Nissan Qashqai (2007-2010). Manual — part 569

SHIFT LOCK SYSTEM

TM-211

< FUNCTION DIAGNOSIS >

[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

SHIFT LOCK SYSTEM

System Description

INFOID:0000000000914573

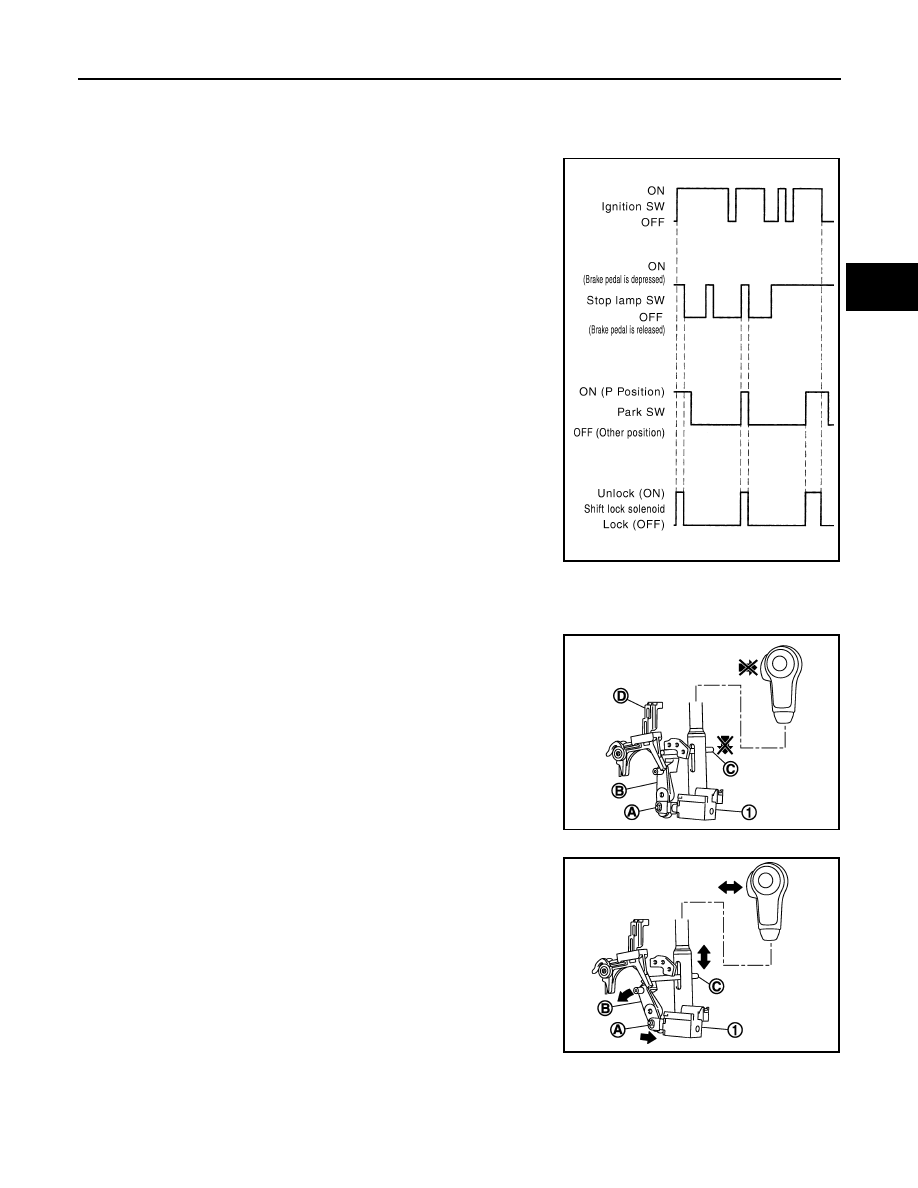

It is designed so that it cannot be shifted from the P position unless

the brake pedal is depressed while the ignition switch is set to ON.

The shift lock is unlocked by turning the shift lock solenoid ON when

the ignition switch is set to ON, the park switch is turned ON (selec-

tor lever is in P position), and the stop lamp switch is turned ON

(brake pedal is depressed) as shown in the operation chart in the fig-

ure. Therefore, the shift lock solenoid receives no ON signal and the

shift lock remains locked if all of the above conditions are not ful-

filled. (However, selector operation is allowed if the shift lock release

button is pressed.)

SHIFT LOCK OPERATION at P POSITION

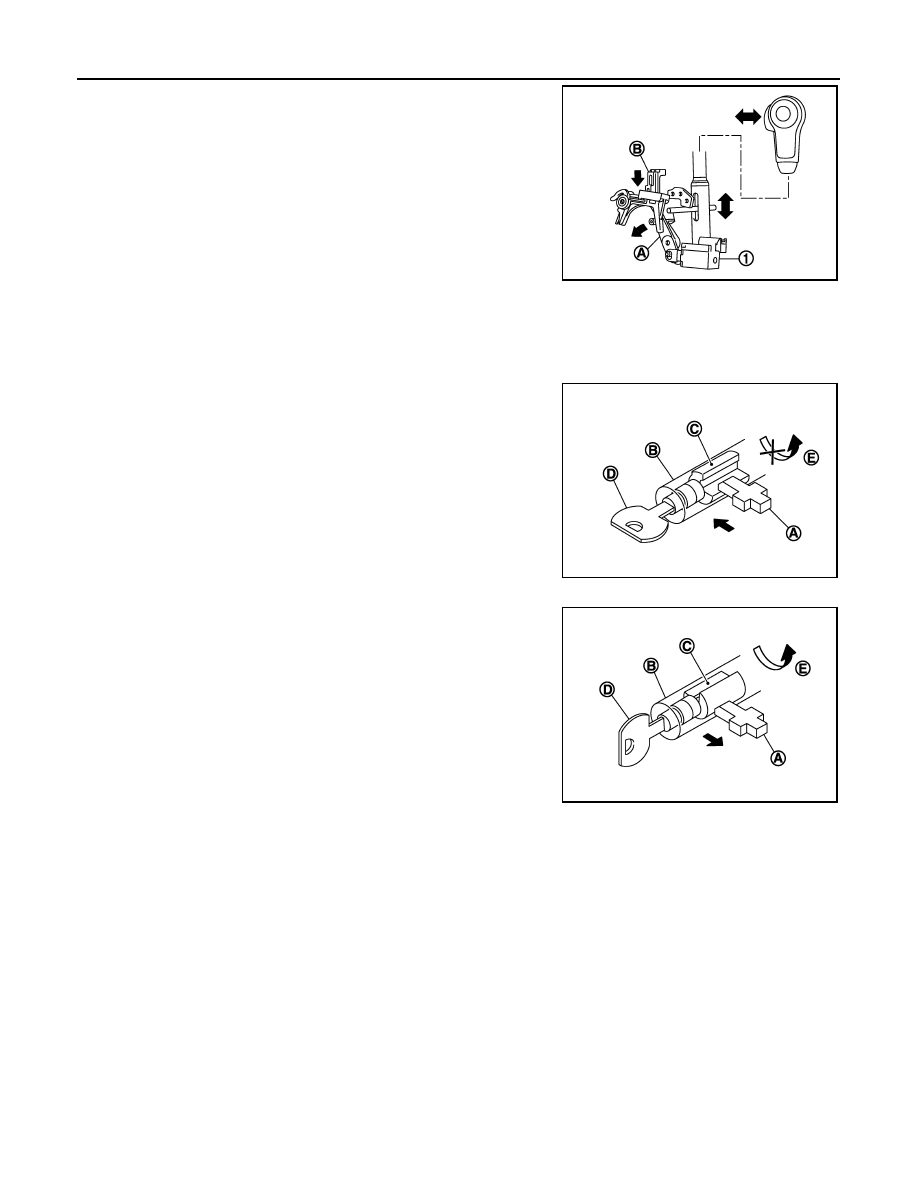

When Brake Pedal Is Not Depressed (No Selector Operation Allowed)

The shift lock solenoid (1) is turned OFF (not energized) and the

solenoid rod (A) is extended with the spring when the brake pedal is

not depressed (no selector operation allowed) with the ignition

switch ON.

The connecting lock lever (B) is located at the position shown in the

figure when the solenoid rod is extended. It prevents the movement

of the detent rod (C). The selector lever cannot be shifted from the P

position for this reason. However, the lock lever is forcibly moved to

the direction opposite to that of the arrow when the shift lock release

button (D) is pressed. Selector operation can be performed.

When Brake Pedal Is Depressed (Shift Operation Allowed)

The shift lock solenoid (1) is turned ON (energized) when the brake

pedal is depressed with the ignition switch ON. The solenoid rod (A)

is compressed with the electromagnetic force. The connecting lock

lever (B) rotates when the solenoid is compressed. Therefore, the

detent rod (C) can be moved. The selector lever can be shifted to

other positions for this reason.

P POSITION HOLD MECHANISM (IGNITION SWITCH LOCK)

JPDIA0183GB

JPDIA0110ZZ

JPDIA0111ZZ

TM-212

< FUNCTION DIAGNOSIS >

[CVT: RE0F10A]

SHIFT LOCK SYSTEM

The shift lock solenoid (1) is not energized when the ignition switch

is in any position other than ON. The shift mechanism is locked and

P position is held. The operation cannot be performed from P posi-

tion if the brake pedal is depressed with the ignition switch ON when

the operation system of shift lock solenoid is malfunctioning. How-

ever, the lock lever (A) is forcibly rotated and the shift lock is

released when the shift lock release button (B) is pressed from

above. The selector operation from P position can be performed.

CAUTION:

Use the shift lock release button only when the selector lever

cannot be operated even if the brake pedal is depressed with

the ignition switch ON.

KEY LOCK MECHANISM

The key is not set to LOCK when the selector lever is not selected to P position. This prevents the key from

being removed from the key cylinder.

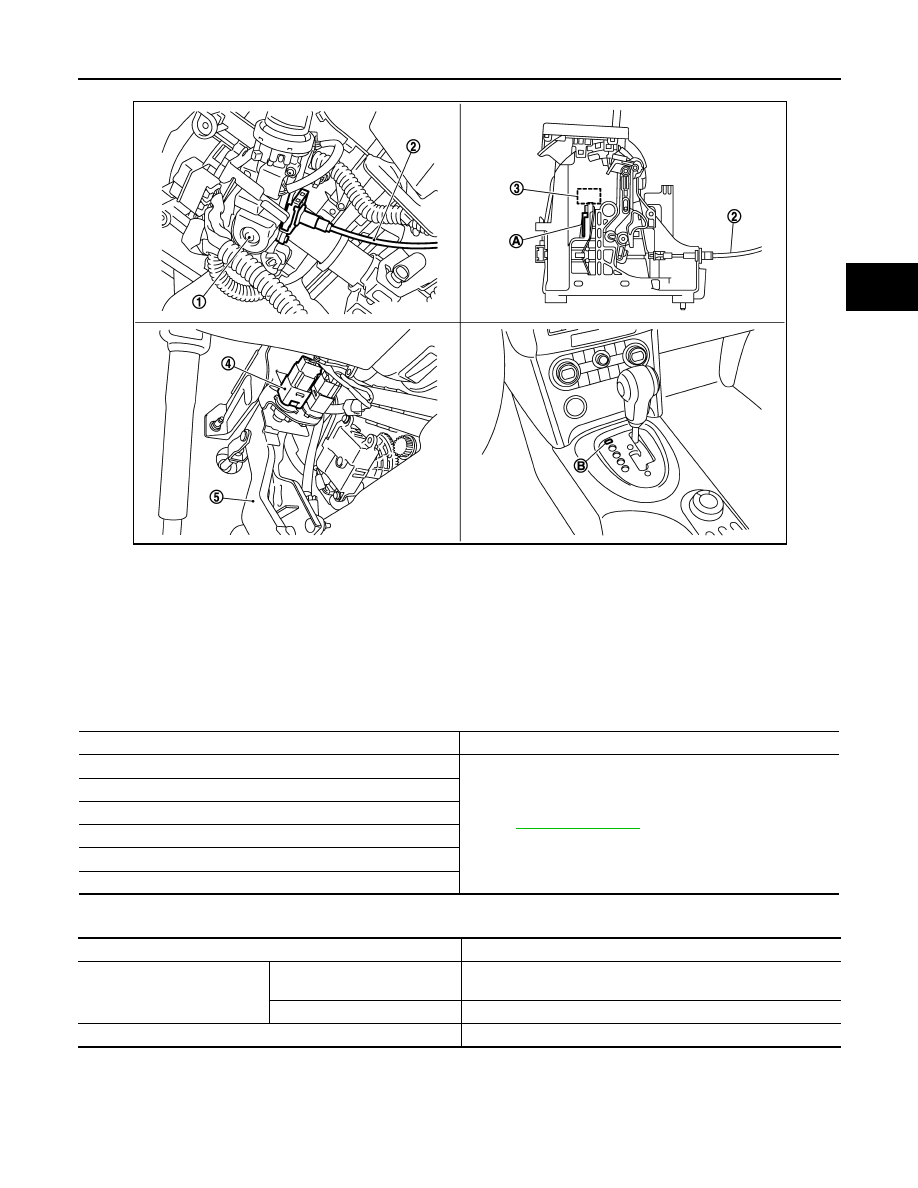

Key Lock Status

The slider (A) in the key cylinder (B) is moved to the left side of the

figure when the selector lever is in any position other than P position.

The rotator (C) that rotates together with the key (D) cannot be

rotated for this reason. The key cannot be removed from the key cyl-

inder because it cannot be turned to LOCK (E).

Key Unlock Status

The slider (A) in the key cylinder (B) is moved to the right side of the

figure when the selector lever is in P position and the finger is

removed from the selector button. The rotator (C) can be rotated for

this reason. The key (D) can be removed from the key cylinder

because it can be turned to LOCK (E).

Component Parts Location

INFOID:0000000000914574

JPDIA0112ZZ

JPDIA0320ZZ

JPDIA0321ZZ

SHIFT LOCK SYSTEM

TM-213

< FUNCTION DIAGNOSIS >

[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

Component Description

INFOID:0000000000927611

SHIFT LOCK

KEY LOCK

1.

Key cylinder

2.

Key interlock cable

3.

Shift lock solenoid

4.

Stop lamp switch

5.

Brake pedal

A.

Park position switch

B.

Shift lock release button*

*: Shift lock release button becomes operative by removing shift lock cover. (LHD only)

JPDIA0119ZZ

Component

Function

Shift lock solenoid

Lock lever

Detent rod

Park position switch

Key interlock cable and rod

Shift lock release button

Component

Function

Key cylinder

Rotator

It rotates together with the key and restricts the slider movement

when the ignition switch is in LOCK position.

Slider

It moves according to the rotation of the lock lever.

Key interlock cable and key interlock rod

Actuation of lock lever is conveyed to slider in the key cylinder.

TM-214

< FUNCTION DIAGNOSIS >

[CVT: RE0F10A]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis Description

INFOID:0000000000988626

DESCRIPTION

The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MI (malfunction indicator) and is stored as a DTC in the ECM

memory, and the TCM memory.

The second is the TCM original self-diagnosis performed by the TCM. The malfunction is stored in the TCM

memory. The detected items are overlapped with OBD self-diagnostic items. For detail, refer to

"CONSULT-III Function (TRANSMISSION)"

OBD FUNCTION

The ECM provides emission-related on board diagnostic (OBD) functions for the CVT system. One function is

to receive a signal from the TCM used with OBD-related parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MI (malfunction indicator) on the instrument panel. Sensors, switches and

solenoid valves are used as sensing elements.

The MI automatically illuminates in “One or Two Trip Detection Logic” when a malfunction is sensed in relation

to CVT system parts.

ONE OR TWO TRIP DETECTION LOGIC OF OBD

One Trip Detection Logic

If a malfunction is sensed during the first test drive, the MI will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

Two Trip Detection Logic

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MI will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MI will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD DIAGNOSTIC TROUBLE CODE (DTC)

How to Read DTC and 1st Trip DTC

DTC and 1st trip DTC can be read by the following methods.

(

with CONSULT-III or

GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by ISO 15031-5.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

- DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

- If the DTC is being detected currently, the time data will be “0”.

- If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

• The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-

III or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-III screen, not on the GST.

For details, refer to

EC-719, "CONSULT-III Function"

(WITH EURO-OBD),

(WITHOUT EURO-OBD).

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст