Infiniti G37 Coupe. Manual — part 1306

DIAGNOSIS AND REPAIR WORK FLOW

TM-77

< BASIC INSPECTION >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

>> GO TO 3.

3.

CHECK DTC

1.

Check DTC.

2.

Perform the following procedure if DTC is detected.

• Record DTC.

• Erase DTC. Refer to

TM-108, "Diagnosis Description"

.

Is any DTC detected?

YES

>> GO TO 4.

NO

>> GO TO 6.

4.

PERFORM DIAGNOSTIC PROCEDURE

Perform “Diagnosis Procedure” for the displayed DTC.

>> GO TO 5.

5.

PERFORM DTC CONFIRMATION PROCEDURE

Perform “DTC CONFIRMATION PROCEDURE” for the displayed DTC.

Is any DTC detected?

YES

>> GO TO 4.

NO

>> GO TO 6.

6.

CHECK SYMPTOM 2

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES

>> GO TO 7.

NO

>> INSPECTION END

7.

ROAD TEST

Perform “ROAD TEST”. Refer to

.

>> GO TO 8.

8.

CHECK SYMPTOM 3

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES

>> GO TO 2.

NO

>> INSPECTION END

Diagnostic Work Sheet

INFOID:0000000001672104

INFORMATION FROM CUSTOMER

KEY POINTS

• WHAT. . Vehicle and A/T model

• WHEN. . Date, Frequencies

• WHERE. . Road conditions

• HOW. . Operating conditions, Symptoms

Customer name

MR/MS

Model and Year

VIN

Trans. Model

Engine

Mileage

Malfunction Date

Manuf. Date

In Service Date

Frequency

❏

Continuous

❏

Intermittent (

times a day)

TM-78

< BASIC INSPECTION >

[5AT: RE5R05A]

DIAGNOSIS AND REPAIR WORK FLOW

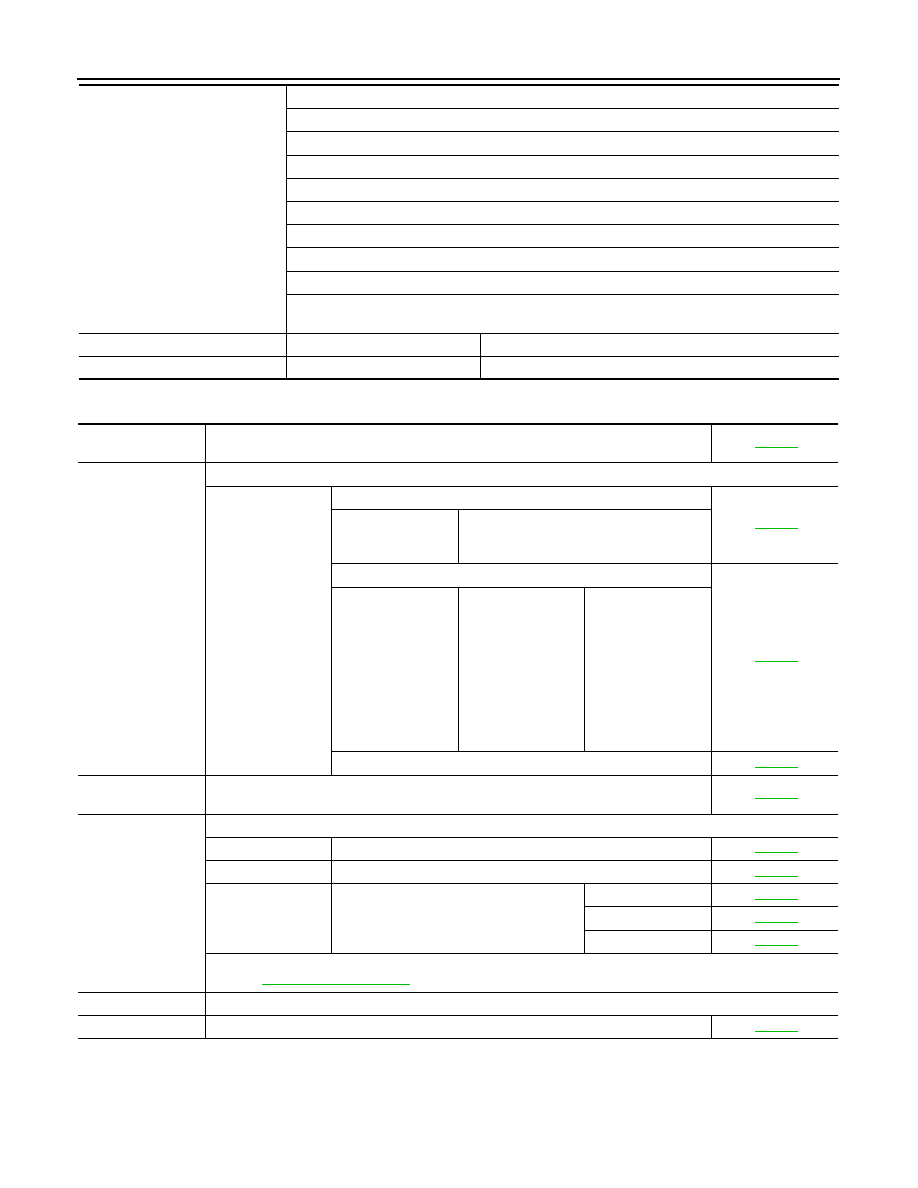

DIAGNOSTIC WORK SHEET

Symptoms

❏

Vehicle does not move.

(

❏

Any position

❏

Particular position)

❏

No up-shift

(

❏

1st

→

2nd

❏

2nd

→

3rd

❏

3rd

→

4th

❏

4th

→

5th)

❏

No down-shift

(

❏

5th

→

4th

❏

4th

→

3rd

❏

3rd

→

2nd

❏

2nd

→

1st)

❏

Lock-up malfunction

❏

Shift point too high or too low.

❏

Shift shock or slip

(

❏

N

→

D

❏

N

→

R

❏

Lock-up

❏

Any drive position)

❏

Noise or vibration

❏

No kick down

❏

No pattern select

❏

Others

(

)

A/T CHECK indicator lamp

❏

Continuously lit

❏

Not lit

Malfunction indicator lamp (MIL)

❏

Continuously lit

❏

Not lit

1

❏

Read the item on cautions concerning fail-safe and understand the customer's com-

plaint.

2

❏

A/T fluid inspection, stall test and line pressure test

❏

A/T fluid inspection

❏

Leak (Repair leak location.)

❏

State

❏

Amount

❏

Stall test

❏

Torque converter

one-way clutch

❏

Front brake

❏

High and low re-

verse clutch

❏

Low coast brake

❏

Forward brake

❏

Reverse brake

❏

Forward one-way

clutch

❏

1st one-way

clutch

❏

3rd one-way

clutch

❏

Engine

❏

Line pressure low

❏

Except for input

clutch and direct

clutch, clutches and

brakes OK

❏

Line pressure test - Suspected part:

3

❏

Perform self-diagnosis. — Check detected items to repair or replace malfunctioning

part.

4

❏

Perform road test.

5-1

❏

Check before engine is started

5-2

❏

Check at idle

5-3

Cruise test

❏

Part 1

❏

Part 2

❏

Part 3

❏

Check malfunction phenomena to repair or replace malfunctioning part after completing all road tests.

5

❏

Drive vehicle to check that the malfunction phenomenon has been resolved.

6

❏

Erase the results of the self-diagnosis from the TCM and the ECM.

A/T CONTROL SYSTEM

TM-79

< FUNCTION DIAGNOSIS >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

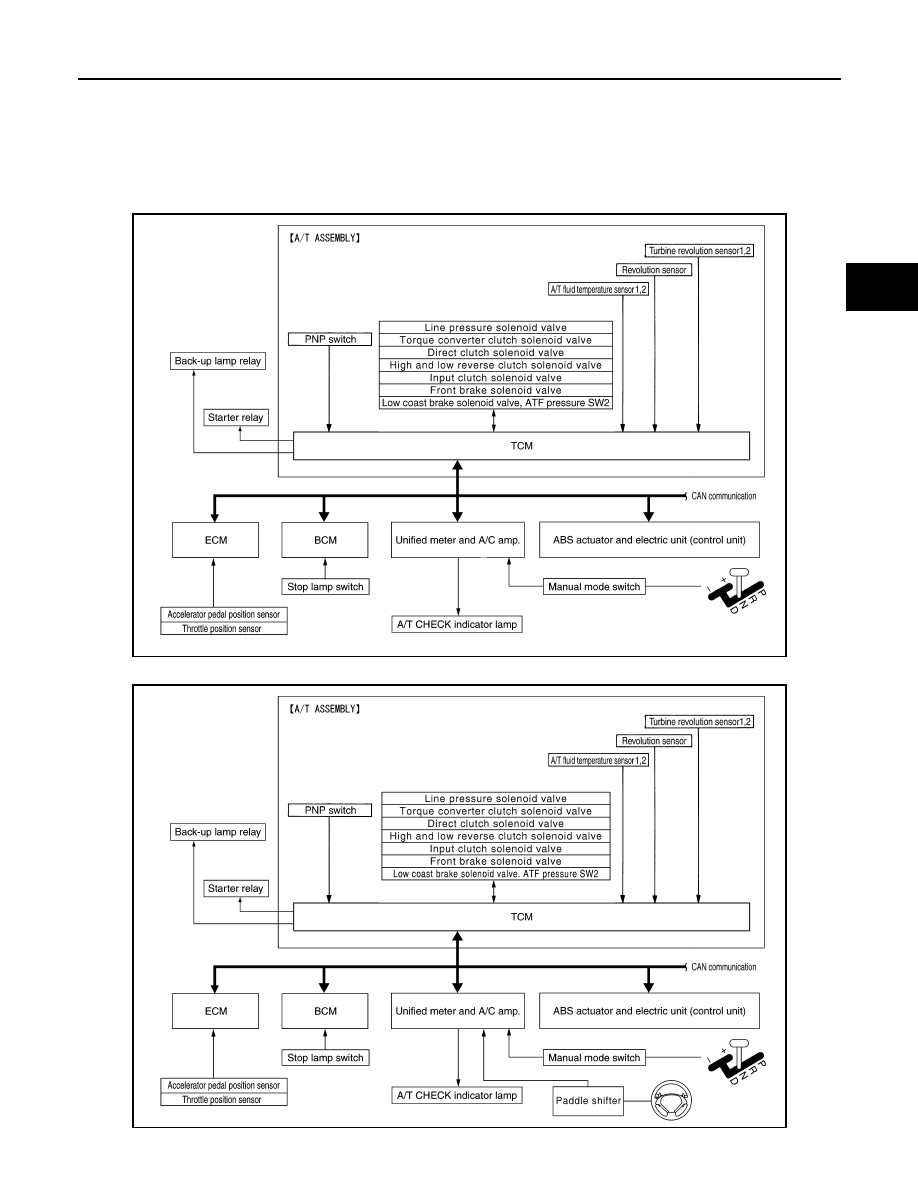

FUNCTION DIAGNOSIS

A/T CONTROL SYSTEM

System Diagram

INFOID:0000000001672105

Without Paddle Shifter

With Paddle Shifter

JSDIA0122GB

JPDIA0049GB

TM-80

< FUNCTION DIAGNOSIS >

[5AT: RE5R05A]

A/T CONTROL SYSTEM

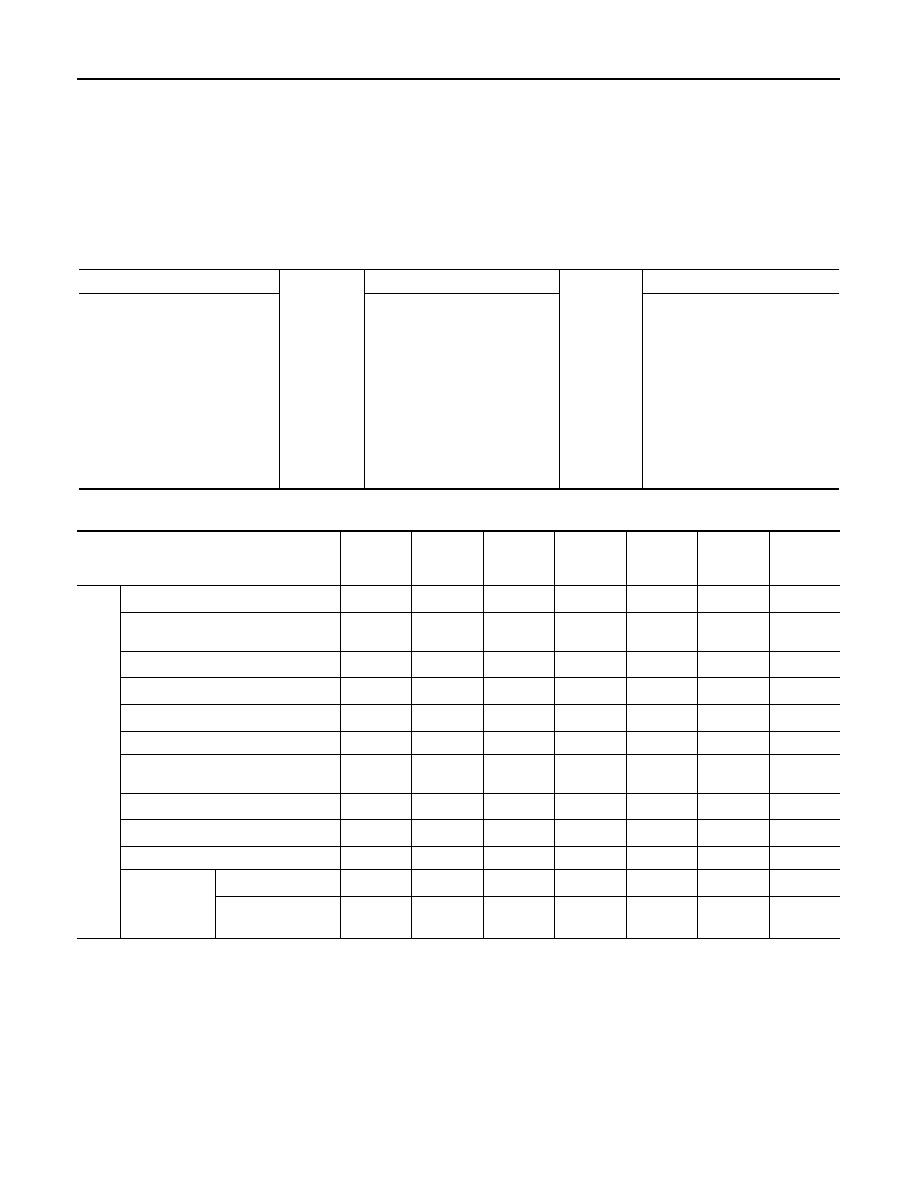

System Description

INFOID:0000000001672106

The A/T senses vehicle operating conditions through various sensors or signals. It always controls the opti-

mum shift position and reduces shifting and lock-up shocks.

TCM FUNCTION

The function of the TCM is to:

• Receive input signals transmitted from various switches and sensors.

• Determine required line pressure, shifting point, lock-up operation, engine brake operation, etc.

• Transmit required output signals to the respective solenoids.

Input/Output Signal of TCM

SENSORS (or SIGNALS)

⇒

TCM

⇒

ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switch

Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III communication

line

Duet-EA control

CAN system

Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Back-up lamp relay

Starter relay

Control item

Line

pressure

control

Vehicle

speed

control

Shift

control

Lock-up

control

Engine

brake

control

Fail-safe

function

*3

Self-diag-

nostics

function

Input

Accelerator pedal position signal

*5

X

X

X

X

X

X

X

Vehicle speed sensor A/T

(revolution sensor)

X

X

X

X

X

X

X

Vehicle speed sensor MTR

*1, *5

X

Closed throttle position signal

*5

X

*2

X

X

X

X

*4

Wide open throttle position signal

*5

X

X

*4

Turbine revolution sensor 1

X

X

X

X

X

Turbine revolution sensor 2

(for 4th speed only)

X

X

X

X

X

Engine speed signals

*5

X

X

X

X

X

X

X

Stop lamp switch signal

*5

X

X

X

X

*4

A/T fluid temperature sensors 1, 2

X

X

X

X

X

X

ASCD or ICC

sensor inte-

grated unit

Operation signal

*5

X

X

X

Overdrive cancel

signal

(*5)

X

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст