Infiniti F50. Manual — part 258

BRAKE MASTER CYLINDER

BR-13

C

D

E

G

H

I

J

K

L

M

A

B

BR

BRAKE MASTER CYLINDER

PFP:46010

Components

EFS0020U

Removal and Installation

EFS0020V

REMOVAL

1.

Drain brake fluid.

2.

Remove the harness connectors for the fluid level sensor and pressure sensor.

3.

Using a flare nut wrench, remove the brake tube from the master cylinder.

4.

Remove the mounting nuts, and remove the master cylinder assembly from the vehicle.

INSTALLATION

CAUTION:

●

Refill with new brake fluid “DOT3”.

●

Never reuse drained brake fluid.

1.

Temporarily tighten the flare nuts on the brake tube to master cylinder by hand.

2.

Install the master cylinder to the brake booster assembly, and tighten the mounting nuts to the specified

torque.

1.

Reservoir cap

2.

Oil filter

3.

Reservoir tank

4.

Seal

5.

Piston stopper

6.

Pin

7.

Cylinder body

8.

O-ring

9.

Piston stopper

10. Pressure sensor

11.

O-ring

12.

Secondary piston assembly

13. Primary piston assembly

14. Plate

15.

Guide assembly

16. Plate

(Not inserted in some vehicles.)

17. Snap-ring

SFIA0894E

BR-14

BRAKE MASTER CYLINDER

CAUTION:

●

Do not damage and stain the rod of the primary piston.

●

Do not reuse the O-ring seal, and primary piston.

●

Apply silicon grease for the O-ring seal and primary pis-

ton.

3.

Using a flare nut torque wrench, tighten the flare nut on the brake tube to the specified torque.

4.

Refill the new brake fluid and bleed air. Refer to

BR-10, "Bleeding Brake System"

Disassembly and Assembly

EFS0020W

DISASSEMBLY

Models without ICC

1.

Tighten the flange of the cylinder body in base in the figure.

CAUTION:

●

Pay attention to the orientation of master cylinder body.

●

Use the copper plate or closes for fixing the body in the

vise.

2.

Using the pin-punch (commercial service tool: dia approx.

4mm), remove pin form the reservoir tank.

3.

Remove the master cylinder assembly from the vise.

4.

Remove the reservoir tank and grommet from the cylinder body.

5.

Push the primary piston and remove the stopper pin from sec-

ondary tank boss hole in the cylinder body.

CAUTION:

Be careful not to damage the inner wall of the cylinder.

NBR386

: 15 - 17 N·m (1.5 - 1.8 kg-m, 11 - 12 ft-lb)

BRA0558D

BRA0559D

BRA0560D

BRAKE MASTER CYLINDER

BR-15

C

D

E

G

H

I

J

K

L

M

A

B

BR

6.

Remove the snap ring in pushing primary piston.

CAUTION:

Be careful not to put out the piston.

7.

Holding the rod of the primary piston, remove the primary piston

assembly, the plate and the guide with pulling straight to prevent

the cup from being caught by the inner wall of the cylinder.

8.

Remove the plate and the guide from the primary piston.

CAUTION:

Be careful not to damage the rod from the inner wall of the

plate.

9.

Tap the flange using a soft block such as wood, and carefully

pull the secondary piston assembly straight out to prevent the

inner wall of the cylinder from being damaged.

Models with ICC

CAUTION:

Be careful not to damage the rod of primary piston with covering cloths in acting.

1.

Tighten the flange of the cylinder body in base in the figure.

CAUTION:

●

Pay attention to the orientation of master cylinder body.

●

Use the copper plate or closes for fixing the body in the

vise.

2.

Push the primary piston and remove the piston stopper from

secondary tank boss hole in the cylinder body.

CAUTION:

Be careful not to damage the inner wall of the cylinder.

BRA0561D

BRA0033D

BRA0558D

SFIA0997E

BR-16

BRAKE MASTER CYLINDER

3.

Remove the snap ring in pushing primary piston.

CAUTION:

Be careful not to put out the piston.

4.

Holding the rod of the primary piston, remove the primary piston

assembly, the plate and the guide with pulling straight to prevent

the cup from being caught by the inner wall of the cylinder.

5.

Remove the plate and the guide from the primary piston.

CAUTION:

Be careful not to damage the rod from the inner wall of the

plate.

6.

Tap the flange using a soft block such as wood, and carefully

pull the secondary piston assembly straight out to prevent the

inner wall of the cylinder from being damaged.

7.

Remove the reservoir tank.

CAUTION:

Remove the reservoir tank only when necessary.

INSPECTION AFTER DISASSEMBLY

Inspect the next items.

Master Cylinder

●

Check the inner wall of the cylinder for damage, wear, corrosion, and pin holes. Replace the cylinder if a

malfunction is detected.

ASSEMBLY

CAUTION:

●

Never use mineral oils such as kerosene or gasoline during the cleaning and assembly processes.

●

Make sure that there is no foreign material such as dirt and dust on the inner wall of the cylinder,

piston, and cup seal. Be careful not to damage the parts with a service tool when assembling.

●

Do not drop the parts. Do not use any dropped parts.

Models without ICC

1.

Apply brake fluid to the inner wall of cylinder body and contact surface of the piston assembly.

2.

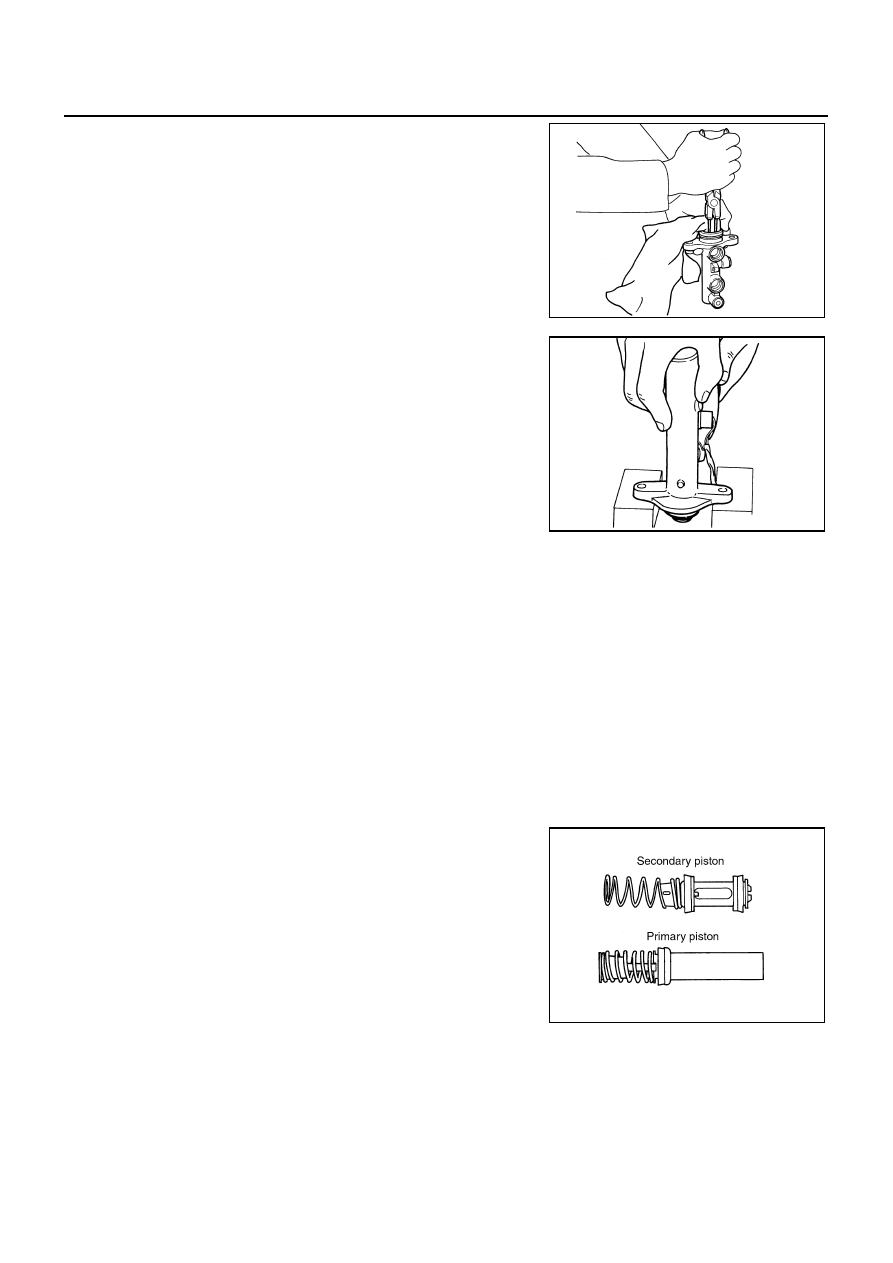

Insert secondary piston and primary piston assembly into cylin-

der body in this order.

CAUTION:

●

Do not reuse the primary and secondary piston assem-

blies.

●

Pay attention to the orientation of the piston cup, and

insert straight to prevent the cup from being caught by

the inner wall of the cylinder.

●

Always replace the inner kit as an assembly.

BRA0561D

BRA0561D

BRA0033D

SFIA0788E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст