Toyota Sequoia (2005). Manual — part 166

–

DIAGNOSTICS

ENGINE

DI–459

653

8

Check whether DTC output recurs (DTC P2A00 or P2A03)

CHECK:

(a)

On the hand–held tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC

INFO / PENDING CODES.

(b)

Read DTCs.

RESULT:

Display (DTC Output)

Proceed To

P2A00 or P2A03

A

No output

B

A

Check air–fuel ratio extremely lean or rich

(See page

B

END

0.02 inch orifice clogged

Pressure sensor low output

P043E

P043F

P0441

P0451

P0452

P0453

P0455

P0456

P2419

P2401

P2402

0.02 inch orifice high–flow

Pressure sensor stuck

Pressure sensor noise

Gross leak

Small leak

Vacuum pump stuck OFF

Vacuum pump stuck ON

Vent valve stuck closed

Vent valve stuck open (vent)

Purge VSV stuck open

Purge VSV stuck closed

Pressure sensor high output

DTCs

Malfunctioning Areas

P2420

P0450

DI–460

–

DIAGNOSTICS

ENGINE

654

EVAP (Evaporative Emission) Inspection Procedure

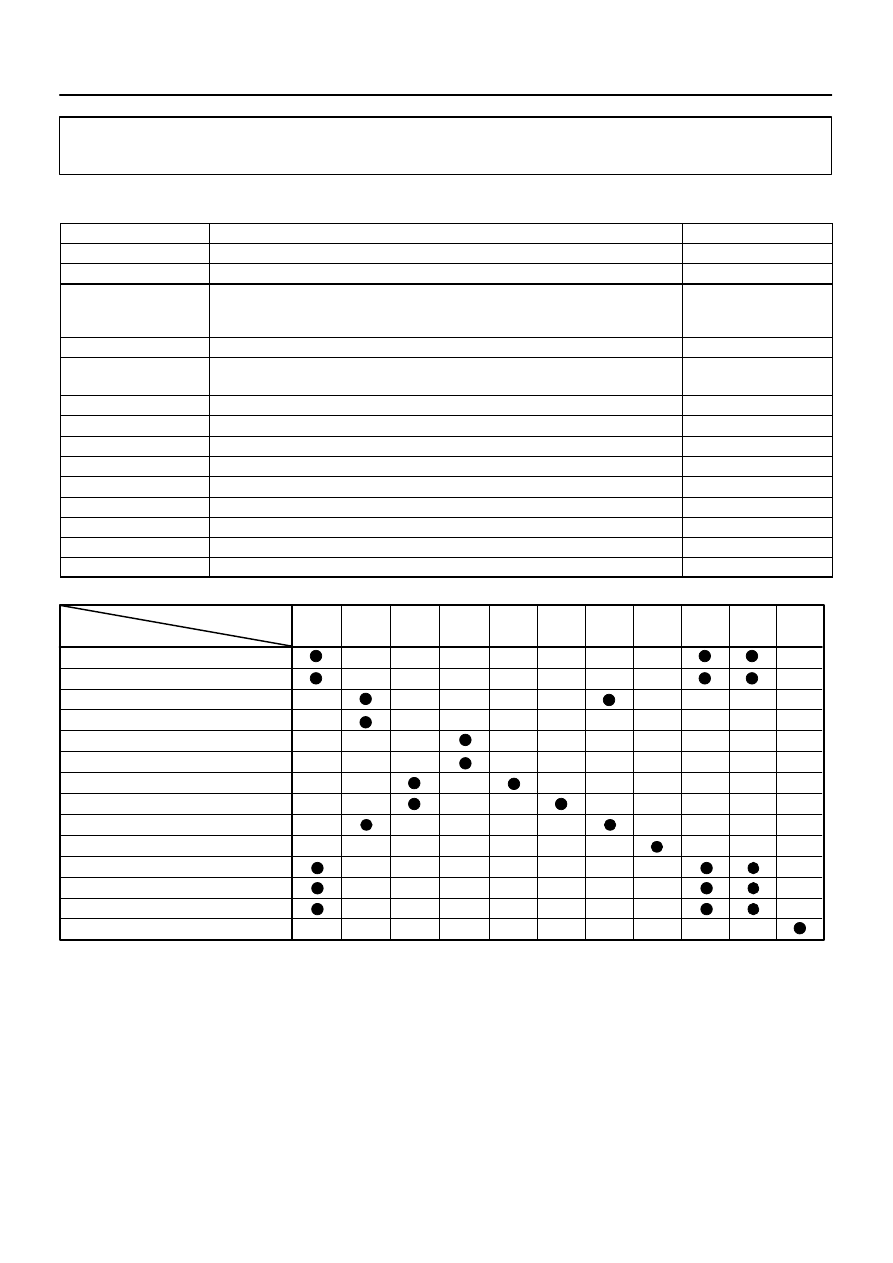

DTCS RELATING TO EVAP SYSTEM

DTCs

Monitoring Items

See Page

P043E

0.02 inch orifice clogged (built into pump module)

P043F

0.02 inch orifice high–flow (built into pump module)

P0441

Purge VSV

(Vacuum Switching Valve) stuck closed

Purge VSV

stuck open

Purge flow

P0450

Pressure sensor (built into pump module) voltage abnormal fluctuation

P0451

Pressure sensor (built into pump module) noising

Pressure sensor stuck (built into pump module)

P0452

Pressure sensor (built into pump module) voltage low

P0453

Pressure sensor (built into pump module) voltage high

P0455

EVAP gross leak

P0456

EVAP small leak

P2401

Vacuum pump stuck OFF (built into pump module)

P2402

Vacuum pump stuck ON (built into pump module)

P2419

Vent valve stuck closed (built into pump module)

P2420

Vent valve stuck open (vent) (built into pump module)

P2610

Soak timer (built into ECM)

If any EVAP system DTCs are set,

the malfunctioning area can be determined using the table below.

NOTICE:

If the 0.02 inch reference pressure difference between the first and second checks is greater than

the specification, the DTCs corresponding to the reference pressure (P043E, P043F, P0441, P0455,

P0456, P2401, P2420) will be all stored.

DIDFZ–01

A23474

Purge VSV

(Vacuum Switching Valve)

EVAP Hose

(To Throttle Body)

EVAP Hose

(From Canister)

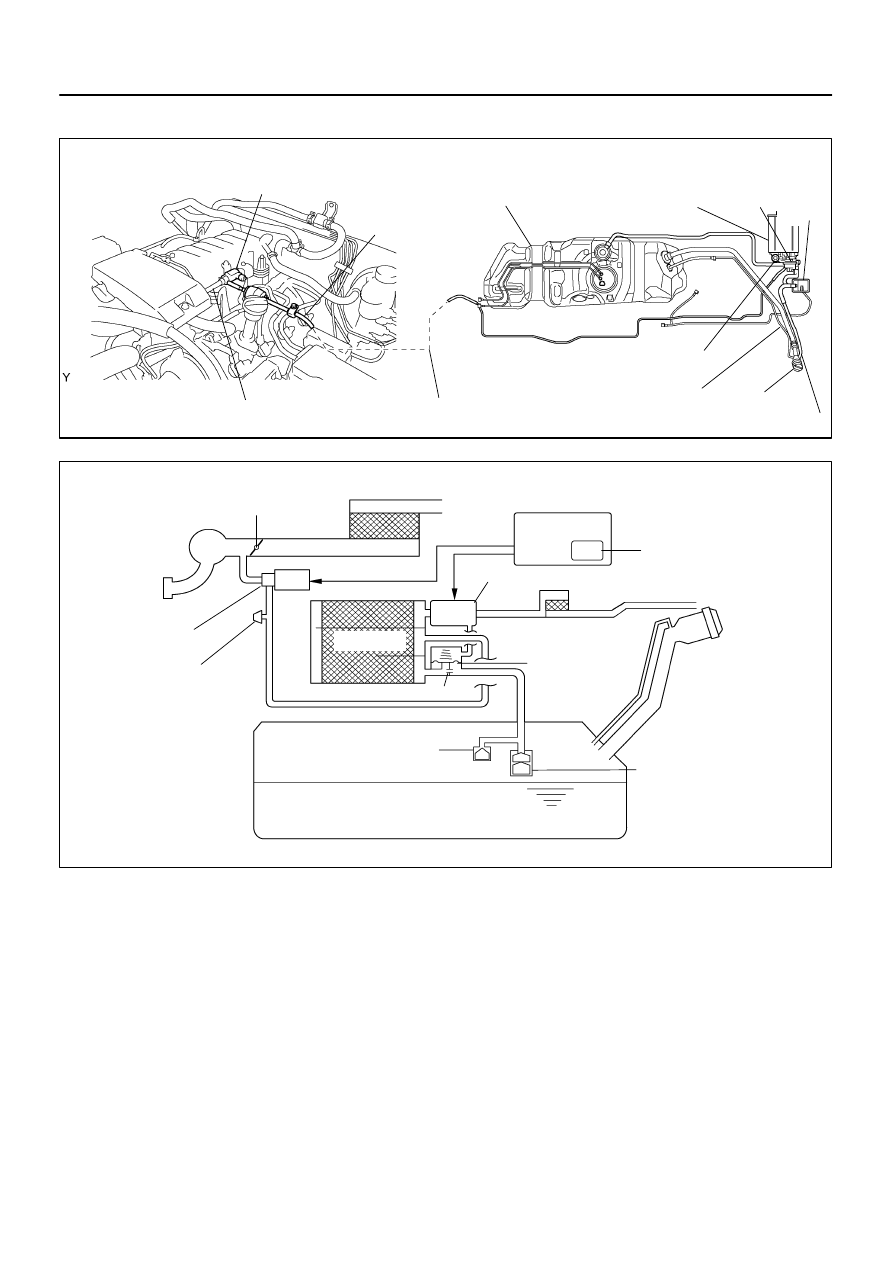

Location of EVAP (Evaporative Emission) system:

Vent Valve

Canister

Pressure Sensor

Vacuum Pump

Purge Line

Fuel Tank

Air Inlet Port

Breeding

Pipe

Fuel Tank Cap

Refueling Valve

Pump Module

Air Filter

A23668

EVAP System Circuit:

Intake Manifold

Purge VSV

Cut–Off Valve

Roll–Over Valve

Canister

Air Filter

fuel tank cap

Service Port

Air Cleaner

Restrictor (0.08 inch)

Refueling Valve

Throttle Valve

ECM

Soak Timer

Pump Module

Fuel Tank

–

DIAGNOSTICS

ENGINE

DI–461

655

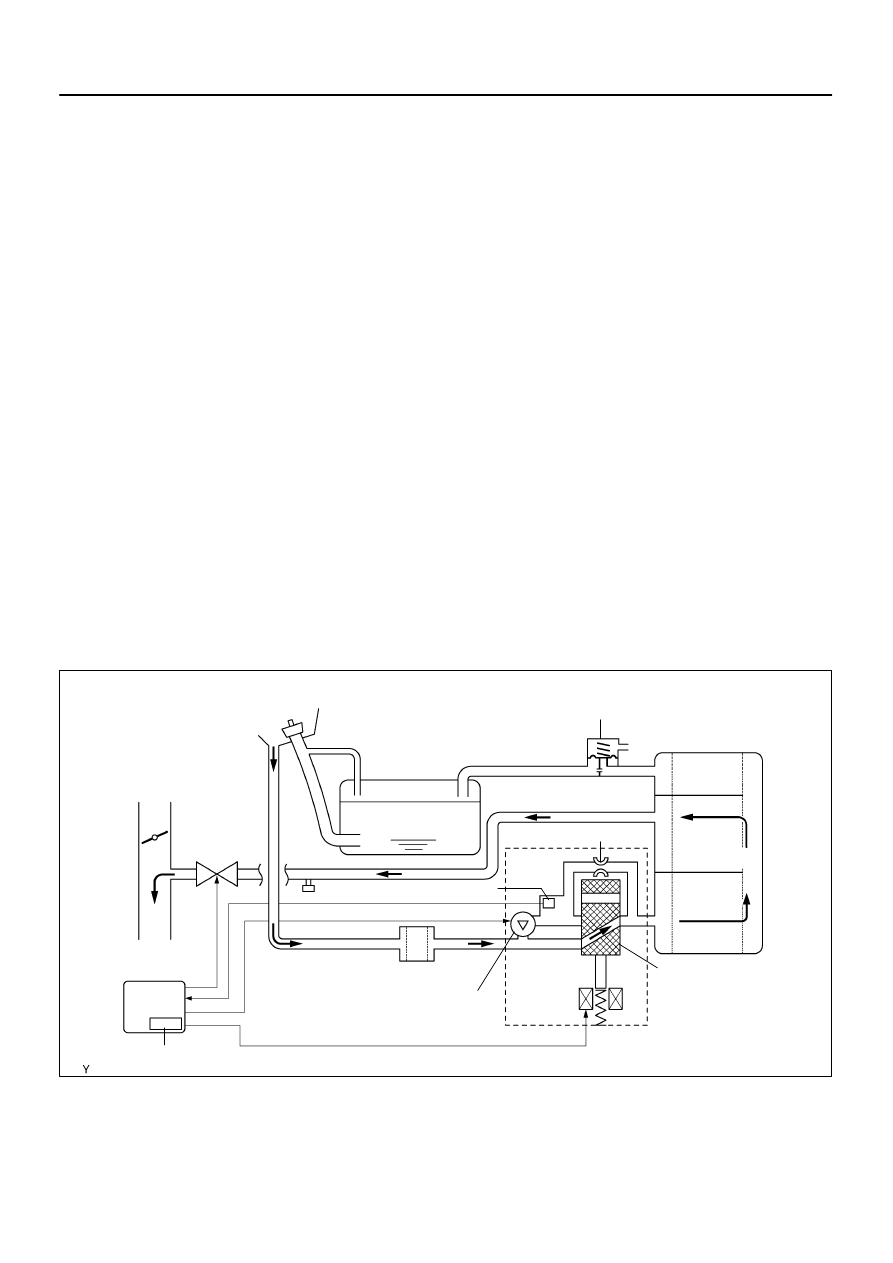

CIRCUIT DESCRIPTION

While the engine is running, if a predetermined condition (closed–loop, etc.) is met, the purge VSV is opened

by the ECM and stored fuel vapors in the canister are purged to the intake manifold. The ECM changes the

duty cycle ratio of the purge VSV to control purge flow volume.

The purge flow volume is also determined by the intake manifold pressure.

Atmospheric pressure is allowed

into the canister through the vent valve to ensure that the purge flow is maintained when the negative pres-

sure (vacuum) is applied to the canister.

The following two monitors run to confirm appropriate EVAP system operation.

A23669

EVAP Purge Flow:

Canister

Purge VSV

(ON)

Vacuum Pump (OFF)

Air Filter

Fuel Tank

fuel tank cap

To Intake Manifold

Pump Module

Pressure Sensor

0.02 Inch Orifice

Vent Valve (OFF)

ECM

Soak Timer

Refueling Valve

To Atmosphere

DI–462

–

DIAGNOSTICS

ENGINE

656

Key–off monitor

This monitor checks for EVAP (Evaporative Emission) system leaks and pump module malfunctions. The

monitor starts 5 hours*

after the ignition switch is turned OFF. More than 5 hours are required to allow enough

time for the fuel to cool down to stabilize the Fuel Tank Pressure (FTP), thus making the EVAP system moni-

tor more accurate.

The electric vacuum pump creates negative pressure (vacuum) in the EVAP system and the pressure is

measured. Finally, the ECM monitors for leaks from the EVAP system, and malfunctions in both the pump

module and purge VSV, based on the EVAP pressure.

HINT:

*:If the engine coolant temperature is not below 35

C 5 hours after the ignition switch is turned off, the moni-

tor check starts 2 hours later. If it is still not below 35

C 7 hours after the ignition switch is turned off, the

monitor check starts 2.5 hours later.

Purge flow monitor

The purge flow monitor consists of the two monitors. The 1st monitor is always conducted every time and

the 2nd monitor is activated if necessary.

The 1st monitor

While the engine is running and the purge VSV (Vacuum Switching Valve) is ON (open), the ECM

monitors the purge flow by measuring the EVAP pressure change. If negative pressure is not

created, the ECM begins the 2nd monitor.

The 2nd monitor

The vent valve is turned ON (closed) and the EVAP pressure is then measured. If the variation

in the pressure is less than 0.5 kpa (3.75 mmHg), the ECM interprets this as the purge VSV being

stuck closed, and illuminates the MIL and sets DTC P0441 (2 trip detection logic).

Atmospheric pressure check:

In order to ensure reliable malfunction detection, the variation between the atmospheric pressures, before

and after conduction of the purge flow monitor, is measured by the ECM.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст