Subaru Legacy (2005 year). Service manual — part 118

EN(H4SO 2.0)(diag)-61

ENGINE (DIAGNOSTICS)

Diagnostics for Engine Starting Failure

7

CHECK HARNESS BETWEEN ECM AND

FUEL PUMP RELAY CONNECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and fuel pump relay connector.

Connector & terminal

RHD model and LHD model (with immo-

bilizer)

(B135) No. 17 — (B362) No. 3:

LHD model (without immobilizer)

(B134) No. 18 — (B362) No. 3:

Is the resistance less than 1

Ω?

Repair the open

circuit of harness

between ECM and

fuel pump relay

connector.

8

CHECK POOR CONTACT.

Check poor contact in ECM connector.

Is there poor contact in ECM

connector?

Repair the poor

contact in ECM

connector.

Check the fuel

injector circuit.

<Ref. to EN(H4SO

2.0)(diag)-62,

FUEL INJECTOR

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>

Step

Check

Yes

No

EN(H4SO 2.0)(diag)-62

ENGINE (DIAGNOSTICS)

Diagnostics for Engine Starting Failure

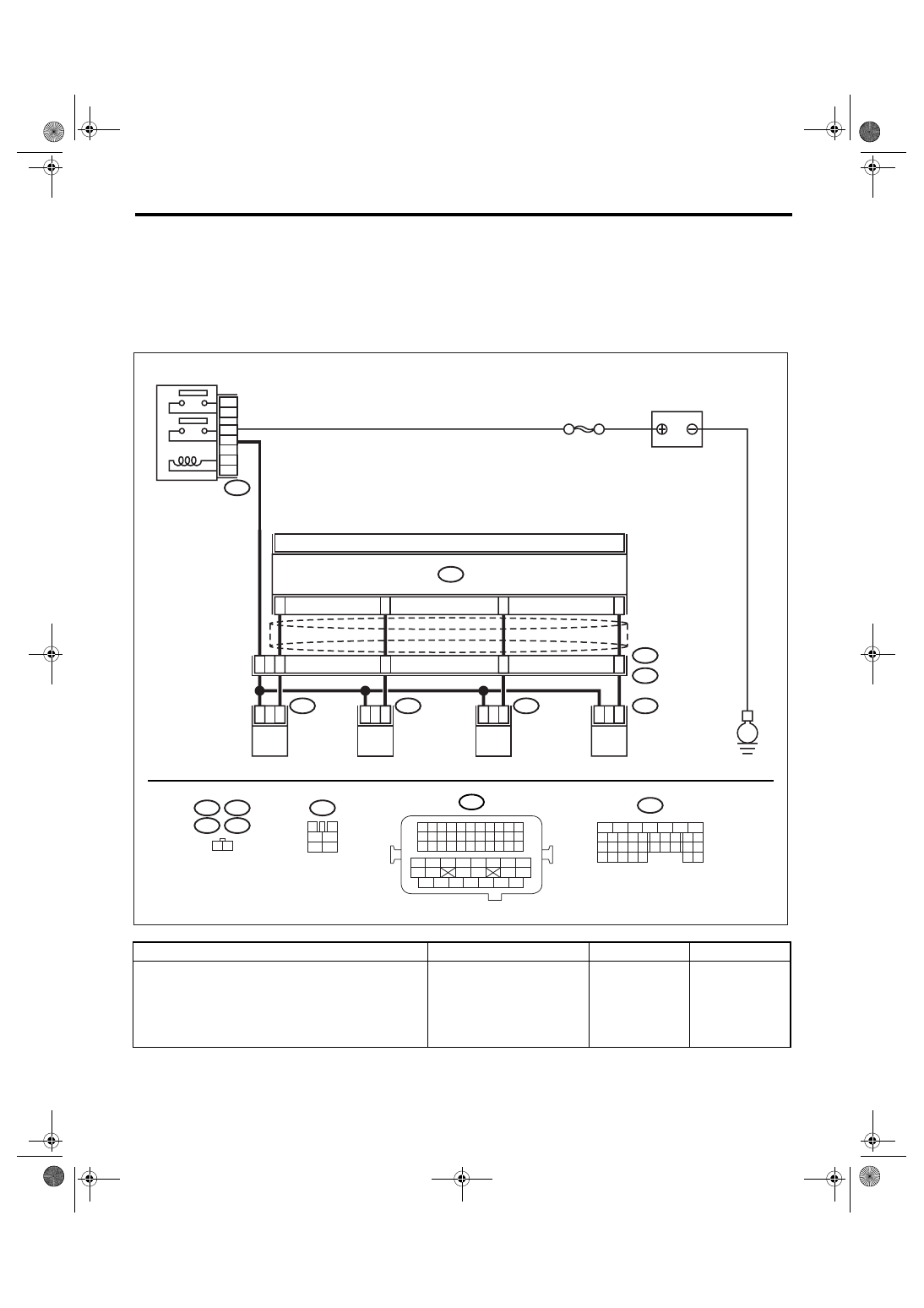

F: FUEL INJECTOR CIRCUIT

CAUTION:

• Check or repair only faulty parts.

• After repair or replacement of faulty parts, perform Clear Memory Mode <Ref. to EN(H4SO 2.0)(di-

ag)-38, OPERATION, Clear Memory Mode.> and Inspection Mode <Ref. to EN(H4SO 2.0)(diag)-32,

PROCEDURE, Inspection Mode.>.

WIRING DIAGRAM:

Step

Check

Yes

No

1

CHECK OPERATION OF EACH FUEL INJEC-

TOR.

While cranking the engine, check each fuel

injector emits operating sound. Use a sound

scope or attach a screwdriver to the injector for

this check.

Does the fuel pump emit oper-

ating sound?

Check the fuel

pressure. <Ref. to

ME(H4SO 2.0)-27,

INSPECTION,

Fuel Pressure.>

EN-03474

E6

E17

E5

E16

1 2

1

2

1

2

1

2

1

2

34

27

17

33

42

48

43

44

45

ECM

B134

E5

E16

E6

E17

B21

E2

FUEL INJECTOR

No. 1

FUEL INJECTOR

No. 2

FUEL INJECTOR

No. 3

FUEL INJECTOR

No. 4

BATTERY

SBF-7

B47

MAIN RELAY

1

2

4

6

3

5

B47

3

4

1

2

5

6

E

B21

1 2 3 4

12 13 14 15

5 6 7 8

16 17 18 19

9 10 11

20 21 22

23 24 25 26 27 28 29 30 31 32 33

35

34

37

36

39

38

41

40

43

42

44

45

47

46

49

48

51

50

53

52

54

B134

5

6

7

8

2

1

9

4

3

10

24

22 23

25

11 12 13 14 15

26 27

28

16 17

18 19 20 21

33 34

29

32

30 31

EN(H4SO 2.0)(diag)-63

ENGINE (DIAGNOSTICS)

Diagnostics for Engine Starting Failure

2

CHECK POWER SUPPLY TO EACH FUEL

INJECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

fuel injector terminal and engine ground.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (

−

):

#2 (E16) No. 2 (+) — Engine ground (

−

):

#3 (E6) No. 2 (+) — Engine ground (

−

):

#4 (E17) No. 2 (+) — Engine ground (

−

):

Is the voltage more than 10 V? Go to step 3.

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

main relay and fuel

injector connector

• Poor contact in

main relay connec-

tor

• Poor contact in

coupling connector

• Poor contact in

fuel injector con-

nector

3

CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and fuel injector connector.

Connector & terminal

#1 (B134) No. 17 — (E5) No. 1:

#2 (B134) No. 27 — (E16) No. 1:

#3 (B134) No. 34 — (E6) No. 1:

#4 (B134) No. 33 — (E17) No. 1:

Is the resistance less than 1

Ω?

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

ECM and fuel

injector connector

• Poor contact in

coupling connector

4

CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

Measure the resistance of harness between

ECM and fuel injector connector.

Connector & terminal

#1 (B134) No. 17 — Chassis ground:

#2 (B134) No. 27 — Chassis ground:

#3 (B134) No. 34 — Chassis ground:

#4 (B134) No. 33 — Chassis ground:

Is the resistance more than 1

M

Ω?

Repair the ground

short circuit of har-

ness between

ECM and fuel

injector connector.

5

CHECK EACH FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between each fuel

injector terminals.

Terminals

No. 1 — No. 2:

Is the resistance 5 — 20

Ω?

Replace the faulty

fuel injector.

6

CHECK POOR CONTACT.

Check poor contact in ECM connector.

Is there poor contact in ECM

connector?

Repair the poor

contact in ECM

connector.

Inspection using

“General Diagnos-

tic Table”. <Ref. to

EN(H4SO

2.0)(diag)-224,

INSPECTION,

General Diagnos-

tic Table.>

Step

Check

Yes

No

EN(H4SO 2.0)(diag)-64

ENGINE (DIAGNOSTICS)

List of Diagnostic Trouble Code (DTC)

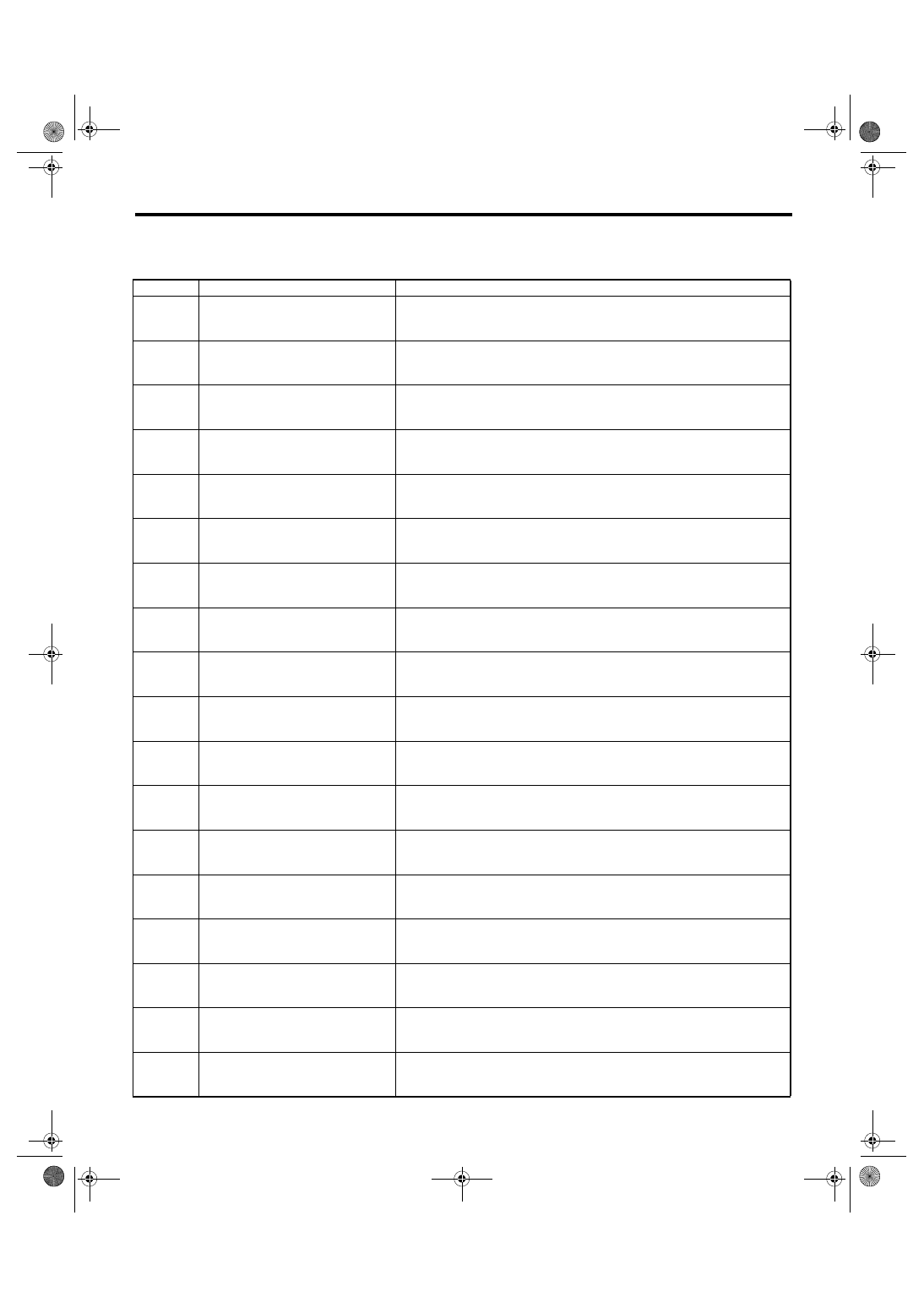

17.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC

Item

NOTE

P0030

HO2S Heater Control Circuit (Bank 1

Sensor 1)

P0031

HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

P0032

HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

P0037

HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

P0038

HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

P0107

Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

P0108

Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

P0112

Intake Air Temperature Sensor 1 Cir-

cuit Low

P0113

Intake Air Temperature Sensor 1 Cir-

cuit High

P0117

Engine Coolant Temperature Circuit

Low

P0118

Engine Coolant Temperature Circuit

High

P0122

Throttle/Pedal Position Sensor/

Switch “A” Circuit Low

P0123

Throttle/Pedal Position Sensor/

Switch “A” Circuit High

P0125

Insufficient Coolant Temperature for

Closed Loop Fuel Control

P0130

O2 Sensor Circuit (Bank1 Sensor1)

P0131

O2 Sensor Circuit Low Voltage (Bank

1 Sensor 1)

P0132

O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1)

P0133

O2 Sensor Circuit Slow Response

(Bank 1 Sensor 1)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст