Nissan Qashqai (2007-2010). Manual — part 1896

MWI-2

DIAGNOSIS SYSTEM (METER) . . . . . ...

Diagnosis Description . . . . . . . . . . . .

CONSULT-III Function (METER/M&A) . . . . ...

COMPONENT DIAGNOSIS . . . . . .

U1000 CAN COMM CIRCUIT . . . . . . .

Description . . . . . . . . . . . . . . . ..

DTC Logic . . . . . . . . . . . . . . . ...

Diagnosis Procedure . . . . . . . . . . . ..

B2205 VEHICLE SPEED . . . . . . . . ...

Description . . . . . . . . . . . . . . . ..

DTC Logic . . . . . . . . . . . . . . . ...

Diagnosis Procedure . . . . . . . . . . . ..

POWER SUPPLY AND GROUND CIRCUIT . .

COMBINATION METER . . . . . . . . . . ...

COMBINATION METER : Diagnosis Procedure ....

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) . . . . . . . .

FUEL LEVEL SENSOR SIGNAL CIRCUIT . ...

2WD . . . . . . . . . . . . . . . . . . ...

2WD : Description . . . . . . . . . . . . ...

2WD : Component Function Check . . . . . ....

2WD : Diagnosis Procedure . . . . . . . . ...

2WD : Component Inspection [Fuel Level Sensor

Unit (Main)] . . . . . . . . . . . . . . . .

4WD . . . . . . . . . . . . . . . . . . ...

4WD : Description . . . . . . . . . . . . ...

4WD : Component Function Check . . . . . ....

4WD : Diagnosis Procedure . . . . . . . . ...

4WD : Component Inspection [Fuel Level Sensor

Unit (Main)] . . . . . . . . . . . . . . . .

4WD : Component Inspection [Fuel Level Sensor

Unit (Sub)] . . . . . . . . . . . . . . . ..

OIL LEVEL SENSOR SIGNAL CIRCUIT . . ..

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ..

Component Inspection . . . . . . . . . . ....

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...

Description . . . . . . . . . . . . . . . ..

Component Function Check . . . . . . . . ...

Diagnosis Procedure . . . . . . . . . . . ..

Component Inspection . . . . . . . . . . ....

OAT SENSOR SIGNAL CIRCUIT . . . . . .

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ..

Component Inspection . . . . . . . . . . ....

ECU DIAGNOSIS . . . . . . . . . .

COMBINATION METER . . . . . . . . .

Reference Value . . . . . . . . . . . . . .

Wiring Diagram - METER - . . . . . . . . . .

Fail Safe . . . . . . . . . . . . . . . . ..

DTC Index . . . . . . . . . . . . . . . ...

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) . . . . .

Reference Value . . . . . . . . . . . . . .

Wiring Diagram - IPDM E/R - . . . . . . . . ..

Fail Safe . . . . . . . . . . . . . . . . .

DTC Index . . . . . . . . . . . . . . . ..

SYMPTOM DIAGNOSIS . . . . . . .

THE FUEL GAUGE POINTER DOES NOT

MOVE . . . . . . . . . . . . . . . . .

2WD . . . . . . . . . . . . . . . . . . ...

2WD : Description . . . . . . . . . . . . ...

2WD : Diagnosis Procedure . . . . . . . . .

4WD . . . . . . . . . . . . . . . . . . ...

4WD : Description . . . . . . . . . . . . ...

4WD : Diagnosis Procedure . . . . . . . . .

THE OIL PRESSURE SWITCH DOES NOT

TURN ON . . . . . . . . . . . . . . ...

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

THE OIL PRESSURE SWITCH DOES NOT

TURN OFF . . . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT . . . . . . . . . . . . . ..

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

THE OIL LEVEL DISPLAY IS INCORRECT . .

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

NORMAL OPERATING CONDITION . . . .

INFORMATION DISPLAY . . . . . . . . . . .

INFORMATION DISPLAY : Description . . . . ..

PRECAUTION . . . . . . . . . . .

PRECAUTIONS . . . . . . . . . . . . .

ON-VEHICLE REPAIR . . . . . . . ...

COMBINATION METER . . . . . . . . .

Exploded View . . . . . . . . . . . . . .

MWI

DIAGNOSIS AND REPAIR WORKFLOW

MWI-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000000892243

DETAILED FLOW

1.

OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.

CHECK SYMPTOM

• Check the symptom based on the information obtained from the customer.

• Check if any other malfunctions are present.

>> GO TO 3.

3.

CHECK ON BOARD DIAGNOSIS OPERATION

Check that the on board diagnosis function operates. Refer to

MWI-21, "Diagnosis Description"

Does the on board diagnosis function operate normally?

YES

>> GO TO 4.

NO

>> Repair or replace the malfunctioning part and go to 6.

4.

CHECK CONSULTIII SELF-DIAGNOSIS RESULTS

Connect CONSULT-III and perform self-diagnosis. Refer to

MWI-23, "CONSULT-III Function (METER/M&A)"

.

Are self-diagnosis results normal?

YES

>> GO TO 5.

NO

>> Repair or replace the malfunctioning part and go to 6.

5.

NARROW DOWN THE MALFUNCTIONING PART BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and repair or replace the identified malfunctioning parts.

>> GO TO 6.

6.

FINAL CHECK

Check that the combination meter operates normally.

Does it operate normally?

YES

>> INSPECTION END

NO

>> GO TO 1.

MWI-4

< FUNCTION DIAGNOSIS >

METER SYSTEM

FUNCTION DIAGNOSIS

METER SYSTEM

METER SYSTEM

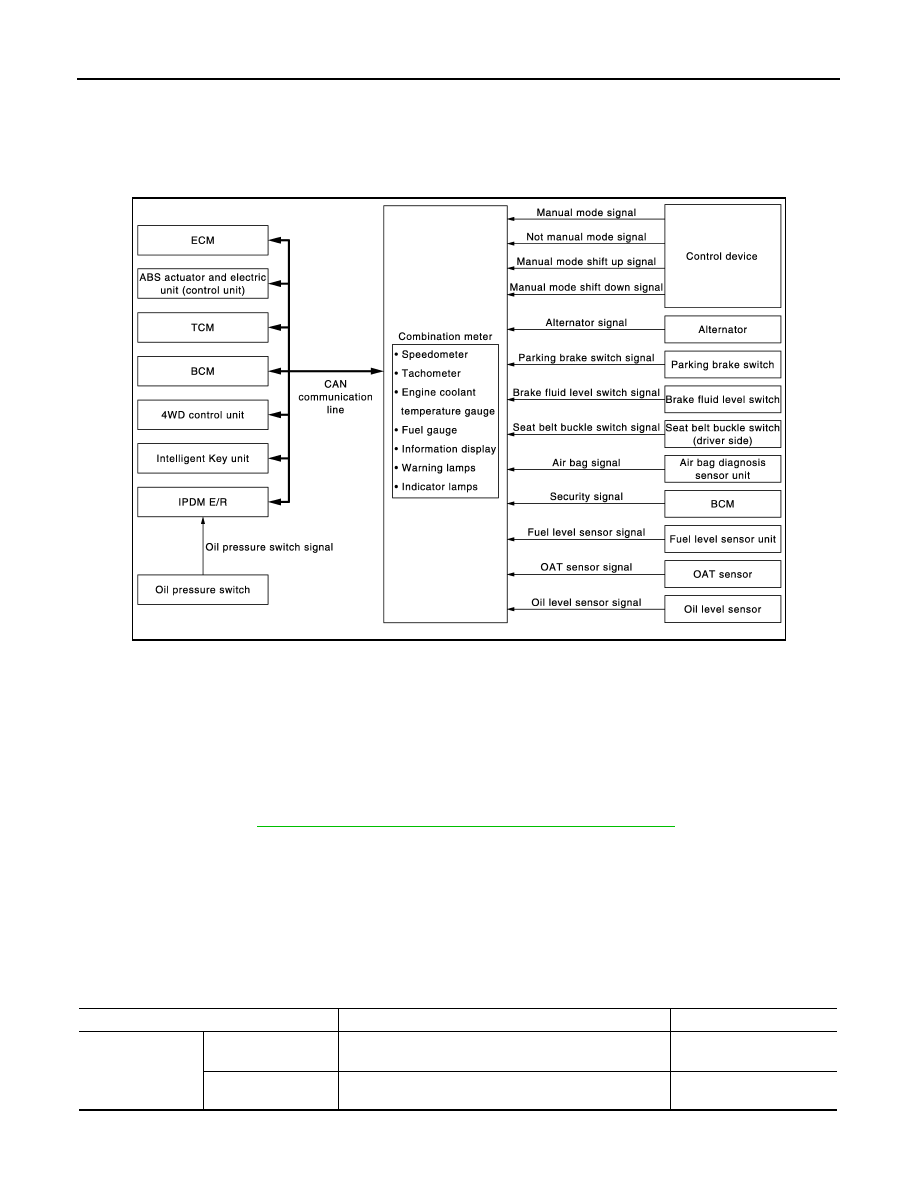

METER SYSTEM : System Diagram

INFOID:0000000000892244

METER SYSTEM : System Description

INFOID:0000000000892245

COMBINATION METER

• The combination meter receives the information required to control the operation of each gauge, indicator/

warning lamp, and information display via CAN communication from each unit, each switch, and sensor.

• The combination meter incorporates a trip computer that displays messages on the information display

according to the information received from various units.

• The combination meter incorporates a buzzer function that sounds an audible alarm with the integrated

buzzer device. Refer to

WCS-4, "WARNING CHIME SYSTEM : System Description"

for further details.

• The combination meter integrates the meter circuit check function and the segment check function that

checks the information display operation.

IPDM E/R

• IPDM E/R reads the ON/OFF signals of the oil pressure switch and transmits the oil pressure switch signal to

the combination meter via BCM with CAN communication.

• IPDM E/R is equipped with the diagnosis function. It can perform the operation check of oil pressure warning

lamp with the auto active test and the diagnosis with CONSULT-III.

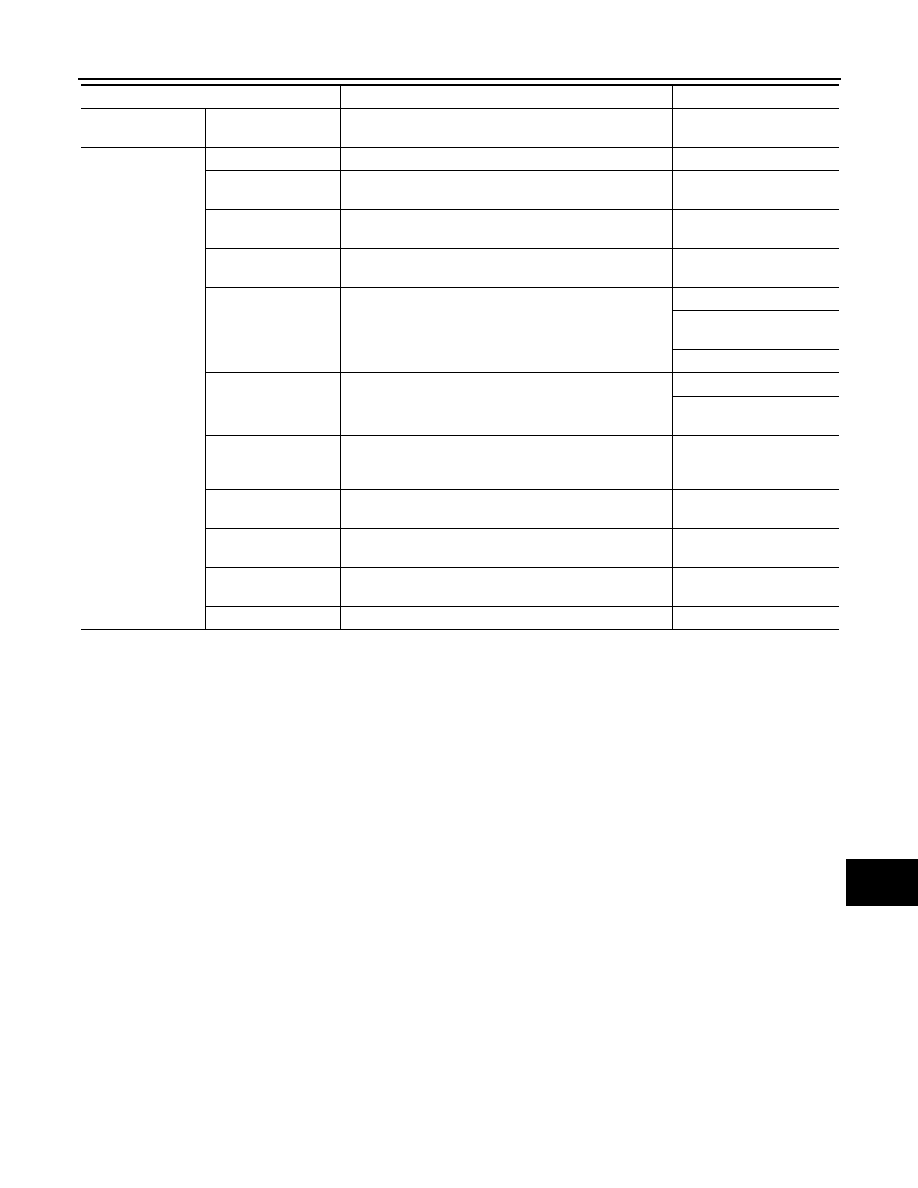

METER CONTROL FUNCTION LIST

JSNIA0288GB

System

Description

Signal source

Meter

Speedometer

Receives vehicle speed signal and indicates vehicle

speed.

ABS actuator and electric

unit (control unit)

Tachometer

Receives engine speed signal and indicates engine

speed.

ECM

MWI

METER SYSTEM

MWI-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

Warning lamp

Oil pressure warning

lamp

Receives oil pressure warning lamp signal and illumi-

nates warning lamp.

IPDM E/R

Information display

Fuel gauge

Receives fuel level sensor signal and indicates fuel level.

Fuel level sensor unit

Engine coolant tem-

perature gauge

Receives engine coolant temperature signal and indi-

cates coolant temperature.

ECM

Maintenance

The remaining distance from the set distance is displayed

for 5 seconds after the ignition switch is turned ON.

ABS actuator and electric

unit (control unit)

Oil level

The oil level is displayed according to the oil level sensor

signal for 5 seconds after the maintenance display.

Oil level sensor

Possible driving dis-

tance

Calculates possible driving distance based on received

fuel consumption monitor signal, vehicle speed signals

and fuel level sensor signal and displays it.

ECM

ABS actuator and electric

unit (control unit)

Fuel level sensor unit

Average fuel con-

sumption

Calculates average fuel consumption in a reset-to-reset

interval based on received vehicle speed signals and fuel

consumption monitor signal and displays it.

ECM

ABS actuator and electric

unit (control unit)

Average vehicle

speed

Calculates average vehicle speed in a reset-to-reset in-

terval based on received vehicle speed signals and dis-

plays it.

ABS actuator and electric

unit (control unit)

Travel time

Displays accumulated key switch ON time from reset to

reset.

—

Odo/trip meter

Calculates accumulated travel distance based on re-

ceived vehicle speed signals and displays it.

ABS actuator and electric

unit (control unit)

Ambient air tempera-

ture

Corrects ambient temperature value based on received

OAT sensor signals and displays it.

OAT sensor

Clock

Time is displayed.

—

System

Description

Signal source

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст