Infiniti EX37. Transaxle and Transmission (2013 year). Manual — part 8

P1730 INTERLOCK

TM-113

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

Diagnosis Procedure

INFOID:0000000008285842

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace damaged parts.

2.

DETECT MALFUNCTIONING ITEM

Disassemble the A/T assembly to check component parts. Refer to

.

NOTE:

Check the component parts, referring to “Possible cause” in “DTC DETECTION LOGIC”. Refer to

.

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-114

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

P1734 7GR INCORRECT RATIO

P1734 7GR INCORRECT RATIO

Description

INFOID:0000000008285843

This malfunction is detected when the A/T does not shift into 7GR position as instructed by TCM. This is not

only caused by electrical malfunction (circuits open or shorted) but by mechanical malfunction such as control

valve sticking, improper solenoid valve operation, etc.

DTC Logic

INFOID:0000000008285844

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• “

” must be performed before starting “DTC CONFIRMATION PROCE-

DURE”.

• Never perform “DTC CONFIRMATION PROCEDURE” before completing the repair, which may cause

secondary malfunction.

• Always drive vehicle at a safe speed.

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK ATF TEMPERATURE

With CONSULT

1.

Start the engine.

2.

Select “ATF TEMP 1” in “Data Monitor” in “TRANSMISSION”.

3.

Check ATF temperature is in the following range.

With GST

1.

Start the engine.

2.

Drive vehicle for approximately 5 minutes in urban areas.

Is ATF temperature within specified range?

YES

>> GO TO 3.

NO

>> Drive vehicle to warm ATF or stop engine to cool ATF.

3.

CHECK SYMPTOM (PART 1)

With CONSULT

1.

Select “7TH GR FNCTN P1734” in “DTC Work Support” in “TRANSMISSION”.

2.

Drive vehicle with manual mode and maintain the following conditions.

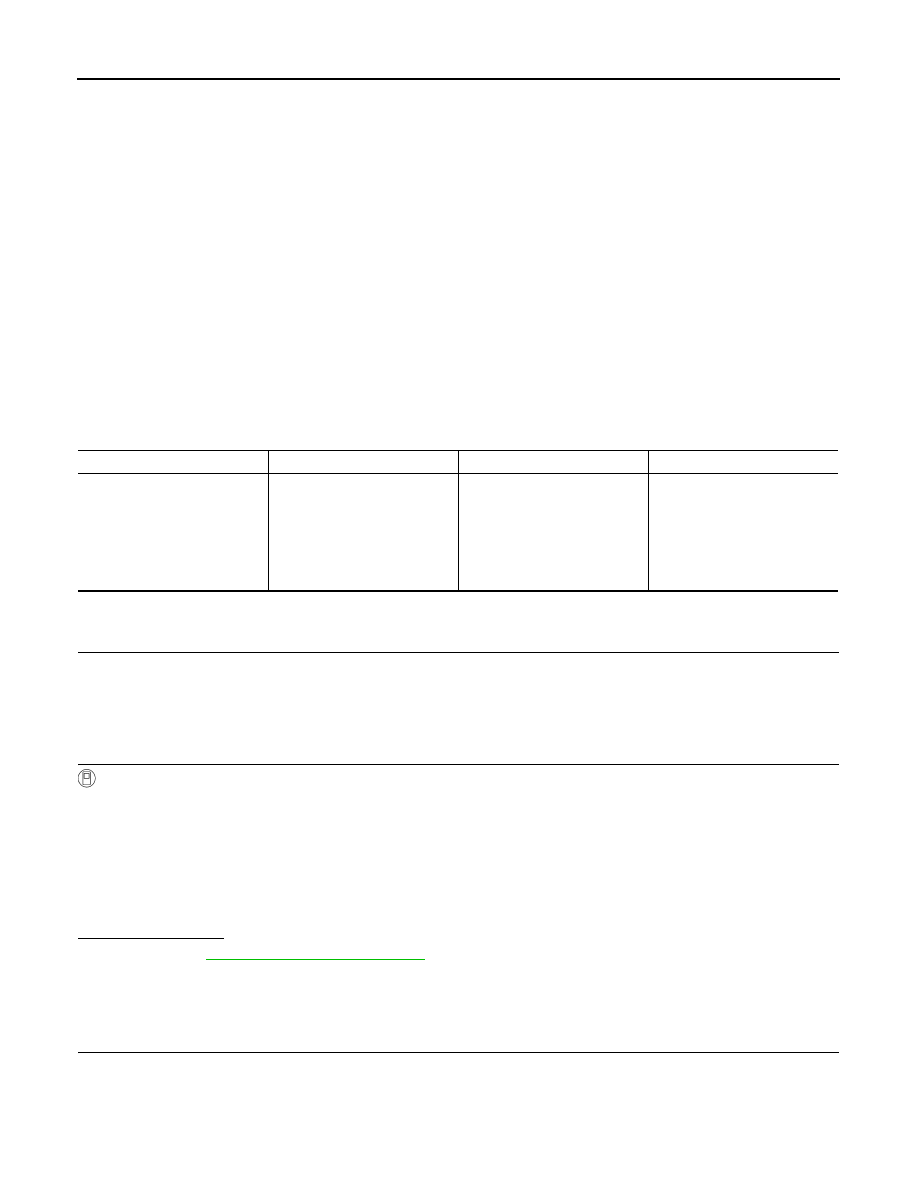

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P1734

Gear 7 Incorrect Ratio

The gear ratio is:

• 0.818 or more

• 0.726 or less

• Input clutch solenoid valve

• Direct clutch solenoid valve

• High and low reverse clutch

solenoid valve

• Front brake solenoid valve

• Low brake solenoid valve

• 2346 brake solenoid valve

• Anti-interlock solenoid valve

• Each clutch and brake

• Output speed sensor

• Input speed sensor 1, 2

• Hydraulic control circuit

ATF TEMP 1

: 20

°

C (68

°

F) – 140

°

C (284

°

F)

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

P1734 7GR INCORRECT RATIO

TM-115

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

3.

Keep the current driving status for 2 seconds or more if CONSULT screen changes from “OUT OF CON-

DITION” to “TESTING”.

CAUTION:

When “TESTING” is not indicated on CONSULT for a long time, check “Self Diagnostic Results” in

“TRANSMISSION”. When a DTC other than “P1734” is detected, check the DTC. Refer to

.

With GST

1.

Drive vehicle and maintain the following conditions for 2 seconds or more.

2.

Check DTC.

Is “OUT OF CONDITION”, “STOP VEHICLE” or “COMPLETED RESULT NG” displayed? / Is “P1734”

detected?

YES-1 (OUT OF CONDITION)>>Perform “Step 3” again.

YES-2 (STOP VEHICLE)>>GO TO 4.

YES-3 (COMPLETED RESULT NG)>>Go to

.

YES-4 (“P1734” is detected)>>Go to

NO

>> GO TO 4.

4.

CHECK SYMPTOM (PART 2)

With CONSULT

1.

Stop vehicle.

2.

Drive vehicle in “D” position allowing it to shift from 1GR to 7GR and check shift timing and shift shock.

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008285845

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace damaged parts.

2.

DETECT MALFUNCTIONING ITEM

Disassemble the A/T assembly to check component parts. Refer to

.

NOTE:

Check the component parts, referring to “Possible cause” in “DTC DETECTION LOGIC”. Refer to

.

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

GEAR

: 7th

ACCELE POSI

: 0.7/8 or more

VEHICLE SPEED

: 10 km/h (7 MPH) or more

Selector lever

: “M” position

Gear position

: 7th

Accelerator pedal opening

: 0.7/8 or more

Vehicle speed

: 10 km/h (7 MPH) or more

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-116

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

P1815 M-MODE SWITCH

P1815 M-MODE SWITCH

Description

INFOID:0000000008285846

• The manual mode switch [mode select switch and position select switch (shift-up/shift-down)] is installed in

the A/T shift selector assembly.

• The mode select switch detects the position (the main shift gate side or manual shift gate side) of the selec-

tor lever and transmits a manual mode signal or a non-manual mode signal to the unified meter and A/C

amp. Then, the TCM receives a manual mode signal or non-manual mode signal from the unified meter and

A/C amp.

• The position select switch (shift-up) detects that the selector lever is shifted to the shift-up side of the manual

shift gate and transmits a manual mode shift up signal to the unified meter and A/C amp. Then, the TCM

receives a manual mode shift up signal from the unified meter and A/C amp.

• The position select switch (shift-down) detects that the selector lever is shifted to the shift-down side of the

manual shift gate and transmits a manual mode shift down signal to the unified meter and A/C amp. Then,

the TCM receives a manual mode shift down signal from the unified meter and A/C amp.

DTC Logic

INFOID:0000000008285847

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1.

Turn ignition switch ON.

2.

Select “SLCT LVR POSI” and “MANU MODE SW” in “Data Monitor” in “TRANSMISSION”.

3.

Maintain the following each conditions more than 2 seconds.

4.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

Is “P1815” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008285848

1.

CHECK MANUAL MODE SWITCH CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect A/T shift selector connector.

3.

Turn ignition switch ON.

4.

Check voltage between A/T shift selector vehicle side harness connector terminals.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P1815

Manual Mode Switch Circuit

The TCM receives multiple sig-

nals from the manual mode

switch or receives no signals for

continuously 2 seconds or

more.

• Harness or connectors

(These switches circuit is

open or shorted.)

• Manual mode select switch

(Into A/T shift selector)

• Manual mode position select

switch (Into A/T shift selector)

SLCT LVR POSI

: D

MANU MODE SW

: ON

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

P1815 M-MODE SWITCH

TM-117

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK MANUAL MODE SWITCH

1.

Turn ignition switch OFF.

2.

Check manual mode switch. Refer to

TM-118, "Component Inspection (Manual Mode Switch)"

.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace damaged parts.

3.

CHECK GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check continuity between A/T shift selector vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace damaged parts.

4.

CHECK HARNESS BETWEEN A/T SHIFT SELECTOR AND UNIFIED METER AND A/C AMP. (PART 1)

1.

Disconnect unified meter and A/C amp. connector.

2.

Check continuity between A/T shift selector vehicle side harness connector terminals and unified meter

and A/C amp. vehicle side harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace damaged parts.

5.

CHECK HARNESS BETWEEN A/T SHIFT SELECTOR AND UNIFIED METER AND A/C AMP. (STEP 2)

Check continuity between A/T shift selector vehicle side harness connector terminals and ground.

A/T shift selector vehicle side harness connector

Voltage (Approx.)

Connector

Terminal

+

−

M137

1

4

Battery voltage

2

3

5

A/T shift selector vehicle side harness connector

Ground

Continuity

Connector

Terminal

M137

4

Existed

A/T shift selector vehicle side harness connector

Unified meter and A/C amp. vehicle side harness

connector

Continuity

Connector

Terminal

Connector

Terminal

M137

1

M66

10

Existed

2

25

3

5

5

11

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-118

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

P1815 M-MODE SWITCH

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace damaged parts.

6.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair or replace damaged parts.

7.

CHECK UNIFIED METER AND A/C AMP.

1.

Reconnect all the connectors.

2.

Turn ignition switch ON.

3.

Select “M RANGE SW”, “NM RANGE SW”, “AT SFT UP SW” and “AT SFT DWN SW” in “Data Monitor” in

“METER/M&A”.

4.

Check the ON/OFF operations of each monitor item. Refer to

.

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Replace unified meter and A/C amp. Refer to

MWI-138, "Removal and Installation"

.

Component Inspection (Manual Mode Switch)

INFOID:0000000008285849

1.

CHECK MANUAL MODE SWITCH

Check continuity between A/T shift selector connector terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Repair or replace damaged parts. Refer to

TM-182, "Removal and Installation"

A/T shift selector vehicle side harness connector

Ground

Continuity

Connector

Terminal

M137

1

Not existed

2

3

5

A/T shift selector connector

Condition

Continuity

Terminal

1

4

Selector lever is shifted to manual shift gate

side

Existed

Other than the above

Not existed

2

Selector lever is shifted to

−

side

Existed

Other than the above

Not existed

3

Selector lever is shifted to + side

Existed

Other than the above

Not existed

5

Selector lever is shifted to manual shift gate

side

Not existed

Other than the above

Existed

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

P2713 PRESSURE CONTROL SOLENOID D

TM-119

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

P2713 PRESSURE CONTROL SOLENOID D

Description

INFOID:0000000008285850

• The high and low reverse clutch solenoid valve is controlled by the TCM in response to signals transmitted

from the transmission range switch, output speed sensor and accelerator pedal position sensor (throttle

position sensor). Gears will then be shifted to the optimum position.

• The high and low reverse clutch solenoid valve controls the high and low reverse clutch control valve in

response to a signal transmitted from the TCM.

DTC Logic

INFOID:0000000008285851

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1.

Start the engine.

2.

Select “BATTERY VOLT”, “MANU MODE SW”, “GEAR” and “VHCL/S SE-A/T” in “Data Monitor” in

“TRANSMISSION”.

3.

Drive the vehicle and maintain the following conditions for 5 seconds or more.

4.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

With GST

Follow the procedure “With CONSULT”.

Is “P2173” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008285852

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P2713

Pressure Control Solenoid D

The high and low reverse clutch

solenoid valve monitor value is

0.2 A or less when the high and

low reverse clutch solenoid

valve command value is more

than 0.75 A.

• Harness or connectors

(Solenoid valve circuit is

open or shorted.)

• High and low reverse clutch

solenoid valve

BATTERY VOLT

: 9 V or more

MANU MODE SW

: ON

GEAR

: 3rd

VHCL/S SE-A/T

: 10 km/h (7 MPH) or more

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-120

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

P2722 PRESSURE CONTROL SOLENOID E

P2722 PRESSURE CONTROL SOLENOID E

Description

INFOID:0000000008285853

• The low brake solenoid valve is controlled by the TCM in response to signals transmitted from the transmis-

sion range switch, output speed sensor and accelerator pedal position sensor (throttle position sensor).

Gears will then be shifted to the optimum position.

• The low brake solenoid valve controls the low brake control valve in response to a signal transmitted from

the TCM.

DTC Logic

INFOID:0000000008285854

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1.

Start the engine.

2.

Select “BATTERY VOLT”, “MANU MODE SW”, “GEAR” and “VHCL/S SE-A/T” in “Data Monitor” in

“TRANSMISSION”.

3.

Drive vehicle and maintain the following conditions for 5 seconds or more.

4.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

With GST

Follow the procedure “With CONSULT”.

Is “P2722” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008285855

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P2722

Pressure Control Solenoid E

The low brake solenoid valve

monitor value is 0.2 A or less

when the low brake solenoid

valve command value is more

than 0.75 A.

• Harness or connectors

(Solenoid valve circuit is

open or shorted.)

• Low brake solenoid valve

BATTERY VOLT

: 9 V or more

MANU MODE SW

: ON

GEAR

: 1st

VHCL/S SE-A/T

: 10 km/h (7 MPH) or more

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

P2731 PRESSURE CONTROL SOLENOID F

TM-121

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

P2731 PRESSURE CONTROL SOLENOID F

Description

INFOID:0000000008285856

• The 2346 brake solenoid valve is controlled by the TCM in response to signals transmitted from the trans-

mission range switch, output speed sensor and accelerator pedal position sensor (throttle position sensor).

Gears will then be shifted to the optimum position.

• The 2346 brake solenoid valve controls the 2346 brake control valve in response to a signal transmitted from

the TCM.

DTC Logic

INFOID:0000000008285857

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1.

Start the engine.

2.

Select “BATTERY VOLT”, “MANU MODE SW”, “GEAR” and “VHCL/S SE-A/T” in “Data Monitor” in

“TRANSMISSION”.

3.

Drive vehicle and maintain the following conditions for 5 seconds or more.

4.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

With GST

Follow the procedure “With CONSULT”.

Is “P2731” detected?

YES

>> Go to

NO

>> INSPECTION END.

Diagnosis Procedure

INFOID:0000000008285858

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P2731

Pressure Control Solenoid F

The 2346 brake solenoid valve

monitor value is 0.2 A or less

when the 2346 brake solenoid

valve command value is more

than 0.75 A.

• Harness or connectors

(Solenoid valve circuit is

open or shorted.)

• 2346 brake solenoid valve

BATTERY VOLT

: 9 V or more

MANU MODE SW

: ON

GEAR

: 2nd

VHCL/S SE-A/T

: 10 km/h (7 MPH) or more

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-122

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

P2807 PRESSURE CONTROL SOLENOID G

P2807 PRESSURE CONTROL SOLENOID G

Description

INFOID:0000000008285859

• The direct clutch solenoid valve is controlled by the TCM in response to signals transmitted from the trans-

mission range switch, output speed sensor and accelerator pedal position sensor (throttle position sensor).

Gears will then be shifted to the optimum position.

• The direct clutch solenoid valve controls the direct clutch control valve in response to a signal transmitted

from the TCM.

DTC Logic

INFOID:0000000008285860

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch

OFF. Then wait at least 10 seconds before performing the next test.

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1.

Start the engine.

2.

Select “BATTERY VOLT”, “MANU MODE SW”, “GEAR” and “VHCL/S SE-A/T” in “Data Monitor” in

“TRANSMISSION”.

3.

Drive vehicle and maintain the following conditions for 5 seconds or more.

4.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

With GST

Follow the procedure “With CONSULT”.

Is “P2807” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008285861

1.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

Is the inspection result normal?

YES

>> Replace control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

DTC

Trouble diagnosis name

DTC is detected is...

Possible cause

P2807

Pressure Control Solenoid G

The direct clutch solenoid valve

monitor value is 0.2 A or less

when the direct clutch solenoid

valve command value is more

than 0.75 A.

• Harness or connectors

(Solenoid valve circuit is

open or shorted.)

• Direct clutch solenoid valve

BATTERY VOLT

: 9 V or more

MANU MODE SW

: ON

GEAR

: 1st

VHCL/S SE-A/T

: 10 km/h (7 MPH) or more

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

P2807 PRESSURE CONTROL SOLENOID G

TM-123

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

NO

>> Repair or replace damaged parts.

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-124

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

MAIN POWER SUPPLY AND GROUND CIRCUIT

MAIN POWER SUPPLY AND GROUND CIRCUIT

Diagnosis Procedure

INFOID:0000000008285862

1.

CHECK TCM POWER SOURCE (PART 1)

1.

Turn ignition switch OFF.

2.

Disconnect A/T assembly connector.

3.

Check voltage between A/T assembly vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 6.

2.

CHECK TCM POWER SOURCE (PART 2)

Check voltage between A/T assembly vehicle side harness connector terminals and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 7.

3.

CHECK TCM GROUND CIRCUIT

Check continuity between A/T assembly vehicle side harness connector terminals and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace damaged parts.

4.

CHECK JOINT CONNECTOR

1.

Remove joint connector. Refer to

TM-185, "Removal and Installation"

2.

Check the continuity between joint connector terminals.

Is the inspection result normal?

A/T assembly vehicle side harness connector

Ground

Condition

Voltage (Approx.)

Connector

Terminal

F51

2

Always

Battery voltage

A/T assembly vehicle side harness connector

Ground

Condition

Voltage (Approx.)

Connector

Terminal

F51

1

Turn ignition switch ON

Battery voltage

Turn ignition switch OFF

0 V

6

Turn ignition switch ON

Battery voltage

Turn ignition switch OFF

0 V

A/T assembly vehicle side harness connector

Ground

Continuity

Connector

Terminal

F51

5

Existed

10

A/T assembly harness connector side

TCM harness connector side

Continuity

Terminal

Terminal

1

1

Existed

2

2

5 5

6

6

10

10

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

MAIN POWER SUPPLY AND GROUND CIRCUIT

TM-125

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

YES

>> GO TO 5.

NO

>> Repair or replace damaged parts.

5.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace the control valve & TCM. Refer to

TM-185, "Removal and Installation"

.

NO

>> Repair or replace damaged parts.

6.

DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between battery positive terminal and A/T assembly vehicle side harness connec-

PG-6, "Wiring Diagram - BATTERY POWER SUPPLY -"

• Battery

• 10A fuse (No.36, located in the fuse, fusible link and relay box). Refer to

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-42, "Intermittent Incident"

.

NO

>> Repair or replace damaged parts.

7.

CHECK HARNESS BETWEEN IPDM E/R AND A/T ASSEMBLY (PART 1)

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R connector.

3.

Check continuity between IPDM E/R vehicle side harness connector terminal and A/T assembly vehicle

side harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair or replace damaged parts.

8.

CHECK HARNESS BETWEEN IPDM E/R AND A/T ASSEMBLY (PART 2)

Check continuity between A/T assembly vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace damaged parts.

9.

DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and IPDM E/R. Refer to

PG-44, "Wiring Diagram - IGNI-

.

• Ignition switch

• 10A fuse (No.43, located in the IPDM E/R). Refer to

PG-96, "Fuse, Connector and Terminal Arrangement"

• IPDM E/R

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-42, "Intermittent Incident"

.

NO

>> Repair or replace damaged parts.

IPDM E/R vehicle side harness connector

A/T assembly vehicle side harness connector

Continuity

Connector

Terminal

Connector

Terminal

E7

58

F51

1

Existed

6

A/T assembly vehicle side harness connector

Ground

Continuity

Connector

Terminal

F51

1

Not existed

6

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-126

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

SHIFT POSITION INDICATOR CIRCUIT

SHIFT POSITION INDICATOR CIRCUIT

Description

INFOID:0000000008285863

TCM transmits a shift position signal and a manual mode indicator signal to the unified meter and A/C amp. via

CAN communication line. While the vehicle is running, the unified meter and A/C amp. displays a shift position

on the combination meter, according to these signals.

Component Function Check

INFOID:0000000008285864

1.

CHECK A/T INDICATOR

CAUTION:

Always drive vehicle at a safe speed.

1.

Start the engine.

2.

Check the actual selector lever position (“P”, “R”, “N”, “D” and “DS”) and the indication of the shift position

indicator mutually coincide.

3.

Drive vehicle in the manual mode, and then check that the actual gear position and the indication of the

shift position indicator mutually coincide when the selector lever is shifted to “UP (+ side)” or “DOWN (

−

side)” side (1GR

⇔

7GR).

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Diagnosis Procedure

INFOID:0000000008285865

1.

CHECK INPUT SIGNALS

With CONSULT

1.

Start the engine.

2.

Select “SLCT LVR POSI” in “Data Monitor” in “TRANSMISSION”.

3.

Check the actual selector lever position (“P”, “R”, “N”, “D” and “DS”) and the indication of the “SLCT LVR

POSI” mutually coincide. Refer to

.

4.

Drive vehicle in the manual mode, and then check that the actual gear position and the indication of the

“SLCT LVR POSI” mutually coincide when the selector lever is shifted to the “UP (+ side)” or “DOWN (

−

side)” side (1GR

⇔

7GR). Refer to

Is the inspection result normal?

YES

>> INSPECTION END

NO-1 [The actual gear position does not change, or shifting into the manual mode is not possible (no gear

shifting in the manual mode possible). Or the shift position indicator is not indicated.]>>•Check manual

mode switch. Refer to

TM-118, "Component Inspection (Manual Mode Switch)"

• Check A/T main system (Fail-safe function actuated).

- Perform “Self Diagnostic Results” in “TRANSMISSION”. Refer to

NO-2 (The actual gear position changes, but the shift position indicator is not indicated.)>>Perform

“Self

Diagnostic Results” in “TRANSMISSION”. Refer to

.

NO-3 (The actual gear position and the indication on the shift position indicator do not coincide.)>>Perform

“Self Diagnostic Results” in “TRANSMISSION”. Refer to

NO-4 (Only a specific position or positions is/are not indicated on the shift position indicator.)>>Check

the

combination meter. Refer to

.

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

SHIFT LOCK SYSTEM

TM-127

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

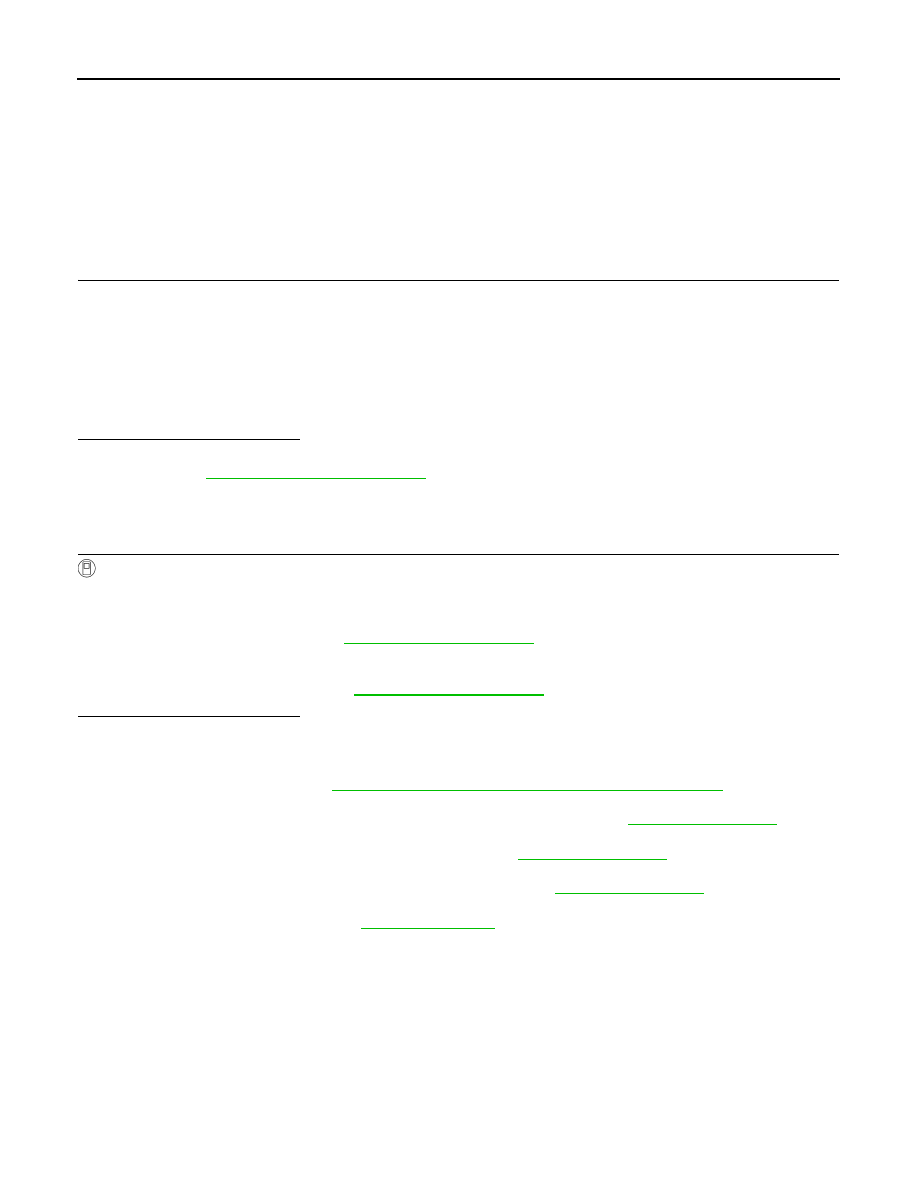

SHIFT LOCK SYSTEM

Wiring Diagram - A/T SHIFT LOCK SYSTEM -

INFOID:0000000008285866

JCDWA0543GB

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

TM-128

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A]

SHIFT LOCK SYSTEM

JRDWC2244GB

2013 EX

-------------------------------------------------------------------------------------------------------------------------------------------------------------

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст