Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Service manual — part 278

EN(H4DOTC)(diag)-336

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

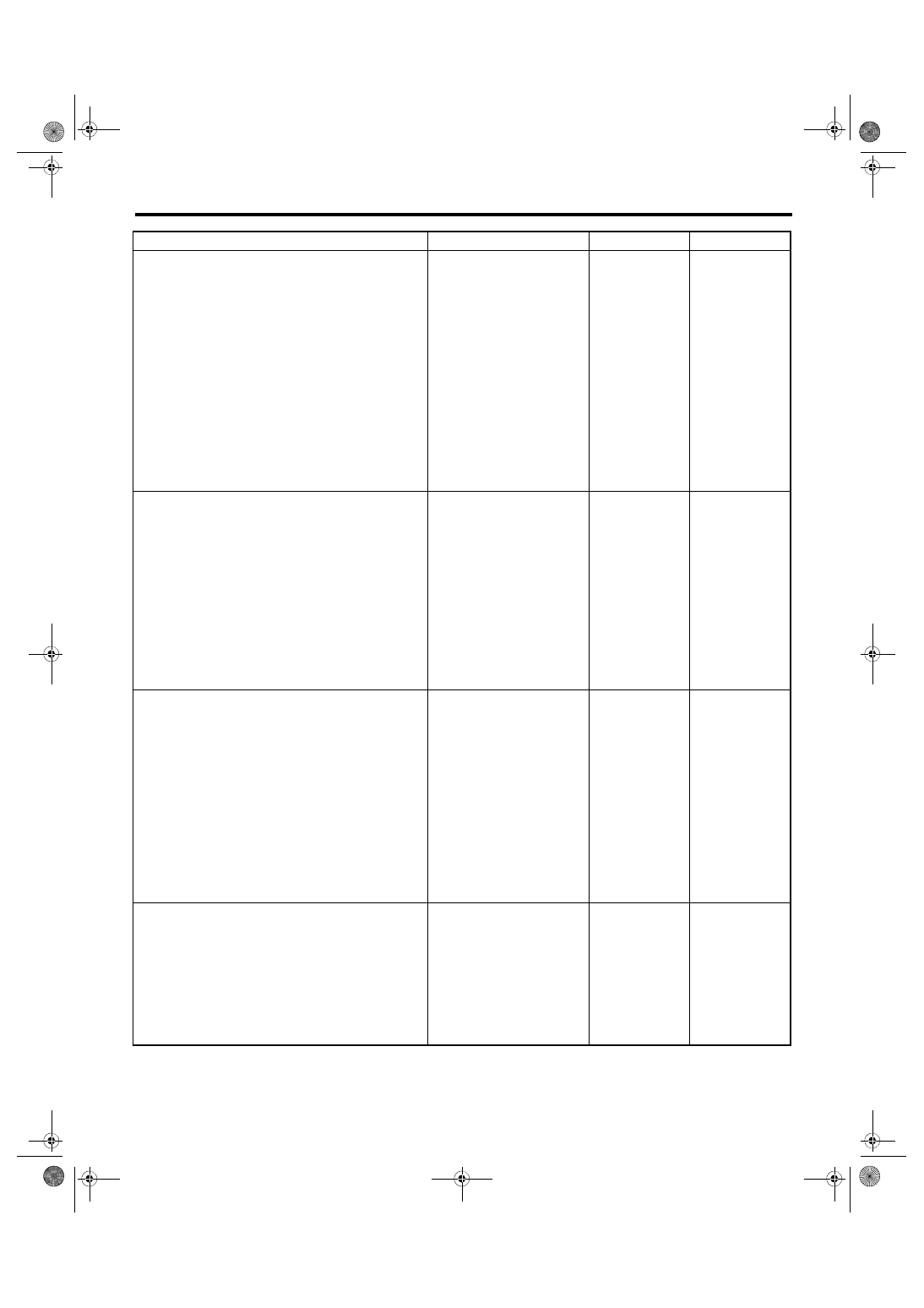

Step

Check

Yes

No

1

CHECK CURRENT DATA.

1) Start the engine.

2) Read the value of «TGV Position Sensor L»

using the Subaru Select Monitor.

NOTE:

Is the value of «TGV Position

Sensor L» 5 V or more?

Even if DTC is

detected, the cir-

cuit has returned to

a normal condition

at this time. Repro-

duce the failure,

and then perform

the diagnosis

again.

NOTE:

In this case, tem-

porary poor con-

tact of connector,

temporary open or

short circuit of har-

ness may be the

cause.

2

CHECK HARNESS BETWEEN ECM AND

TUMBLE GENERATOR VALVE ASSEMBLY

LH CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from tumble gen-

erator valve assembly LH.

3) Start the engine.

4) Read the value of «TGV Position Sensor L»

using the Subaru Select Monitor.

NOTE:

Is the value of «TGV Position

Sensor L» 5 V or more?

Repair the short

circuit to power in

harness between

ECM connector

and tumble gener-

ator valve assem-

bly LH connector.

3

CHECK HARNESS BETWEEN ECM AND

TUMBLE GENERATOR VALVE ASSEMBLY

LH CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness between

tumble generator valve assembly LH connector

and engine ground.

Connector & terminal

(E51) No. 2 — Engine ground:

Is the resistance less than 5 Ω? Go to step

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM

connector

and tumble gener-

ator valve assem-

bly LH connector

• Poor contact of

ECM connector

• Poor contact of

coupling connector

4

CHECK FOR POOR CONTACT.

Check for poor contact of tumble generator

valve assembly LH connector.

Is there poor contact of the tum-

ble generator valve assembly

LH connector?

Repair the poor

contact of tumble

generator valve

assembly LH con-

nector.

EN(H4DOTC)(diag)-337

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

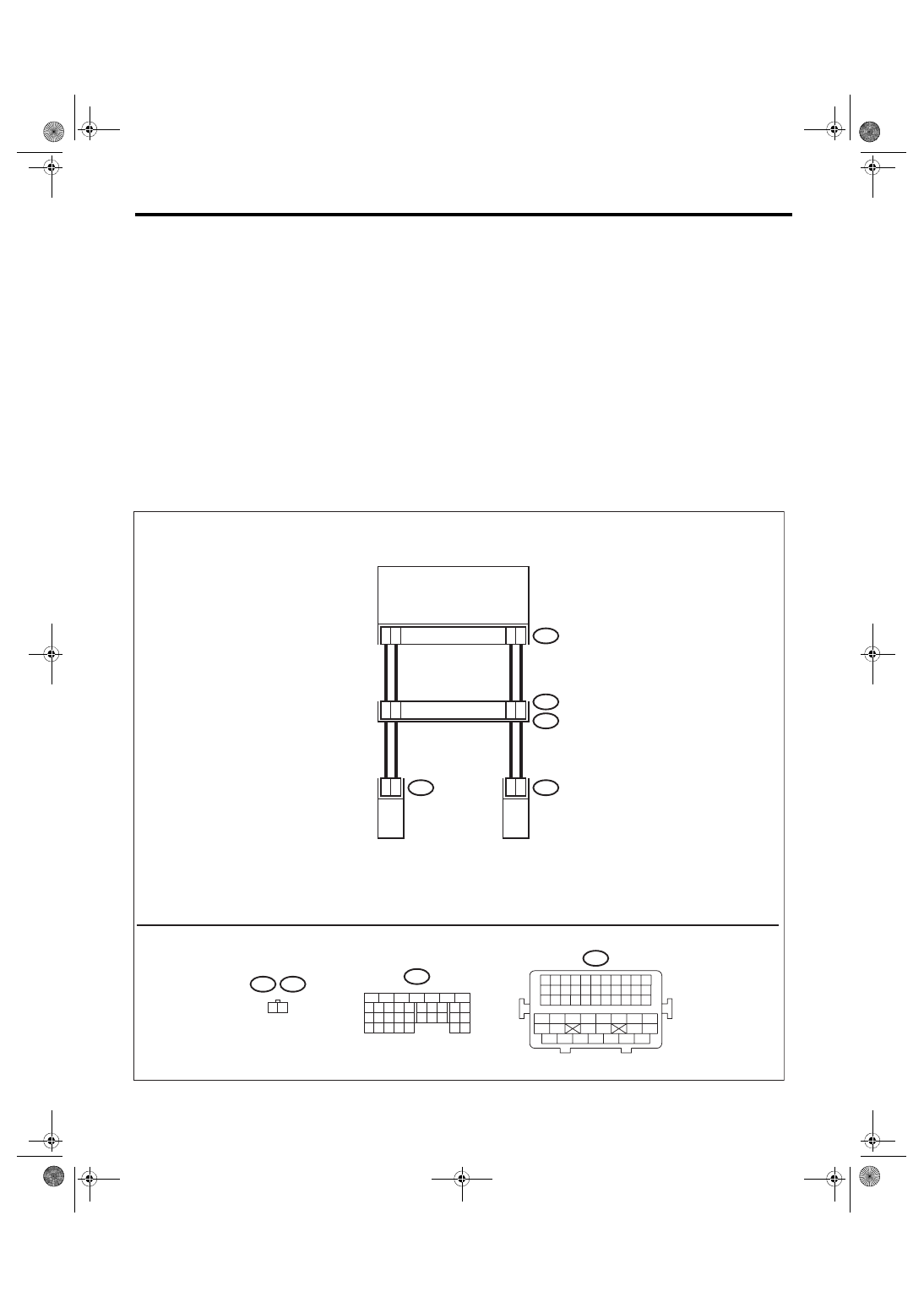

EC:DTC P2088 INTAKE CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT

LOW (BANK 1)

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-234, DTC P2088 INTAKE CAMSHAFT POSITION AC-

TUATOR CONTROL CIRCUIT LOW (BANK 1), Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

Improper idling

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-63,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-49, PROCE-

WIRING DIAGRAM:

• Engine electrical system, without SI-DRIVE <Ref. to WI-32, WITHOUT SI-DRIVE, WIRING DIAGRAM,

• Engine electrical system, with SI-DRIVE <Ref. to WI-48, WITH SI-DRIVE, WIRING DIAGRAM, Engine

ECM

E38

E37

1 2

7

1

6

1

B134

4

3

7

2

2

2

1

2

B21

E2

3

3

2

3

2

1

E38

2

1

E37

18

27

19 20 21 22 23

26

24 25

28 29

33

32

34

30 31

9

8

15

14

13

12

11

10

17

16

1

2

3

4

5

6

7

B134

15 16 17 18 19 20 21 22

23 24 25 26 27 28 29 30 31 32 33

13 14

11

12

9 10

7 8

5 6

3 4

1 2

34 35 36 37 38 39 40 41

42 43

44 45

46 47

48 49 50 51 52 53 54

B21

EN-09254

INTAKE OIL FLOW

CONTROL SOLENOID

VALVE LH

INTAKE OIL FLOW

CONTROL SOLENOID

VALVE RH

EN(H4DOTC)(diag)-338

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

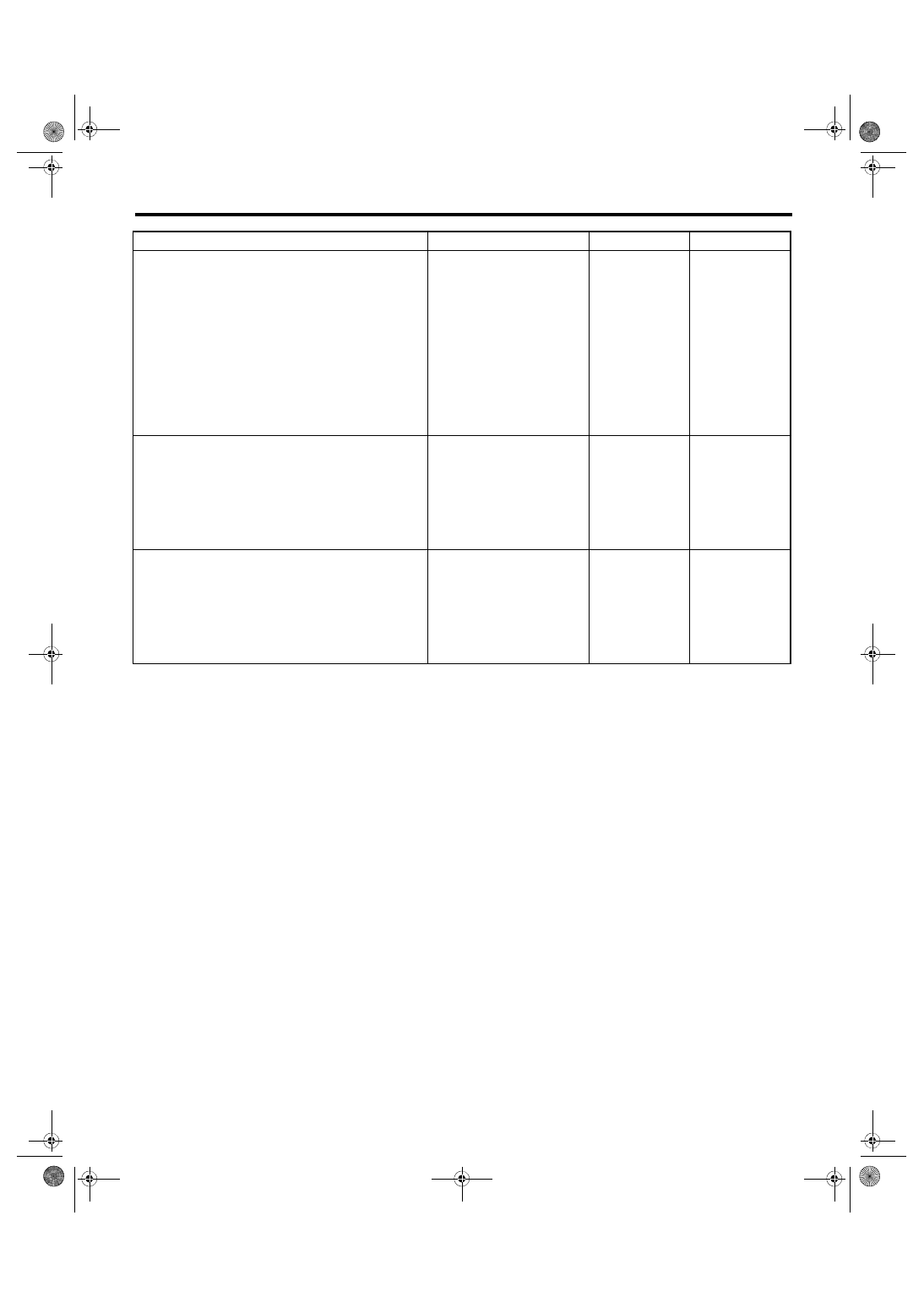

Step

Check

Yes

No

1

CHECK HARNESS BETWEEN ECM AND OIL

FLOW CONTROL SOLENOID VALVE RH

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM and

oil flow control solenoid valve RH.

3) Measure the resistance of harness between

ECM connector and oil flow control solenoid

valve RH connector.

Connector & terminal

(B134) No. 34 — (E38) No. 1:

(B134) No. 27 — (E38) No. 2:

Is the resistance less than 1 Ω? Go to step

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM

connector

and oil flow control

solenoid valve RH

connector

• Poor contact of

coupling connector

2

CHECK HARNESS BETWEEN ECM AND OIL

FLOW CONTROL SOLENOID VALVE RH

CONNECTOR.

Measure the resistance between ECM connec-

tor and chassis ground.

Connector & terminal

(B134) No. 34 — Chassis ground:

(B134) No. 27 — Chassis ground:

Is the resistance 1 MΩ or

more?

Repair the short

circuit to ground in

harness between

ECM connector

and oil flow control

solenoid valve RH

connector.

3

CHECK OIL FLOW CONTROL SOLENOID

VALVE.

Measure the resistance between oil flow control

solenoid valve terminals.

Terminals

No. 1 — No. 2:

Is the resistance 6 — 12 Ω?

Repair the poor

contact of ECM

and oil flow control

solenoid valve RH

connector.

EN(H4DOTC)(diag)-339

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

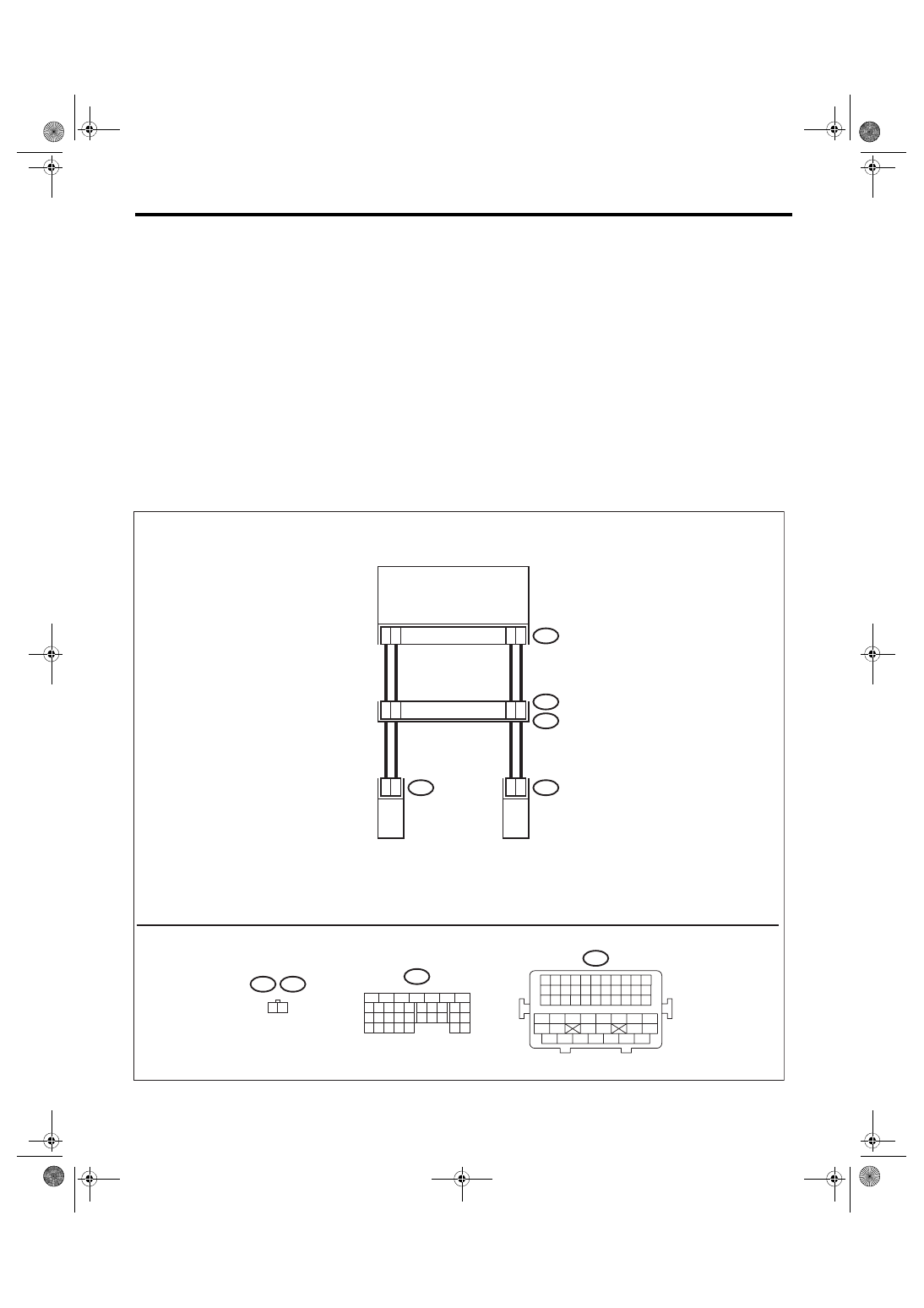

ED:DTC P2089 INTAKE CAMSHAFT POSITION ACTUATOR CONTROL CIRCUIT

HIGH (BANK 1)

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-235, DTC P2089 INTAKE CAMSHAFT POSITION AC-

TUATOR CONTROL CIRCUIT HIGH (BANK 1), Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

Improper idling

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-63,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-49, PROCE-

WIRING DIAGRAM:

• Engine electrical system, without SI-DRIVE <Ref. to WI-32, WITHOUT SI-DRIVE, WIRING DIAGRAM,

• Engine electrical system, with SI-DRIVE <Ref. to WI-48, WITH SI-DRIVE, WIRING DIAGRAM, Engine

ECM

E38

E37

1 2

7

1

6

1

B134

4

3

7

2

2

2

1

2

B21

E2

3

3

2

3

2

1

E38

2

1

E37

18

27

19 20 21 22 23

26

24 25

28 29

33

32

34

30 31

9

8

15

14

13

12

11

10

17

16

1

2

3

4

5

6

7

B134

15 16 17 18 19 20 21 22

23 24 25 26 27 28 29 30 31 32 33

13 14

11

12

9 10

7 8

5 6

3 4

1 2

34 35 36 37 38 39 40 41

42 43

44 45

46 47

48 49 50 51 52 53 54

B21

EN-09254

INTAKE OIL FLOW

CONTROL SOLENOID

VALVE LH

INTAKE OIL FLOW

CONTROL SOLENOID

VALVE RH

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст