Infiniti QX56 (JA60). Manual — part 719

PB-10

< ON-VEHICLE REPAIR >

PARKING BRAKE SHOE

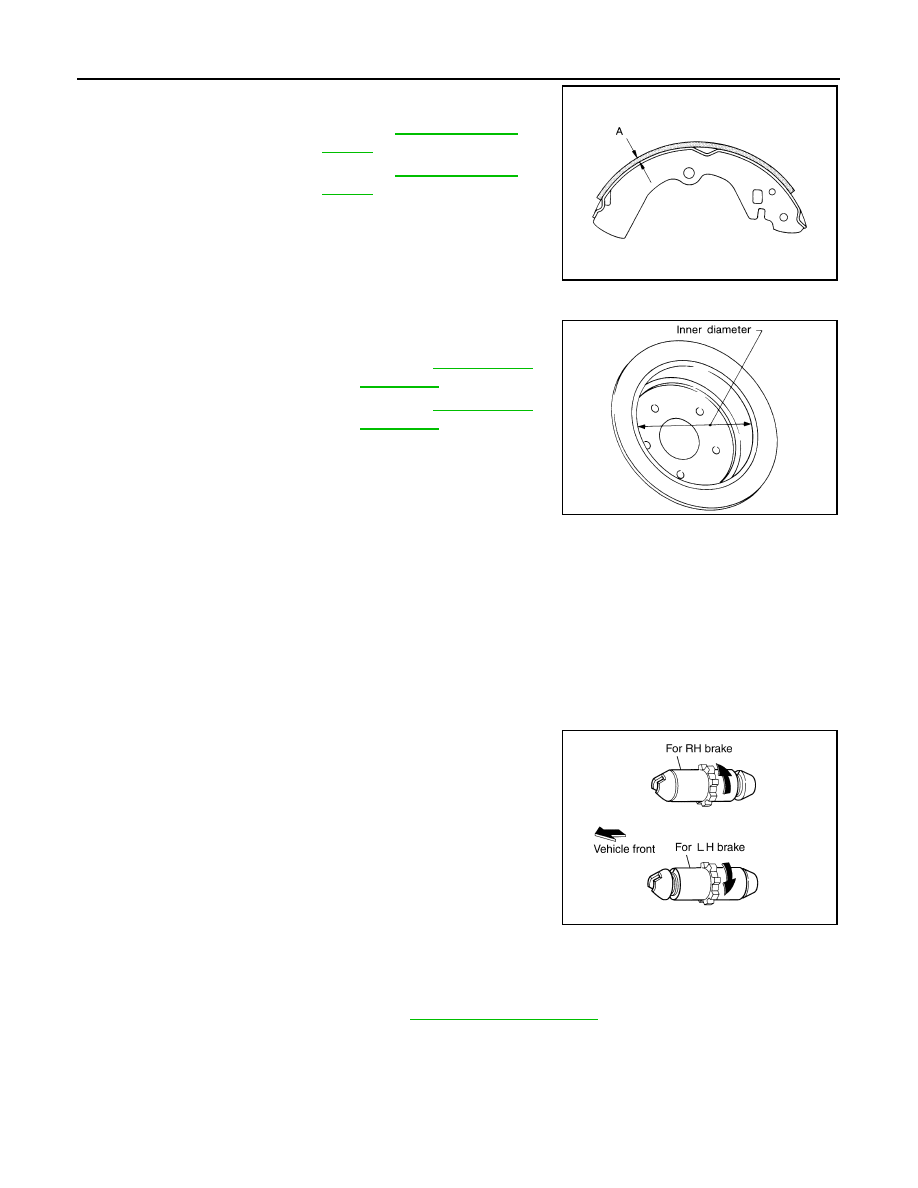

• Check thickness of lining.

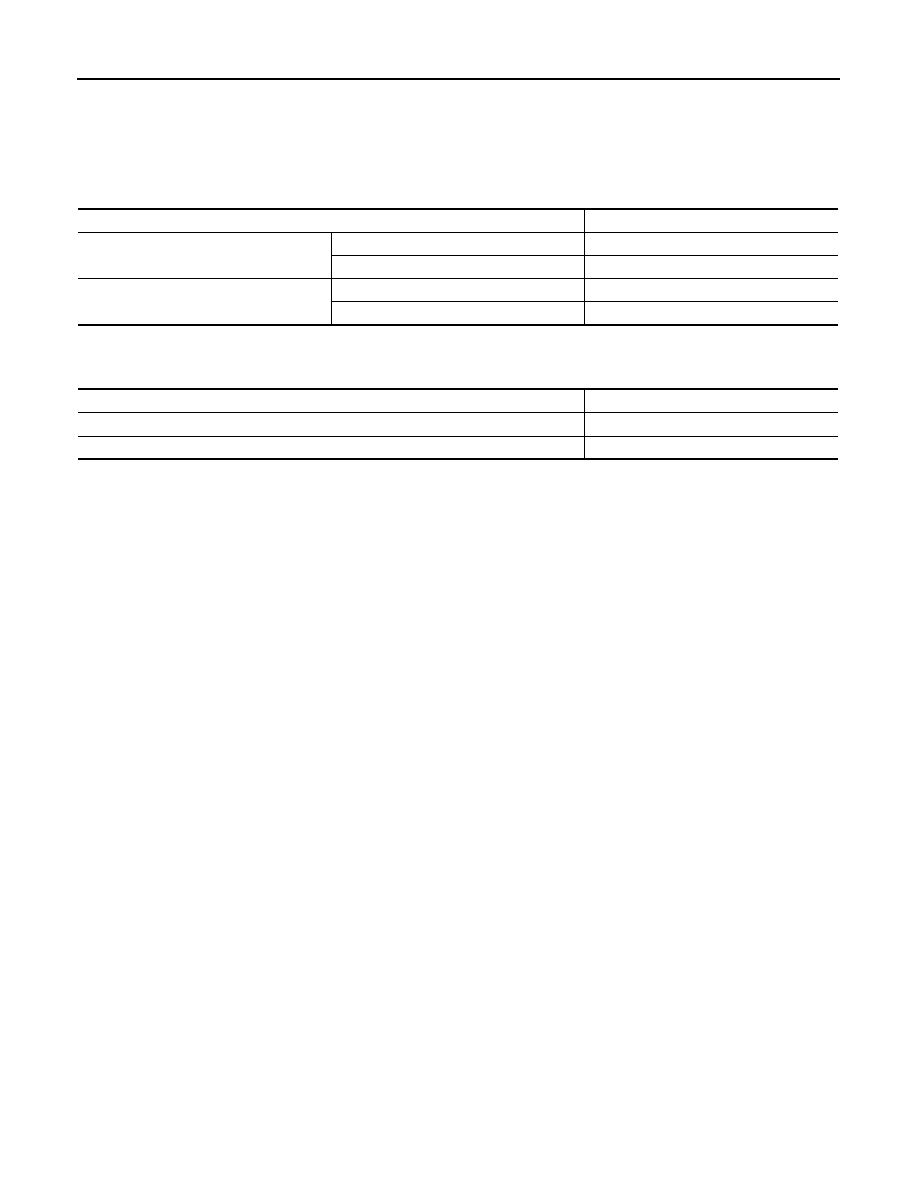

Disc Rotor Inner Diameter Inspection

• Check inner diameter inside drum area of disc rotor.

Other Inspections

• Check shoe sliding surface on back plate for excessive wear and damage.

• Check anti-rattle pins for excessive wear and corrosion.

• Check return springs for sagging.

• Check adjuster for rough operation.

• When disassembling adjuster, apply PBC (Poly Butyl Cuprysil) grease or equivalent to the threads.

• Check either visually or with a vernier caliper to see if there is any excessive wear, cracks, or damage inside

drum area of disc rotor.

INSTALLATION

Installation is in the reverse order of removal.

• Apply brake grease to the specified points during assembly.

• Assemble adjuster so that threaded part expands when rotating it

in the direction shown by the arrow.

• Shorten adjuster by rotating it.

NOTE:

After replacing brake shoes or disc rotors, or if brakes do not function well, perform break-in operation as fol-

lows.

1. Adjust parking brake pedal stroke. Refer to

.

2. Perform parking brake break-in operation by driving the vehicle forward under the following conditions:

• Vehicle speed at 40 km/h (25 MPH)

• Apply parking brake with an operating force of 196 N (20.0 kg-f, 44.1 lb-f) set

• Apply parking brake for a period of 30 seconds

CAUTION:

• To prevent lining from getting too hot, allow a cool off period of approximately 5 minutes after

every break-in operation.

Standard thickness (A)

: Refer to

Wear limit thickness (A) : Refer to

SBR021A

Standard inner diameter

Wear limit of inner diameter

SBR768A

SFIA0153E

PARKING BRAKE SHOE

PB-11

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

M

A

B

PB

N

O

P

• Do not perform excessive break-in operations, because it may cause uneven or early wear of lin-

ing.

3. After break-in operation, check pedal stroke of parking brake. Readjust if it is no longer at the specified

stroke. Refer to

PB-12

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Parking Brake

INFOID:0000000005147936

Unit: mm (in)

Parking Brake Control

INFOID:0000000005147937

Type

Disc rotor with inner drum

Brake lining

Standard thickness (new)

3.79

± 0.21 (0.149 ± 0.008)

Wear limit thickness

0.5 (0.020)

Drum inner diameter (disc)

Standard inner diameter (new)

205

± 0.13 (8.07 ± 0.01)

Wear limit of inner diameter

205.7 (8.10)

Control type

Foot pedal

Number of notches [under force of 196 N (20.0 kg-f, 44.1 lb-f)]

3 – 4 notches

Number of notches when warning lamp switch comes on

1 notch

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

D

E

F

G

H

I

J

K

L

B

SECTION

PCS

A

O

P

N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

BASIC INSPECTION . . . . . . . . .

DIAGNOSIS AND REPAIR WORKFLOW . . ..

Work Flow . . . . . . . . . . . . . . . .....

FUNCTION DIAGNOSIS . . . . . . . ...

RELAY CONTROL SYSTEM . . . . . . . ..

System Diagram . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . ...

Component Parts Location . . . . . . . . . ....

POWER CONTROL SYSTEM . . . . . . . .

System Diagram . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . ...

SIGNAL BUFFER SYSTEM . . . . . . . .

System Diagram . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . ...

POWER CONSUMPTION CONTROL SYS-

TEM . . . . . . . . . . . . . . . . .

System Diagram . . . . . . . . . . . . . ..

System Description . . . . . . . . . . . . .

Component Parts Location . . . . . . . . . ..

DIAGNOSIS SYSTEM (IPDM E/R) . . . . . .

Diagnosis Description . . . . . . . . . . . .

CONSULT - III Function (IPDM E/R) . . . . . ...

COMPONENT DIAGNOSIS . . . . . . .

U1000 CAN COMM CIRCUIT . . . . . . ...

Description . . . . . . . . . . . . . . . ...

DTC Logic . . . . . . . . . . . . . . . .

Diagnosis Procedure . . . . . . . . . . . ...

POWER SUPPLY AND GROUND CIRCUIT .

Diagnosis Procedure . . . . . . . . . . . ...

ECU DIAGNOSIS . . . . . . . . . . .

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) . . . .

Reference Value . . . . . . . . . . . . . ..

Terminal Layout . . . . . . . . . . . . . ...

Physical Values . . . . . . . . . . . . . ...

Wiring Diagram . . . . . . . . . . . . . .

Fail Safe . . . . . . . . . . . . . . . . ..

DTC Index . . . . . . . . . . . . . . . ...

PRECAUTION . . . . . . . . . . . ..

PRECAUTIONS . . . . . . . . . . . . .

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect . . . . . . . . ...

REMOVAL AND INSTALLATION . . . ...

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) . . . .

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст