Nissan Qashqai (2007-2010). Manual — part 510

STR-26

< ON-VEHICLE REPAIR >

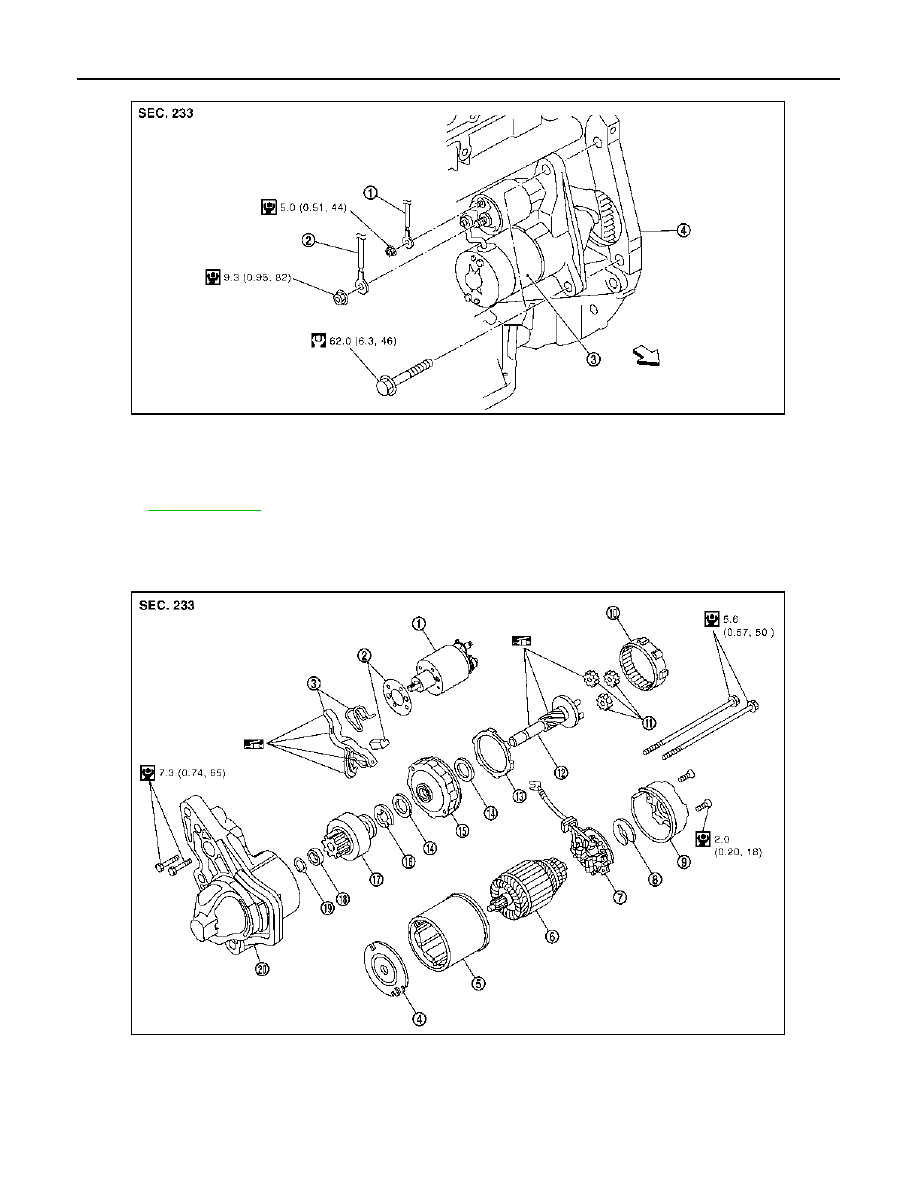

STARTER MOTOR

DISASSEMBLY

Type: S114-902A

1.

“S” terminal harness

2.

“B” terminal harness

3.

Starter motor

4.

Cylinder block

: Engine front

Refer to

for symbols in the figure.

PKIC8095E

1.

Magnetic switch assembly

2.

Dust cover kit

3.

Shift lever set

4.

Center bracket (A)

5.

Yoke assembly

6.

Armature assembly

7.

Brush holder assembly

8.

Thrust washer

9.

Rear cover assembly

10. Internal gear

11.

Planetary gear

12. Pinion shaft

JPBIA0549GB

STARTER MOTOR

STR-27

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

STR

N

P

O

MR20DE MODELS : Removal and Installation

INFOID:0000000000955723

REMOVAL

1.

Disconnect the battery cable from the negative terminal.

2.

Disconnect the oil pressure switch connector.

3.

Remove “B” terminal nut and “B” terminal harness.

4.

Remove “S” terminal nut and “S” terminal harness.

5.

Remove starter motor mounting bolts.

6.

Remove starter motor upward from the vehicle.

CAUTION:

Never damage oil pressure switch when removing starter motor.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

MR20DE MODELS : Disassembly and Assembly

INFOID:0000000000955724

ASSEMBLY

Apply high-temperature grease to lubricate the bearing, gears and frictional surface when assembling

the starter.

Carefully observe the following manuals.

Pinion Protrusion Length Adjustment

CLEARANCE

• With pinion driven out by magnetic switch, push pinion back to

remove slack and measure clearance “L” between the front edge

of the pinion and the pinion stopper.

• Adjust with the adjusting plate if the measurement value is not in

the specified area.

MR20DE MODELS : Inspection

INFOID:0000000000955725

13. Packing

14. Thrust washer

15. Center bracket (P)

16. E-ring

17. Pinion assembly

18. Pinion stopper

19. Pinion stopper clip

20. Gear case assembly

: High-temperature grease point

Refer to

for symbols not described on the above.

Clearance “L”

: Refer to SDS

SKIB0229E

PKID0786E

STR-28

< ON-VEHICLE REPAIR >

STARTER MOTOR

INSPECTION

Magnetic Switch Check

• Before starting to check, disconnect the battery cable from the negative terminal.

• Disconnect “M” terminal of starter motor.

1.

Continuity test [between “S” terminal (A) and switch body]

• Replace magnetic switch if continuity does not exist.

2.

Continuity test [between “S” terminal (A) and “M” terminal (C)]

• Replace magnetic switch if continuity does not exist.

Pinion/Clutch Check

1.

Inspect pinion teeth.

• Replace pinion if teeth are worn or damaged. (Also check con-

dition of ring gear teeth.)

2.

Inspect reduction gear teeth (If equipped).

• Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3.

Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

• Replace pinion assembly if it is locked or rotated in both direc-

tions or unusual resistance is evident.

Brush Check

• Check wear of brush.

• Replace brush if the measurement value is less than the specified

value.

Brush Spring Check

B

: “B” terminal

C

: “M” terminal

SKIB9002E

B

: “B” terminal

SKIB9003E

SEL630BA

Minimum length of brush

: Refer to SDS

SEL014Z

STARTER MOTOR

STR-29

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

STR

N

P

O

• Check brush spring tension with brush spring detached from

brush.

• Replace brush spring if the measurement value is less than the

specified value.

Brush Holder Check

1.

Perform insulation test between brush holder (positive side) and

its base (negative side).

• Replace brush holder assembly if continuity does not exist.

2.

Check brush to see if it moves smoothly.

• If brush holder is bent, replace it; if sliding surface is dirty,

clean.

Yoke Check

Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunctioning

parts as an assembly.

CAUTION:

Never clamp yoke in a vise or strike it with a hammer.

Armature Check

1.

Continuity test (between two segments side by side)

• Replace armature assembly if continuity does not exist.

2.

Insulation test (between each commutator bar and shaft)

• Replace armature assembly if continuity exists.

Spring tension (with new

brush)

: Refer to SDS

SEL015Z

SKIB0460E

SEL305H

SKIB0461E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст