Nissan Qashqai (2007-2010). Manual — part 530

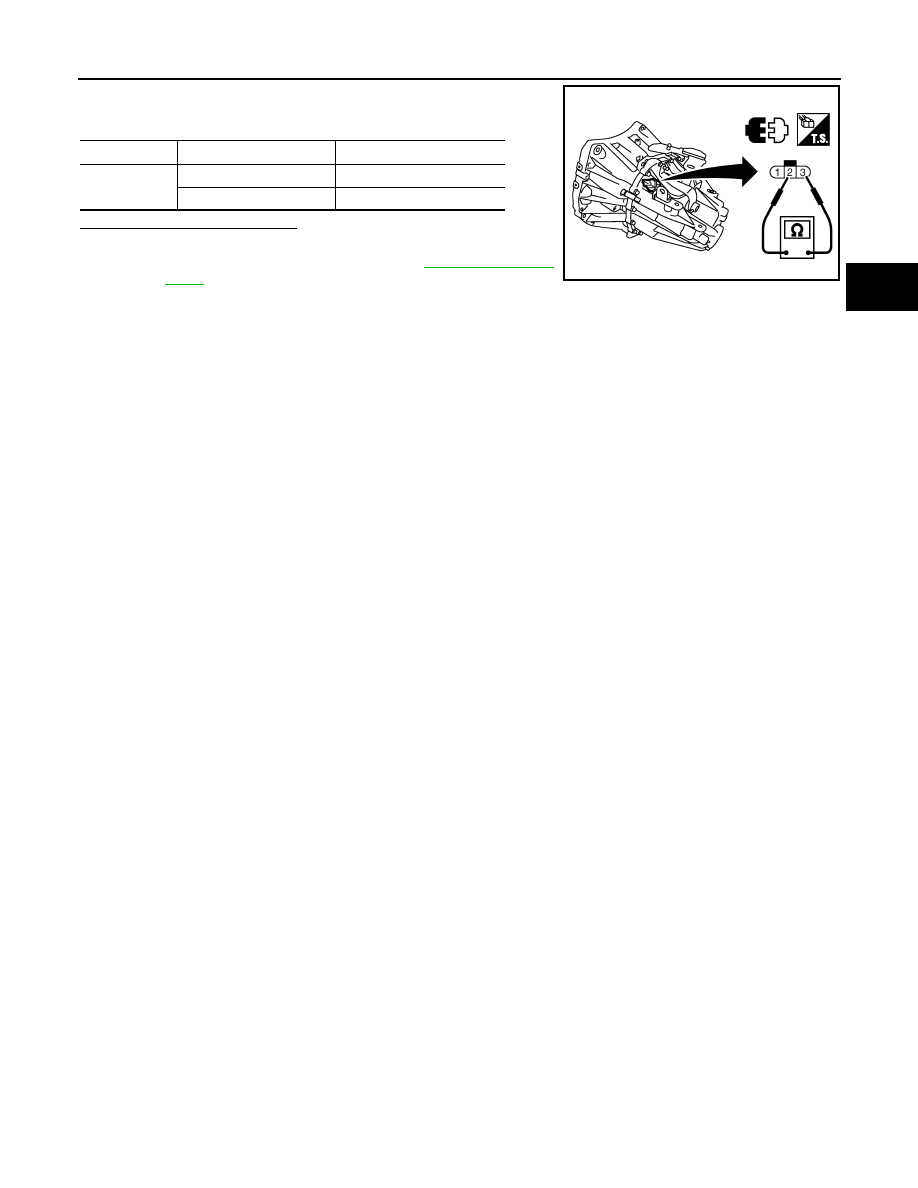

POSITION SWITCH

TM-55

< COMPONENT DIAGNOSIS >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

Check continuity between position switch terminals with control lever

turned to 1st to 6th and reverse position.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace position switch. Refer to

.

Terminals

Gear position

Continuity

2 – 3

Neutral

Existed

Except neutral

Not existed

JPDIC0091ZZ

TM-56

< SYMPTOM DIAGNOSIS >

[6MT: RS6F94R]

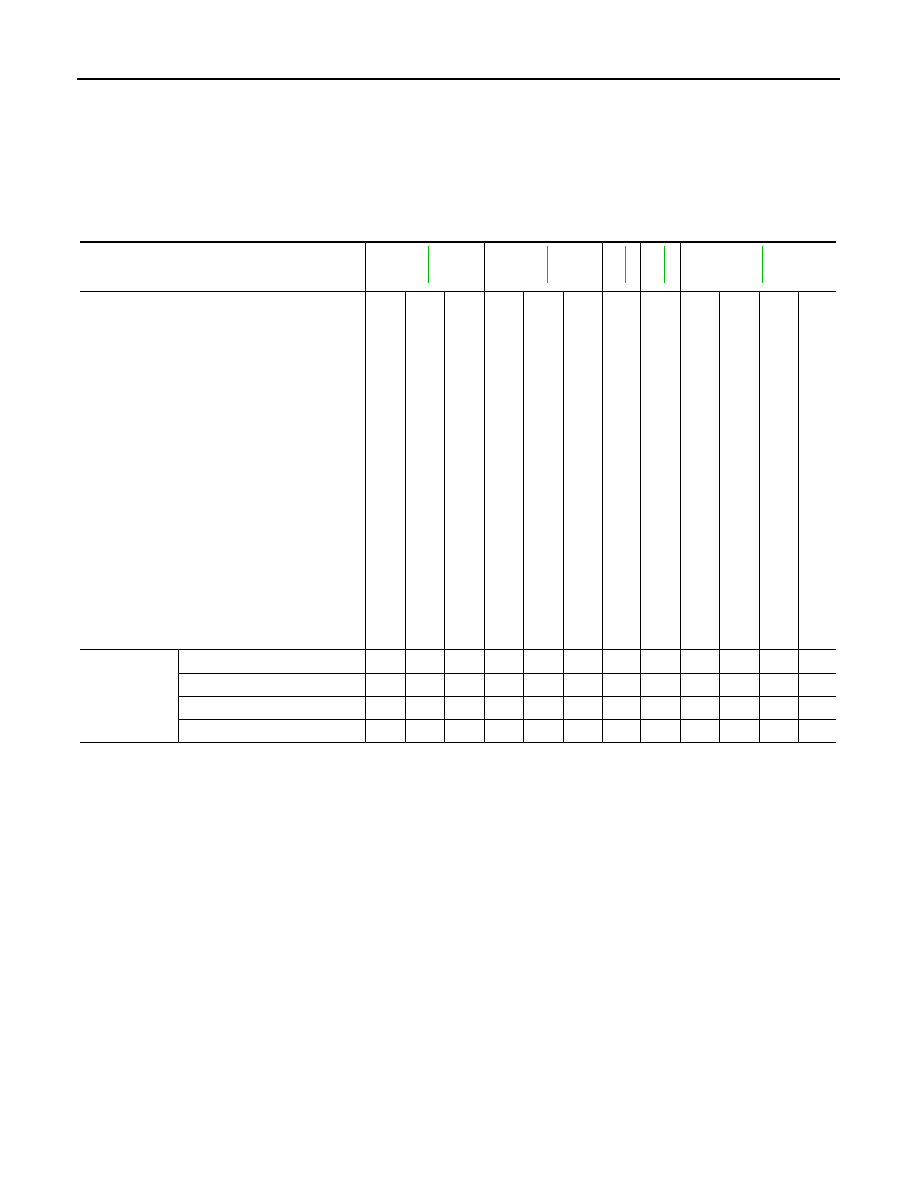

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

INFOID:0000000001070320

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference page

SUSPECTED PARTS

(Possible cause)

OIL

(Oil

lev

e

l is

l

o

w

.)

OI

L (W

ro

ng

oi

l.

)

OIL

(Oil

lev

e

l is

h

igh

.)

GASKET

(Damaged)

OIL SEAL (W

orn or

damaged)

O-RING (W

orn

or

da

ma

ge

d)

SHIF

T CONTROL L

INKAGE

(W

o

rn)

SHIF

T FORK (W

o

rn)

GEAR (W

o

rn o

r da

m

age

d)

BEAR

ING

(W

orn

o

r

da

ma

ge

d)

BAUL

K

RING (W

orn

o

r da

ma

ge

d)

INSE

R

T

S

P

RING (Dam

ag

ed

)

Symptoms

Noise

1

2

3

3

Oil leakage

3

1

2

2

2

Hard to shift or will not shift

1

1

2

3

3

Jumps out of gear

1

2

2

PRECAUTIONS

TM-57

< PRECAUTION >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Service Notice or Precautions for Manual Transaxle

INFOID:0000000001070321

CAUTION:

• If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder).

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding

parts may damage seal of CSC and may cause clutch fluid leakage.

• Never reuse transaxle gear oil, once it has been drained.

• Check oil level or replace gear oil with vehicle on level surface.

• During removal or installation, keep inside of transaxle clear of dust or dirt.

• Check for the correct installation status prior to removal or disassembly. If matching marks are

required, be certain they do not interfere with the function of the parts they are applied.

• In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to out-

side. If tightening sequence is specified, use it.

• Never damage sliding surfaces and mating surfaces.

TM-58

< PREPARATION >

[6MT: RS6F94R]

PREPARATION

PREPARATION

PREPARATION

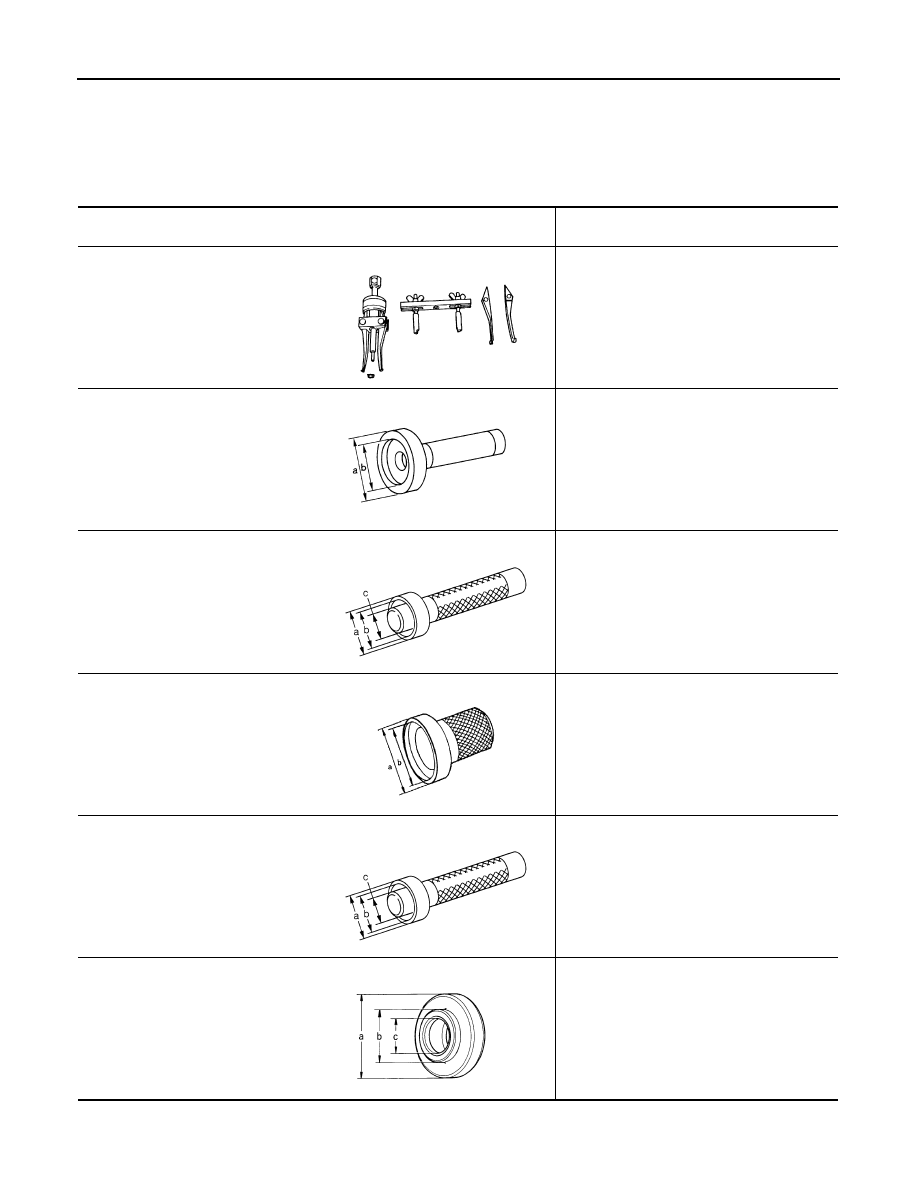

Special Service Tools

INFOID:0000000001070322

Tool number

Tool name

Description

KV381054S0

Puller

Removing mainshaft front bearing outer race

KV38100200

Drift

a: 65 mm (2.56 in) dia.

b: 49 mm (1.93 in) dia.

• Installing mainshaft front bearing outer race

• Installing mainshaft rear bearing outer race

• Installing differential side bearing outer race

(clutch housing side)

ST33220000

Drift

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.

Installing input shaft oil seal

ST33400001

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing differential side bearing outer race

(transaxle case side)

KV38100300

Drift

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.

Installing differential side oil seal

ST36720030

Drift

a: 70 mm (2.76 in) dia.

b: 40 mm (1.57 in) dia.

c: 29 mm (1.14 in) dia.

• Installing input shaft rear bearing

• Installing mainshaft front bearing inner race

ZZA0601D

ZZA1143D

ZZA1046D

ZZA0814D

ZZA1046D

ZZA0978D

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст