Subaru Legacy III (2000-2003 year). Service manual — part 757

VDC-64

VDC (DIAGNOSTICS)

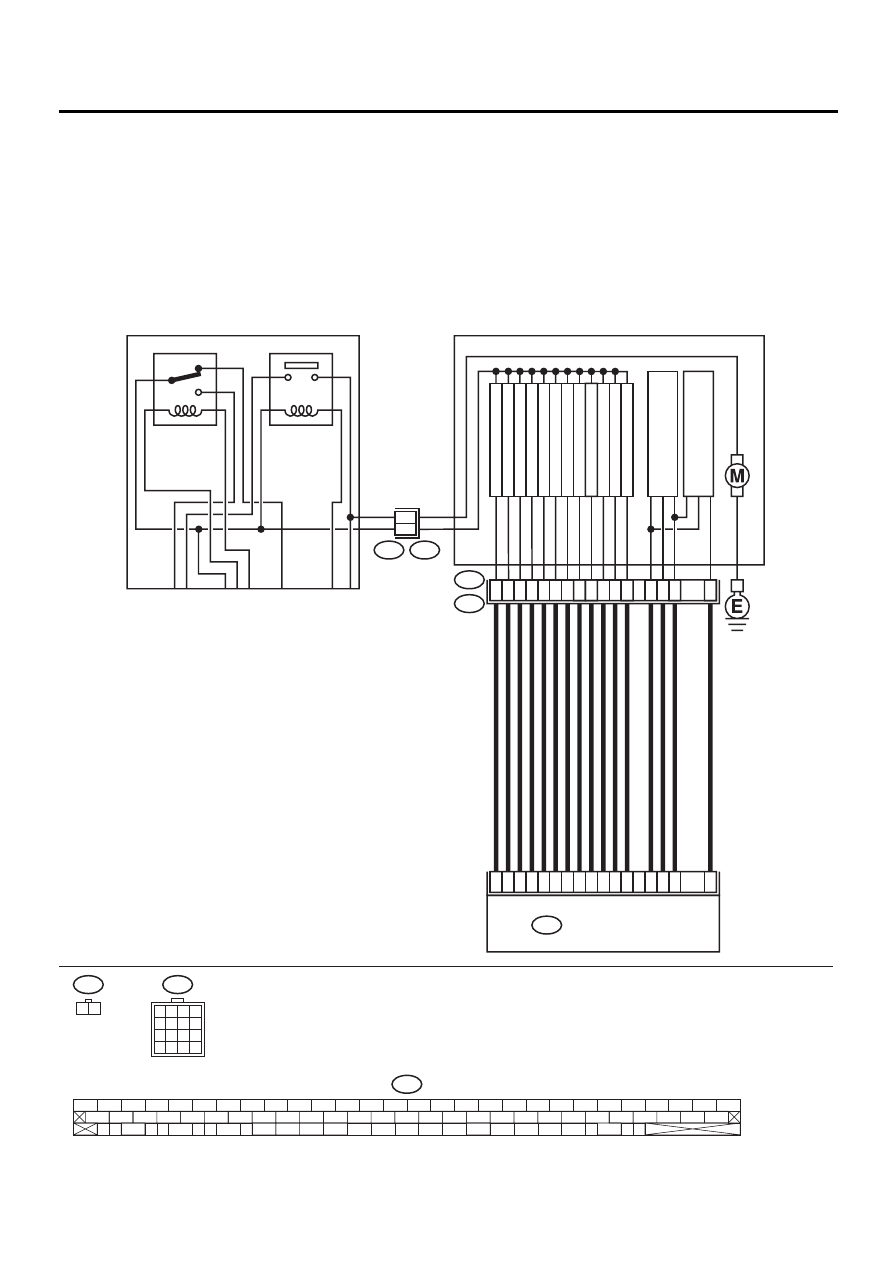

DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR

T: DTC 62 ABNORMAL INLET AND CUT SOLENOID VALVE CIRCUIT(S) (SEC-

ONDARY CUT)

DIAGNOSIS:

• Faulty harness/connector

• Faulty solenoid valve in VDCH/U

TROUBLE SYMPTOM:

• ABS does not operate.

• VDC does not operate.

WIRING DIAGRAM:

VDC00142

VDC1

1 2

F91

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

10

9

11

12

15

13

16

14

VDC HYDRAULIC UNIT

VDC5

F91

VDC CONTROL MODULE

F87

FR OUTLET

FR INLET

RL OUTLET

RL INLET

RR OUTLET

RR INLET

PRIMAR

Y CUT

PRIMAR

Y SECTION

SECOND

AR

Y CUT

PRIMAR

Y

PRESSURE SENSOR

SECOND

A

R

Y

PRESSURE SENSOR

SECOND

AR

Y SECTION

FL OUTLET

FL INLET

51

30

3

31

4

23

50

24

25

2

26

36

76

77

78

29

4

5

1

6

2

7

3

8

VDC2

VDC1

1

2

F87

56 57

59 60

62 63

65

82 83

80

27

28

25

26

23

24

21

22

19

20

17

18

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

54

55

52

53

50

51

81

48

49

46

47

44

45

78

79

76

77

75

42

43

40

41

74

72

73

70

71

39

37

38

35

36

69

67

68

66

33

34

61

64

31

32

29

30

58

RELAY BOX

MOTOR RELAY

VALVE RELAY

VDC-65

VDC (DIAGNOSTICS)

DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR

Step

Value

Yes

No

1

CHECK RESISTANCE OF SOLENOID

VALVE.

1) Turn ignition switch to OFF.

2) Disconnect two connectors (VDC1, F91)

from VDCH/U.

3) Measure resistance between VDCH/U con-

nector terminals.

Connector & terminal

DTC 31/(VDC5) No. 5 — (VDC2) No. 2:

DTC 33/(VDC5) No. 8 — (VDC2) No. 2:

DTC 35/(VDC5) No. 7 — (VDC2) No. 2:

DTC 37/(VDC5) No. 6 — (VDC2) No. 2:

DTC 61/(VDC5) No. 9 — (VDC2) No. 2:

DTC 62/(VDC5) No. 12 — (VDC2) No. 2:

Is the measured value within the specified

range?

8.04 — 9.04

Ω

Replace VDCH/U.

<Ref. to VDC-8,

VDC Control Mod-

ule (VDCCM).>

2

CHECK GROUND SHORT OF SOLENOID

VALVE.

Measure resistance between VDCH/U connec-

tor and chassis ground.

Connector & terminal

DTC 31/(VDC5) No. 5 — Chassis

ground:

DTC 33/(VDC5) No. 8 — Chassis

ground:

DTC 35/(VDC5) No. 7 — Chassis

ground:

DTC 37/(VDC5) No. 6 — Chassis

ground:

DTC 61/(VDC5) No. 9 — Chassis

ground:

DTC 62/(VDC5) No. 12 — Chassis

ground:

Does the measured value exceed the specified

value?

1 M

Ω

Replace VDCH/U.

<Ref. to VDC-8,

VDC Control Mod-

ule (VDCCM).>

3

CHECK BATTERY SHORT OF SOLENOID

VALVE.

1) Disconnect connector from VDCCM.

2) Measure voltage between VDCH/U con-

nector and chassis ground.

Connector & terminal

DTC 31/(VDC5) No. 5 (+) — Chassis

ground (

−−−−

):

DTC 33/(VDC5) No. 8 (+) — Chassis

ground (

−−−−

):

DTC 35/(VDC5) No. 7 (+) — Chassis

ground (

−−−−

):

DTC 37/(VDC5) No. 6 (+) — Chassis

ground (

−−−−

):

DTC 61/(VDC5) No. 9 (+) — Chassis

ground (

−−−−

):

DTC 62/(VDC5) No. 12 (+) — Chassis

ground (

−−−−

):

Is the measured value less than the speci-

fied value?

1 V

Replace VDCH/U.

<Ref. to VDC-8,

VDC Control Mod-

ule (VDCCM).>

VDC-66

VDC (DIAGNOSTICS)

DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR

4

CHECK BATTERY SHORT OF SOLENOID

VALVE.

1) Turn ignition switch to ON.

2) Measure voltage between VDCH/U con-

nector and chassis ground.

Connector & terminal

DTC 31/(VDC5) No. 5 (+) — Chassis

ground (

−−−−

):

DTC 33/(VDC5) No. 8 (+) — Chassis

ground (

−−−−

):

DTC 35/(VDC5) No. 7 (+) — Chassis

ground (

−−−−

):

DTC 37/(VDC5) No. 6 (+) — Chassis

ground (

−−−−

):

DTC 61/(VDC5) No. 9 (+) — Chassis

ground (

−−−−

):

DTC 62/(VDC5) No. 12 (+) — Chassis

ground (

−−−−

):

Is the measured value less than the speci-

fied value?

1 V

Replace VDCH/U.

<Ref. to VDC-8,

VDC Control Mod-

ule (VDCCM).>

5

CHECK BATTERY SHORT OF HARNESS.

1) Turn ignition switch to OFF.

2) Measure voltage between VDCCM connec-

tor and chassis ground.

Connector & terminal

DTC 31/(F87) No. 30 (+) — Chassis

ground (

−−−−

):

DTC 33/(F87) No. 24 (+) — Chassis

ground (

−−−−

):

DTC 35/(F87) No. 23 (+) — Chassis

ground (

−−−−

):

DTC 37/(F87) No. 31 (+) — Chassis

ground (

−−−−

):

DTC 61/(F87) No. 25 (+) — Chassis

ground (

−−−−

):

DTC 62/(F87) No. 26 (+) — Chassis

ground (

−−−−

):

Is the measured value less than the speci-

fied value?

1 V

Repair harness

between VDCCM

and VDCH/U.

6

CHECK BATTERY SHORT OF HARNESS.

1) Turn ignition switch to ON.

2) Measure voltage between VDCCM connec-

tor and chassis ground.

Connector & terminal

DTC 31/(F87) No. 30 (+) — Chassis

ground (

−−−−

):

DTC 33/(F87) No. 24 (+) — Chassis

ground (

−−−−

):

DTC 35/(F87) No. 23 (+) — Chassis

ground (

−−−−

):

DTC 37/(F87) No. 31 (+) — Chassis

ground (

−−−−

):

DTC 61/(F87) No. 25 (+) — Chassis

ground (

−−−−

):

DTC 62/(F87) No. 26 (+) — Chassis

ground (

−−−−

):

Is the measured value less than the speci-

fied value?

1 V

Repair harness

between VDCCM

and VDCH/U.

Step

Value

Yes

No

VDC-67

VDC (DIAGNOSTICS)

DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR

7

CHECK GROUND SHORT OF HARNESS.

1) Turn ignition switch to OFF.

2) Measure resistance between VDCCM con-

nector and chassis ground.

Connector & terminal

DTC 31/(F87) No. 30 — Chassis ground:

DTC 33/(F87) No. 24 — Chassis ground:

DTC 35/(F87) No. 23 — Chassis ground:

DTC 37/(F87) No. 31 — Chassis ground:

DTC 61/(F87) No. 25 — Chassis ground:

DTC 62/(F87) No. 26 — Chassis ground:

Does the measured value exceed the spec-

ified value?

1 M

Ω

Repair harness

between VDCCM

and VDCH/U.

8

CHECK HARNESS/CONNECTOR BETWEEN

VDCCM AND VDCH/U.

1) Connect connector (F91) to VDCH/U.

2) Measure resistance between VDCCM con-

nector and VDCH/U connector.

Connector & terminal

DTC 31/(F87) No. 30 — (VDC2) No. 2:

DTC 33/(F87) No. 24 — (VDC2) No. 2:

DTC 35/(F87) No. 23 — (VDC2) No. 2:

DTC 37/(F87) No. 31— (VDC2) No. 2:

DTC 61/(F87) No. 25 — (VDC2) No. 2:

DTC 62/(F87) No. 26 — (VDC2) No. 2:

Is the measured value within the specified

range?

7 — 10

Ω

Repair harness/

connector

between VDCCM

and VDCH/U.

9

CHECK POOR CONTACT IN CONNECTORS.

Is there poor contact in connectors between

VDCCM and VDCH/U?

There is poor contact.

Repair connector.

10

CHECK VDCCM.

1) Connect all connectors.

2) Erase the memory.

3) Perform inspection mode.

4) Read out the diagnostic trouble code.

Is the same diagnostic trouble code as in

the current diagnosis still being output?

Same DTC indicated.

Repair VDCCM.

<Ref. to VDC-8,

VDC Control Mod-

ule (VDCCM).>

11

CHECK ANY OTHER DIAGNOSTIC TROU-

BLE CODES APPEARANCE.

Are other diagnostic trouble codes being out-

put?

Other DTC indicated.

Proceed with the

diagnosis corre-

sponding to the

diagnostic trouble

code.

A temporary poor

contact.

Step

Value

Yes

No

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст