressure upon the gauge is

in

direct proportion to the pressure being exerted

upon the steering wheel. When testing, apply

pressure to the steering wheel very gradually

while carefully observing the pressure gauge.

3.

Check, and if necessary replenish, the fluid

reservoir.

4. Examine the power steering units and

connections for leaks.

All

leaks must be

rectified before attempting to test the system.

5.

Check the steering pump drive belt for

condition and tension, rectify as necessary.

6. Assemble the test equipment and fit to the

vehicle as illustrated.

7.

Open the tap in the adaptor.

8.

Bleed the system but exercise extreme care

when carrying out this operation

so

as not to

overload the pressure gauge.

9.

With the system in good condition, the

pressures should be as follows:

a. Steering

wheel

held hard on full lock and

engine running at 1,000 rev/min, the pressure

should be 70

to

77

kgf/cm².

b. With the engine idling and the steering

wheel held hard on full lock, the pressure

should be

28

kgf/cm² minimum.

These checks should be carried out first on one lock,

then on the other.

CAUTION: Under no circumstances must the

steering wheel be held on full lock for more than

30

seconds in any one minute, otherwise there

will

be a tendency for the oil to overheat and

possible damage to the seals may result.

bleed screw. When fluid seepage past the

bleed screw is observed, retighten the screw.

5.

Ensure that the fluid level is in alignment with

the mark on the reservoir dipstick.

6.

Wipe

off

all fluid released during bleeding.

7. Check all hose joints, pump and steering box

for fluid leaks under pressure by holding the

steering hard on

full

lock in both directions.

CAUTION: Do not maintain this pressure

for

more than

30

seconds in any one minute, to

avoid causing the oil to overheat and possible

damage to the seals, The steering should

be

smooth lock-to-lock in both directions, that is, no

heavy or light spots when changing direction

when the vehicle is stationary.

10.

Release the steering wheel and allow the

engine

to

idle. The pressure should be below

7

kgflcm².

8.

Carry out a short road test. If necessary,

repeat the complete foregoing procedure.

REISSUED:

FEB

1993

21

STEERING

11.

If

the pressures recorded during the foregoing

ADJUST POWER STEERING

BOX

-

Adwest

test are outside the specified range, or

Lightweight box

pressure imbalance

I

S

recorded, a fault exists

in the system.

To

determine if the fault is in

NOTE: The condition of adjustment which must

the steering box

or

the pump, close the

be checked

is one

of

minimum backlash without

adaptor tap for a period not exceeding five

overtightness when the wheels are

in the

seconds.

straight-ahead position.

12.

If

the gauge fails to register the specified

pressures, the pump

is

inefficient and the

1.

Jack up the front

of

the vehicle until the

pump relief valve should be examined and

wheels are clear of the ground.

renewed as necessary.

13.

Repeat the foregoing test after renewing the

WARNING: Wheels must

be chocked in

all

relief valve and bleeding the system. If the

circumstances.

pump still fails to achieve the specified

pressures, the pump should be overhauled or

2.

Gently rock the steering wheel about the

a new unit fitted.

straight-ahead position to obtain the 'feel'

of

14.

If

pump delivery is satisfactory and low

the backlash present. This backlash must not

pressure or marked imbalance exists, the fault

be more than 9,5

mm.

must

be

in the steering box valve and worm

3.

Continue the rocking action whilst an assistant

assembly.

slowly tightens the steering box adjuster

screw after slackening the locknut until the rim

movement

is

reduced

to 9,5 mm maximum.

4.

Tighten the locknut, then turn the steering

wheel

from lock

to

lock and check that no

excessive tightness exists at any point.

5.

Lower the vehicle

to

ground level and remove

the wheel chocks.

6. Road test the vehicle.

A.

Steering box

B. Steering pump

C. Existing hose from steering box

22

REISSUED: FEB 1993

STEERING

PIPE CONNECTIONS TO STEERING

BOX

When fitting a new or overhauled steering box

observe the following procedure.

1.

Remove dust caps from ports.

2.

Immediately fit pipes finger tight.

3. Tighten the 16 mm union nut to 20 Nm.

4.

Tighten the 14 mm union nut

to

15

Nm.

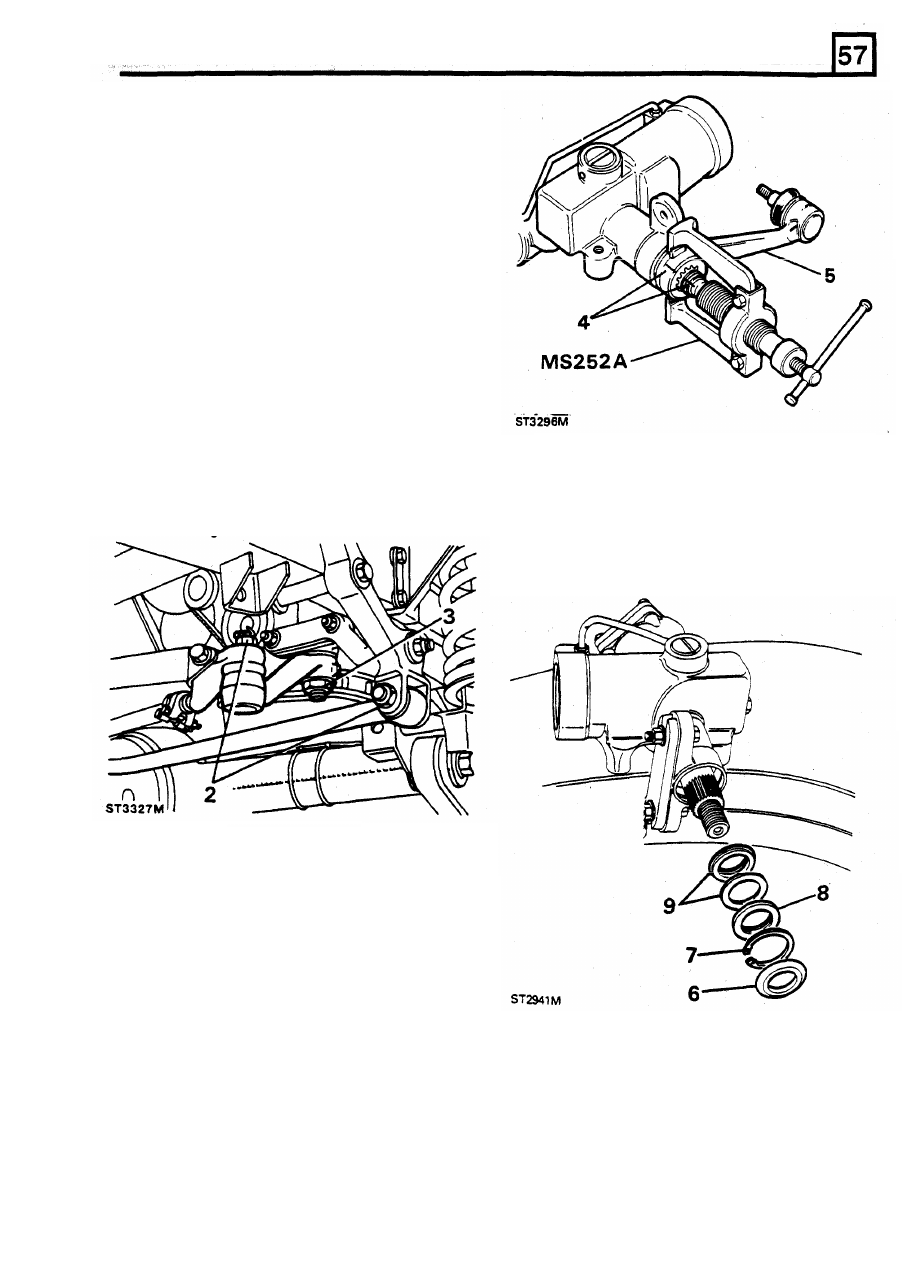

STEERING BOX SECTOR SHAFT SEAL - renew

with steering box fitted to vehicle

Special tools

Drop arm puller MS 252A / LRT-57-012

Seal replacer LST 125A / LRT-57-010

1.

Working

from

beneath the vehicle set the

steering in approximately the straight ahead

6.

Remove the dust seal, if fitted, and clean the

position.

area around the sector shaft seal.

2.

Release the ball pin from the drag link, and

7.

Remove the circlip.

one end

of

Panard rod.

8.

To

remove the seal pack, drill

two

3 , 0 mm

3. Release the lock tab from the drop arm

holes diametrically opposite into the metal dirt

retaining nut and remove

the

nut

seal. Insert a 4 mm self tapping screw in each

hole then, with pliars pull the seal from the

box.

9.

Remove the extrusion washer and inner seal.

4.

Before removing the drop arm, mark its

relationship to the sector shaft to assist

assembly.

5. Using pulley MS

252A

or a suitable

alternative, withdraw the drop arm.

10.

With

a

suitable

probe,

remove

the

anti-extrusion washer and inner seal.

REISSUED:

FEB

1993

23

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст