Nissan Qashqai (2007-2010). Manual — part 668

FRONT COIL SPRING AND STRUT

FSU-9

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

ON-VEHICLE REPAIR

FRONT COIL SPRING AND STRUT

Exploded View

INFOID:0000000000970530

Removal and Installation

INFOID:0000000000970531

REMOVAL

1.

Remove tires from vehicle.

2.

Remove lock plat.

BR-19, "FRONT BRAKE (WITH ABS) : Exploded View"

"FRONT BRAKE (WITH ESP) : Exploded View"

BR-63, "FRONT BRAKE (WITH ABS) :

BR-65, "FRONT BRAKE (WITH ESP) : Exploded View"

(RHD with

ESP).

3.

Remove cap and mounting nut on the upper side of stabilizer connecting rod, and then remove stabilizer

connecting rod from strut assembly.

4.

Separate steering knuckle from strut assembly.

5.

Remove mounting bolts of strut mounting insulator, and then remove strut assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

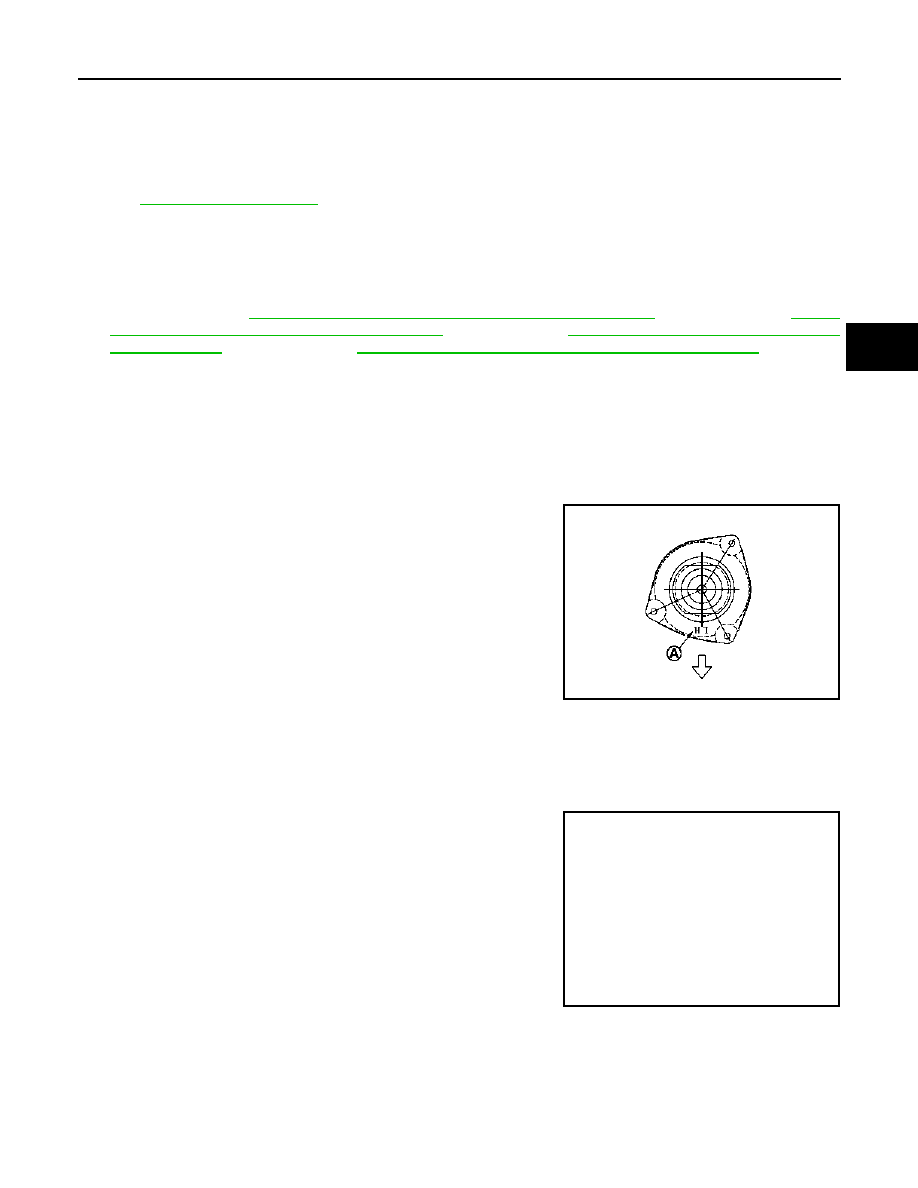

• Make sure the identification mark (A) on strut mounting insulator

as shown in the figure.

• Perform final tightening of bolts and nuts, under unladen conditions

with tires on level ground.

Disassembly and Assembly

INFOID:0000000000970532

DISASSEMBLY

CAUTION:

Never damage strut assembly piston rod when removing components from strut assembly.

1.

Install strut attachment (A) (SST: ST35652000) to strut assem-

bly and secure it in a vise.

CAUTION:

When installing the strut attachment to strut assembly,

wrap a shop cloth around strut to protect from damage.

: Vehicle front

PDIA1228E

JPEIA0006ZZ

FSU-10

< ON-VEHICLE REPAIR >

FRONT COIL SPRING AND STRUT

2.

Using a spring compressor (A) (commercial service tool), com-

press coil spring between strut mounting bearing and lower rub-

ber seat (on strut assembly) until coil spring with a spring

compressor is free.

CAUTION:

Be sure a spring compressor is securely attached to coil

spring. Compress coil spring.

3.

Make sure coil spring with a spring compressor between strut

mounting bearing and lower rubber seat (strut assembly) is free.

And then remove piston rod lock nut while securing the piston

rod tip so that piston rod does not turn.

4.

Remove strut mounting insulator and strut mounting bearing,

and bound bumper from strut.

5.

After remove coil spring with a spring compressor, and then gradually release a spring compressor.

CAUTION:

Loosen while making sure coil spring attachment position does not move.

6.

Remove lower rubber seat from strut.

7.

Remove the strut attachment (SST: ST35652000) from strut.

ASSEMBLY

1.

Install strut attachment (SST: ST35652000) to strut and secure it in a vise.

CAUTION:

When installing the strut attachment to strut assembly, wrap a shop cloth around strut to protect

from damage.

2.

Install lower rubber seat.

3.

Install bound bumper.

4.

Compress coil spring using a spring compressor (commercial service tool), and install it onto strut assem-

bly.

CAUTION:

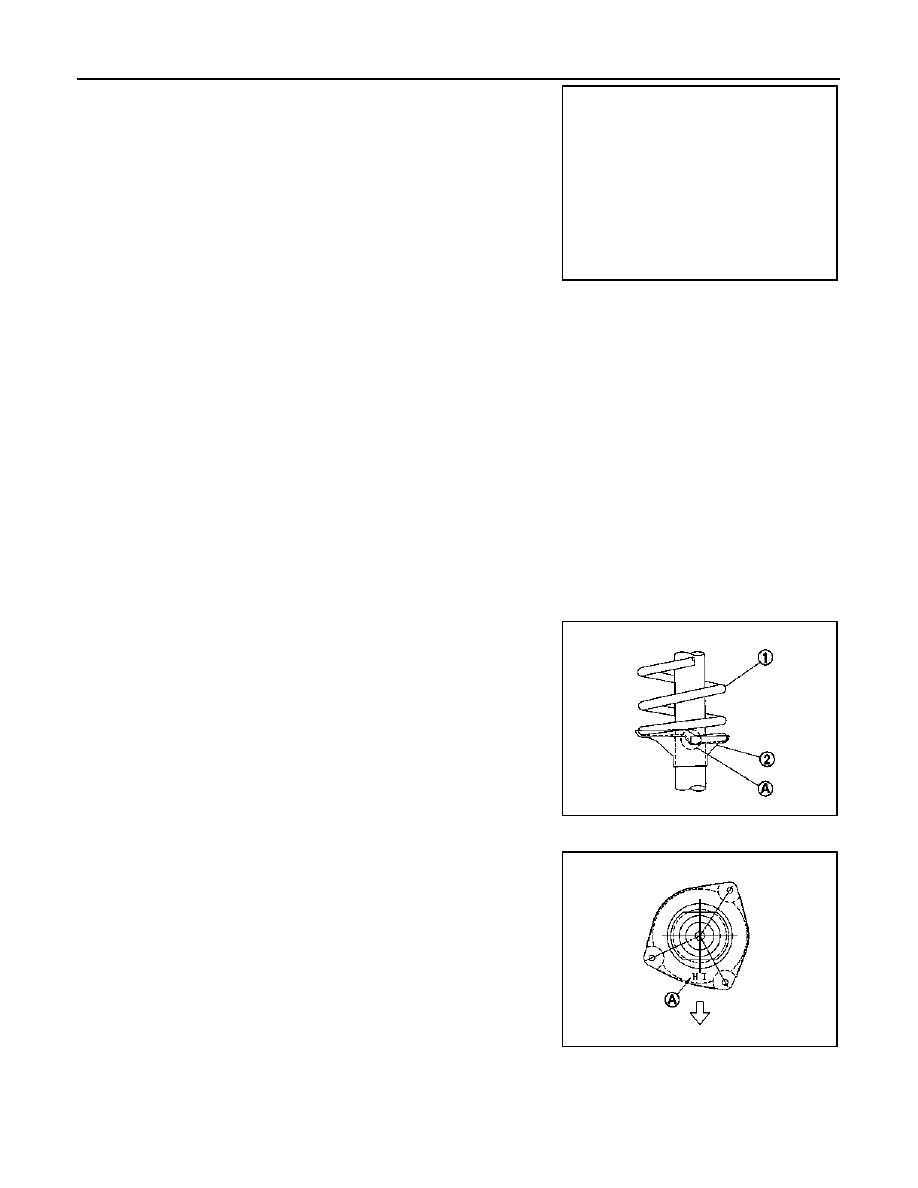

• Face tube side of coil spring (1) downward. Align the

lower end (A) to lower rubber seat (2).

• Be sure a spring compress is securely attached to coil

spring. Compress coil spring.

5.

Install strut mounting bearing and strut mounting insulator to strut.

• Installation position of strut mounting insulator as shown in the

figure.

6.

Secure piston rod tip so that piston rod does not turn, then

tighten piston rod lock nut with specified torque.

CAUTION:

Never reuse piston rod lock nut.

7.

Gradually release a spring compressor, and remove coil spring.

CAUTION:

Loosen while making sure coil spring attachment position does not move.

8.

Remove the strut attachment from strut assembly.

Inspection

INFOID:0000000000970533

JPEIA0007ZZ

JPEIA0027ZZ

A

: Identification mark

: Vehicle front

PDIA1228E

FRONT COIL SPRING AND STRUT

FSU-11

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

INSPECTION AFTER INSTALLATION

1.

Adjust neutral position of steering angle sensor. Refer to

BRC-78, "ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement"

(with ESP).

2.

Check wheel alignment. Refer to

FSU-7, "Wheel Alignment Inspection"

.

INSPECTION AFTER DISASSEMBLY

Strut

Check the following items, and replace the parts if necessary.

• Strut for deformation, cracks or damage

• Piston rod for damage, uneven wear or distortion

• For oil leakage

Strut Mounting Insulator and Rubber Parts Inspection

Check strut mounting insulator for cracks and rubber parts for wear. Replace it if necessary.

Coil Spring

Check coil spring for cracks, wear or damage. Replace it if necessary.

FSU-12

< ON-VEHICLE REPAIR >

TRANSVERSE LINK

TRANSVERSE LINK

Exploded View

INFOID:0000000000970534

Removal and Installation

INFOID:0000000000970535

REMOVAL

1.

Remove tires from vehicle.

2.

Remove transverse link from steering knuckle.

3.

Remove transverse link from suspension member.

NOTE:

Transverse link cannot be pulled out because the mounting bolt

(

) of transverse link at the rear of the mounting area located

on the front side of vehicle hits against the stabilizer bar. There-

fore, get stabilizer bar out of the way to remove the transverse

link.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of bolts and nuts at the front suspension member, under unladen conditions with

tires on level ground.

Inspection

INFOID:0000000000970536

INSPECTION AFTER REMOVAL

Visual Inspection

Check the following:

• Transverse link and bushing for deformation, cracks or damage. Replace it if necessary.

• Ball joint boot for cracks or other damage, and also for grease leakage. Replace it if necessary.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

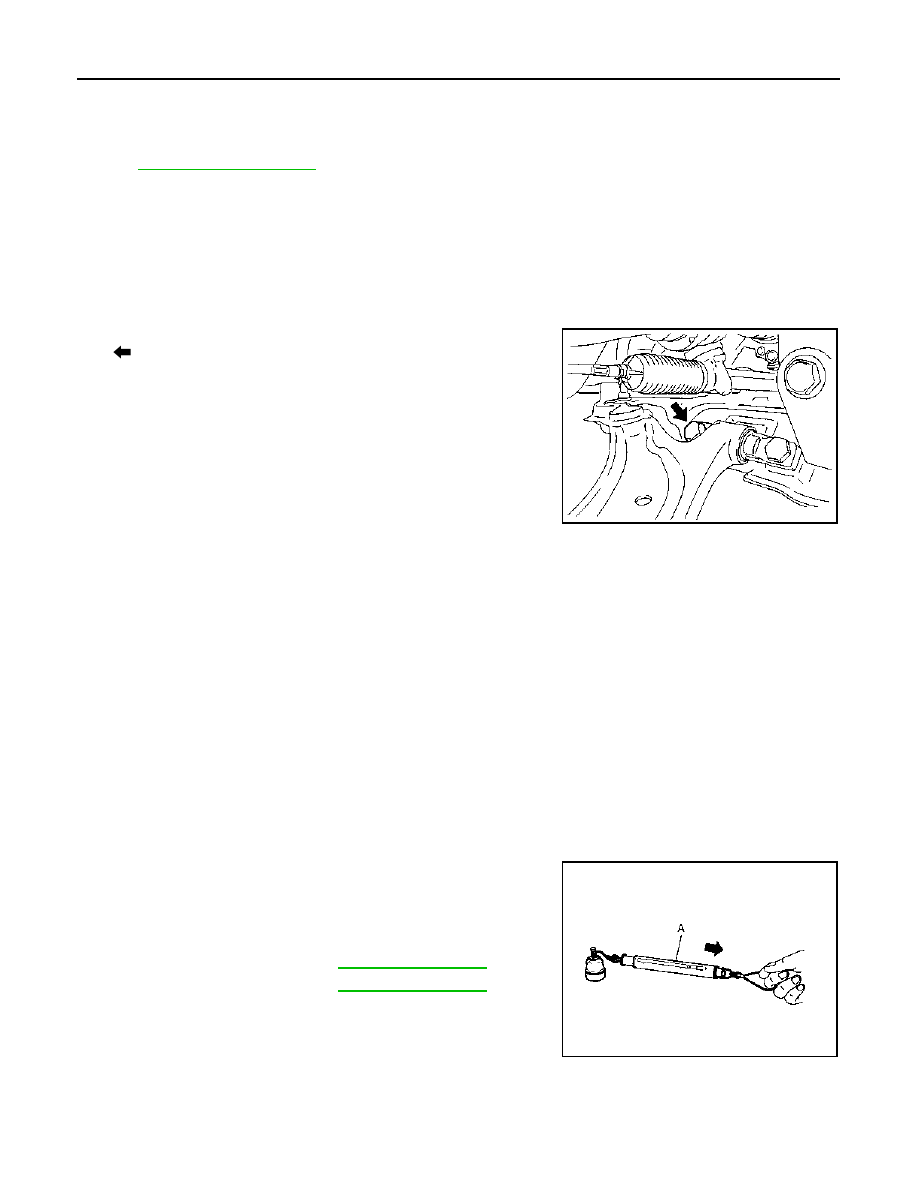

NOTE:

Before measurement, move ball stud at least ten times by hand to check for smooth movement.

• Hook a spring balance (A) at cotter pin mounting hole. Confirm

spring balance measurement value is within specifications when

ball stud begins moving.

- If swing torque exceeds standard range, replace transverse link

assembly.

Axial End Play Inspection

• Move tip of ball stud in axial direction to check for looseness.

SEIA0633J

Standard

Swing torque

Spring balance

measurement

JPEIA0005ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст