Mitsubishi Lancer Evolution IX. Manual — part 171

INPUT SIGNAL PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-247

Step 4. Connector check: C-226 ETACS-ECU

connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO :

Repair the defective connector.

Step 5. Check the wiring harness between D-01

door switch (front: RH) connector terminal No.3

and C-226 ETACS-ECU connector terminal No.10.

NOTE:

Prior to the wiring harness inspection, check joint

connector C-217, and repair if necessary.

• Check the input line for open circuit.

Q: Is the check result normal?

YES :

Go to Step 6.

NO :

Repair the wiring harness.

Step 6. Retest the system.

Check that the door switch (front: RH) signal is

received normally.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

Cope with Intermittent Malfunction

NO :

Replace the ETACS-ECU.

AC310461

Junction block (rear view)

Connector: C-226

AB

<RHD>

Junction block side

AC310461

Junction block (rear view)

Connector: C-226

AB

<RHD>

Junction block side

AC310471

Harness side

AB

Connector: D-01

<RHD>

AC310458

Harness side

Junction block (front view)

Connector: C-217

AC

<RHD>

INPUT SIGNAL PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-248

INSPECTION PROCEDURE L-4: The column switch (lighting and turn-signal lamp switch) signal is not

received.

CAUTION

Whenever the ECU is replaced, ensure that the

input signal circuit is normal.

COMMENTS ON TROUBLE SYMPTOM

Input signal from the column switch (lighting and

turn-signal lamp switch) is used to operate the func-

tions below. If the signal is abnormal, these functions

will not work normally.

• Lamp reminder function

• Headlamp and tail lamp

• Fog lamp

• Turn signal lamp

POSSIBLE CAUSES

• Malfunction of the column switch

• Damaged harness wires and connectors

DIAGNOSTIC PROCEDURE

Step 1. Check the column switch connector.

Check that the wiper and washer switch connector,

the lighting switch connector and the switch body

connector are in good condition.

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Repair the defective connector.

Step 2. Check the column switch (lighting switch

and switch body).

Refer to GROUP 54A

− Column switch

.

Q: Is the check result normal?

YES :

Go to Step 3.

NO :

Replace the column switch.

Step 3. M.U.T.-II/III diagnosis code.

Check that the ETACS-ECU sets a diagnosis code.

Q: Is the diagnosis code set?

YES :

Refer to diagnosis code chart

.

NO :

Go to Step 4.

Step 4. Retest the system.

Replace the column switch, and check if the column

switch (lighting, turn-signal lamp) sends signal.

(1) Replace the column switch.

(2) Check if the column switch (lighting and

turn-signal switch) sends signal.

Q: Is the check result normal?

YES :

The procedure is complete.

NO :

Replace the ETACS-ECU.

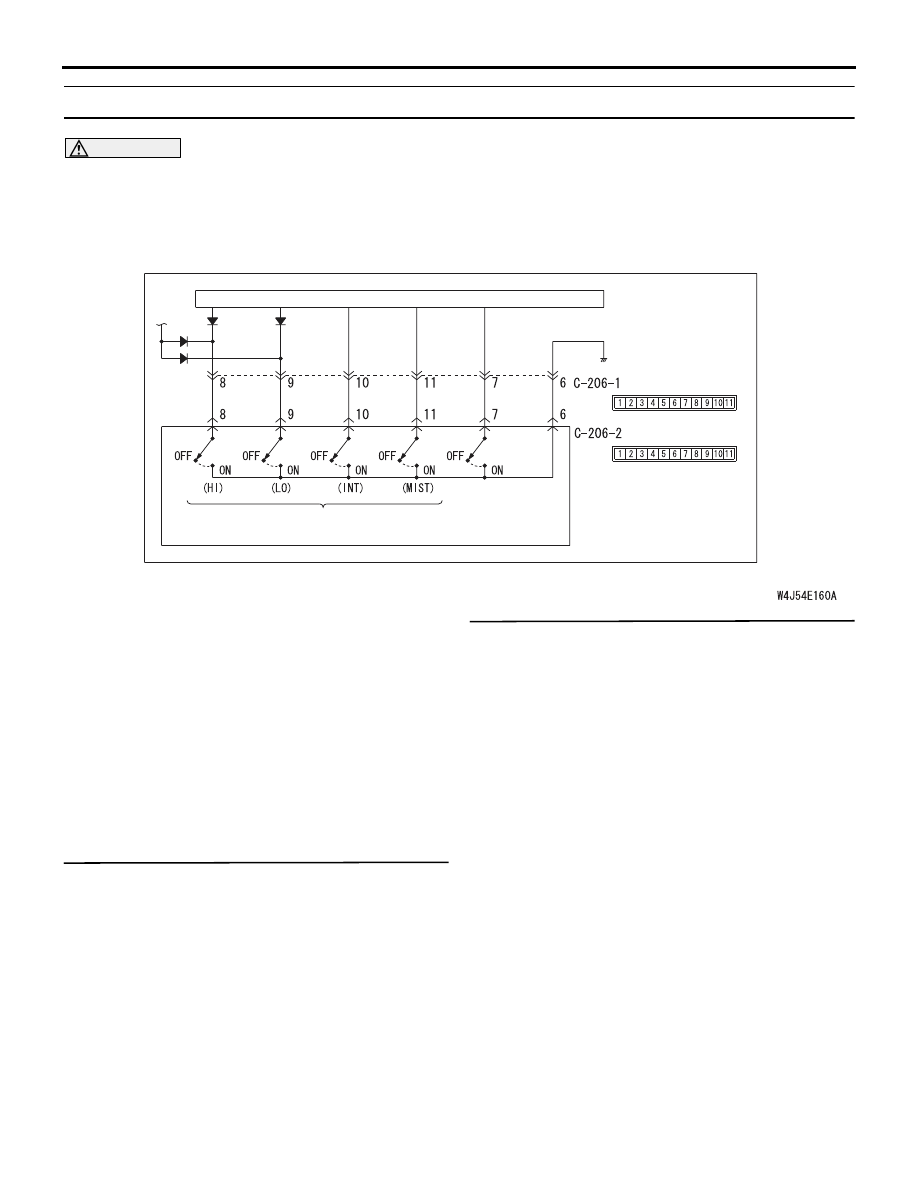

COLUMN-ECU

DIMMER·

PASSING SWITCH

TURN-SIGNAL

LAMP SWITCH

LIGHTING

SWITCH

COLUMN SWITCH

Lighting Switch Input Circuit

INPUT SIGNAL PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-249

INSPECTION PROCEDURE L-5: The column switch (windshield wiper/washer) signal is not received.

CAUTION

Whenever the ECU is replaced, ensure that the

input signal circuit is normal.

COMMENTS ON TROUBLE SYMPTOM

Input signal from the column switch (wiper switch) is

used to operate the functions below. If the signal is

abnormal, these functions will not work normally.

• Windshield wiper and washer

POSSIBLE CAUSES

• Malfunction of the column switch

• Damaged harness wires and connectors

DIAGNOSTIC PROCEDURE

Step 1. M.U.T.-II/III diagnosis code.

Check that the ETACS-ECU sets a diagnosis code.

Q: Is the diagnosis code set?

YES :

Refer to diagnosis code chart

NO :

Go to Step 2.

Step 2. Retest the system.

Replace the column switch, and check if the column

switch (windshield wiper washer) sends signal.

(1) Replace the column switch.

(2) Check if the column switch (windshield

wiper/washer) sends signal.

Q: Is the check result normal?

YES :

The procedure is complete.

NO :

Replace the ETACS-ECU.

WINDSHIELD

WASHER

SWITCH

WINDSHIELD

WIPER SWITCH

UPPER

SIDE

UPPER

SIDE

COLUMN SWITCH

COLUMN-ECU

Windshield Wiper and Washer Switch Input Circuit

INPUT SIGNAL PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-250

INSPECTION PROCEDURE L-6: The windshield intermittent wiper volume signal is not received.

CAUTION

Whenever the ECU is replaced, ensure that the

input signal circuit is normal.

COMMENTS ON TROUBLE SYMPTOM

The intermittent wiper interval is calculated in

accordance with the input signal from the windshield

intermittent wiper volume. If this signal is abnormal,

the wiper interval can not be adjusted.

POSSIBLE CAUSES

• Malfunction of the column switch

• Malfunction of the ETACS-ECU

• Damaged harness wires and connectors

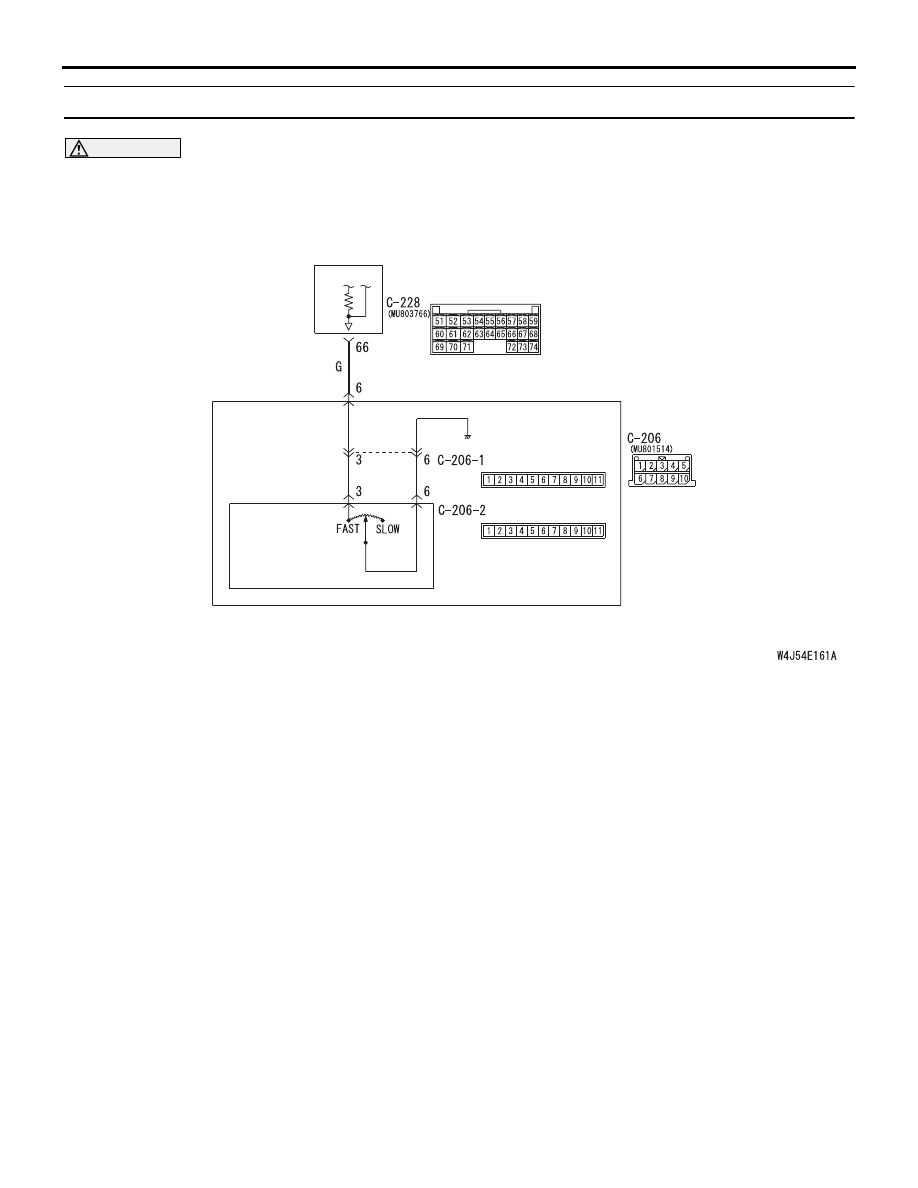

COLUMN

SWITCH

WINDSHIELD

INTERMITTENT

WIPER INTERVAL

ADJUSTING KNOB

UPPER

SIDE

UPPER

SIDE

ETACS-

ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

Windshield Intermittent Wiper Interval Adjusting Knob Input Circuit

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст