Mitsubishi Lancer Evolution IX. Manual — part 437

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-223

STEP 16. Connector check: C-119 and C-121

engine-ECU connectors

Q: Is the check result normal?

YES :

Go to Step 17 .

NO :

Repair or replace the connector.

STEP 17. Check harness between B-124 (terminal

No. 2) intake camshaft position sensor connector

and C-119 (terminal No. 53) engine-ECU

connector.

• Check output line for damage.

Q: Is the check result normal?

YES :

Go to Step 18 .

NO :

Repair the damaged harness wire.

AK501998

65

43

50

42

49

41

48

60

61

64

46

47

58

59

67

68

45

56

66

52 51

44

53

62

54

63

57

55

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

30

21

22

23

24

25

26

27

28

29

31

32

33

34

35

1

10

AB

Connector: C-119, C-121

C-119 (GR)

C-121 (GR)

C-119 (GR)

C-121 (GR)

C-121 Harness side connector

C-119 Harness side connector

<L. H. drive vehicles>

<R. H. drive vehicles>

AK502002

1

2

3

AB

Connector: B-124

B-124 (B)

Harness side

connector

AK501994

65

43

50

42

49

41

48

60

61

64

46

47

58

59

67

68

45

56

66

52 51

44

53

62

54

63

57

55

AB

Connector: C-119

C-119 (GR)

C-119 (GR)

Harness side connector

<L. H. drive vehicles>

<R. H. drive vehicles>

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-224

STEP 18. Check harness between B-124 (terminal

No. 1) intake camshaft position sensor connector

and C-121 (terminal No. 34) engine-ECU

connector.

• Check earthing line for damage.

Q: Is the check result normal?

YES :

Go to Step 19 .

NO :

Repair the damaged harness wire.

STEP 19. Check the intake camshaft position

sensing cylinder.

Q: Is the check result normal?

YES :

Go to Step 20 .

NO :

Replace the intake camshaft position

sensing cylinder.

STEP 20. Check the trouble symptoms.

Q: Does trouble symptom persist?

YES :

Replace the intake camshaft position

sensor.

NO :

Intermittent malfunction (Refer to GROUP

00

− How to Use

Troubleshooting/Inspection Service Points

).

AK502002

1

2

3

AB

Connector: B-124

B-124 (B)

Harness side

connector

AK501995

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

30

21

22

23

24

25

26

27

28

29

31

32

33

34

35

1

10

AB

Connector: C-121

C-121 (GR)

C-121 (GR)

Harness side connector

<L. H. drive vehicles>

<R. H. drive vehicles>

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-225

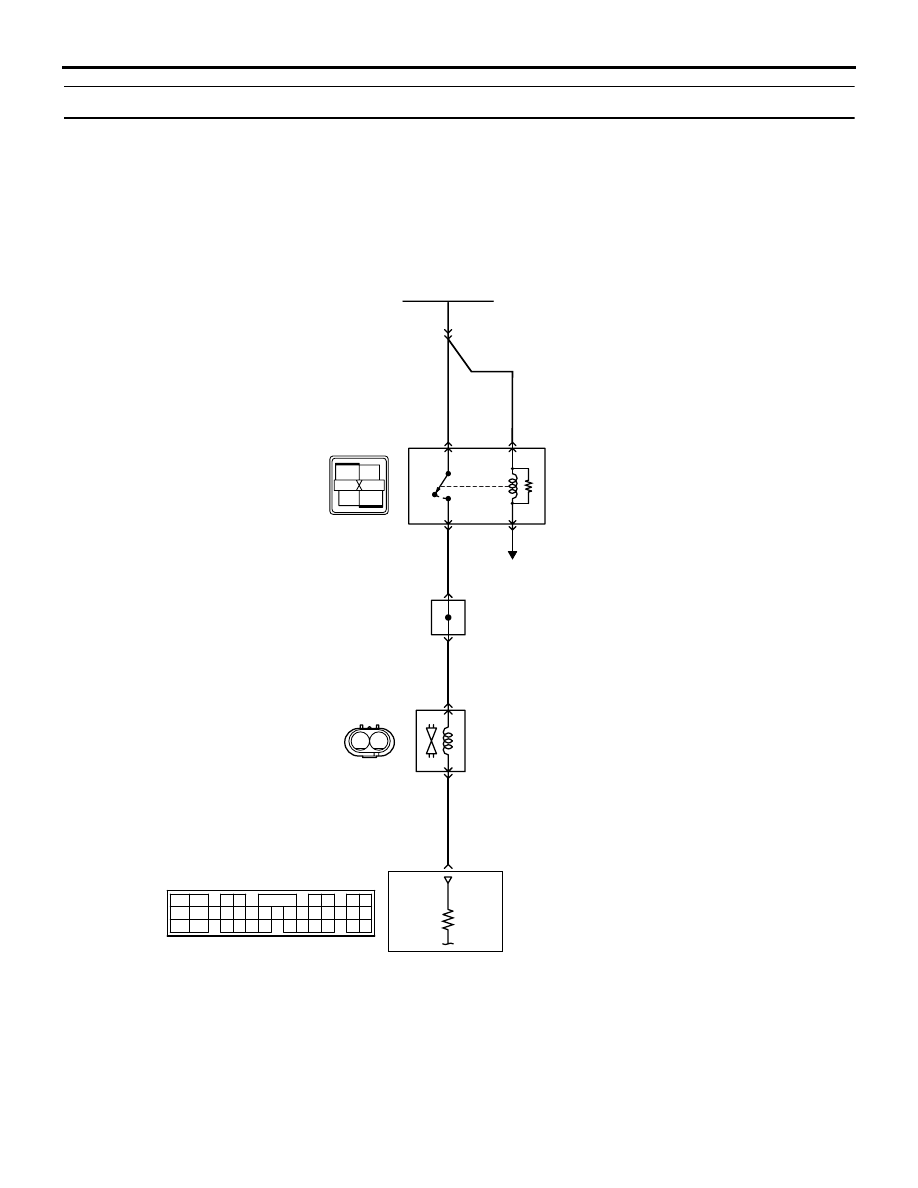

Code No. P1021: Oil Feeder Control Valve System

1

2

3

4

AK501822

1 2

2

3 4

5 6

7 8

9

11 12 13 14 15 16 17 18 19 20

30

21 22 23

24 25

26 27 28 29

3132 33

34 35

1

10

33

28

C-105

J/C (6)

AB

Engine

control

relay

R-Y

R-Y

P-B

B-12X

Oil feeder control

valve

1

2

4

1

2

32

3

Oil feeder control valve circuit

Battery

B-Y

B-Y

B-Y

C-121

(MU803784)

B-123

MU802779

Engine-ECU

Wire colour code

B: Black LG: Light green G: Green L: Blue W: White Y: Yellow SB: Sky blue BR: Brown O: Orange GR: Gray

R: Red P: Pink V: Violet PU: Purple

To engine-ECU

NOTE

*1: L.H. drive vehicles

*2: R.H. drive vehicles

6 <A-13> (*1) or

13 <C-31> (*2)

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-226

OPERATION

• Power is supplied to the oil feeder control valve

(terminal No. 1) from the engine control relay (ter-

minal No. 4).

• The engine-ECU (terminal No. 32) makes the

power transistor in the unit be in ON position, and

that makes currents go on the oil feeder control

valve (terminal No. 2).

FUNCTION

• The oil feeder control valve controls the phase

angle of the intake camshaft by the signal from

the engine-ECU.

TROUBLE JUDGMENT

Check Condition

• The oil feeder control valve does not operate.

Judgment Criterion

• The oil feeder control valve drive terminal voltage

of the engine-ECU is not normal for 4 seconds or

more.

PROBABLE CAUSE

• Failed oil feeder control valve

• Open/short circuit in oil feeder control valve cir-

cuit or loose connector contact

• Failed engine-ECU

DIAGNOSIS PROCEDURE

STEP 1. Connector check: B-123 oil feeder

control valve connector

Q: Is the check result normal?

YES :

Go to Step 2 .

NO :

Repair or replace the connector.

STEP 2. Perform resistance measurement at

B-123 oil feeder control valve connector.

• Disconnect connector, and measure at control

valve side.

• Resistance between terminal No. 1 and No. 2.

OK: 6.9

− 7.9 Ω (at 20°C)

Q: Is the check result normal?

YES :

Go to Step 3 .

NO :

Replace the oil feeder control valve.

STEP 3. Perform voltage measurement at B-123

oil feeder control valve connector.

• Disconnect connector, and measure at harness

side.

• Ignition switch: ON

• Voltage between terminal No. 1 and earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 5 .

NO :

Go to Step 4 .

AK502003

1

2

AB

Connector: B-123

B-123 (B)

Harness side

connector

AK502003

1

2

AB

Connector: B-123

B-123 (B)

Harness side

connector

AK502003

1

2

AB

Connector: B-123

B-123 (B)

Harness side

connector

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст