Nissan Qashqai (2007-2010). Manual — part 38

EM-100

< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

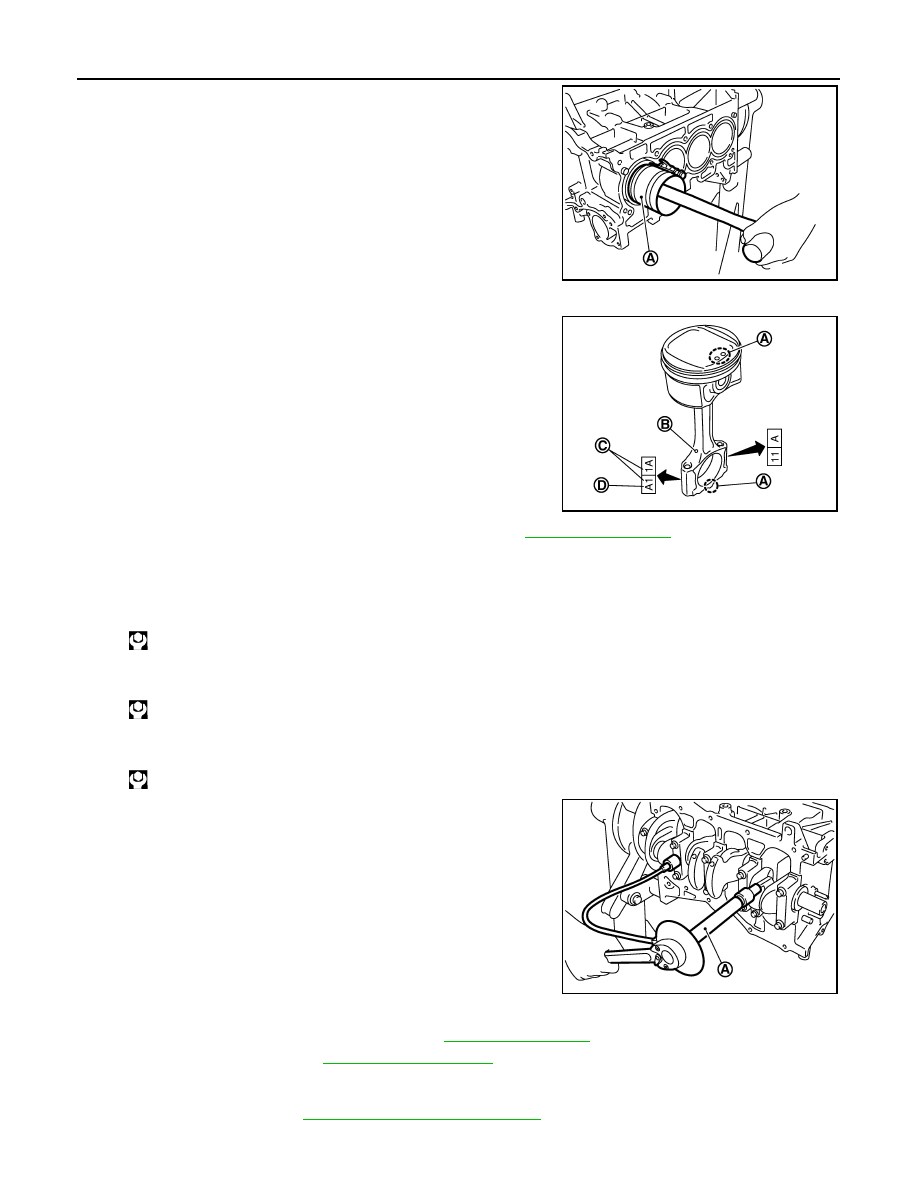

• Using the piston ring compressor (SST: EM03470000) (A) or

suitable tool, install piston with the front mark on the piston

head facing the front of the engine.

CAUTION:

• Be careful not to damage matching surface with con-

necting rod cap.

• Be careful not to damage the cylinder wall and crank-

shaft pin, resulting from an interference of the connect-

ing rod big end.

12. Install connecting rod cap.

• Match the stamped cylinder number marks (C) on connecting

rod with those on connecting rod cap to install.

13. Inspect outer diameter of connecting rod cap bolts. Refer to

.

14. Tighten connecting rod bolt with the following procedure:

a.

Apply new engine oil to the threads and seats of connecting rod bolts.

b.

Tighten bolts in several steps.

c.

Completely loosen bolts.

d.

Tighten bolts in several steps.

e.

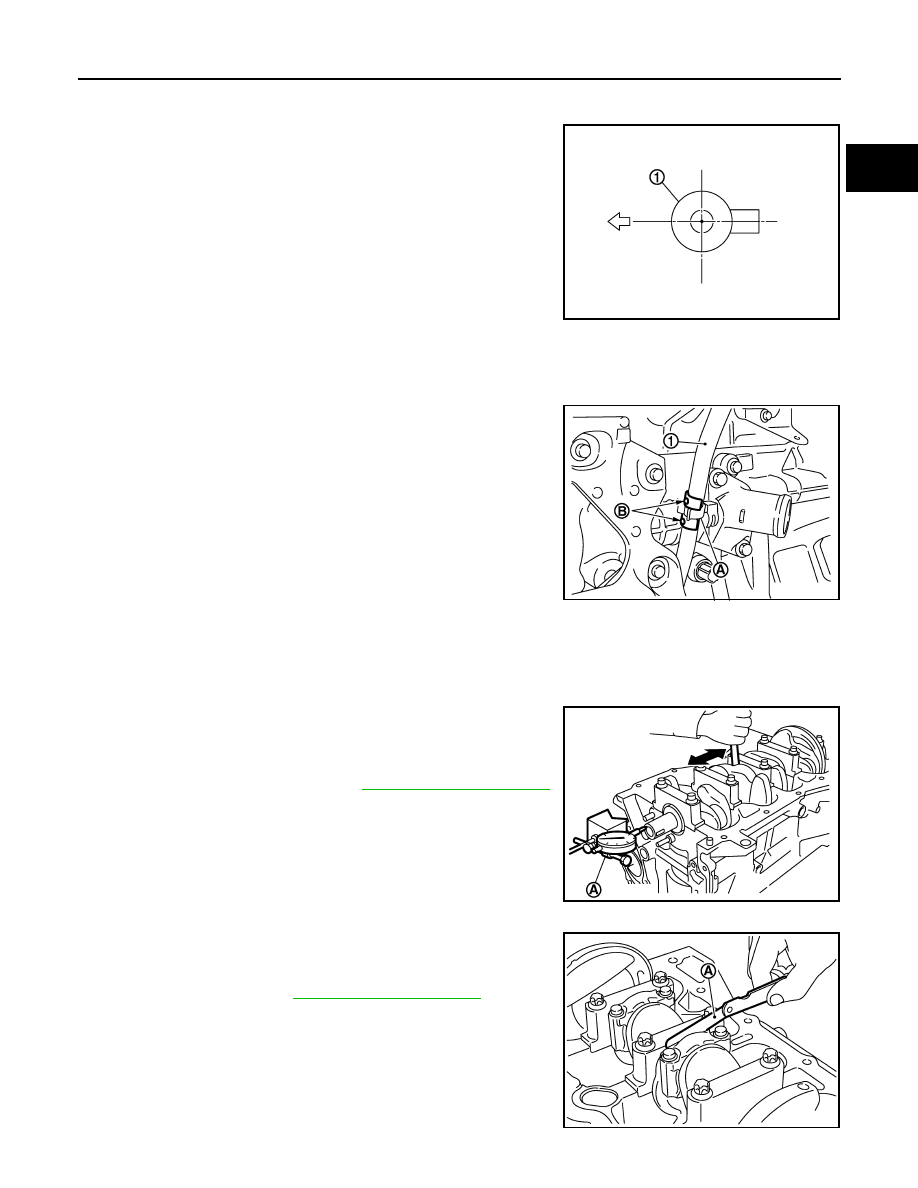

Then turn all bolts 60 degrees clockwise (angle tightening).

CAUTION:

Confirm the tightening angle by using the angle wrench

[SST: KV10112100] (A) or protractor. Avoid judgment by

visual inspection without the tool.

• After tightening connecting rod bolt, make sure that crankshaft rotates smoothly.

• Check the connecting rod side clearance. Refer to

15. Install oil pan (upper). Refer to

NOTE:

Install the rear oil seal after installing the oil pan (upper).

16. Install rear oil seal. Refer to

EM-89, "Removal and Installation"

.

17. Install flywheel.

PBIC3765E

A

: Front mark

B

: Oil hole

D

: Connecting rod big end grade

JPBIA0537ZZ

: 27.5 N·m (2.8 kg-m, 20 ft-lb)

: 0 N·m (0 kg-m, 0 ft-lb)

: 19.6 N·m (2.0 kg-m, 14 ft-lb)

PBIC3753E

CYLINDER BLOCK

EM-101

< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Secure crankshaft with a stopper plate [SST: KV11105210], and tighten mounting bolts crosswise over

several times.

18. Install knock sensor (1).

• Install connectors so that they are positioned towards the rear

of the engine.

CAUTION:

• Never tighten mounting bolt while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Make sure that there is no foreign material on the cylinder

block mating surface and the back surface of knock sensor.

• Make sure that knock sensor does not interfere with other parts.

19. Install crankshaft position sensor (POS) and cover.

• Tighten bolts with it seated completely.

20. For the oil level gauge guide (1), fix the position (B) shown in the

figure to the water inlet clip (A) after inserting to the cylinder

block side.

21. Assemble in the reverse order of disassembly after this step.

Inspection

INFOID:0000000000893892

CRANKSHAFT END PLAY

• Measure the clearance between thrust bearings and crankshaft

arm when crankshaft is moved fully forward or backward with a dial

indicator (A).

• If the measured value exceeds the limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE

• Measure the side clearance between connecting rod and crank-

shaft arm with a feeler gauge (A).

• If the measured value exceeds the limit, replace connecting rod,

and measure again. If it still exceeds the standard, replace crank-

shaft also.

: Engine front

PBIC3754E

PBIC3755E

Standard and Limit

: Refer to

.

PBIC3762E

Standard

: Refer to

.

PBIC3763E

EM-102

< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

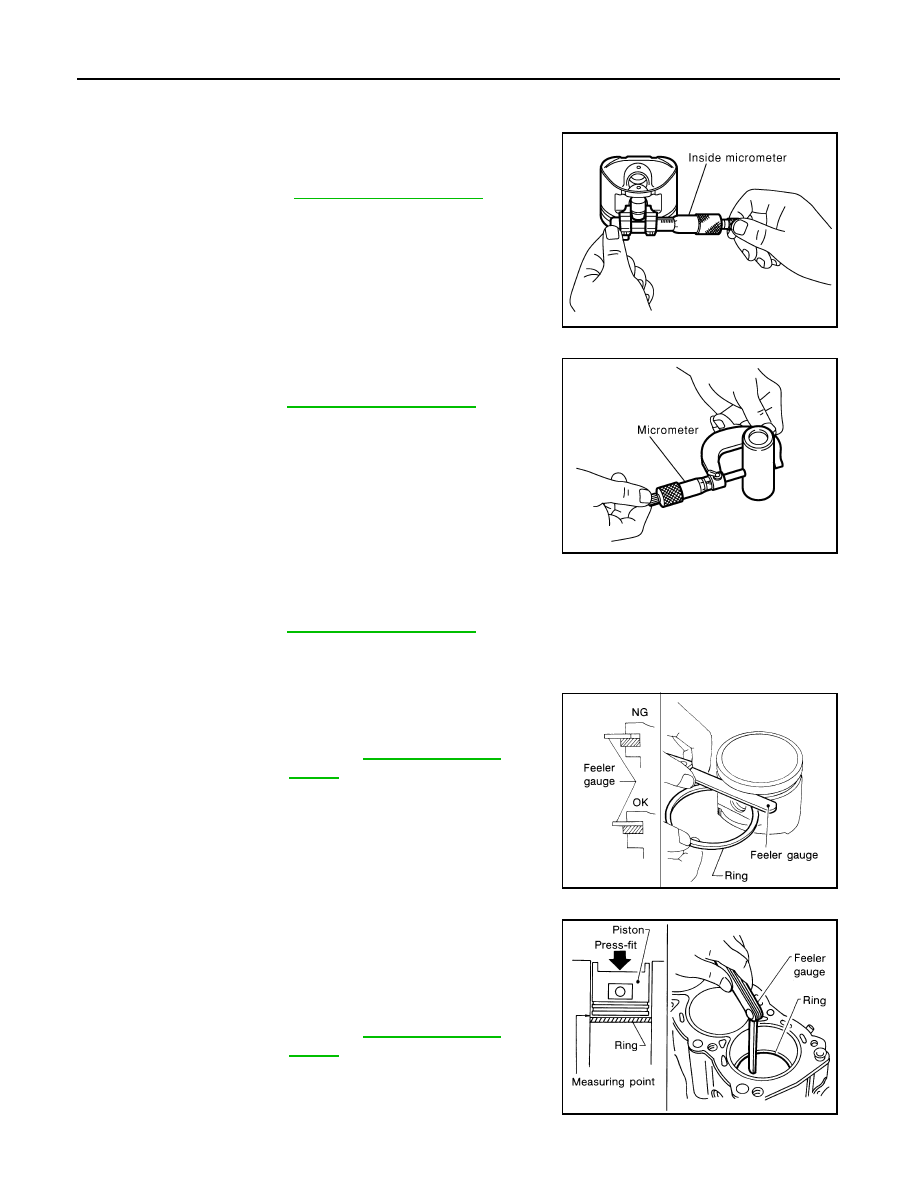

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

Measure the inner diameter of piston pin hole with an inside

micrometer.

Piston Pin Outer Diameter

Measure the outer diameter of piston pin with a micrometer.

Piston to Piston Pin Oil Clearance

(Piston to piston pin oil clearance) = (Piston pin hole diameter) – (Piston pin outer diameter)

• If oil clearance is out of the standard, replace piston and piston pin assembly.

PISTON RING SIDE CLEARANCE

• Measure the side clearance of piston ring and piston ring groove

with a feeler gauge.

• If the measured value exceeds the limit, replace piston ring, and

measure again. If it still exceeds the limit, replace piston also.

PISTON RING END GAP

• Make sure that cylinder bore inner diameter is within the specifica-

tion. Refer to "Cylinder Bore Inner Diameter".

• Lubricate with new engine oil to piston and piston ring, and then

insert piston ring until middle of cylinder with piston, and measure

piston ring end gap with a feeler gauge.

• If the measured value exceeds the limit, replace piston ring.

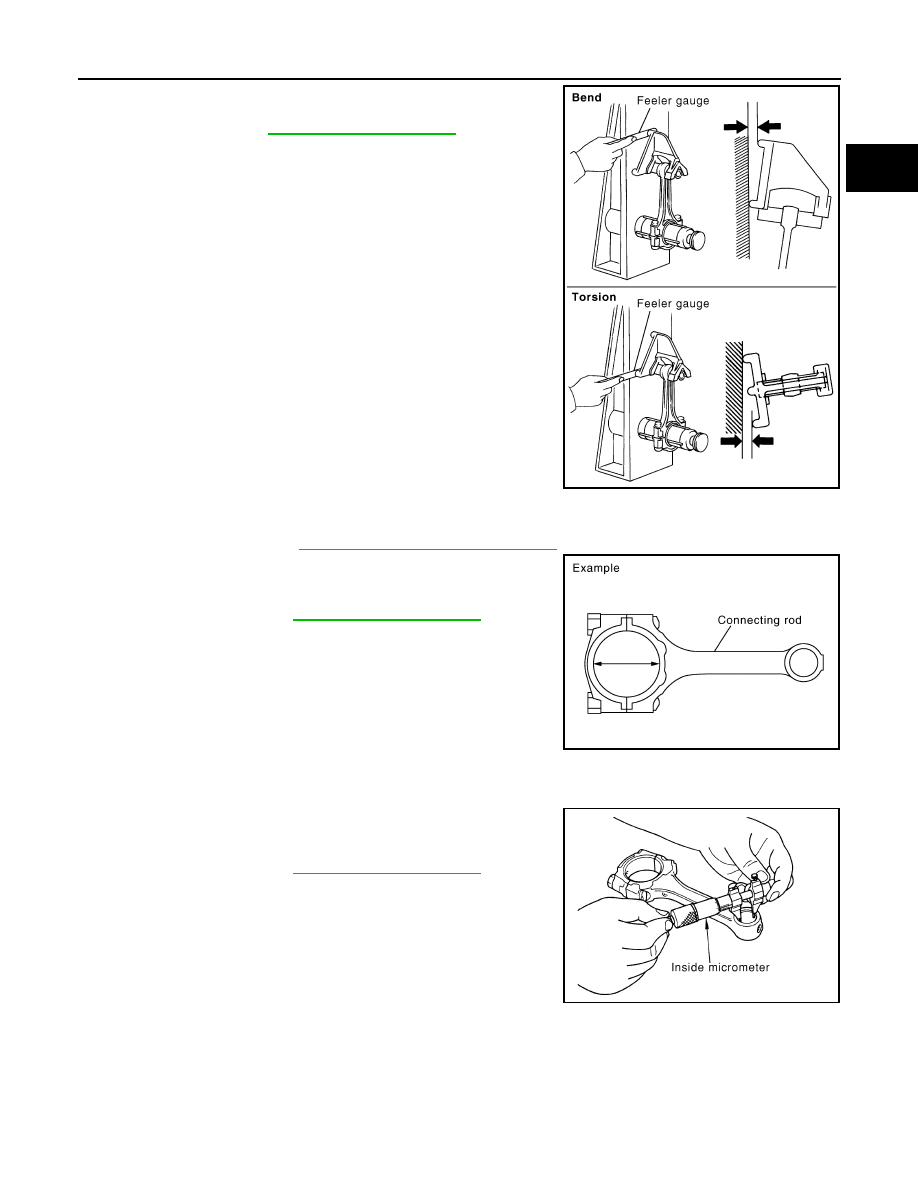

CONNECTING ROD BEND AND TORSION

Standard

: Refer to

PBIC0116E

Standard

PBIC0117E

Standard

Standard and Limit

: Refer to

.

SEM024AA

Standard and Limit

: Refer to

.

SEM822B

CYLINDER BLOCK

EM-103

< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Check with a connecting rod aligner.

• If it exceeds the limit, replace connecting rod assembly.

CONNECTING ROD BIG END DIAMETER

• Install connecting rod cap without connecting rod bearing installed, and tightening connecting rod bolts to

the specified torque. Refer to

EM-94, "Disassembly and Assembly"

• Measure the inner diameter of connecting rod big end with an

inside micrometer.

• If out of the standard, replace connecting rod assembly.

CONNECTING ROD SMALL END CLEARANCE

Connecting Rod Small End Inner Diameter

Measure the inner diameter of connecting rod small end with an

inside micrometer.

Piston Pin Outer Diameter

Limit

: Refer to

.

PBIC2077E

Standard

: Refer to

.

PBIC1641E

Standard

: Refer to

.

PBIC0120E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст