Infiniti M35/M45 Y50. Manual — part 870

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-25

C

D

E

F

G

H

I

J

L

M

A

B

LT

CONSULT-II Functions (IPDM E/R)

NKS003O9

CONSULT-II can display each diagnostic item using the diagnostic test mode shown following.

CONSULT-II BASIC OPERATION

Refer to

GI-38, "CONSULT-II Start Procedure"

.

DATA MONITOR

Operation Procedure

1.

Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2.

Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3.

When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4.

Touch “START”.

5.

Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1.

Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2.

Touch item to be tested, and check operation.

3.

Touch “START”.

4.

Touch “STOP” while testing to stop the operation.

Diagnosis Mode

Description

SELF-DIAGNOSTIC RESULTS

Refer to

DATA MONITOR

The input/output data of IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR

The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST

IPDM E/R sends a drive signal to electronic components to check their operation.

ALL SIGNALS

Monitors all items.

MAIN SIGNALS

Monitors the predetermined item.

SELECTION FROM MENU

Selects items and monitors them.

Item name

CONSULT-II

screen display

Display

or unit

Monitor item selection

Description

ALL

SIGNALS

MAIN

SIGNALS

SELECTION

FROM

MENU

Position lights request

TAIL&CLR REQ

ON/OFF

×

×

×

Signal status input from BCM

Headlamp low beam request

HL LO REQ

ON/OFF

×

×

×

Signal status input from BCM

Headlamp high beam request

HL HI REQ

ON/OFF

×

×

×

Signal status input from BCM

Front fog lights request

FR FOG REQ

ON/OFF

×

×

×

Signal status input from BCM

Test item

CONSULT-II

screen display

Description

Tail lamp relay output

TAIL LAMP

Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPS

Allows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON,

LO ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output

Allows fog lamp relay to operate by switching operation ON-OFF at your option.

LT-26

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Headlamp High Beam Does Not Illuminate (Both Sides)

NKS003OA

1.

CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

1.

Select “BCM” on CONSULT-II. Select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2.

Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

Make sure that “HI BEAM SW” turns ON-OFF linked with opera-

tion of lighting switch.

Without CONSULT-II

Refer to

LT-239, "Combination Switch Inspection"

OK or NG

OK

>> GO TO 2.

NG

>> Check combination switch (lighting switch). Refer to

LT-239, "Combination Switch Inspection"

2.

HEADLAMP ACTIVE TEST

With CONSULT-II

1.

Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on

“SELECT DIAG MODE” screen.

2.

Select “LAMPS” on “SELECT TEST ITEM” screen.

3.

Touch “HI” screen.

4.

Make sure headlamp high beam operation.

Without CONSULT-II

1.

Start auto active test. Refer to

2.

Make sure headlamp high beam operation.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 4.

3.

CHECK IPDM E/R

1.

Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

2.

Make sure “HL LO REQ” and “HL HI REQ” turns ON when light-

ing switch is in HI position.

OK or NG

OK

NG

>> Replace BCM. Refer to

BCS-15, "Removal and Installa-

When lighting switch is

HIGH position

: HI BEAM SW ON

PKIA7585E

Headlamp high beam should operate

(Headlamp high beam repeats ON–OFF every 1 second).

Headlamp high beam should operate.

SKIA5774E

When lighting switch is

HIGH position

: HL LO REQ ON

: HL HI REQ ON

PKIA7638E

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-27

C

D

E

F

G

H

I

J

L

M

A

B

LT

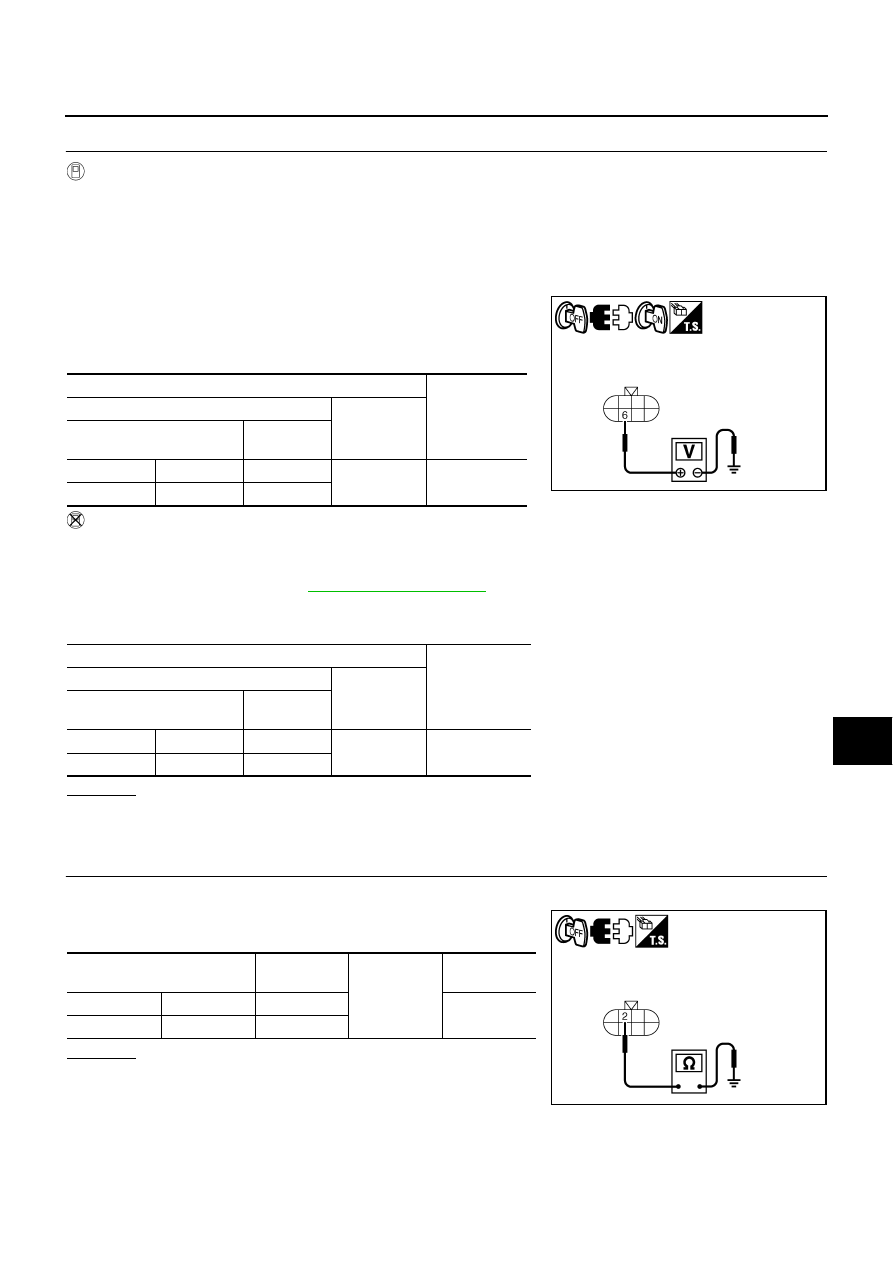

4.

CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1.

Turn ignition switch OFF.

2.

Disconnect front combination lamp RH and LH connector.

3.

Select “IPDM E/R” on CONSULT-II, select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4.

Select “LAMPS” on “SELECT TEST ITEM” screen.

5.

Touch “HI” screen.

6.

When headlamp high beam is operating, check voltage between

front combination lamp (RH and LH) harness connector and

ground. (Headlamp high beam repeats ON-OFF every 1 sec-

ond.)

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Disconnect front combination lamp connector.

3.

Start auto active test. Refer to

.

4.

When headlamp high beam is operating, check voltage between front combination lamp (RH and LH) har-

ness connector and ground.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 7.

5.

CHECK HEADLAMP GROUND

1.

Turn ignition switch OFF.

2.

Check continuity between front combination lamp (RH and LH)

harness connector and ground.

OK or NG

OK

>> GO TO 6.

NG

>> Repair harness or connector.

Terminal

Voltage

(Approx.)

(+)

(-)

Front combination lamp

connector

Terminal

RH

E47

6

Ground

Battery voltage

LH

E54

6

Terminal

Voltage

(Approx.)

(+)

(-)

Front combination lamp

connector

Terminal

RH

E47

6

Ground

Battery voltage

LH

E54

6

SKIB4749E

Front combination lamp

connector

Terminal

Ground

Continuity

RH

E47

2

Yes

LH

E54

2

SKIB4750E

LT-28

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

6.

CHECK BULB

Check bulbs of lamp (both side).

OK or NG

OK

>> Check connecting condition headlamp harness connector.

NG

>> Replace headlamp bulb.

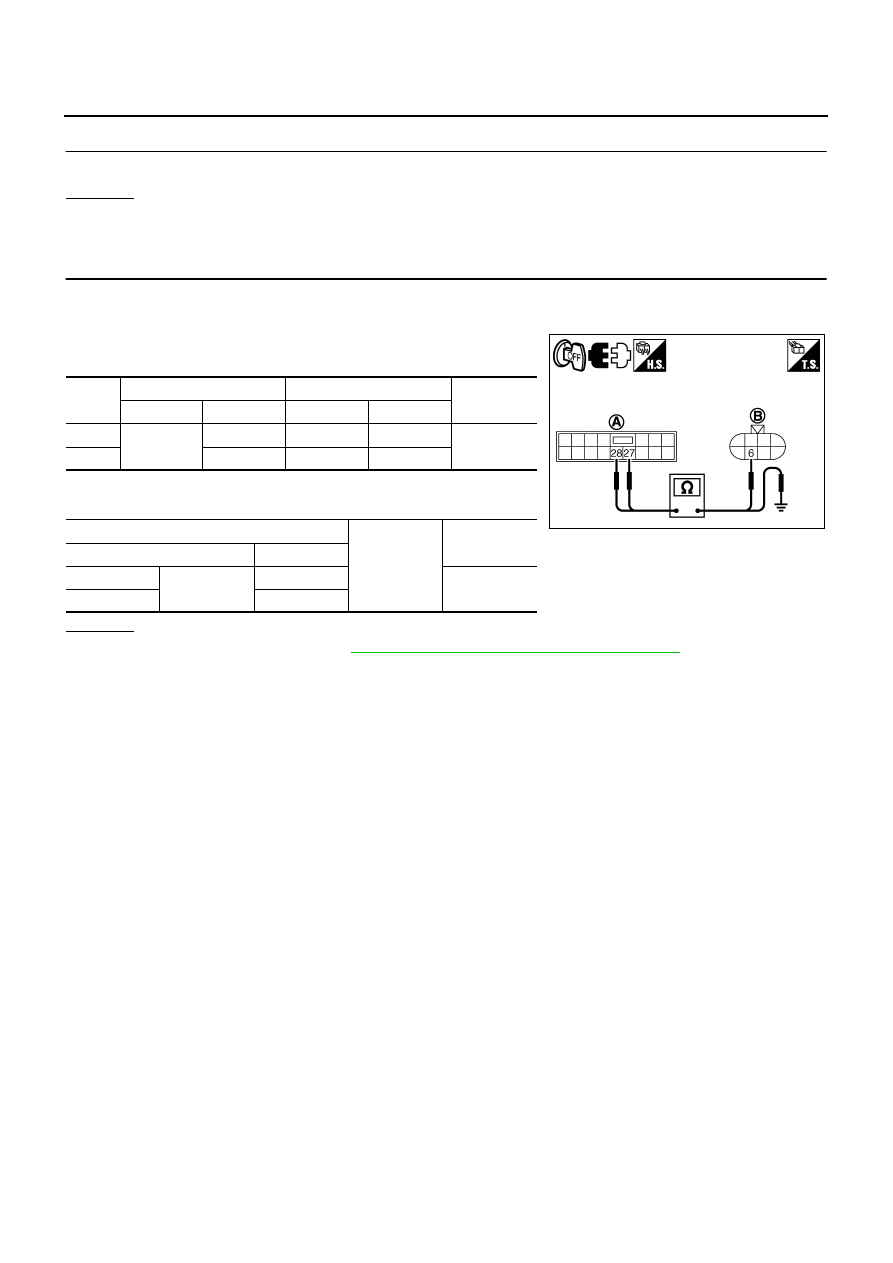

7.

CHECK CIRCUIT BETWEEN IPDM E/R AND FRONT COMBINATION LAMP

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R connector.

3.

Check continuity between IPDM E/R harness connector (A) and

front combination lamp (RH and LH) harness connector (B).

4.

Check continuity between IPDM E/R harness connector (A) and

ground.

OK or NG

OK

PG-31, "Removal and Installation of IPDM E/R"

NG

>> Repair harness or connector.

Circuit

A

B

Continuity

Connector

Terminal

Connector

Terminal

RH

E7

27

E47

6

Yes

LH

28

E54

6

A

Ground

Continuity

Connector

Terminal

RH

E7

27

No

LH

28

SKIB4753E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст