Mitsubishi Lancer Evolution IX. Manual — part 358

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-11

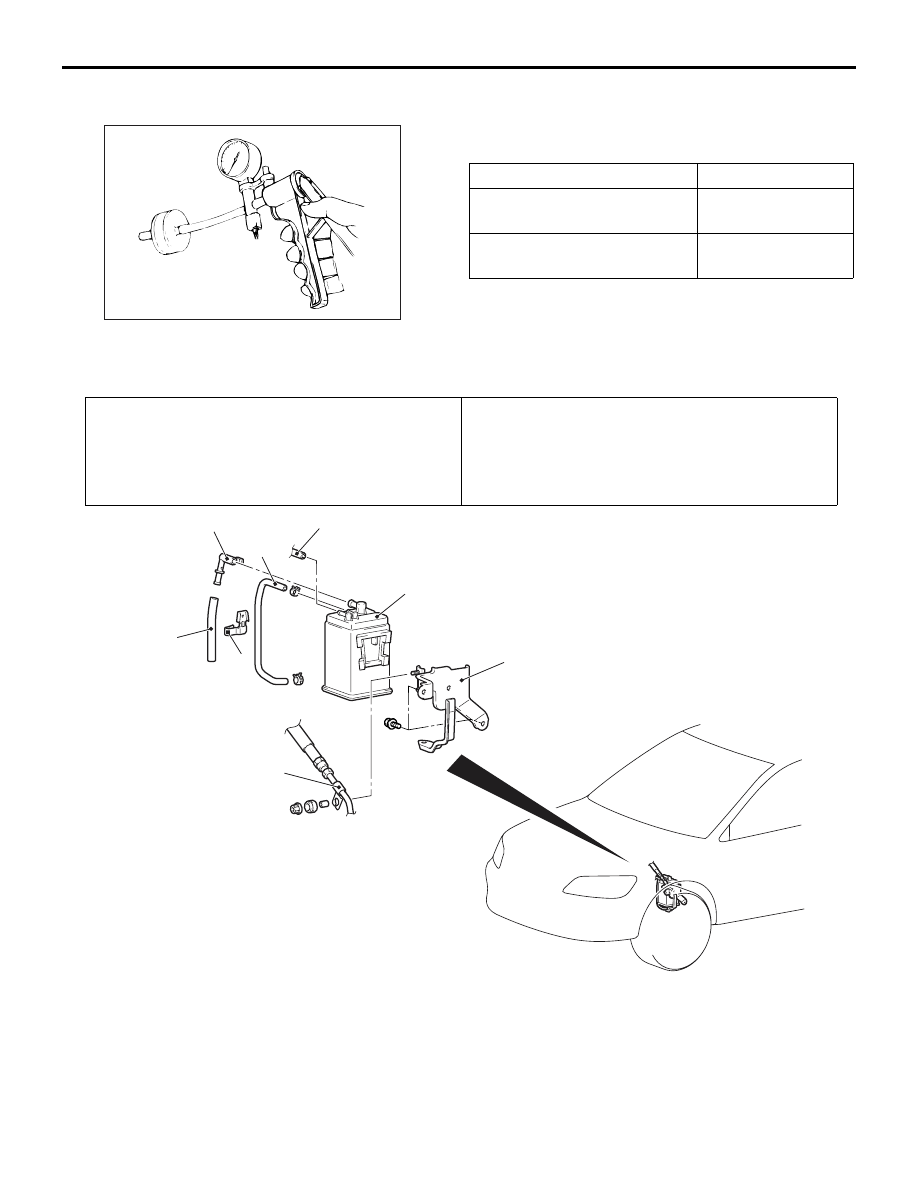

PURGE PORT VACUUM CHECK

M1173001500252

AK304231AB

Red stripe

Throttle body

1. Disconnect the vacuum hose (red stripe) from the

throttle body and connect a hand vacuum pump to

the nipple.

2. Plug the vacuum hose (red stripe).

AK100011

AC

Vac-

uum

Engine speed (r/min)

3. Start the engine.

4. Check that a fairly constant negative pressure is

generated regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

PURGE CONTROL SOLENOID VALVE

CHECK

M1173001700405

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

AK100012 AC

Battery

A

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check airtightness by applying negative pressure

with voltage applied directly from the battery to the

purge control solenoid valve and without applying

voltage.

Battery voltage

Normal condition

Applied

Negative pressure

leaks

Not applied

Negative pressure

maintained

AK100013

5. Measure the resistance between the terminals of

the solenoid valve.

Standard value: 30

− 34 Ω (at 20°C)

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-12

CHECK VALVE CHECK

M1173006200085

AK200373

Connect a hand vacuum pump to the check valve,

apply negative pressure and check the airtightness.

Connect nipple colour

Normal condition

Black

Negative pressure

leaks

Brown

Negative pressure

is maintained

FUEL VAPOUR CANISTER REMOVAL AND INSTALLATION

M1173004200186

Pre-removal Operation

• Air Pipe C, Air Hose D Removal (Refer to GROUP 15,

Intercooler

• Battery and Battery Tray Removal

• Air Cleaner Assembly Removal (Refer to GROUP 15, Air

Cleaner

).

Post-installation Operation

• Air Cleaner Assembly Installation (Refer to GROUP 15,

Air Cleaner

).

• Battery and Battery Tray Installation

• Air Pipe C, Air Hose D Installation (Refer to GROUP 15,

Intercooler

AC310639

AB

1

2

3

4

5

6

7

8

Removal steps

1.

Emission vacuum hose connection

2.

Fuel vapour control line hose

3.

Fuel vapour control check valve

4.

Fuel vapour control line hose

5.

Fuel vapour control line clamp

6.

Fuel vapour canister

7.

Fuel high-pressure hose clamp

8.

Fuel vapour canister bracket

Removal steps (Continued)

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-13

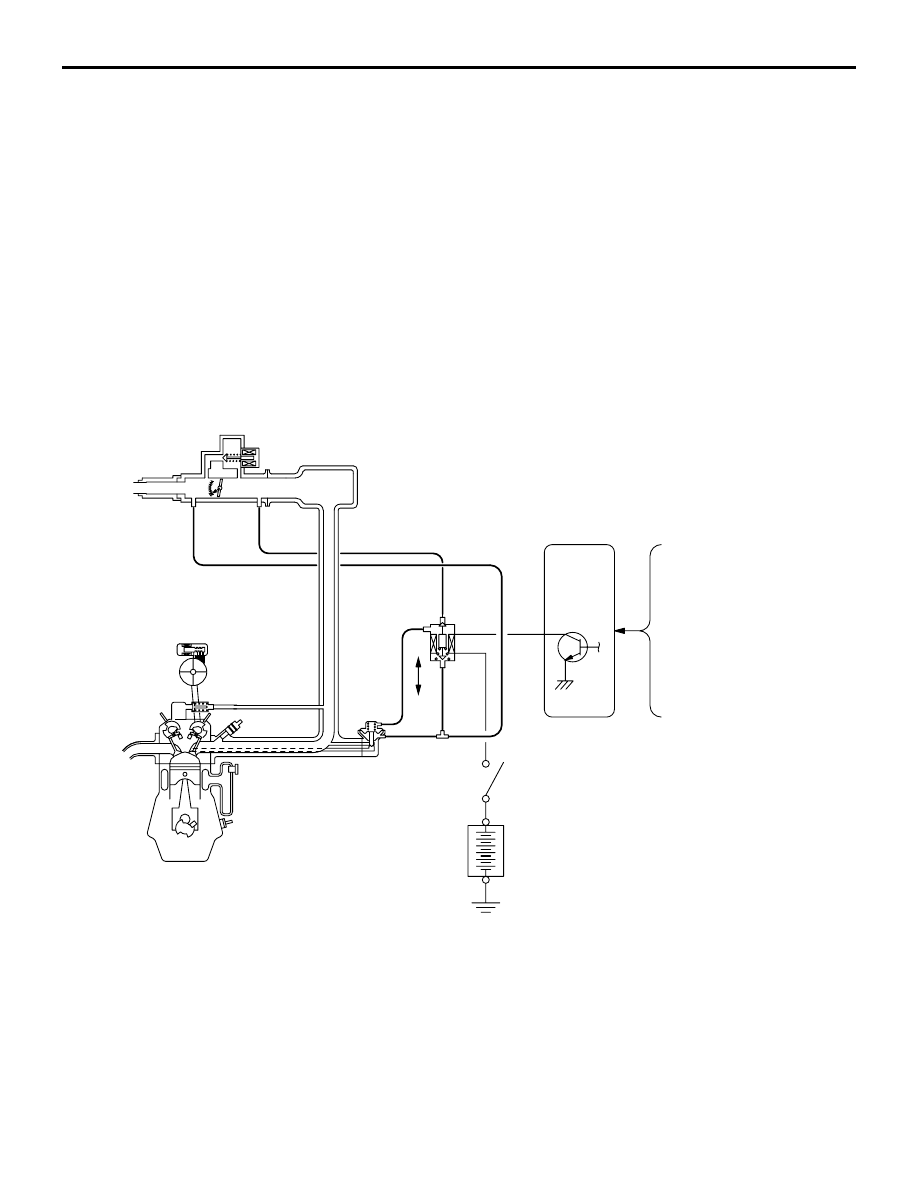

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

GENERAL INFORMATION (EGR SYSTEM)

M1173005200684

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level.

When the air/fuel mixture combustion temperature is

high, a large quantity of NOx is generated in the

combustion chamber.

Therefore, this system recirculates part of emission

gas from the exhaust port of the cylinder head to the

combustion chamber through the inlet manifold to

decrease the air/fuel mixture combustion tempera-

ture, resulting in reduction of NOx.

The EGR flow rate is controlled by the EGR valve so

as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not recircu-

late exhaust gases under one of the following condi-

tions.

Otherwise, the EGR valve is opened and recirculates

exhaust gases.

• The engine coolant temperature is low.

• The engine is at idle.

• The throttle valve is widely opened.

SYSTEM DIAGRAM

AK501846 AB

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

Barometric

pressure sensor

EGR control

Solenoid valve

Engine

control

relay

Battery

OFF

EGR valve

ON

Engine-ECU

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-14

COMPONENT LOCATION (EGR SYSTEM)

M1173007600309

AK304234AB

EGR control

solenoid valve

AK304235AB

EGR valve

EGR SYSTEM CHECK

M1173002600393

AK304236AB

EGR control

solenoid valve

Green stripe

Three-way terminal

1. Disconnect the vacuum hose (Green stripe) from

the EGR valve, and then connect a hand vacuum

pump via the three-way terminal.

2. When the engine is hot or cold, check the

condition of vacuum by racing the engine.

When engine is cold

(Engine coolant temperature: 20

°C or less)

Throttle valve

Normal vacuum

condition

Open quickly

No vacuum will

generate (the same

as barometric

pressure.)

When engine is hot

(Engine coolant temperature: 80

°C or higher)

Throttle valve

Normal vacuum

condition

Open quickly

It will momentarily

rise over 13 kPa

3. Disconnect the three-way terminal.

AK304237AB

EGR control

solenoid valve

Green stripe

4. Connect the hand vacuum pump to the EGR

valve nipple (Green stripe).

5. Check whether the engine stalls or the idling is

unstable when a vacuum of 27 kPa or higher is

applied during idling.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст